VIT hardware cording communication bus control system of commercial vehicle

A control system and communication bus technology, applied in vehicle components, circuits or fluid pipelines, transportation and packaging, etc., can solve problems such as cumbersome processes, large consumption of non-renewable raw materials, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Embodiment 1: Realization and control of the high beam function of vehicle headlights

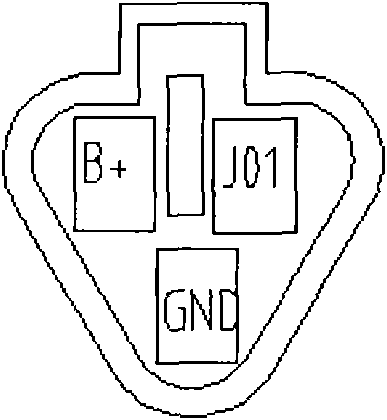

[0081] 1 Analyze the composition of the subsystem Headlight high beam light bulb + headlight controller (located inside the headlight, shared with the low beam, position light, turn signal and electric horn in the headlight) + connecting wire (one J01 signal line, one GDN ground line, one B + Power supply) + connector of headlight and main system (unified 3-port connector) + main controller (common part of VIT system, located in instrument) + control mechanism (located on combination switch, common with traditional system) +Power system (shared by the whole system)

[0082] 2 Analyze the function and power load of the subsystem. The bulb power of the high beam of the headlight is 70W*2 (because the vehicle has two high beams, one on the left and one on the left), and the load of this subsystem is registered in the power load list of the whole system.

[0083] 3 Determine the execut...

Embodiment 2

[0090] Example 2: Design and Implementation of Charging Indication System

[0091] 1 Analyze the composition of the subsystem Generator D+terminal+connector+main controller+connecting wire+instrument indicator system

[0092] 2 Analytical logic function Excite the generator + indicate the working status of the generator through the instrument

[0093] 3 Design the indication condition and indication circuit, and calculate the system capacity as 500mA

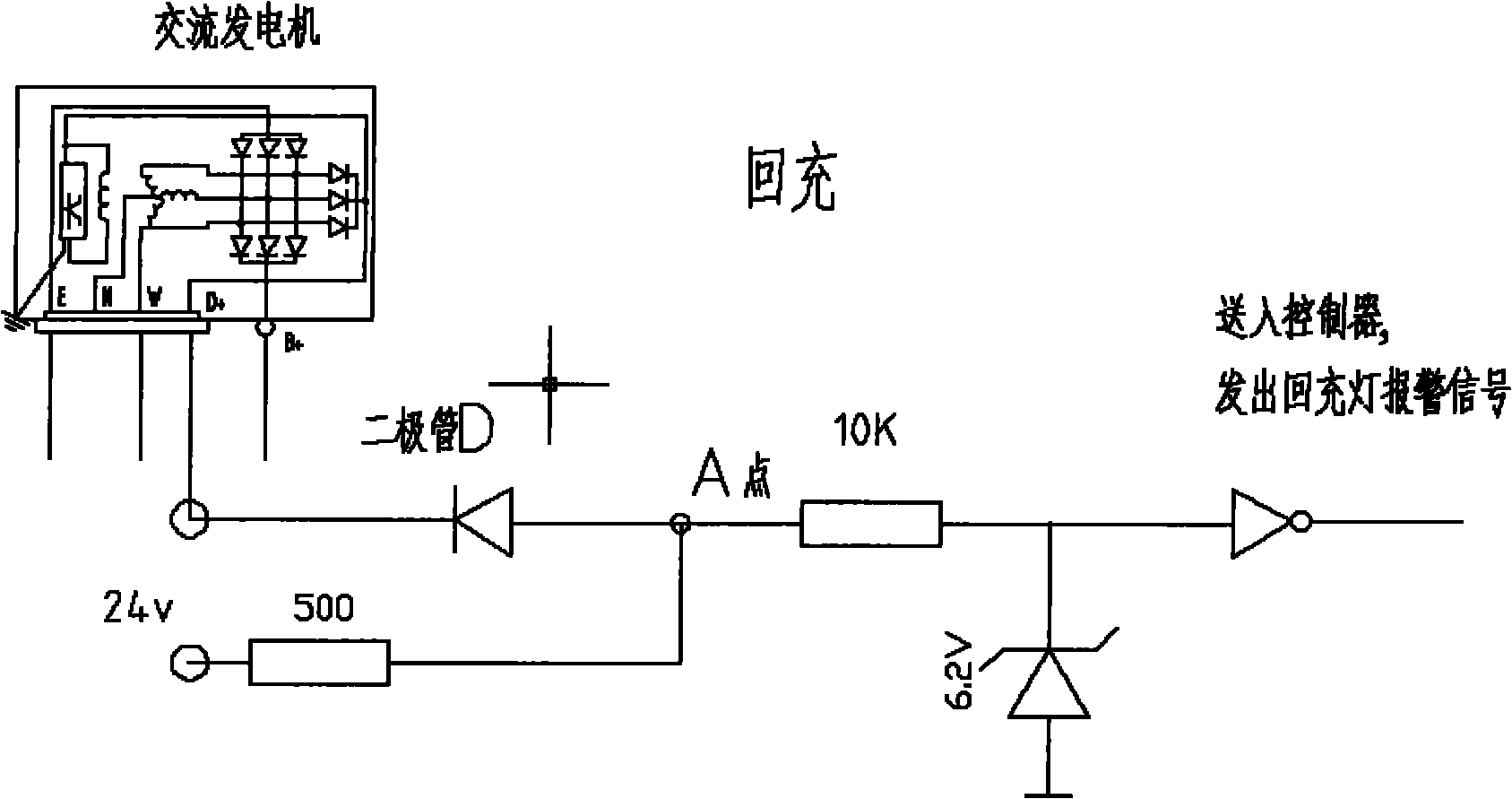

[0094] Such as image 3 As shown, the design circuit diagram of the charging indication control circuit:

[0095] The excitation current of the alternator is provided by the 24V port, which is controlled by the ON position of the key door, and the alarm voltage is set by the clamp diode. System alarm.

[0096] 4. Determine the capacity of the control circuit. After calculation, choose 0.5mm2 polyvinyl chloride thin-walled wire, and the standard is VW 603 06.

[0097] 5 Determine the connector model According to the plan, th...

Embodiment 3

[0100] Implementation 3: Realization and control of low beam function of vehicle headlights

[0101] 1 Analyze the composition of the subsystem Headlight low beam light bulb + headlight controller (located inside the headlight, shared with the high beam, position light, turn signal and electric horn in the headlight) + connecting wire (one control wire, one ground wire, one live wire) + the connector between the headlight and the main system (a unified 3-port connector) + the main controller (a common part of the VIT system, located in the instrument) + the control mechanism ( Located on the combination switch, common to the traditional system) + power supply system (shared by the whole system)

[0102] 2 Analyze the function and power load of the subsystem. The bulb power of the low beam of the headlight is 70W*2 (because the vehicle has two high beams, one on the left and one on the left), and the load of this subsystem is registered in the power load list of the whole syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com