Pressure-free guide type double-copper-foil cutting forming system

A copper foil cutting technology, which is applied in the field of non-pressing and extracting double copper foil cutting and forming system, can solve the problems of lower product yield, lead slip, copper foil surface wrinkles, etc., to improve precision and quality, Avoid slipping and wrinkling, and ensure the effect of cutting length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

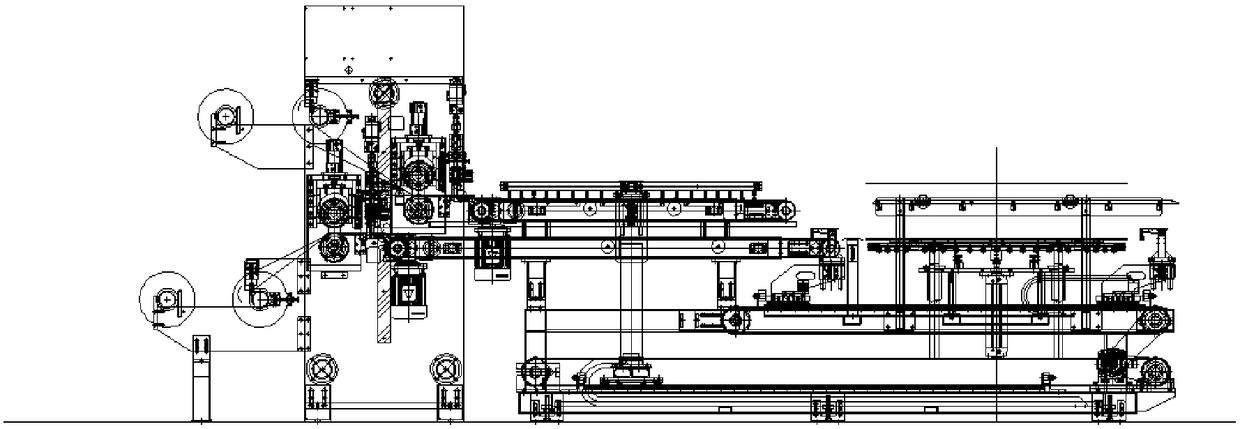

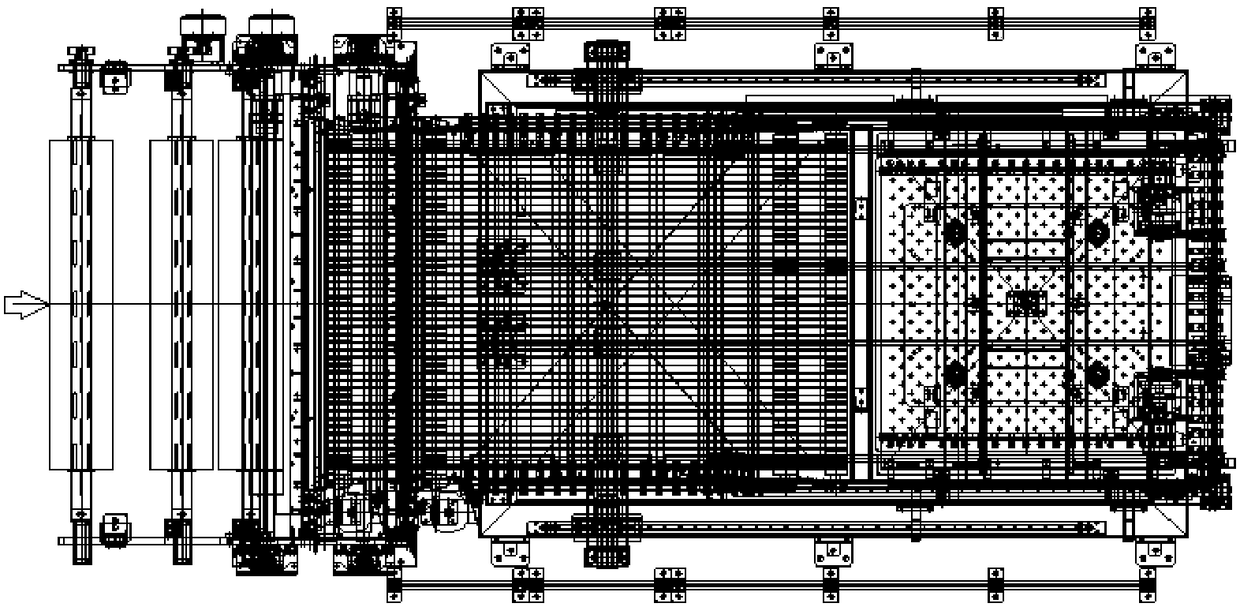

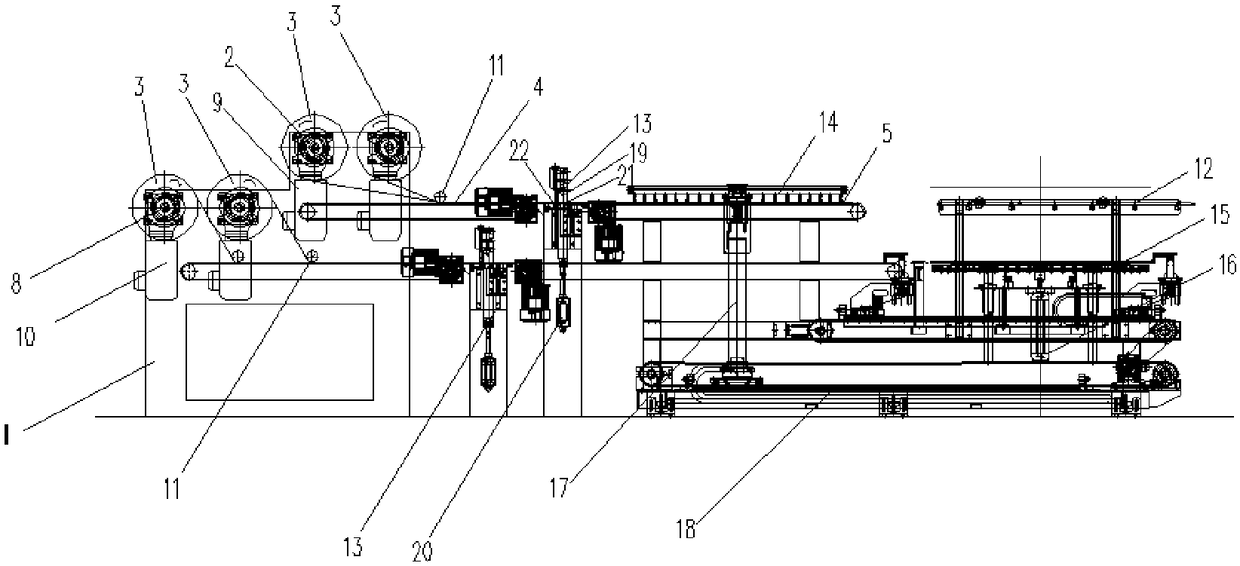

[0024] Embodiment: A non-pressing and extracting copper foil cutting and forming system, including a frame 1 and a copper foil cutting and conveying mechanism, at least one set of copper foil cutting and conveying mechanisms are arranged at intervals along the longitudinal direction on the frame 1, wherein The copper foil cutting and conveying mechanism includes a chuck 2, a sending drive device 9, a first plane conveying device 4, a first air pressure providing device, a cutting mechanism 13, a second plane conveying device 5 and a second air pressure providing device. The disk 2, the first plane conveying device 4, the cutting mechanism 13 and the second plane conveying device 5 are arranged sequentially along the copper foil conveying direction, and the chuck 2 is rotatably mounted on the frame 1, and the copper foil roll 3 can be coaxial Fixedly installed on the chuck 2, the sending drive device 9 drives the chuck 2 to rotate, and one end of the copper foil on the copper fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com