Production method and matched production line of fiber reinforced composite ribbon

A composite material and fiber-reinforced technology, applied in metal processing and other directions, can solve the problems of manual collection of flat belt production efficiency, measurement accuracy, cutting accuracy, etc., and achieve the effect of saving labor, accurate cutting length, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

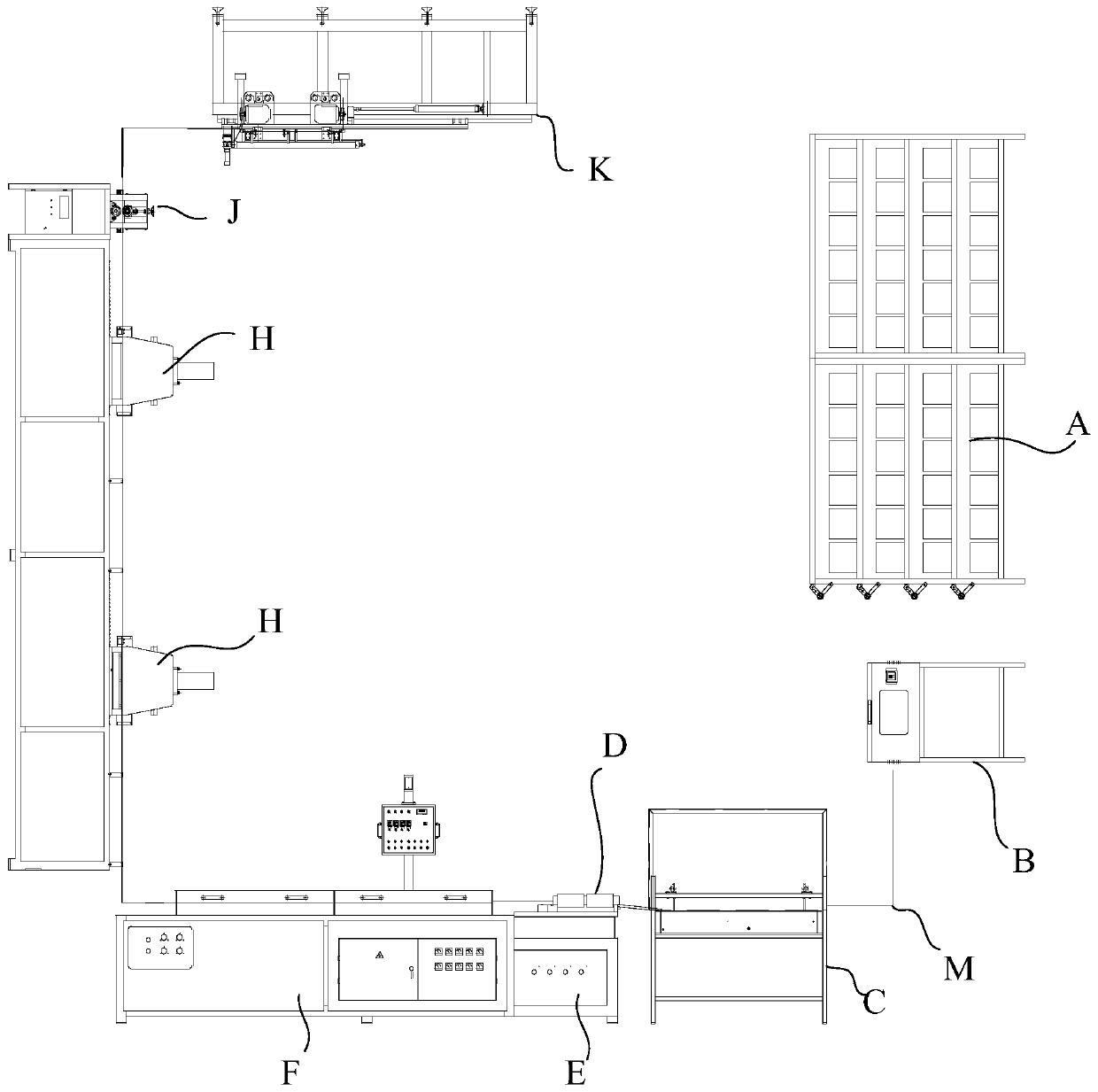

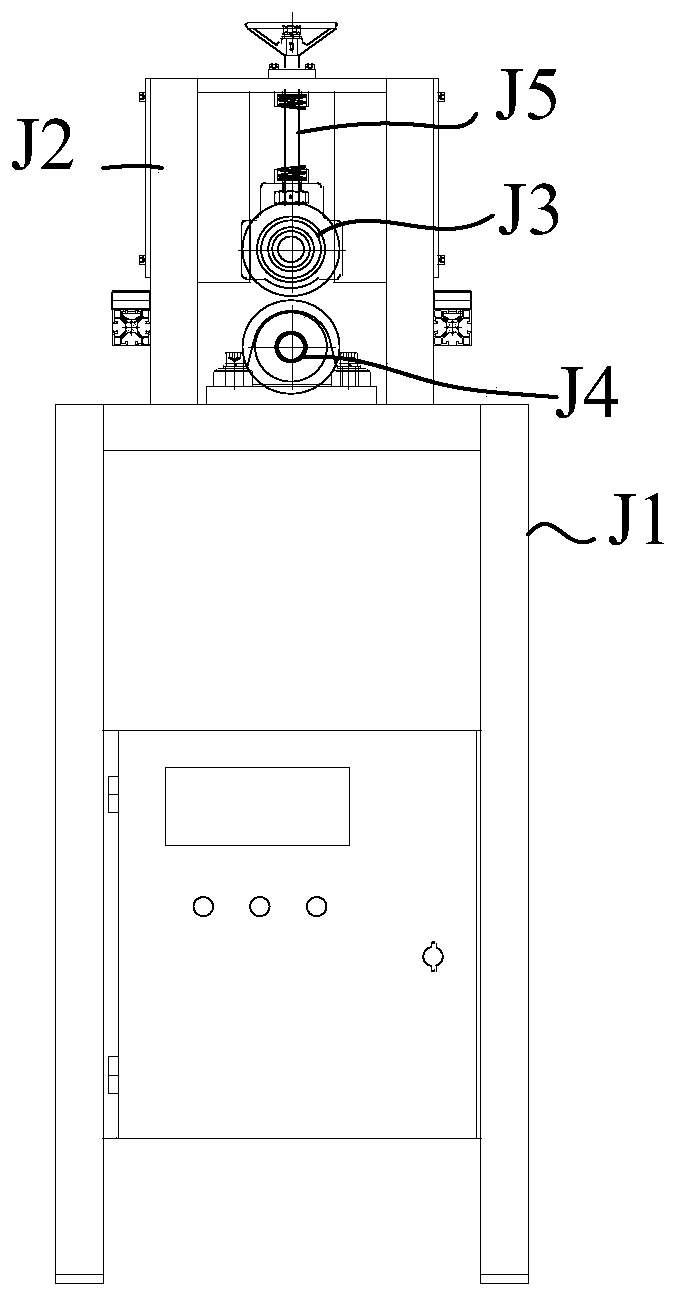

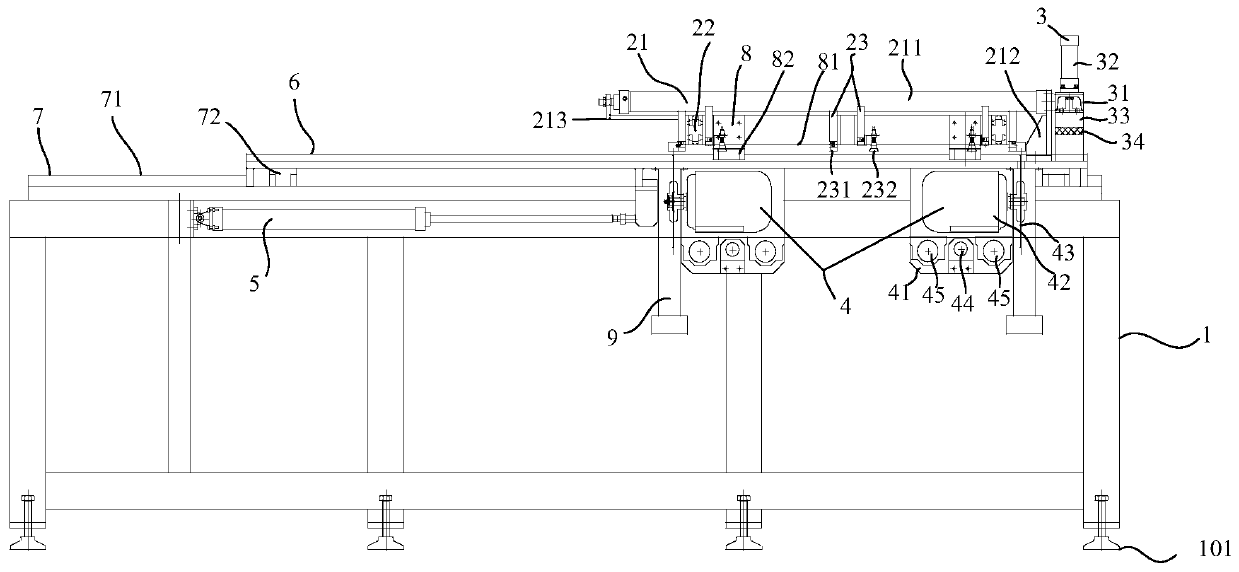

[0049] Example 1, such as figure 1 As shown, the present invention provides a production method of fiber-reinforced composite material flat belt, and a corresponding supporting production line is set for the production method.

[0050] The production method of its fiber-reinforced composite flat belt specifically includes the following steps:

[0051] 1) select glass fiber and dehumidify it;

[0052] 2) dipping the dehumidified glass fiber;

[0053] 3) Then heating and forming, and straightening treatment;

[0054] 4) solidify and dry it again to obtain the flat tape primary product;

[0055] 5) Finally, the primary product of the sling is cut to length to obtain the final sling product;

[0056]The selected glue for dipping in step 2) is resin.

[0057] Let's talk about how to realize the industrial production of flat belt in combination with the whole production line.

[0058] 1. After the glass fiber is pulled out from the creel with tension, it enters the dehumidifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com