Time controlling device for fast heating soldering iron

A technology of time control and overtime control, applied in the direction of program control, computer control, general control system, etc., can solve problems such as hidden safety hazards and poor effects, and achieve the effect of ensuring output time, wide voltage adaptability, and avoiding fire hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

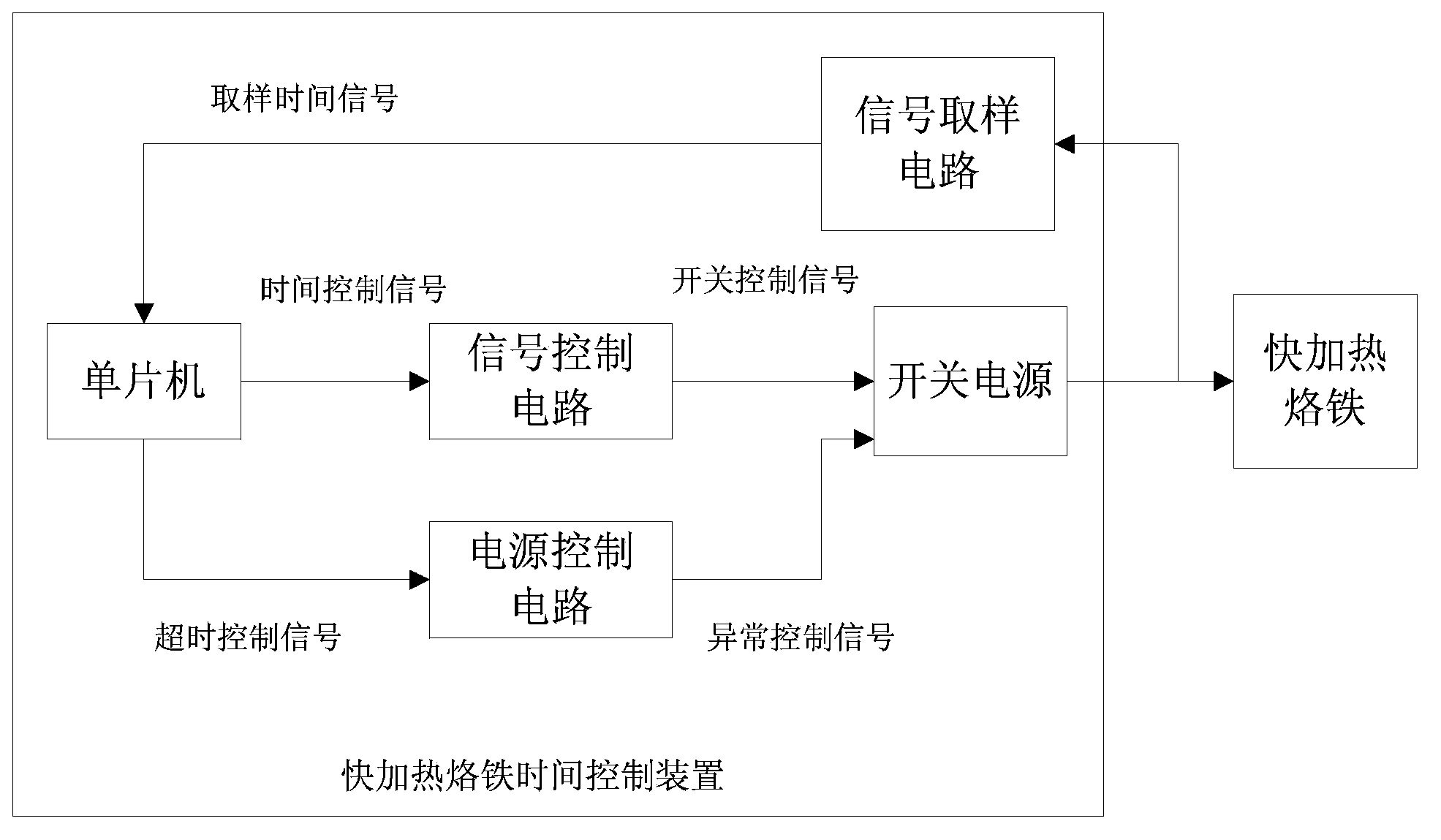

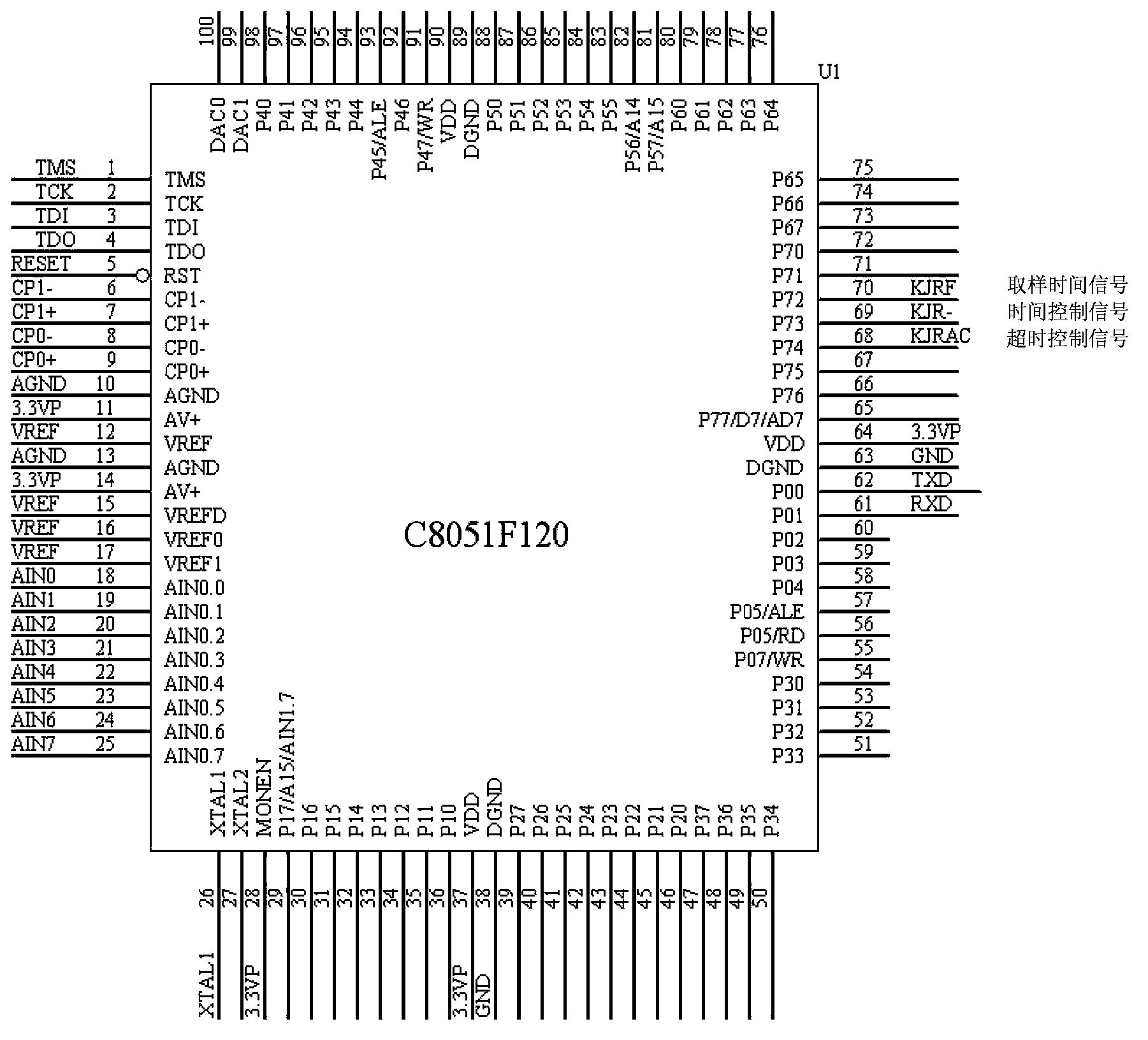

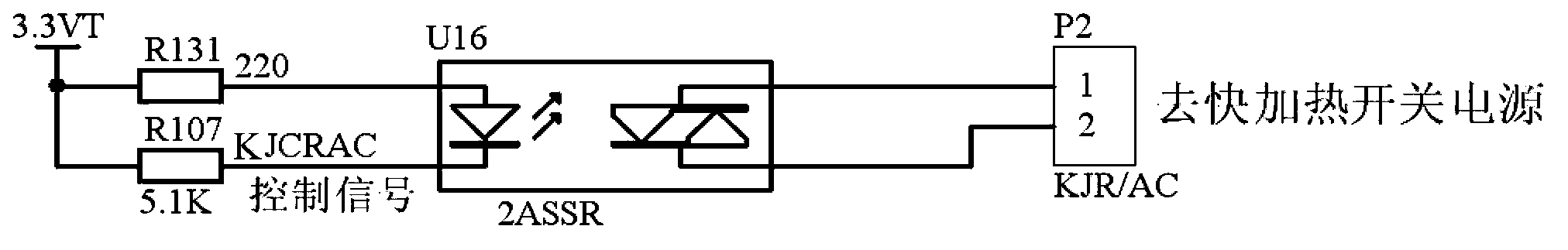

[0024] The fast heating soldering iron time control device of the present invention is based on the single-chip microcomputer U1 (this example adopts C8051F120) in the control circuit, controls the fast heating time through the signal control circuit, the signal sampling circuit takes samples, compares the input and output working time, and maintains the constant temperature of the soldering iron. In abnormal circumstances, the fast heating power supply is shut off through the power supply control circuit. The signal control circuit realizes the protection of the abnormal situation of the single chip microcomputer.

[0025] Such as Figure 1-5 As shown, the present invention takes the single-chip microcomputer U1 as the core, and according to the working sequence requirements of the fast-heating soldering iron of the tie-down machine, first e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com