Flying shearing machine

A technology for flying shears and workpieces, applied in the field of flying shears, can solve problems such as unreasonable adjustment of side clearance, shear deviation, and irregular shearing, and achieve improved product shearing quality, accurate cutting length, and high productivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

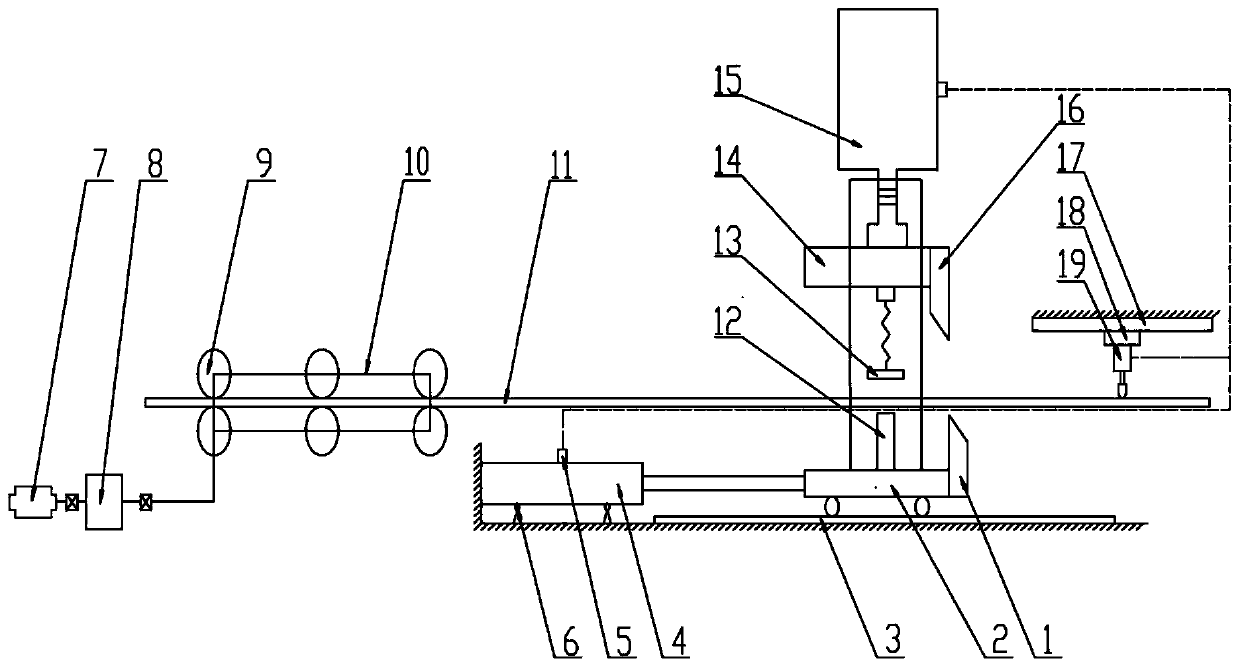

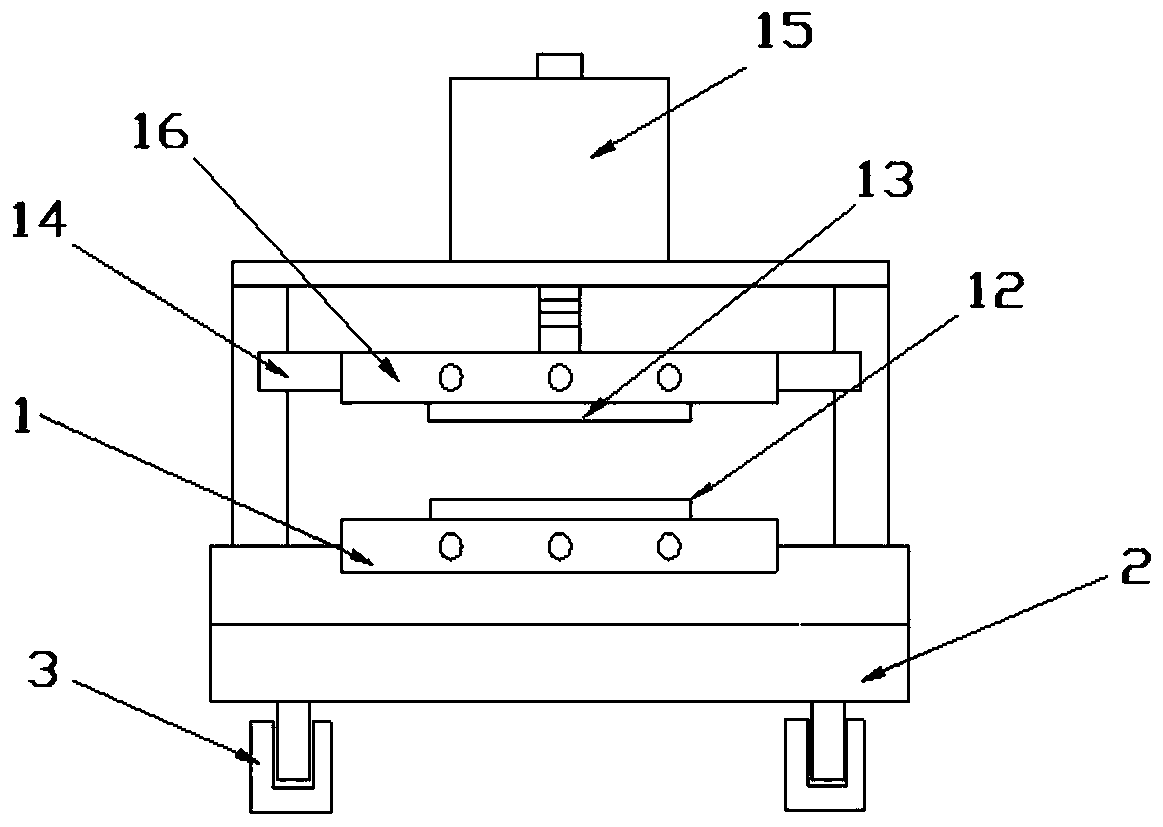

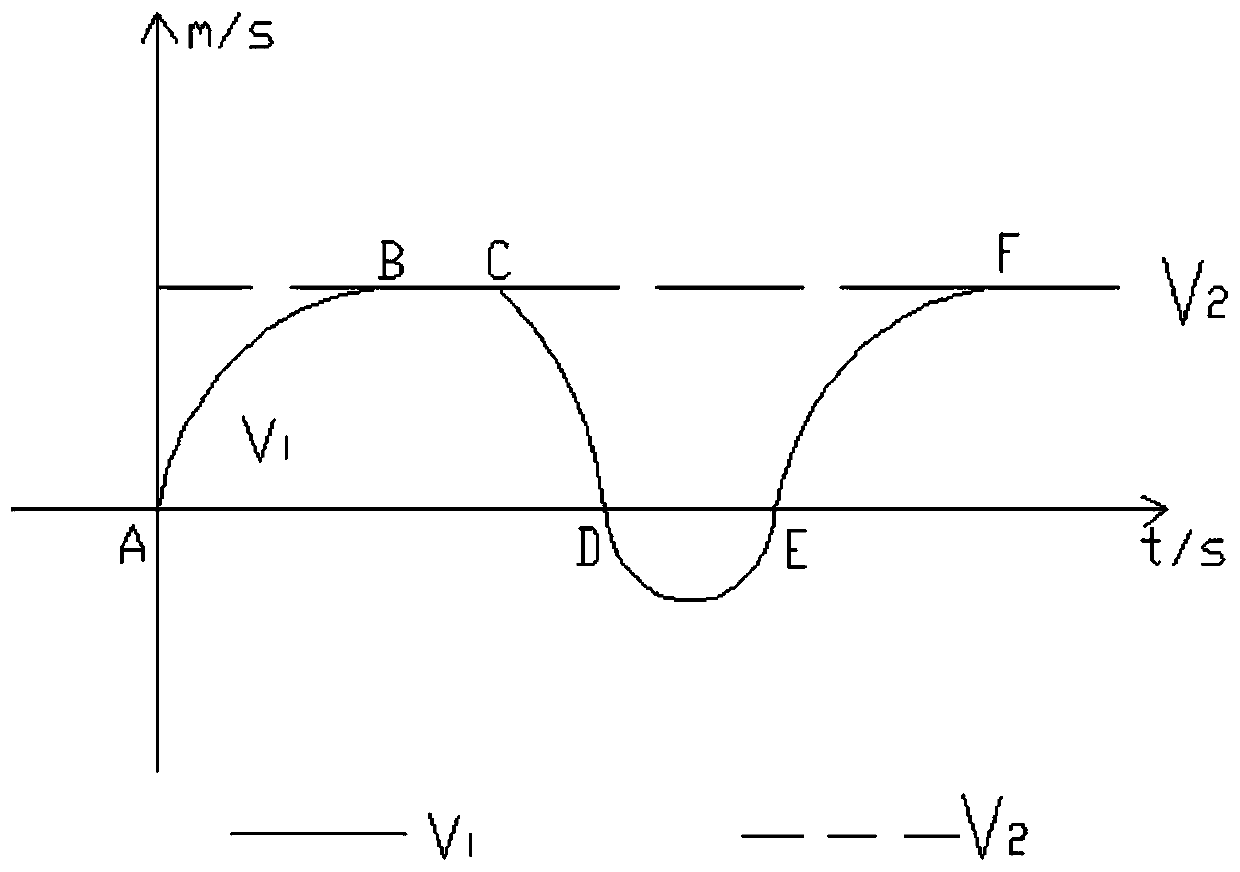

[0018] Such as Figure 1 to Figure 3 As shown, the present invention provides a flying shear, comprising a knife-carrying trolley 2, a lower knife block 1 and a bearing frame arranged on the knife-carrying trolley 2, used to control the knife-carrying trolley 2 to move along a first direction and make the The first actuator 4 whose speed is consistent with the feed speed of the workpiece, the moving tool rest 14, the second actuator 15 which is arranged on the carrier and is used to control the moving tool rest 14 to move in the vertical direction, The upper knife block 16 arranged on the movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com