The method of sticking solid veneer to hyperboloid grc board

A technology of solid wood veneer and double-curved surface, applied in chemical instruments and methods, wood layered products, lamination auxiliary operations, etc., can solve problems such as hollowing, easy cracking, and falling off, so as to reduce changes and ensure adhesion effect, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

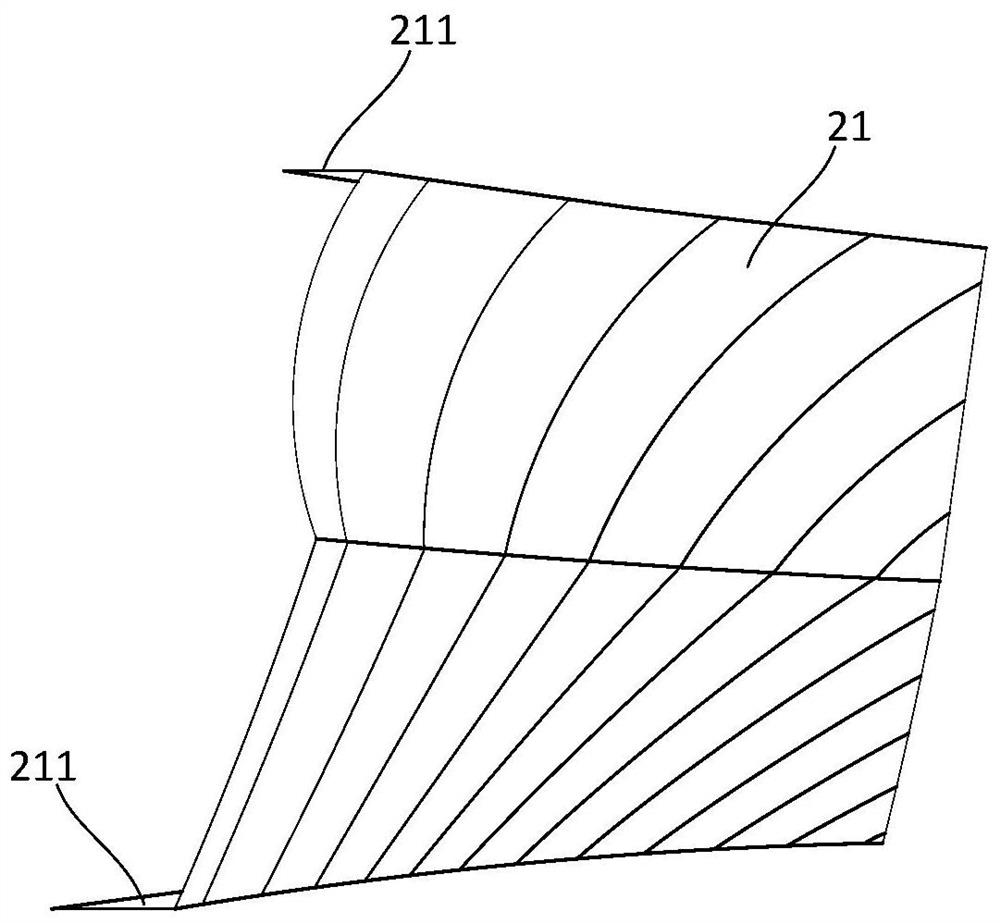

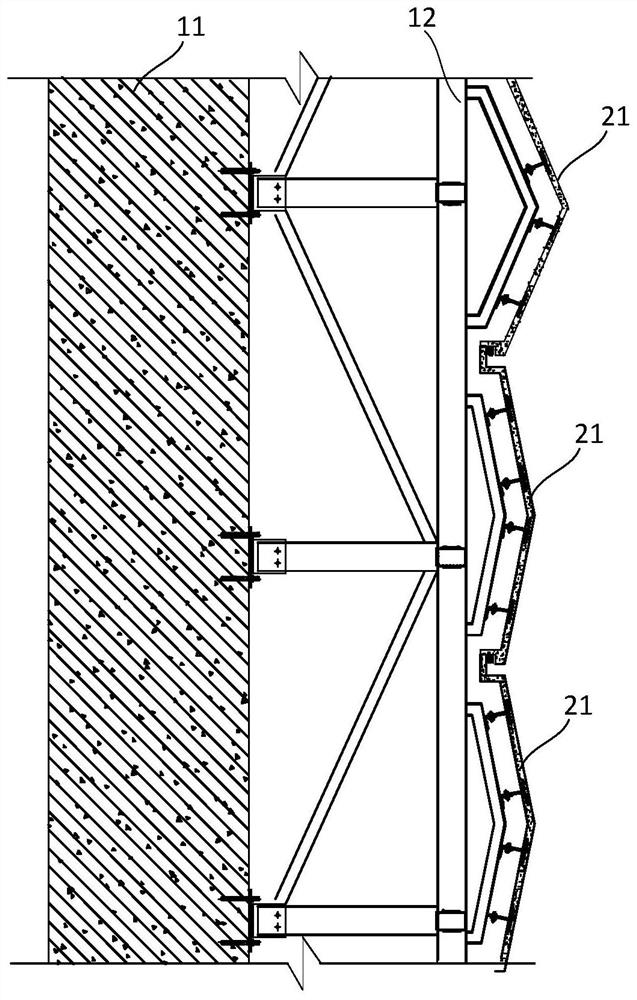

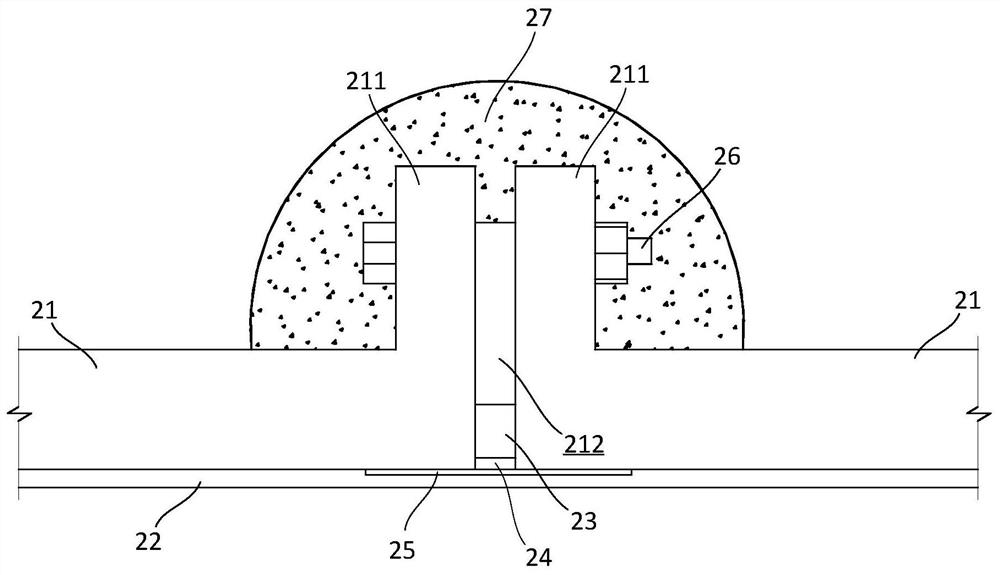

[0034] refer to figure 1 with image 3 , the present invention provides a method for pasting solid veneer on a hyperboloid GRC board. The GRC board includes a hyperboloid surface. The difficulty of the problem is large; the solid veneer itself has poor material deformation performance, and the method of the present invention selects the joint process between GRC boards and the pasting process of the solid veneer, so that the firmness, flatness and decorative effect of the pasted solid veneer are all better; Humidity has a great influence on the sticking of the solid veneer, and the method of the invention can prevent the sticking of the solid veneer from falling off and hollowing. Below in conjunction with accompanying drawing, the method for sticking solid veneer of hyperboloid GRC board of the present invention is described.

[0035] Such ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com