Patents

Literature

39results about How to "Control cutting length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

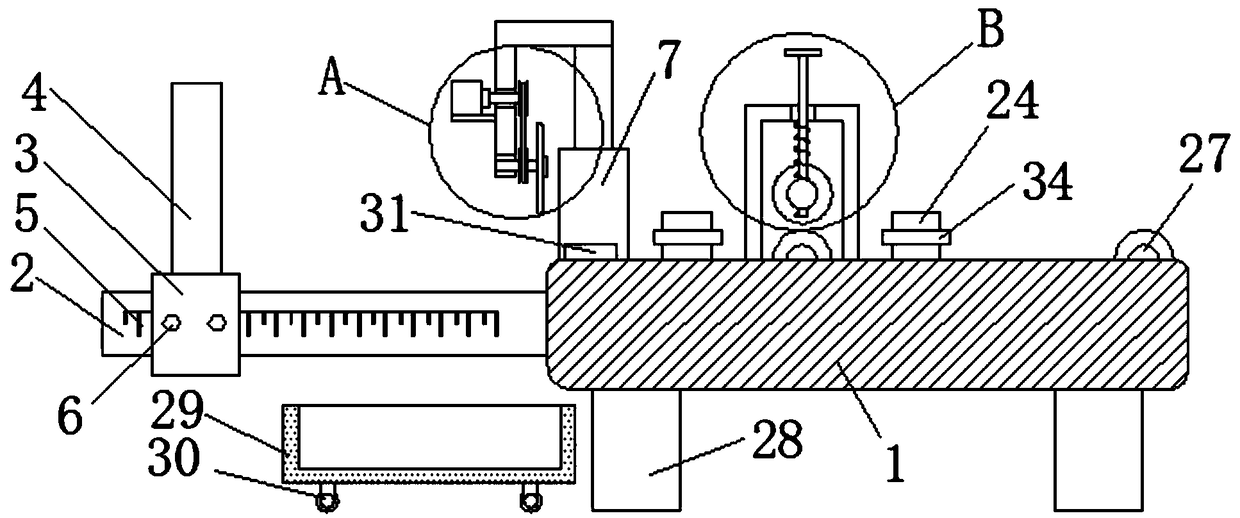

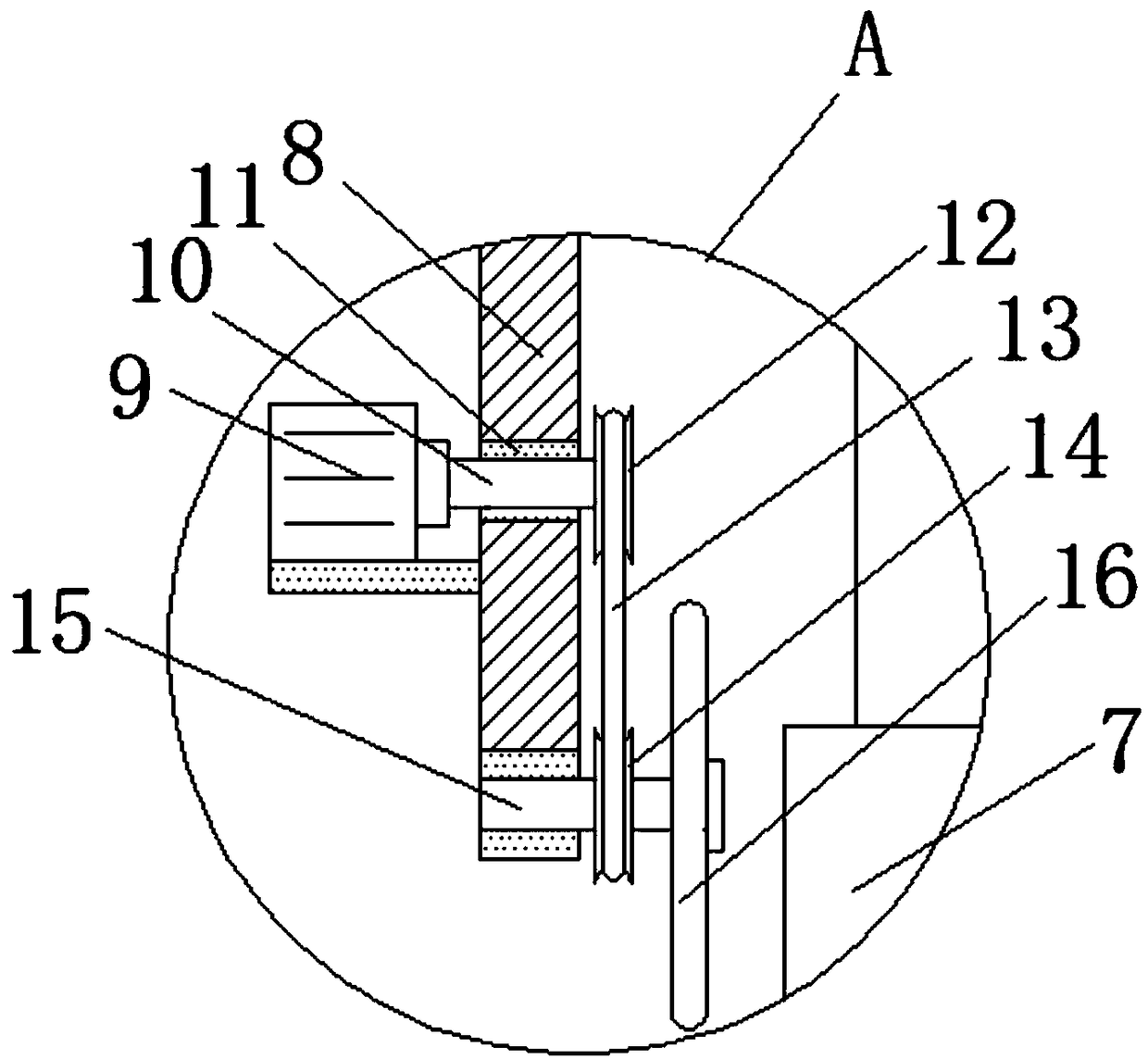

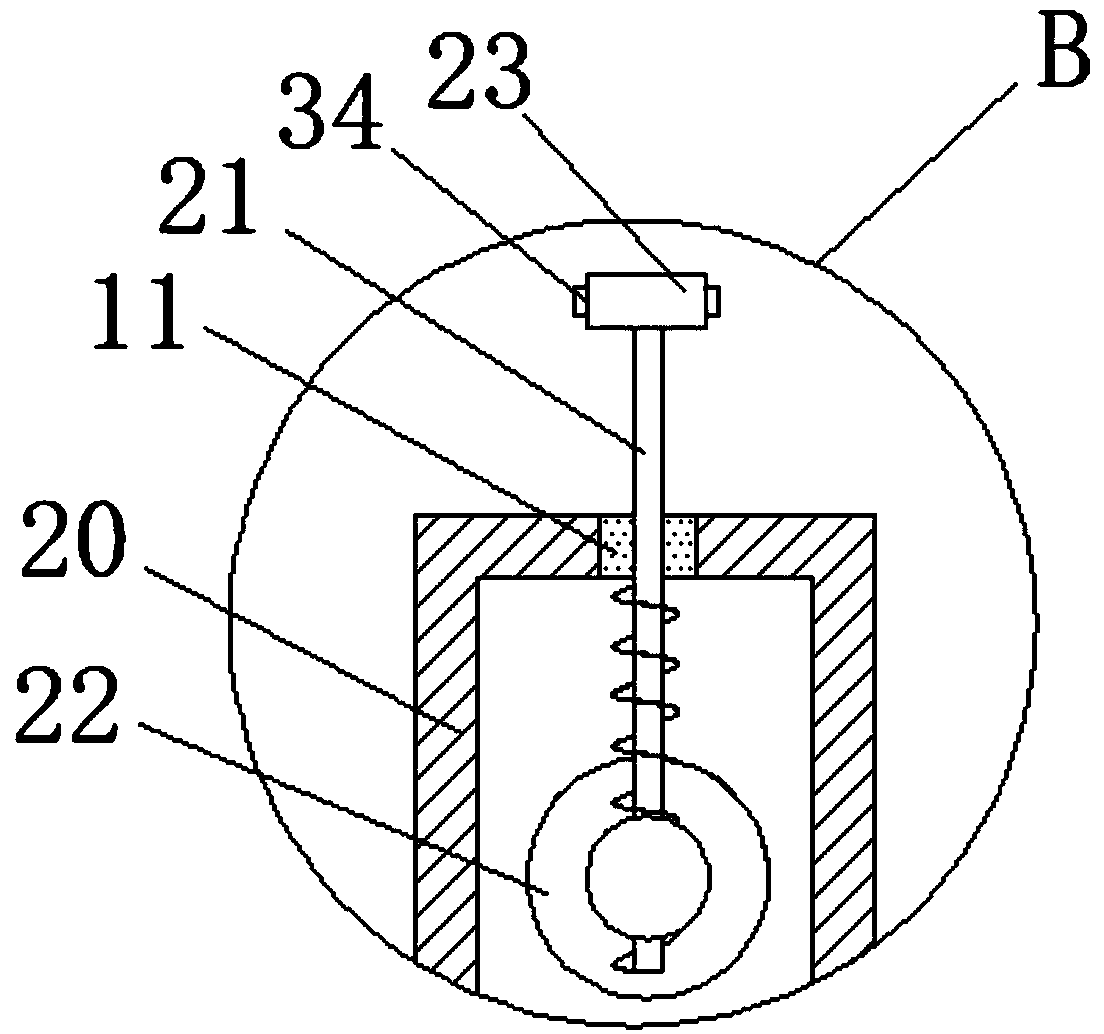

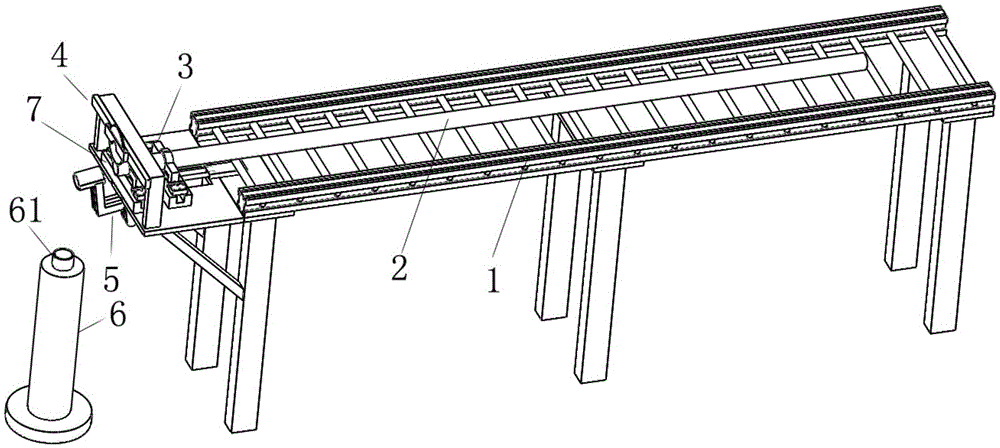

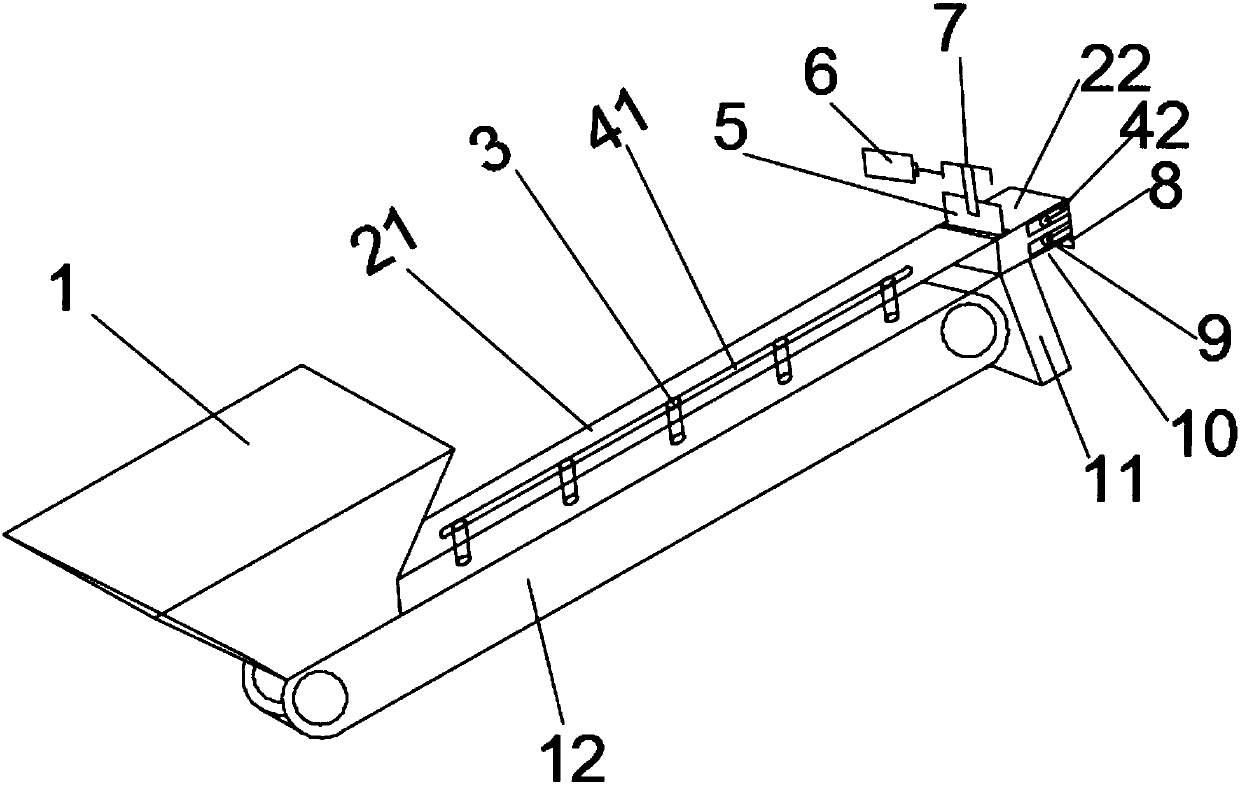

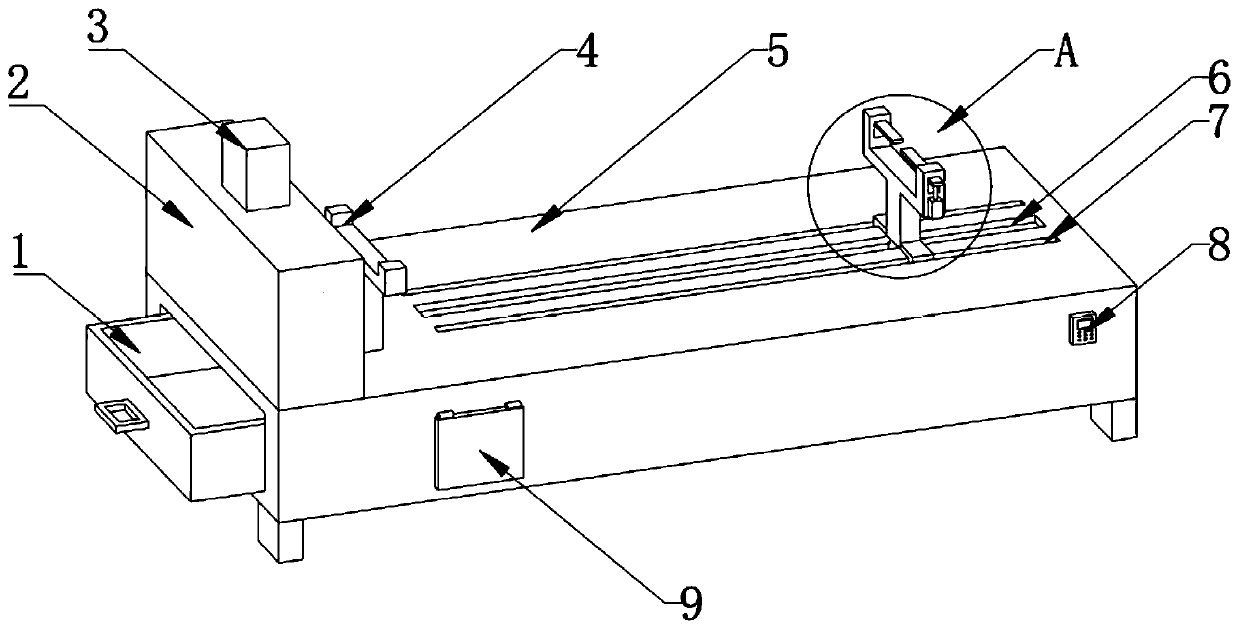

Steel bar cropping machine with cropping size precisely-adjusting function for construction industry

InactiveCN108971394AEasy to moveControl cutting lengthMetal working apparatusArchitectural engineeringRebar

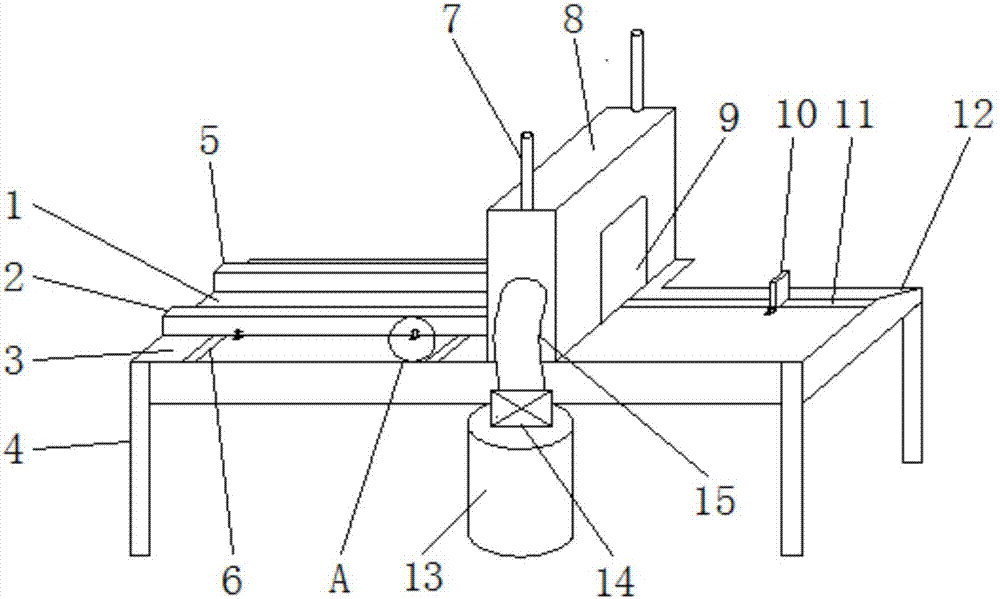

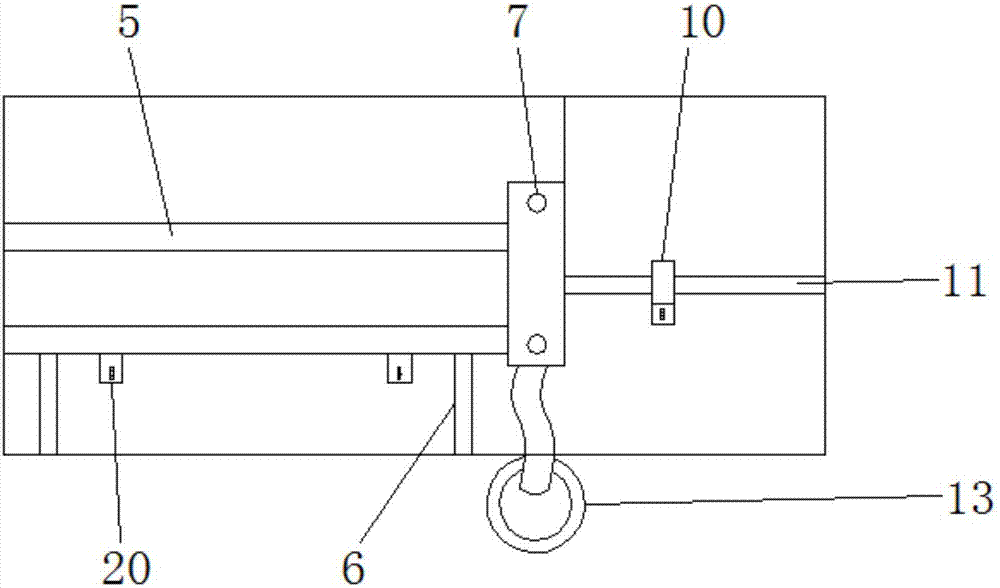

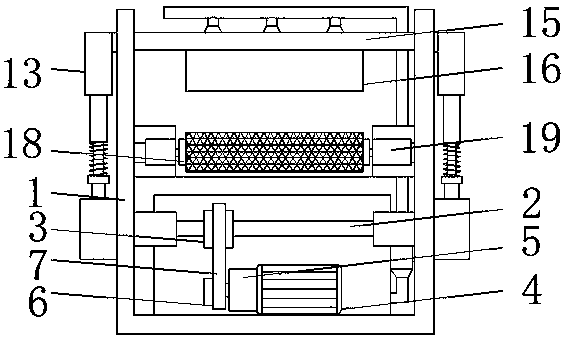

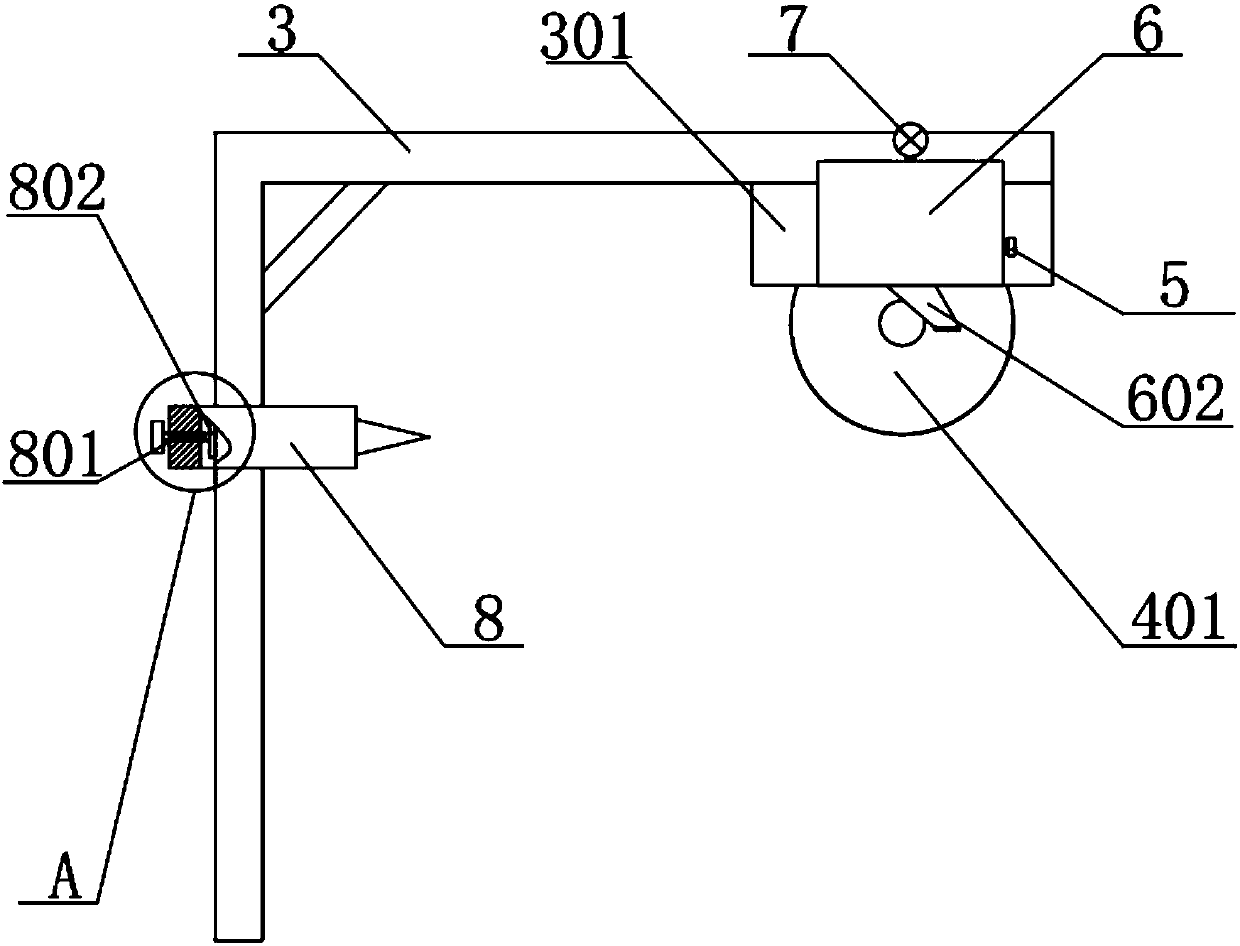

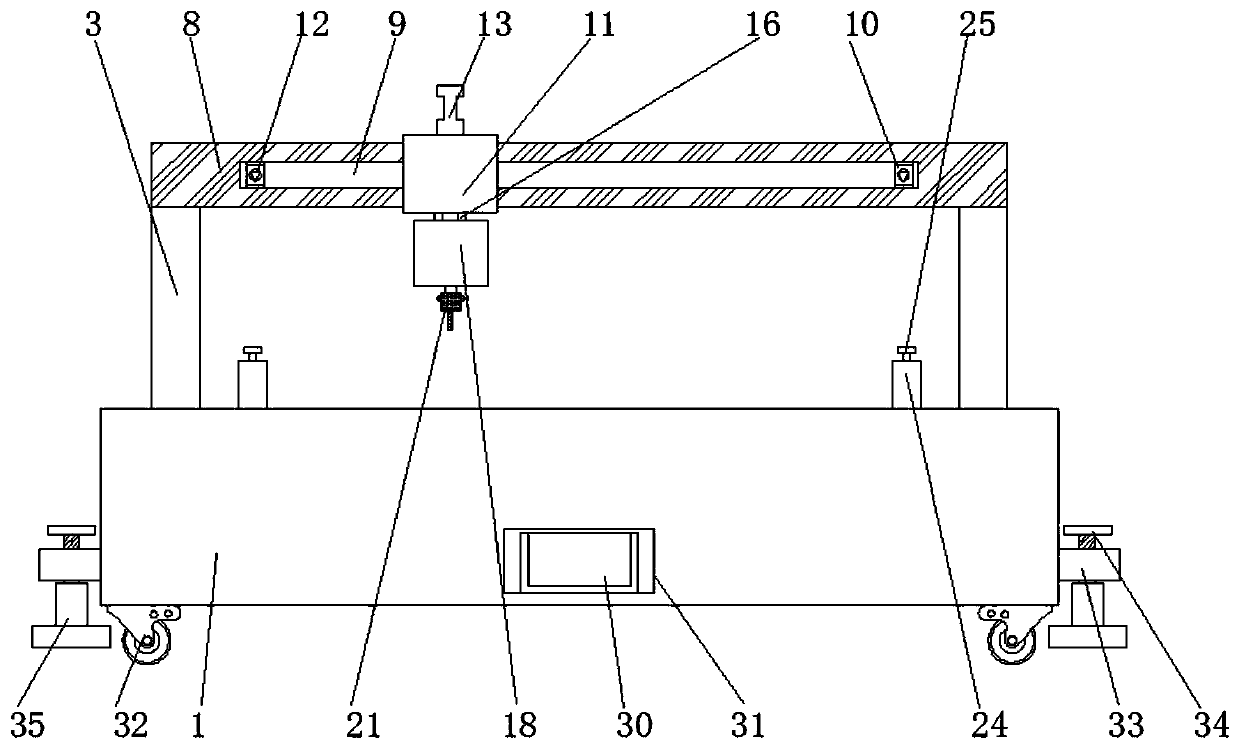

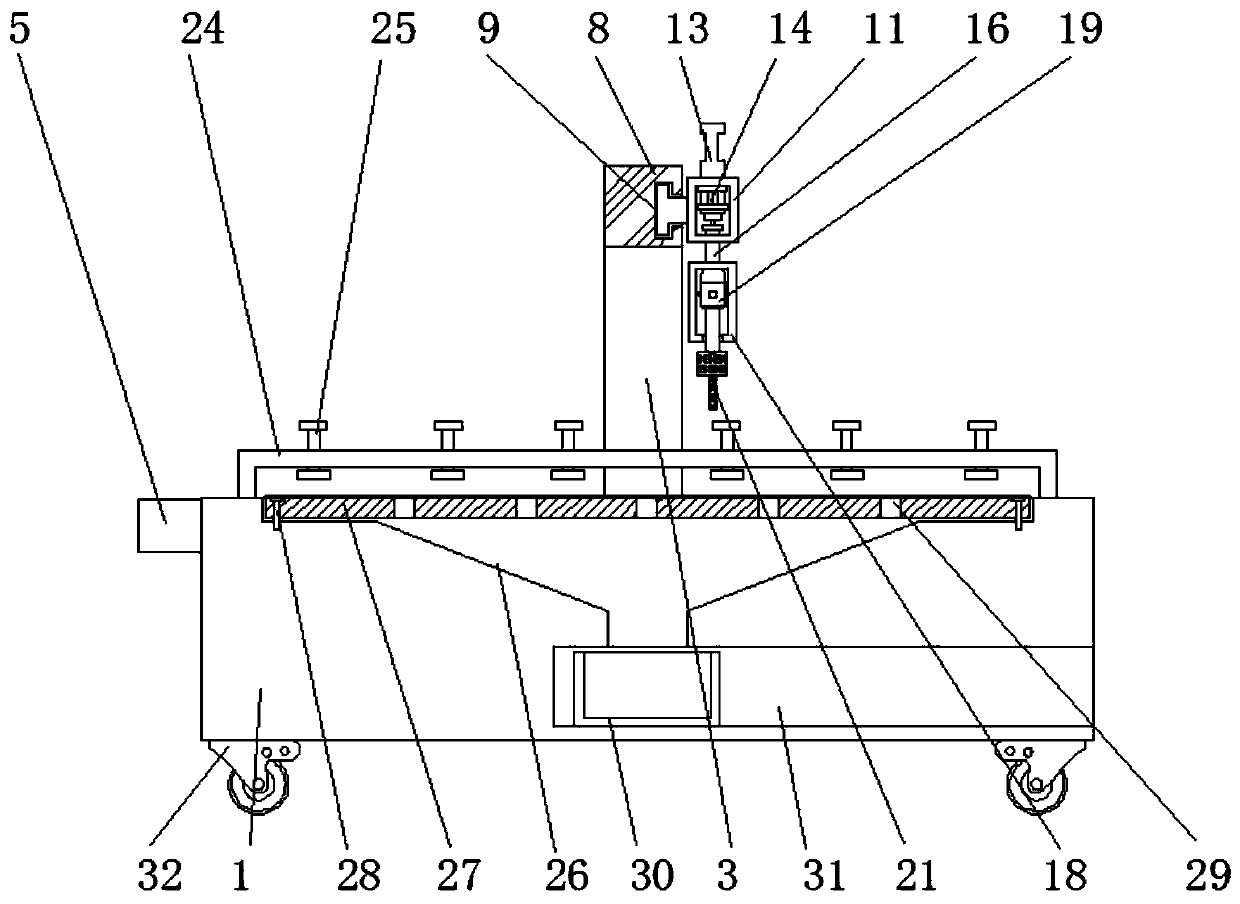

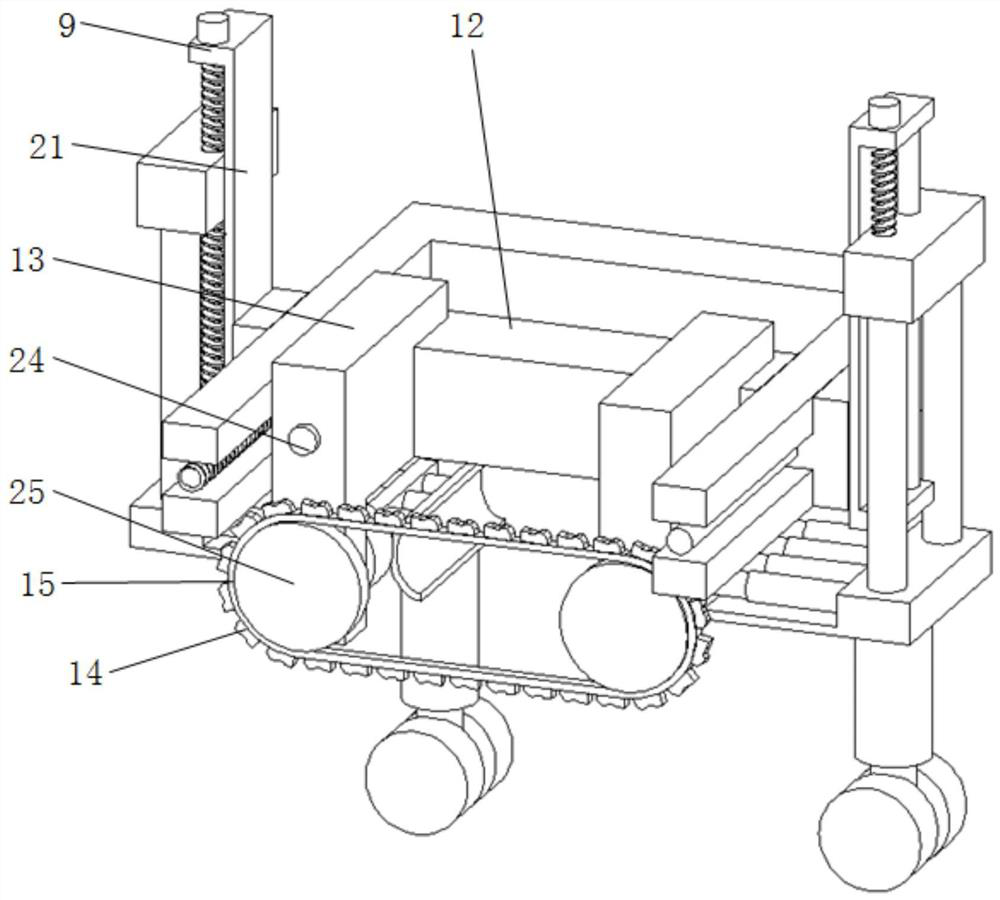

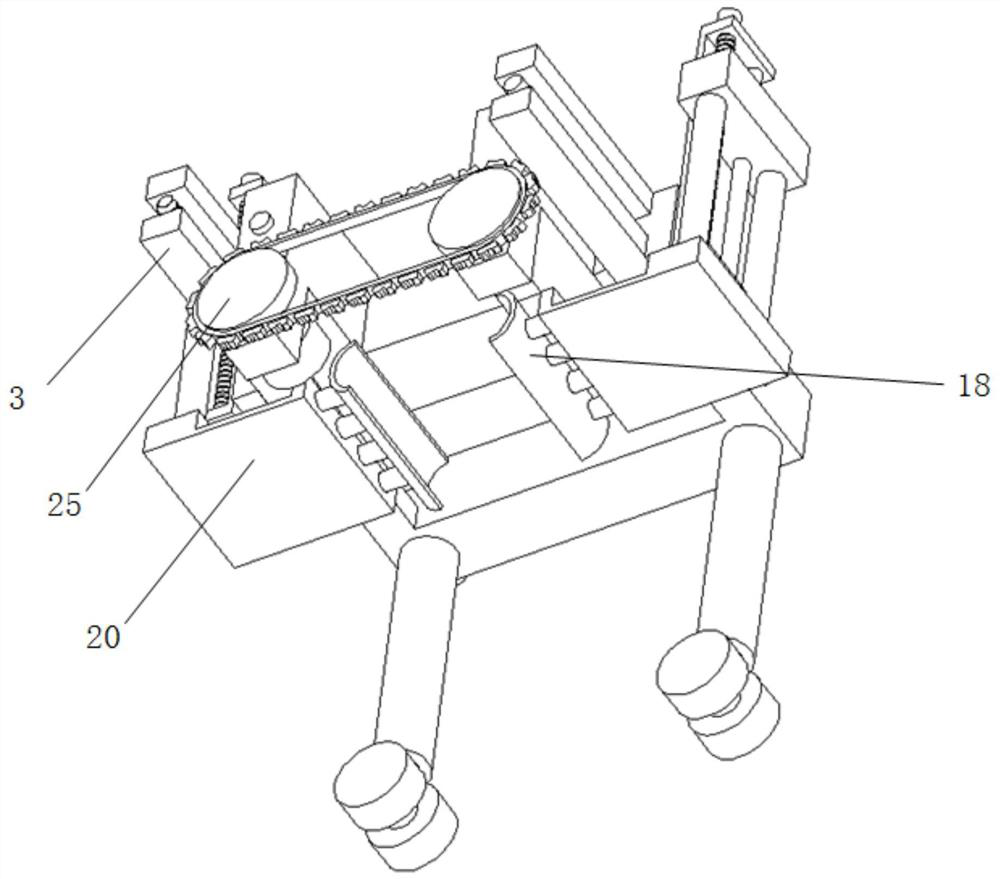

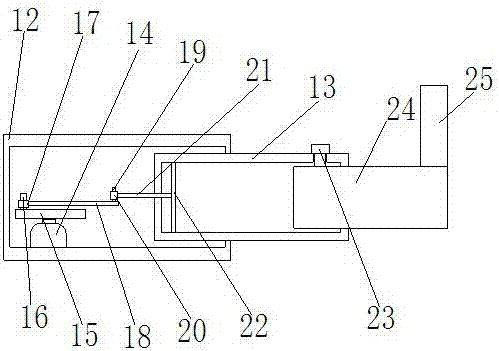

The invention discloses a steel bar cropping machine with a cropping size precisely-adjusting function for the construction industry. The steel bar cropping machine comprises a base, one end of the base is fixedly connected with two sets of sliding rails, a first motor is mounted on one side of the lower end of an L-shaped fixing plate, a first rotating shaft is fixedly connected to an output shaft of the first motor, and the first rotating shaft is mounted on one side of the L-shaped fixing plate through a bearing; and the interior of a fixing block is in threaded connection with a second lead screw, and a clamping plate is mounted at one end of the second lead screw through a bearing. The two sets of sliding rails are mounted at one end of the base, and thus a baffle can slide on the sliding rails through sliding blocks; the sliding blocks are fixed to the sliding rails through screws, and meanwhile, moving of the sliding blocks is also facilitated; and the sliding blocks are moved through a graduated scale on one side of the corresponding sliding rail according to the steel bar cutting length, thus the baffle can abut a steel bar, the cutting length of the steel bar is controlled, and thus the cutting length of the steel bar is more precise.

Owner:潍坊华高信息科技有限公司

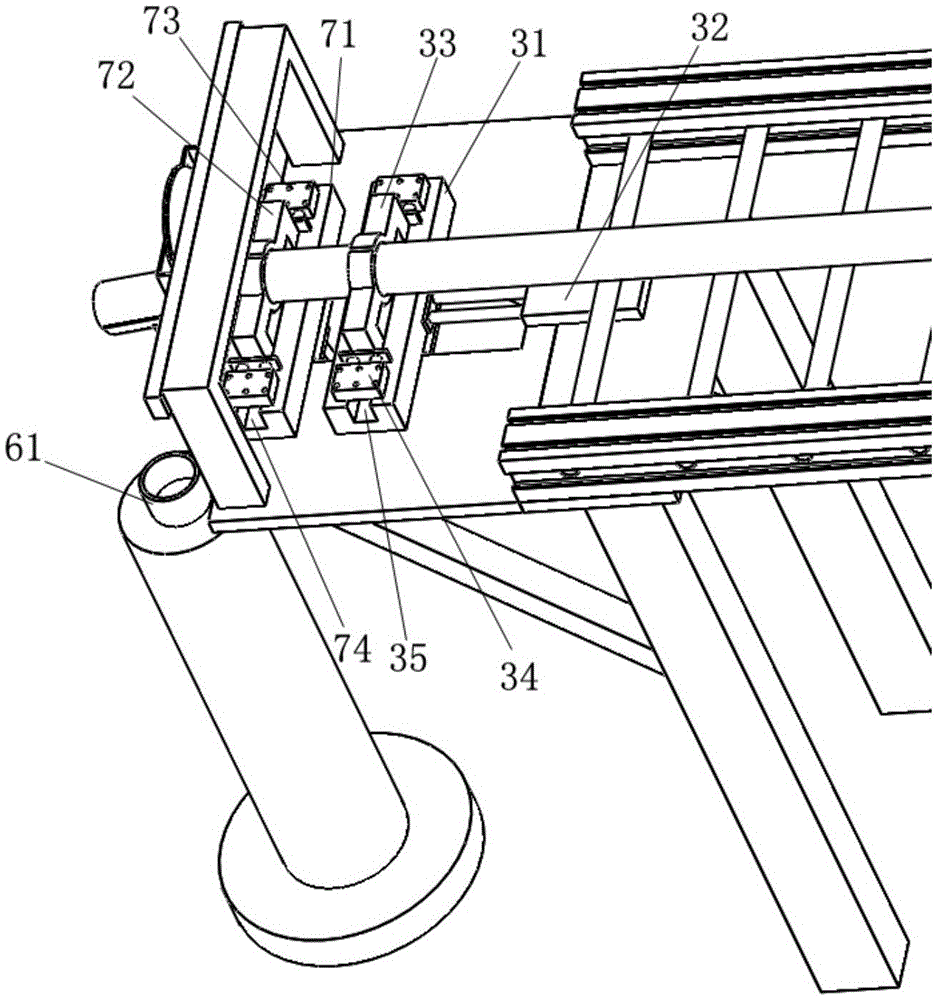

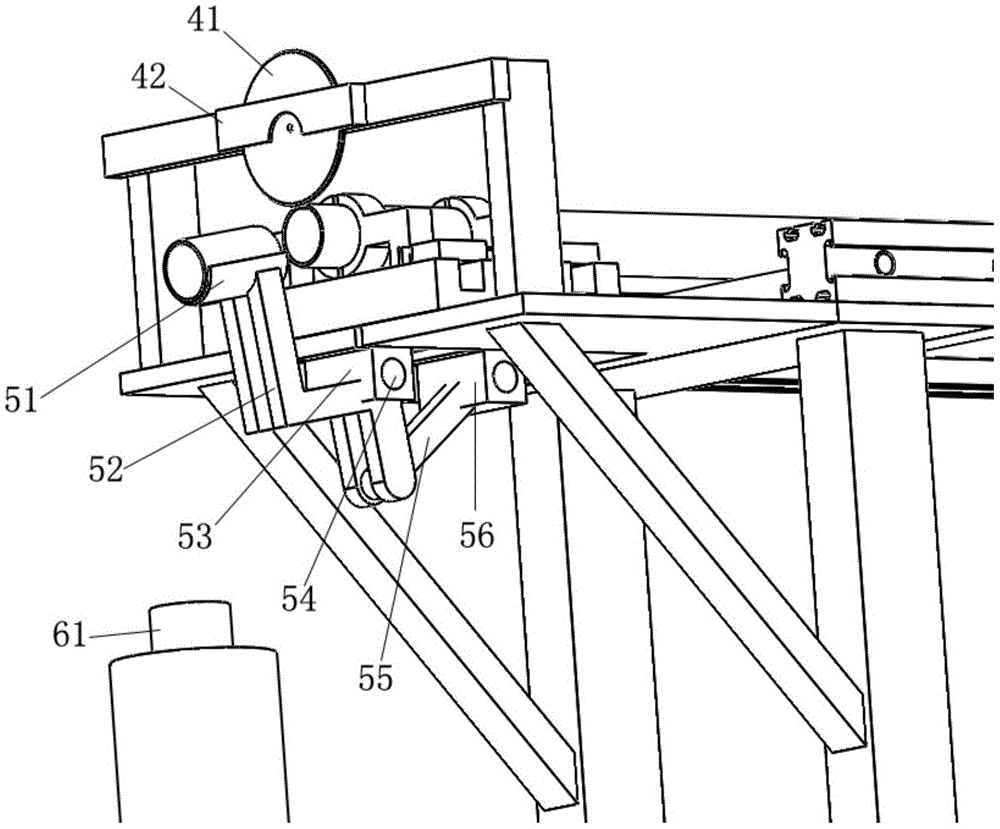

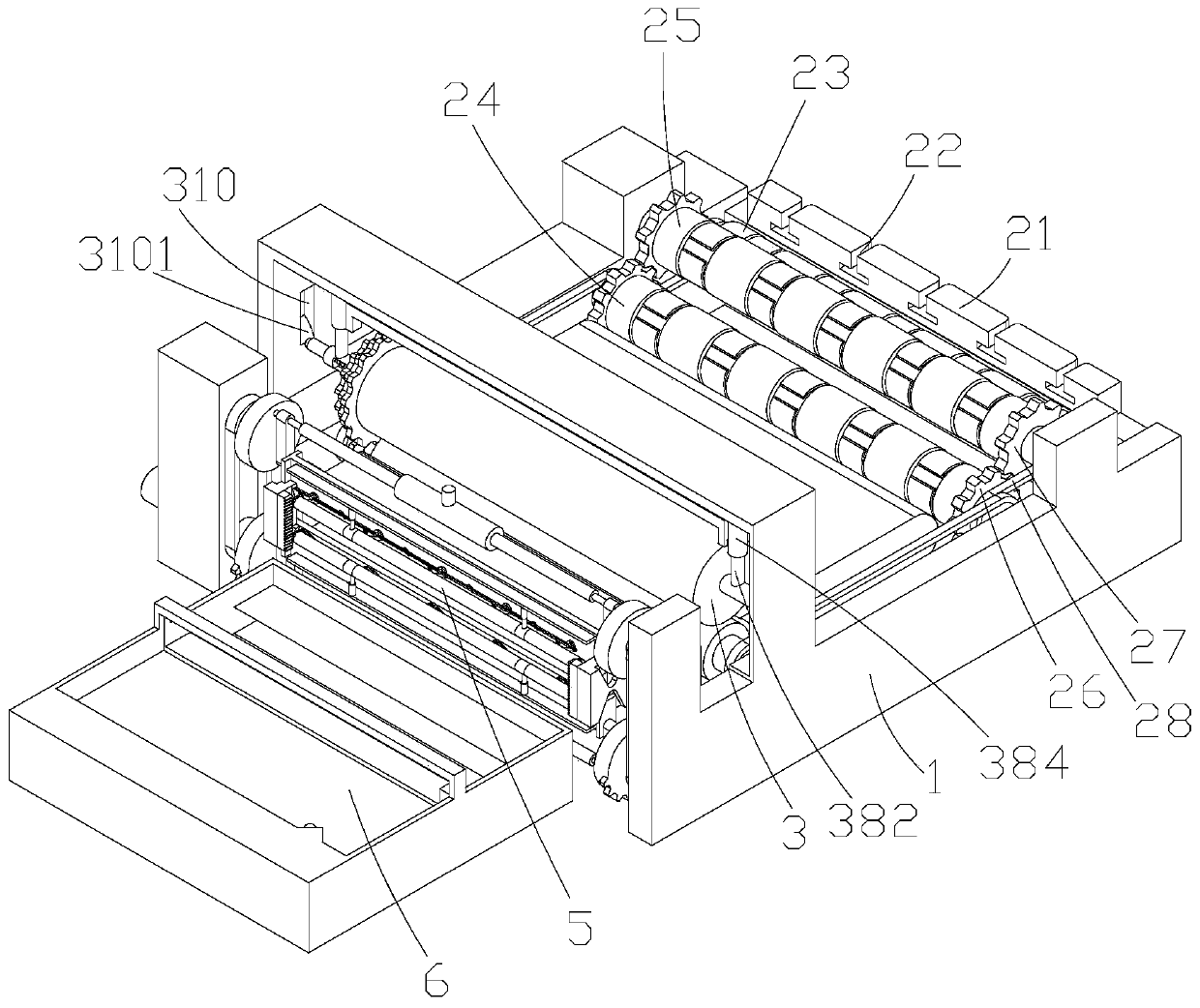

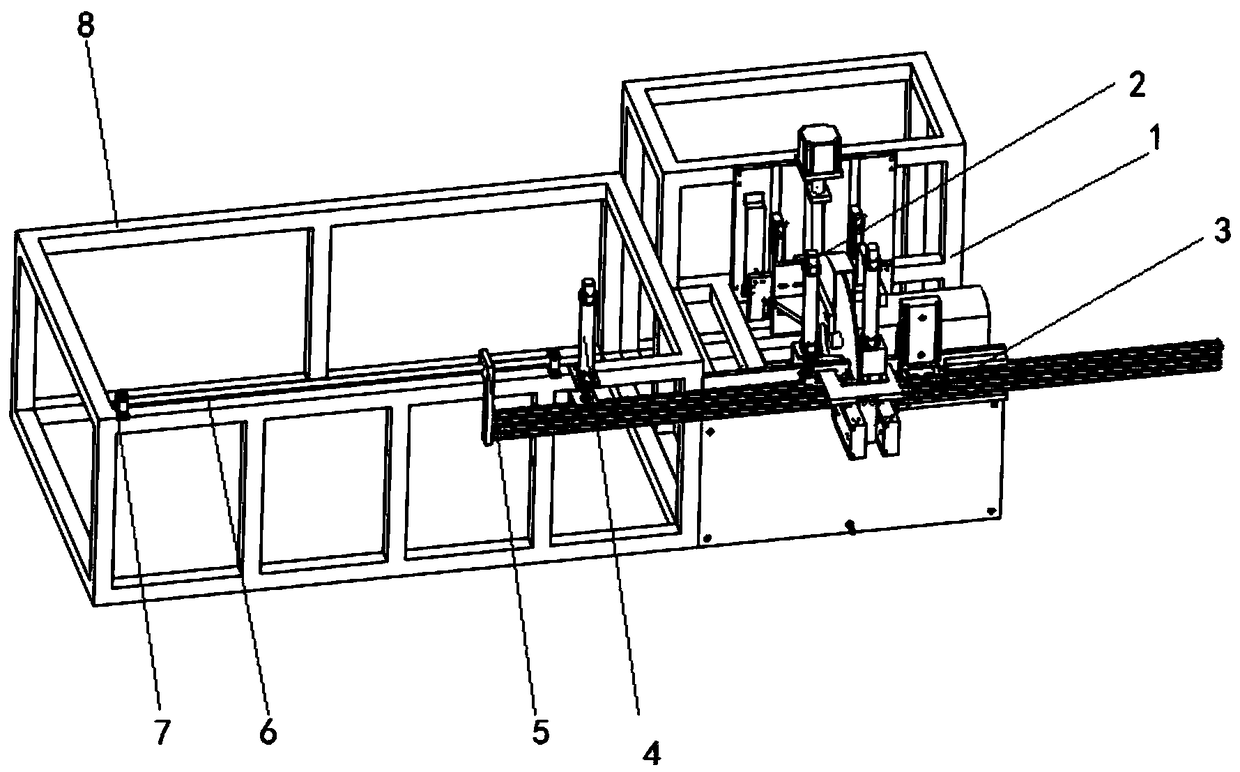

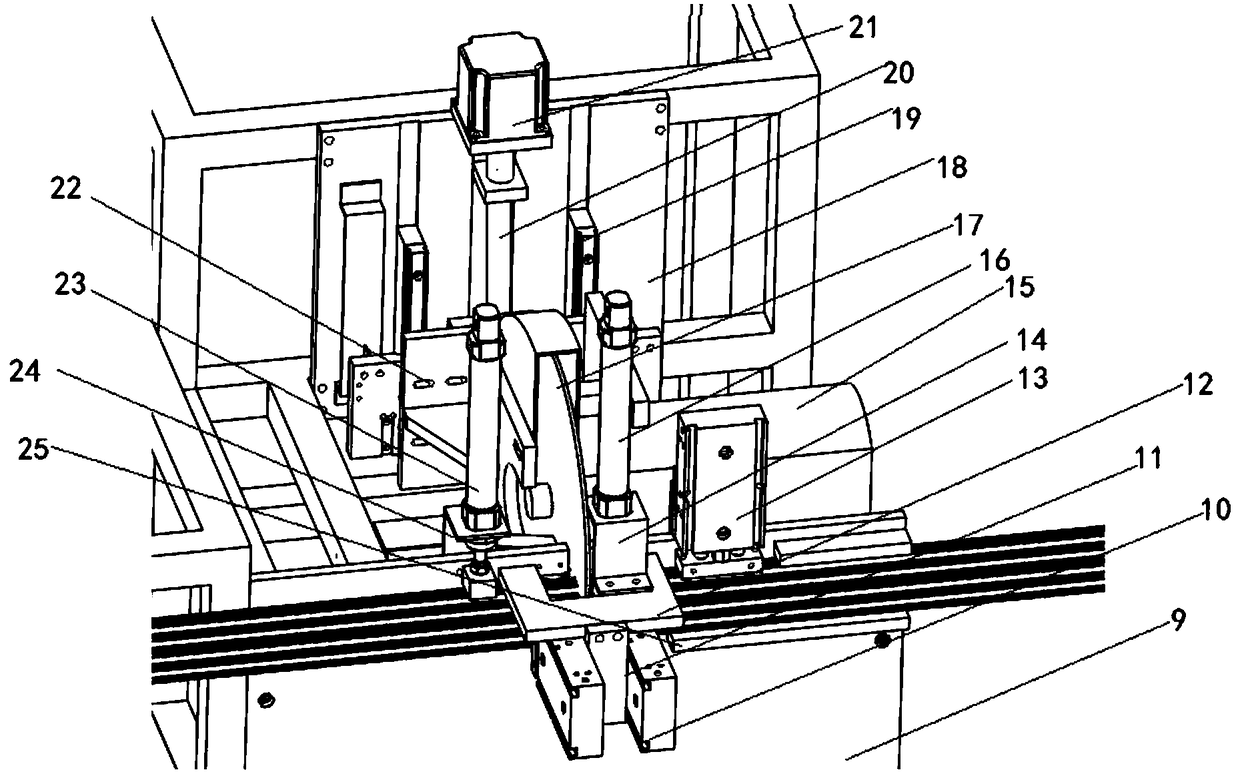

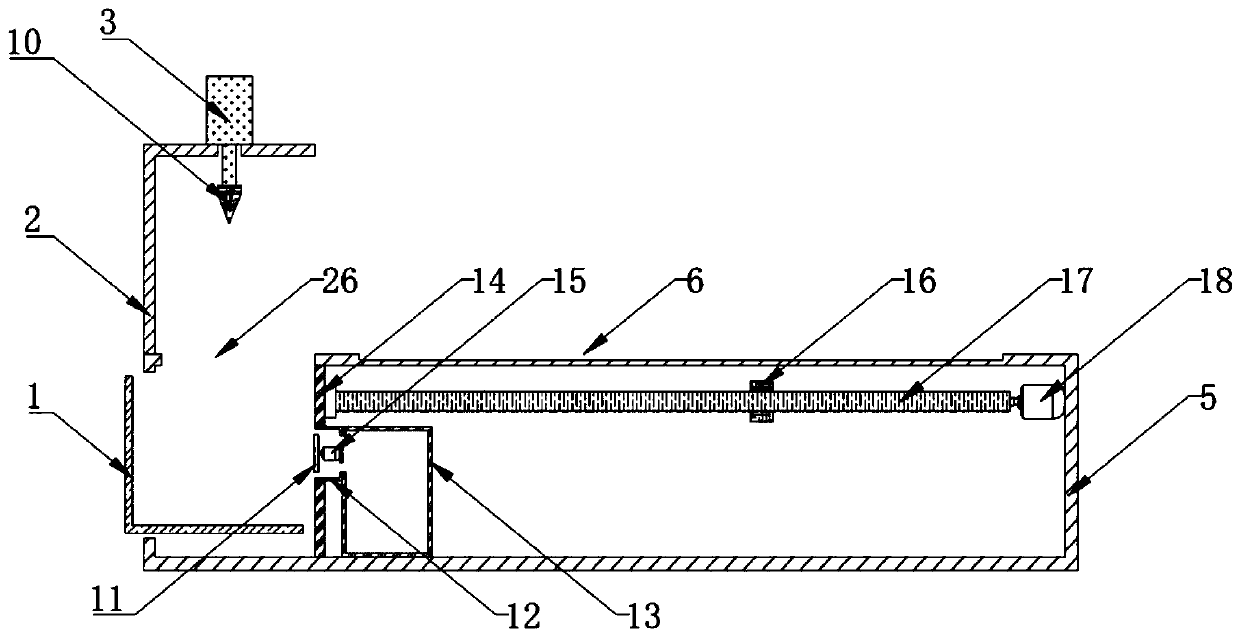

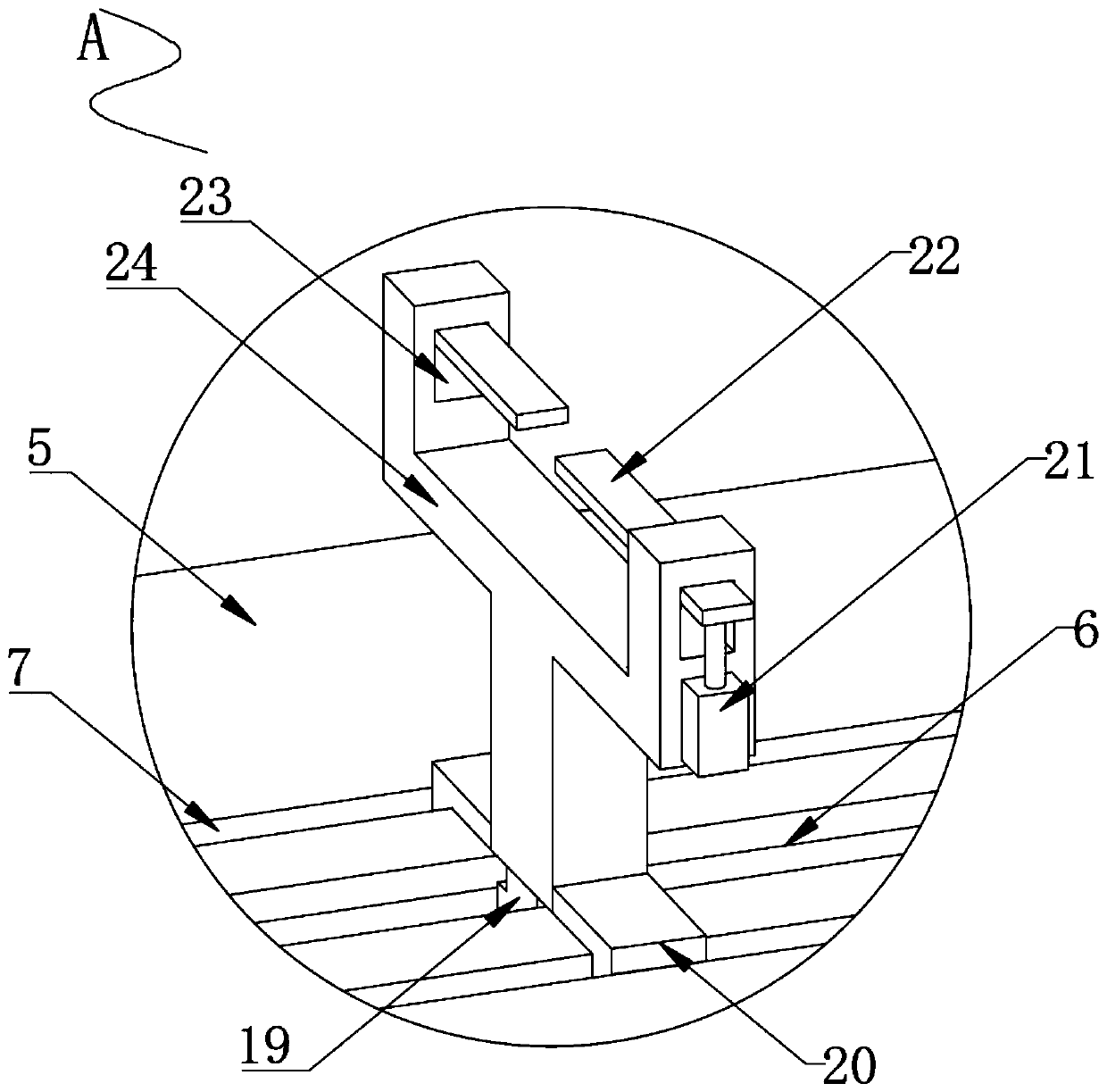

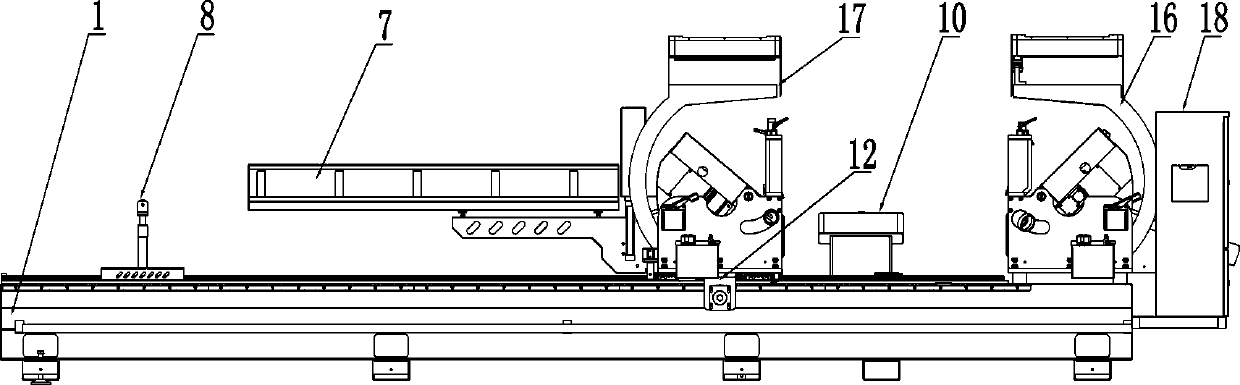

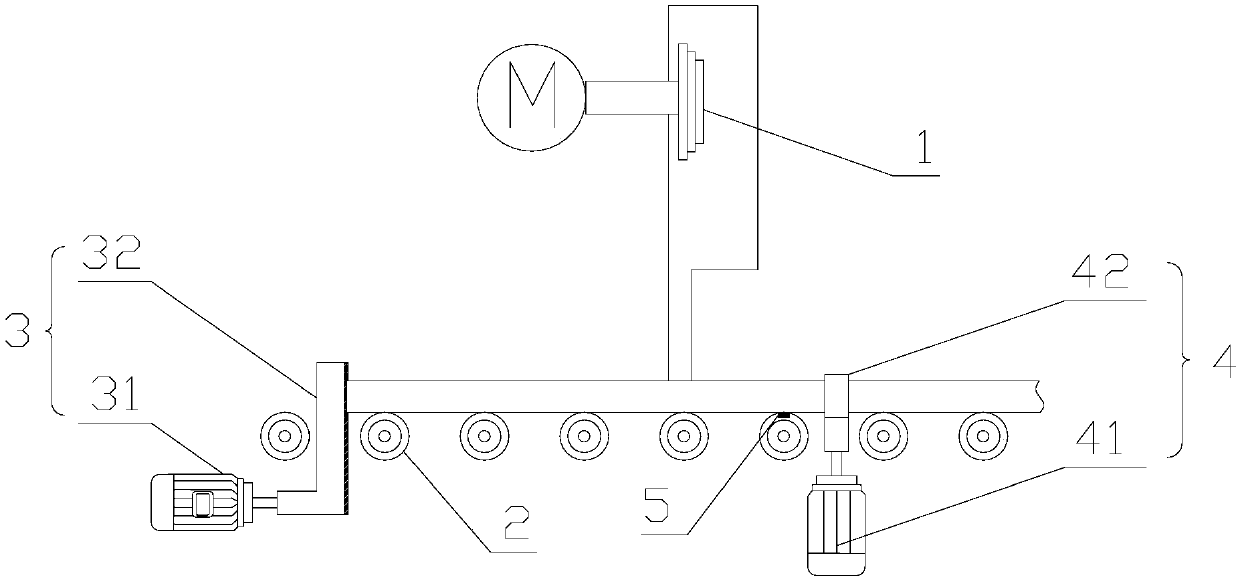

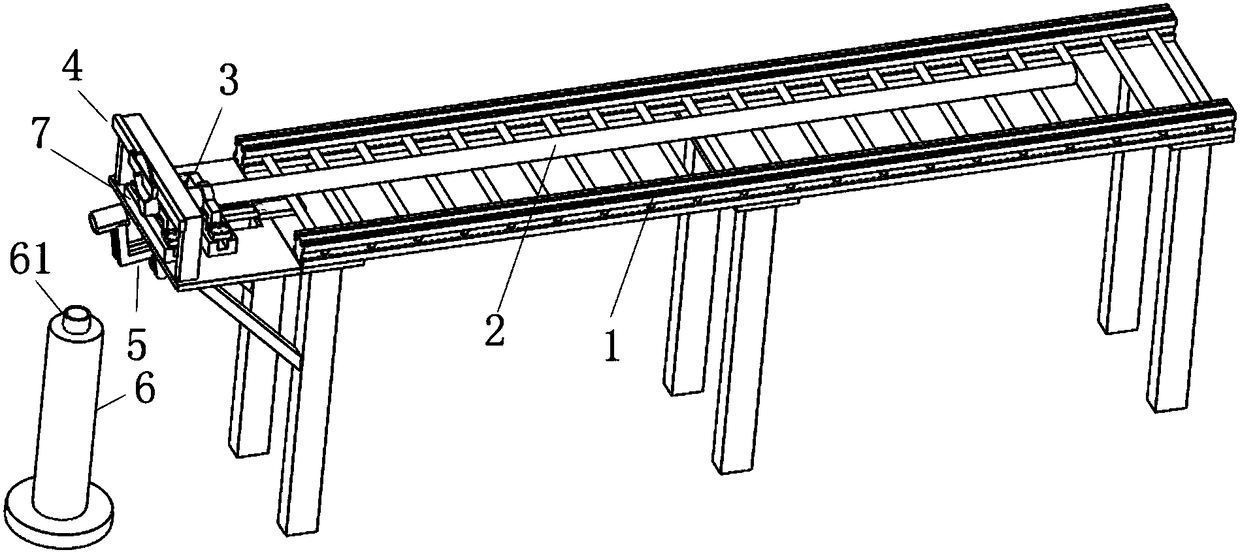

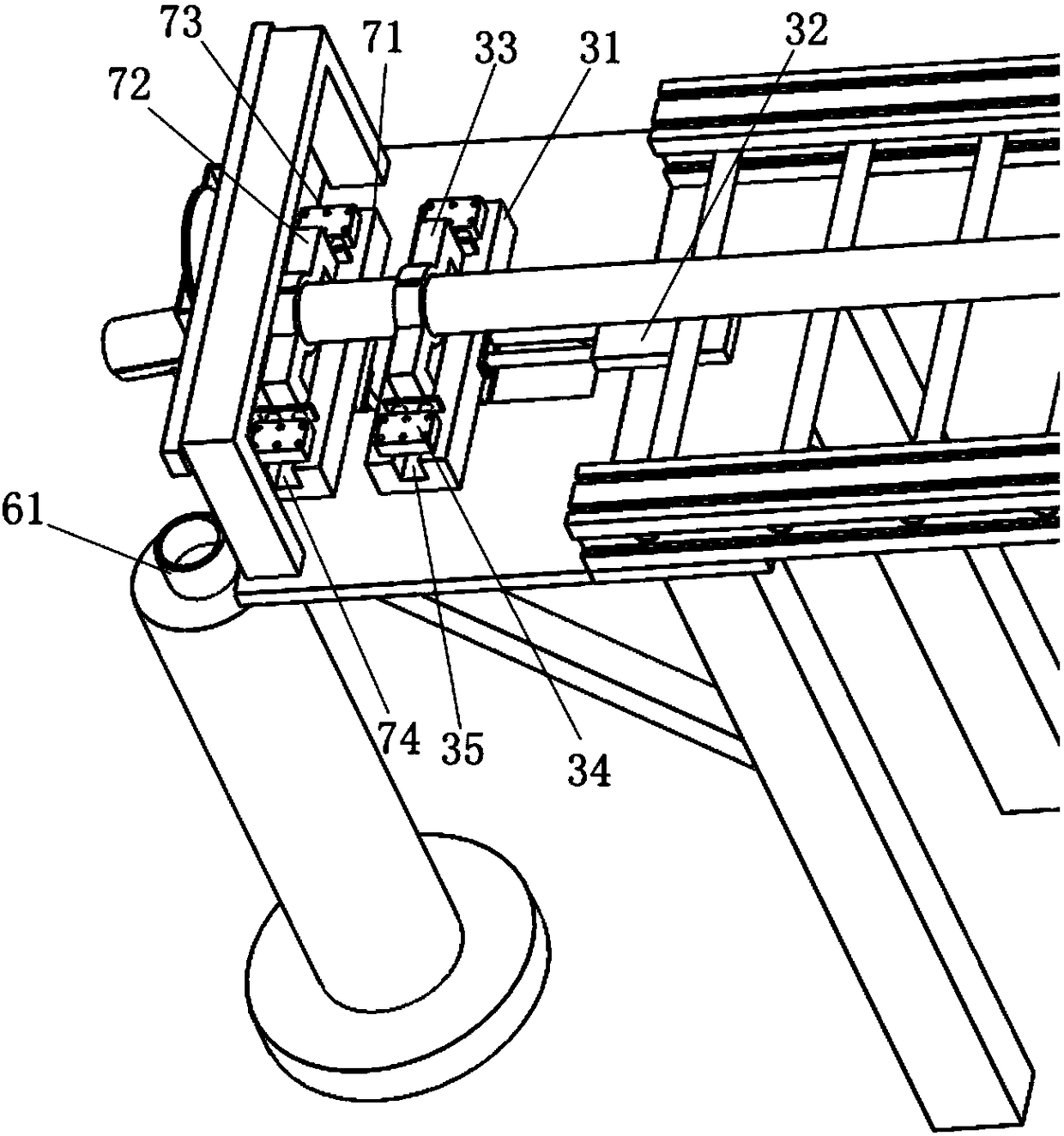

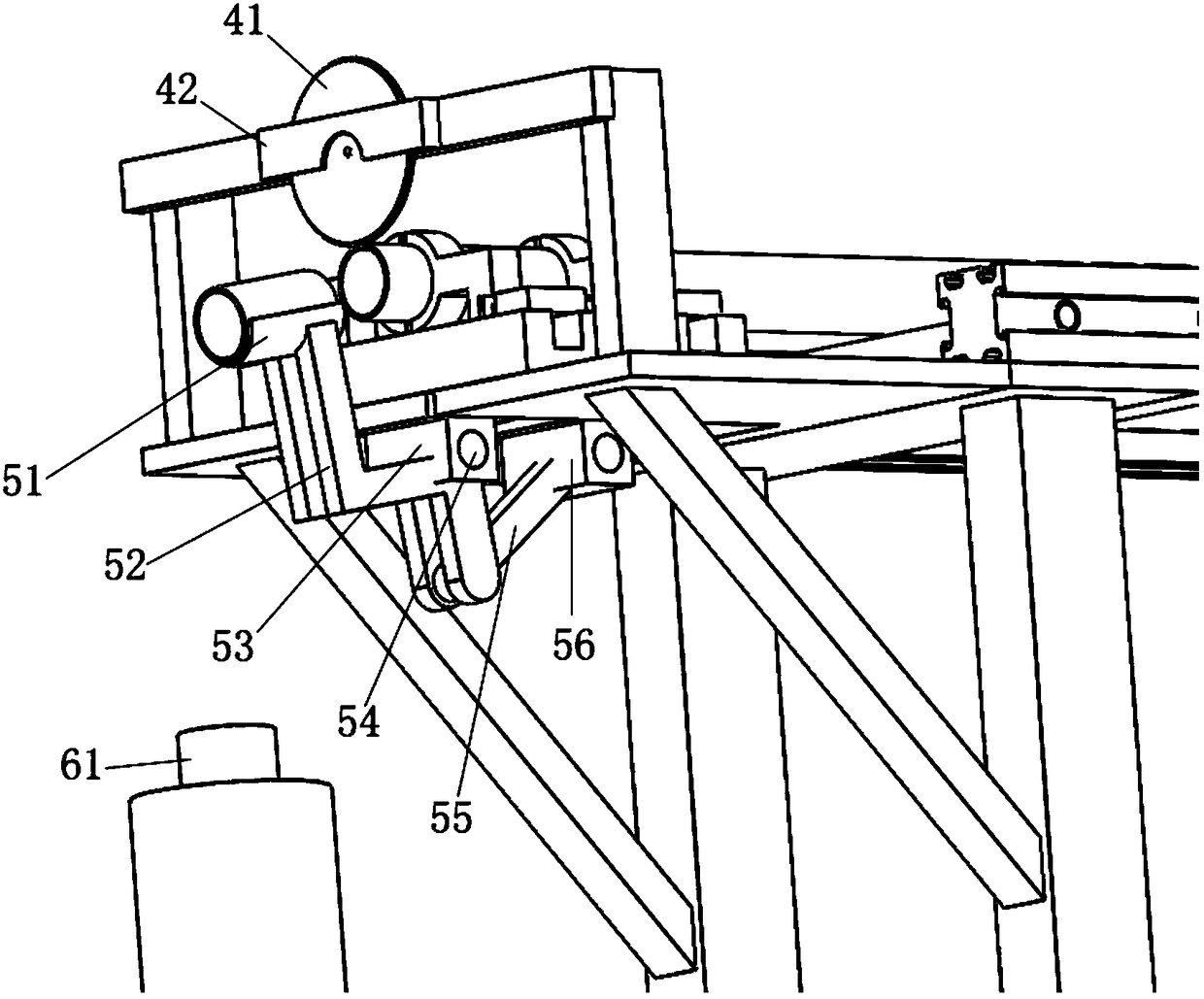

Pipe blanking equipment

InactiveCN105618847AControl cutting lengthHigh degree of automationMetal sawing devicesEngineeringManipulator

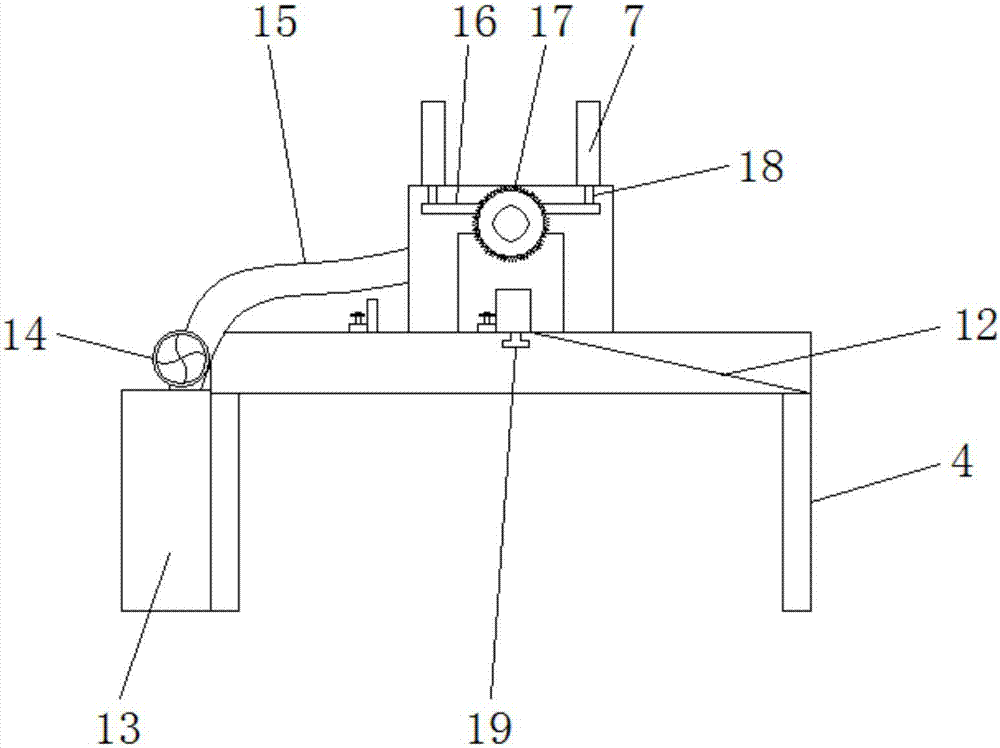

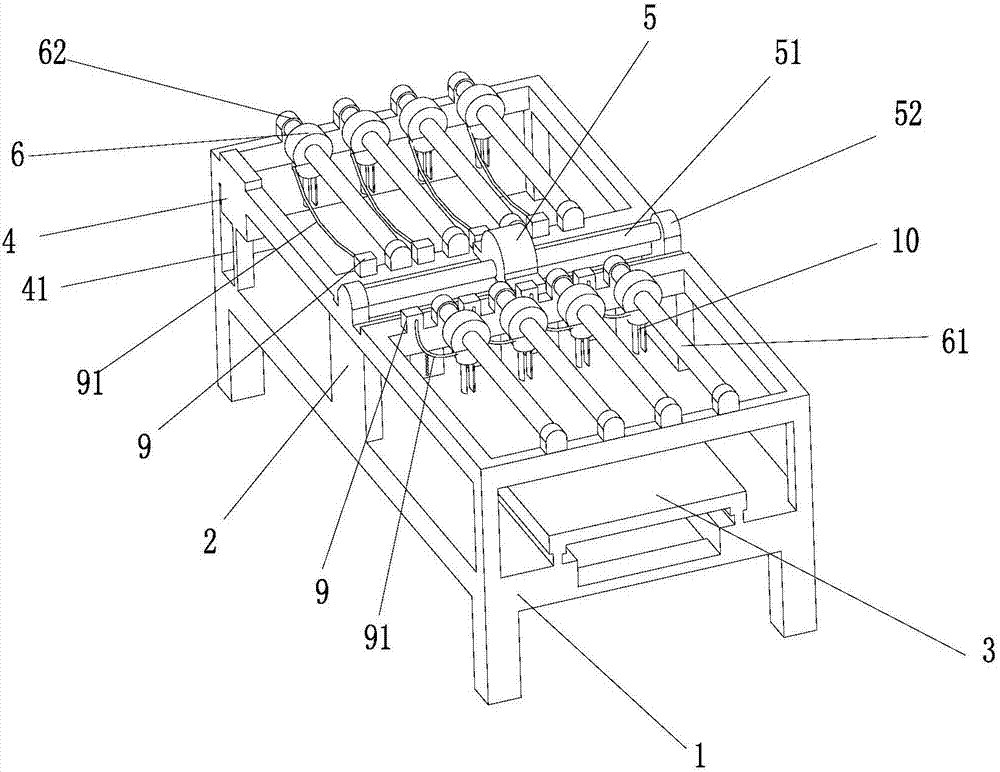

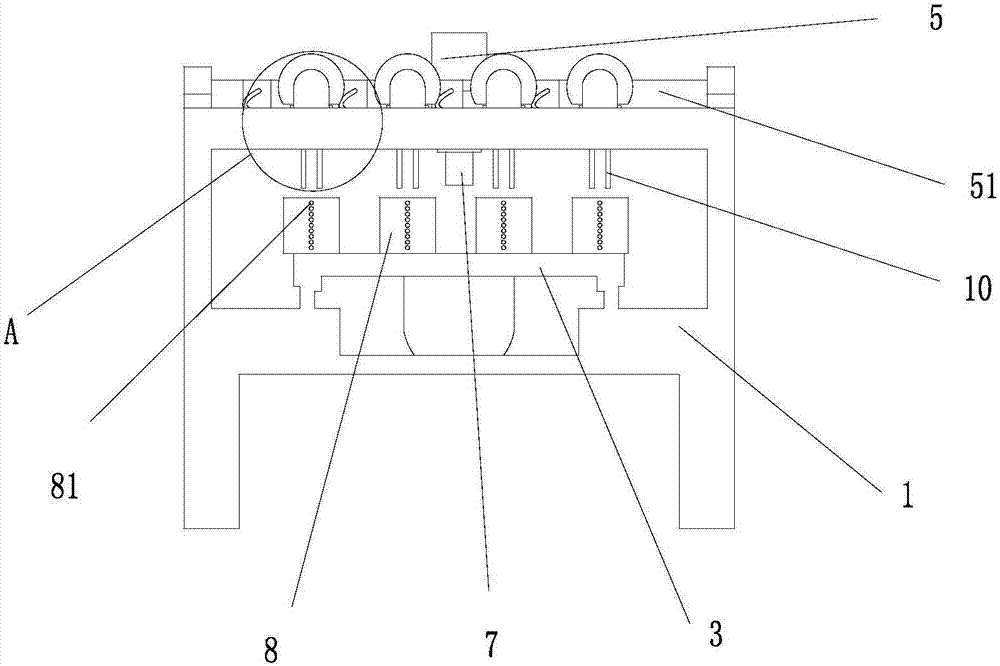

The invention discloses pipe blanking equipment. The pipe blanking equipment comprises a pipe supporting frame, wherein a pipe conveying device and a pipe cutting device are arranged on one side of the pipe supporting frame, the pipe cutting device is suspended above a to-be-cut end of a to-be-cut pipe, the pipe conveying device comprises a telescopic clamping conveying mechanism, and the telescopic clamping conveying mechanism comprises a moving sliding block, a driving part for driving the moving sliding block to move in the axial direction of the pipe and a first clamping manipulator arranged on the moving sliding block and used for clamping and releasing the pipe. The pipe blanking equipment can realize even cutting, fixed-length cutting or head-and-tail cutting of the pipe and is high in automation degree, high in blanking speed and easy to control.

Owner:SHANDONG UNIV OF SCI & TECH

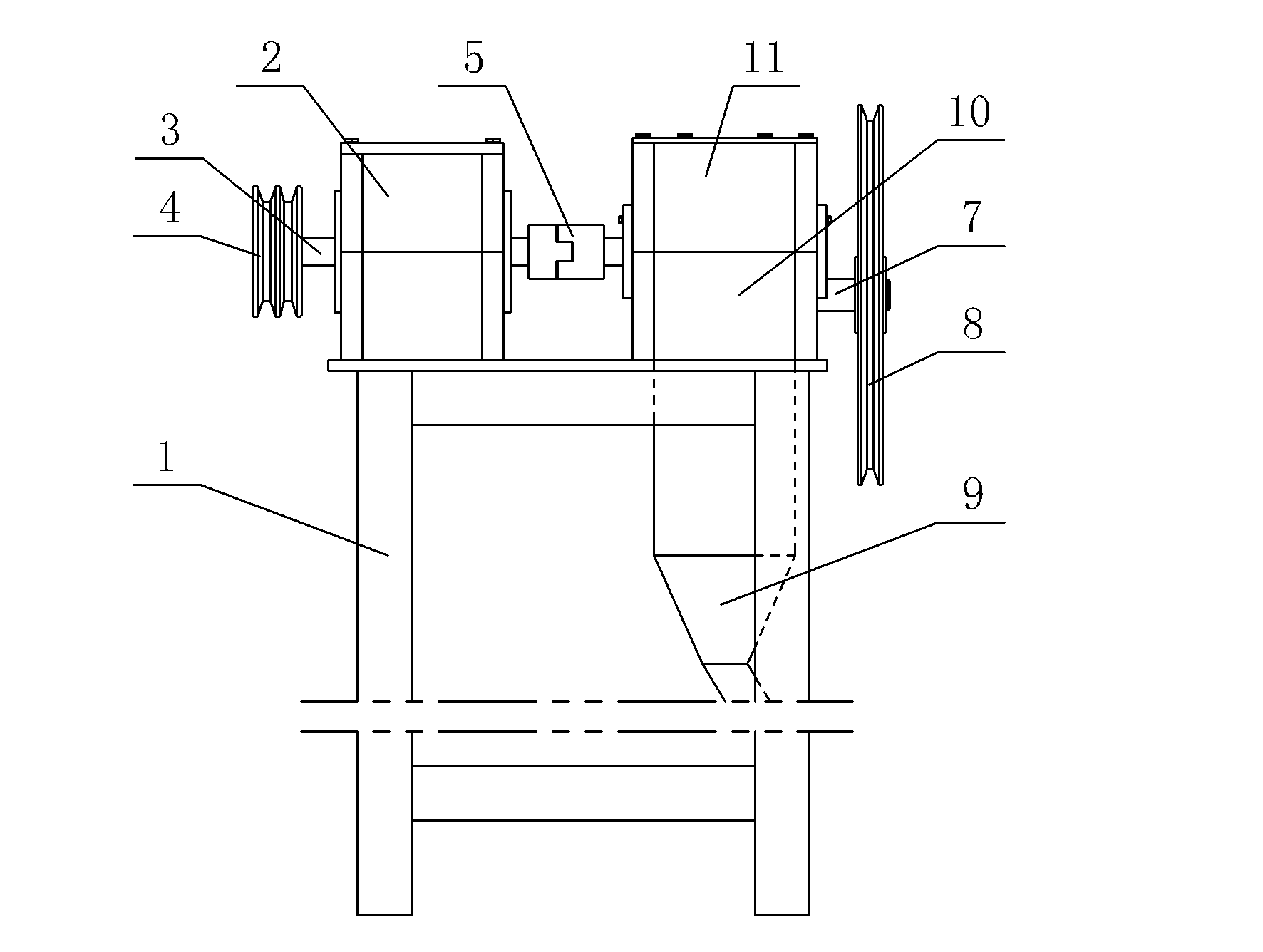

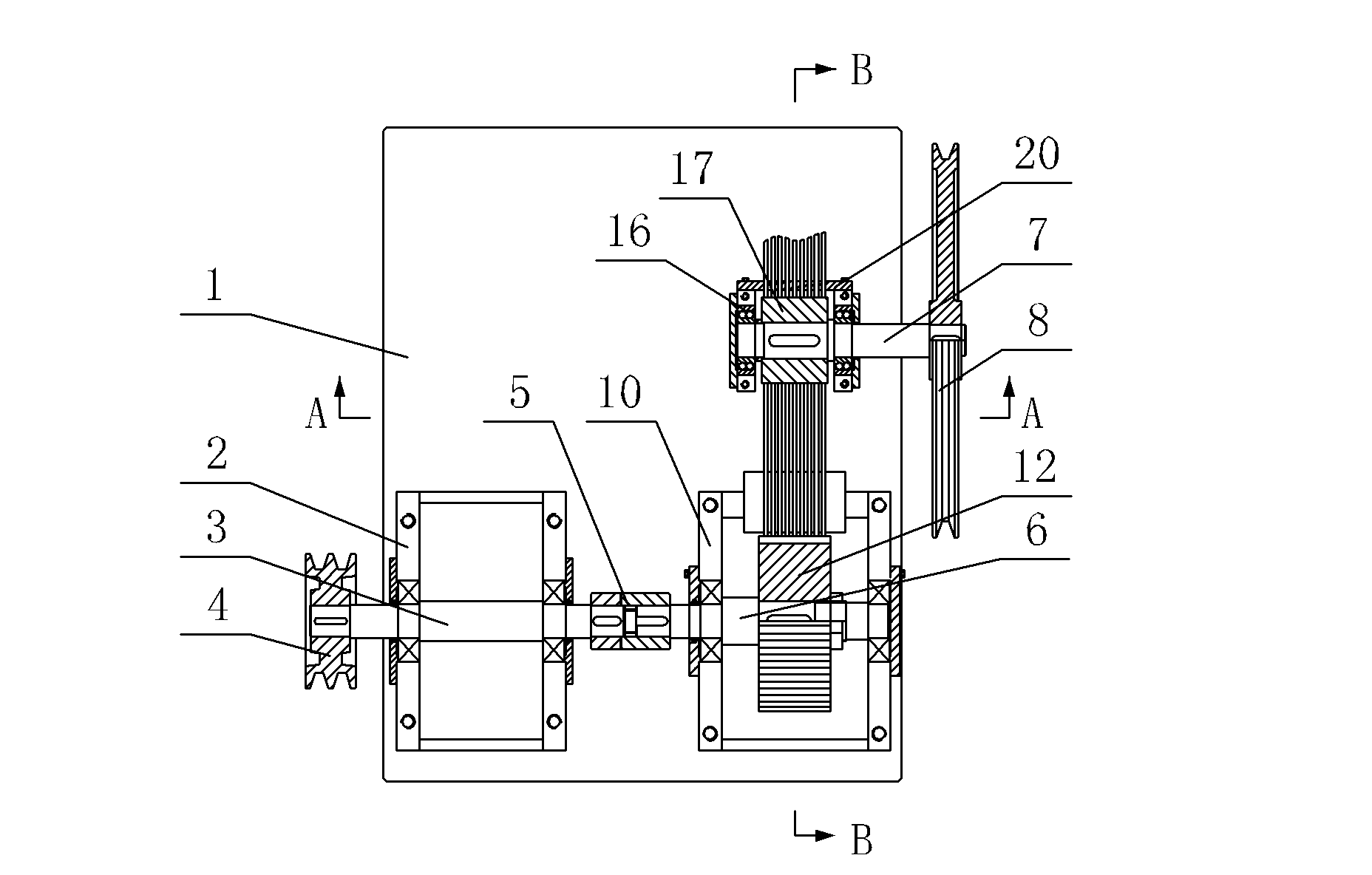

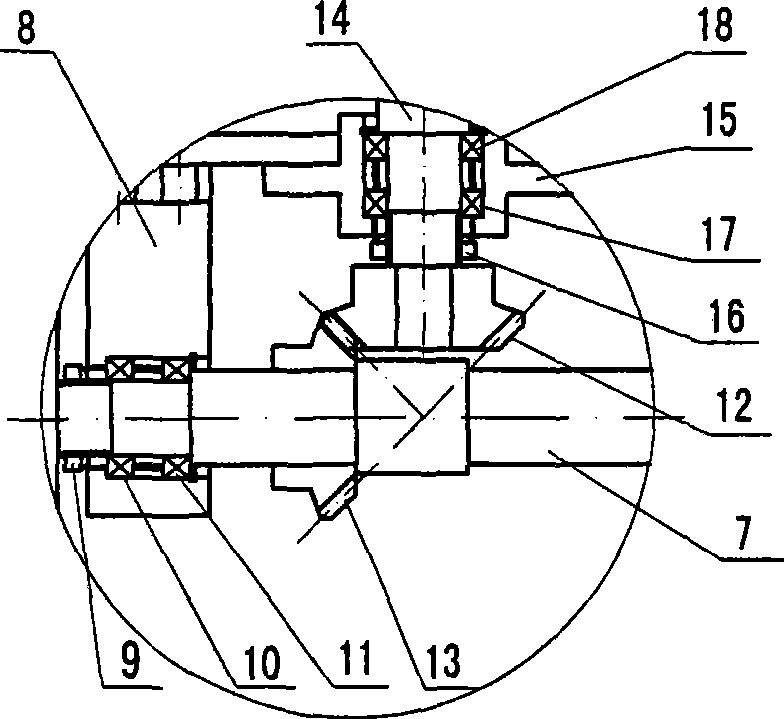

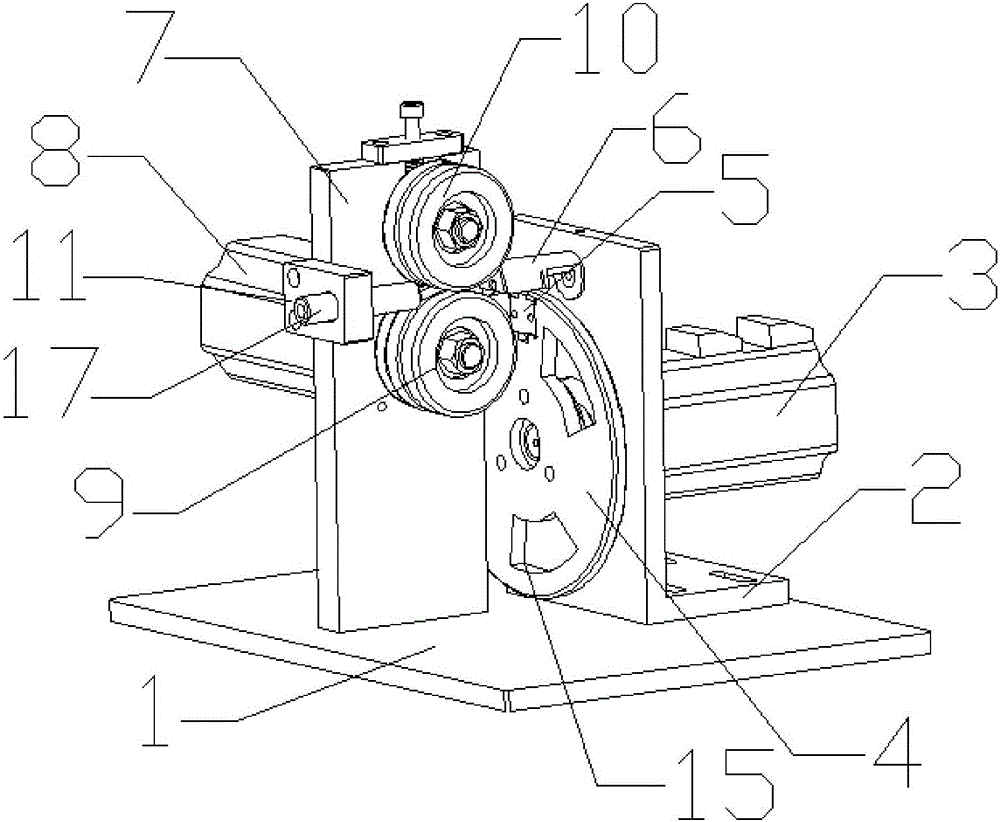

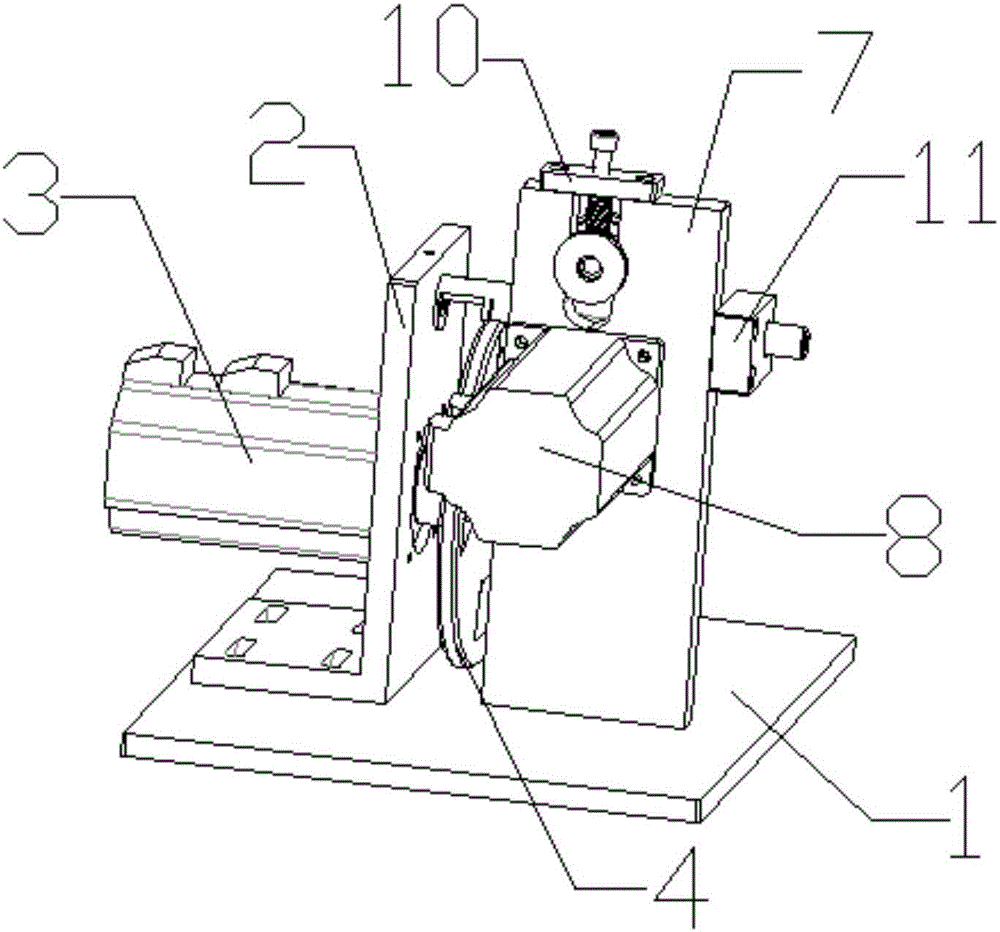

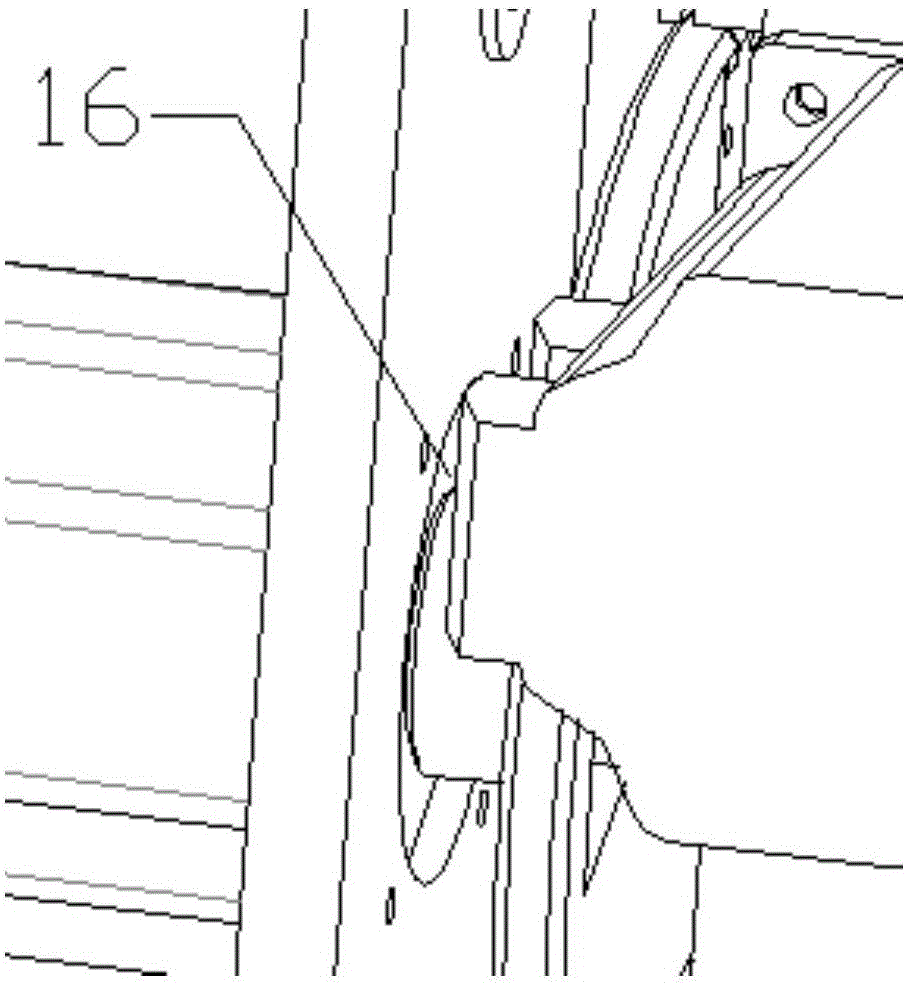

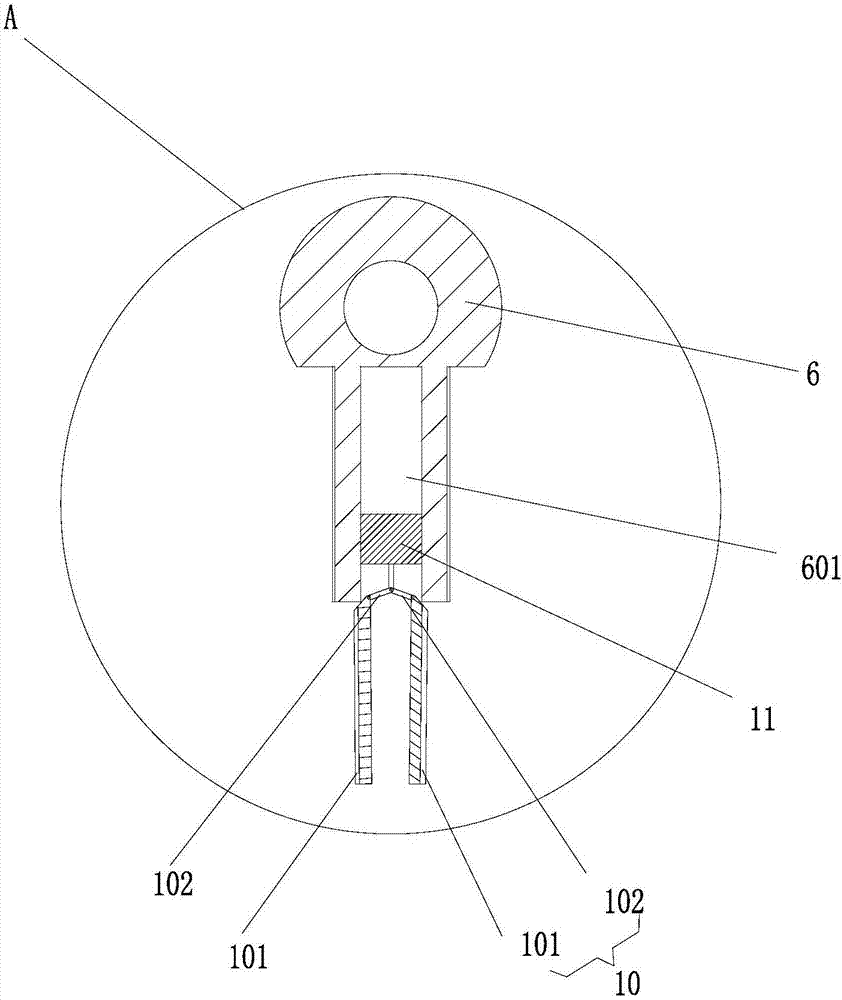

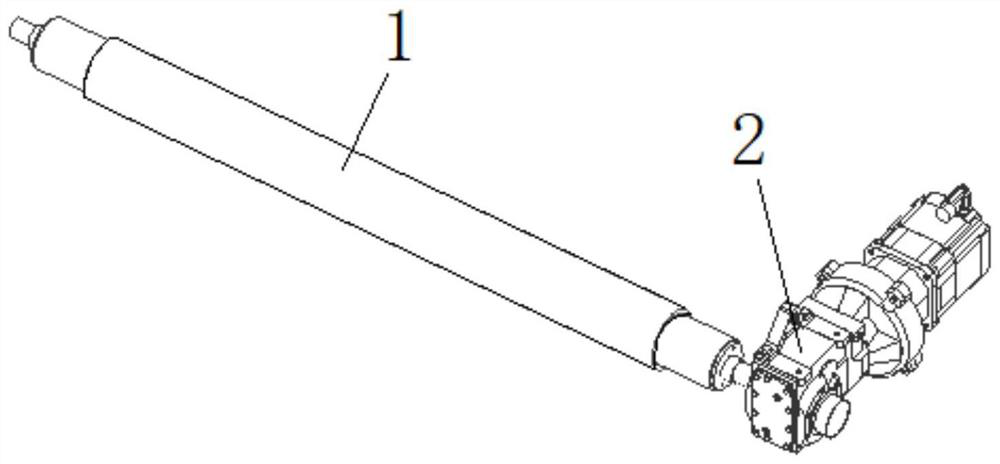

Ball cutter for steel wires

The invention relates to the field of steel wire shot granule forming, in particular to a ball cutter for steel wires. The ball cutter comprises a frame, wherein one end on the top of the frame is provided with a cutting input shaft through a bearing on a support box, while the other end is provided with a cutting device; a cutting pulley fixed connected to one end of the cutting input shaft is connected with a cutting motor through a belt, and the other end of the cutting input shaft is connected with a cutting shaft of the cutting device through a jaw clutch; the frame in front of a steel wire inlet of the cutting device is provided with a wire feeder; a wire feeding pulley on the outer end part of a wire feeding shaft of the wire feeder is connected with a frequency conversion motor through a belt; and the frame below the cutting device is provided with a steel shot collecting device corresponding to a steel shot outlet of the cutting device. The ball cutter is simple in structure, convenient to use, time-saving, labor-saving and high in efficiency; the length of steel shots can be convenient to adjust freely, the granularity is uniform and the quality is high; and the ball cutter is suitable for cutting high-hardness materials such as stainless steel wires, high carbon steel wires and the like.

Owner:山东开泰工业科技有限公司

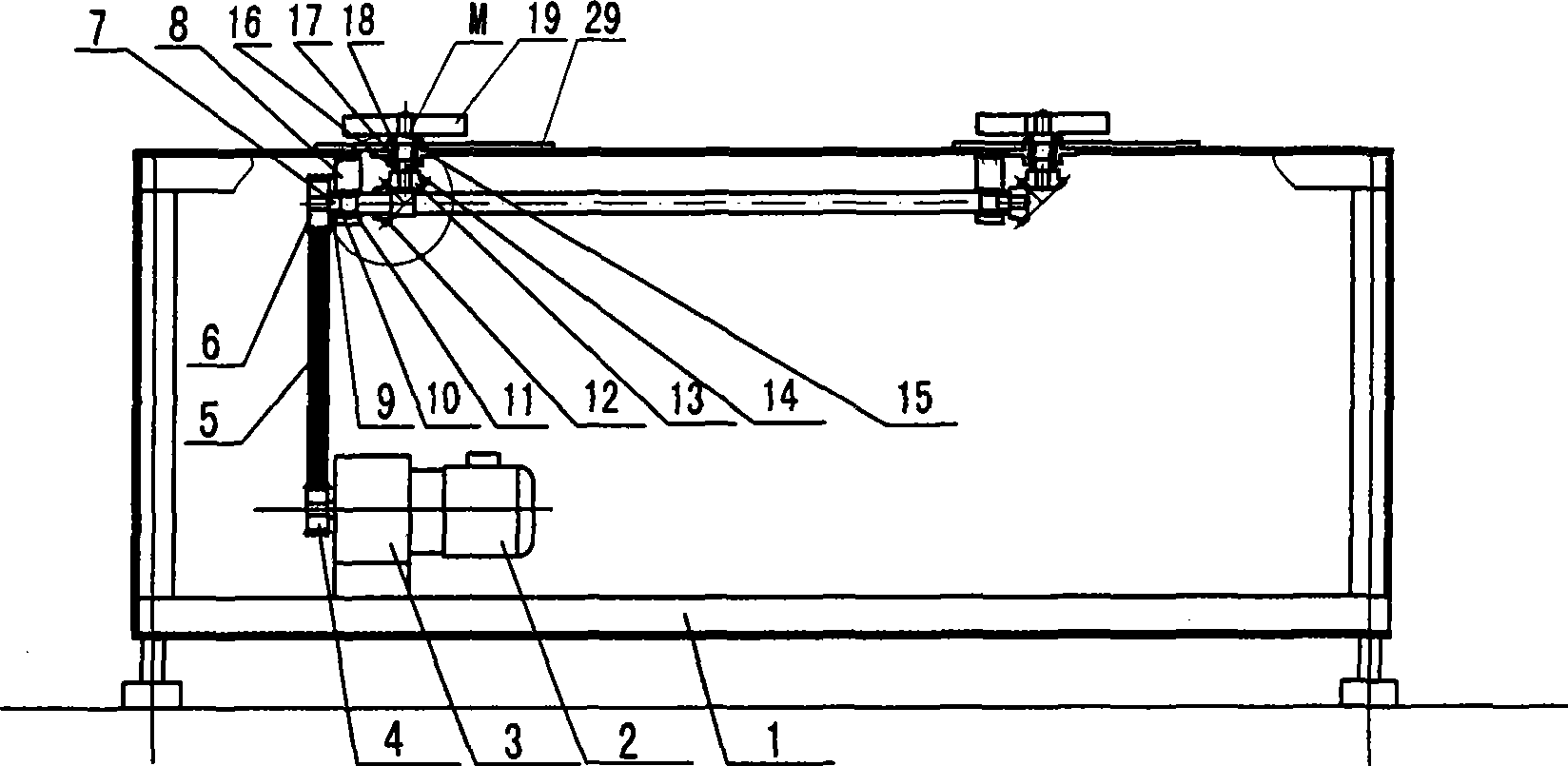

Shearing type at-sea laver harvester

The invention relates to a shear type offshore laver harvester. The harvester comprises a machine frame, an engine, a reduction gearbox, a belt-type transmission chain, a transmission shaft, a bevel gear transmission mechanism, a turning disc, a crank link transmission mechanism, a movable cutting tool and a fixed cutting tool, wherein the motor and the reduction gearbox are arranged on the machine frame, an output shaft of the engine is connected with an input shaft of the reduction gearbox, tan output shaft of the reduction gearbox is in transmission connection with the transmission shaft through the belt-type transmission chain, the transmission shaft is loaded on the machine frame, the transmission shaft is in transmission connection with the turning disc through the bevel gear transmission mechanism, the turning disc is in transmission connection with the movable cutting tool through the crank link transmission mechanism to allow the movable cutting tool to move left and right and shear relative to the fixed cutting tool, and fixed cutting tool is arranged on the machine frame below the movable cutting tool. The invention has the advantages of effectively controlling cut length of laver, avoiding crushing the laver like the prior laver harvester, achieving high cutting quality, along with simple structure, more mechanical advantages, stable transmission, and can meet requirements for high-efficient harvest of large areas of laver.

Owner:JIANGSU MORNING ENVIRONMENTAL PROTECTION TECH CO LTD

Slicing machine facilitating fixing for bamboo wood processing

InactiveCN107225643AImprove cut qualityAvoid displacementCane mechanical workingVeneer manufactureWood processingHydraulic cylinder

The invention discloses a slicer for bamboo and wood processing which is easy to fix, comprising a slicer main body, a first positioning block, a second positioning block, a hydraulic cylinder, a cutting port, a third positioning block, a sliding slope, a fan, a cutting piece and Turn the handle, the main body of the slicer is provided with a processing table, the lower ends of the first positioning block and the third positioning block are provided with sliding blocks, and the second positioning block is arranged on the rear side of the first positioning block. The hydraulic cylinder is arranged above the cutting frame, the cutting port is arranged on both sides of the cutting frame, the third positioning block is arranged on the right side of the cutting frame through the second sliding groove and the sliding block, and the cutting piece is supported by The frame is arranged inside the cutting frame, and the rotating handle is arranged under the first positioning block and the third positioning block. In the easy-to-fix slicer for bamboo and wood processing, a sliding slope is set on the rear side of the third positioning block to make the cut bamboo and wood slide to a designated position, which is beneficial to the transportation of the cut bamboo and wood.

Owner:安吉县怡成竹木工艺品厂

Cleaning and cutting all-in-one equipment for vegetable processing

InactiveCN109015777AImprove processing efficiencyReduce labor intensityMetal working apparatusFood treatmentVegetable processingDrive wheel

The invention discloses cleaning and cutting all-in-one equipment for vegetable processing. The cleaning and cutting all-in-one equipment for vegetable processing comprises a frame, a belt, cam-link mechanisms, a crossbeam and a cleaning pipe. A rotary shaft is mounted in the frame. A driven wheel is mounted on the rotary shaft. A driving motor is mounted on the lower portion of the rotary shaft.A driving wheel is mounted at the rotary shaft end of the driving motor. The driving wheel is in transmission connection with the driven wheel through the belt. The two ends of the rotary shaft are connected with the cam-link mechanisms mounted on the two side faces of the frame. Each cam-link mechanism comprises an outer cover, a cam, a roller driven part and a damping connecting rod, wherein thebottom of the damping connecting rod is inserted into the outer cover, the bottom end of the damping connecting rod is connected with the roller driven part arranged in the outer cover, and the roller driven part is arranged above the cam. The upper ends of the two damping connecting rods are connected with the two ends of the crossbeam through connecting blocks. The cleaning and cutting all-in-one equipment for vegetable processing has cleaning and cutting functions and is high in processing efficiency and convenient to use.

Owner:徐州佳联农业发展有限公司

Spiral briquetting machine

InactiveCN101758636ASolve the disadvantages of not needing to cut first and then briquettingControl cutting lengthShaping pressAgricultural engineeringEnergy conservation

The invention relates to a spiral briquetting machine, which comprises a taper type briquetting module, a spiral compressing chamber, a spiral extruding shaft sub-assembly, a seamed frame, a feeding hopper and the like. The machine is characterized in that straw feed is axially fed in a rotating plate for location, and then enters the spiral compressing chamber after being cut through two cutters, thereby realizing the idea that the straw are briquetted directly after being cutting up, and achieving the aims of high efficiency, low resistance and energy conservation.

Owner:高华东

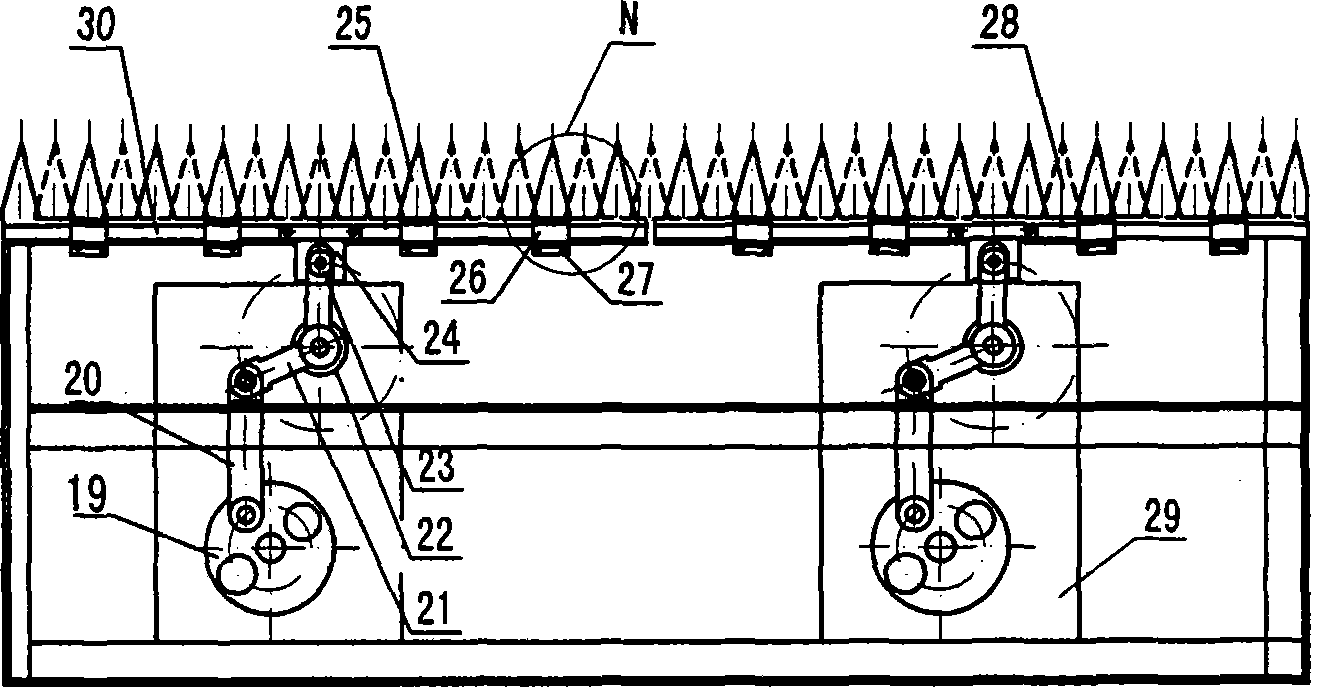

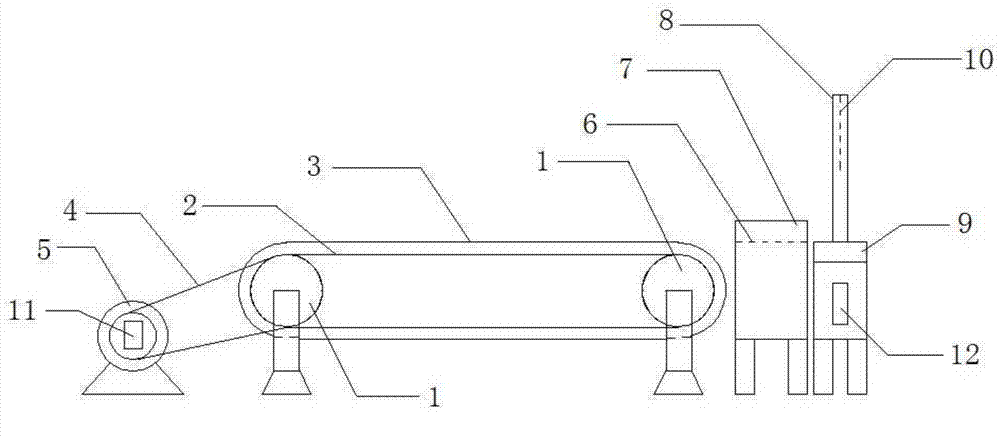

Variable-distance straw cutting-off device

The invention discloses a variable-distance straw cutting-off device, relates to the field of environmental-friendly mechanical equipment, and is used for solving the problem that lengths of straws cut off by an existing straw cutting-off device are uncontrollable. The variable-distance straw cutting-off device comprises a feed inlet, a straw chopper and a discharge port, and further comprises a conveying belt, a top cover, a crank connecting rod mechanism, a motor, a baffle and a cutting-off table; the top cover comprises a first top cover and a second top cover; the feed inlet is formed above one end part of the conveying belt; the first top cover is arranged at the upper part of the conveying belt; a first sliding rail is arranged at the top of the first top cover; a plurality of combing pillars pointing to the conveying belt are arranged on the first sliding rail; an end part, which is far away from the feed inlet, of the first top cover is provided with the straw chopper and the cutting-off table arranged up and down; the first top cover and the second top cover are respectively arranged at both sides of the straw chopper; the baffle is arranged at an end part of the second top cover; a second sliding rail and a pulley are arranged on the side wall of the second top cover; the pulley is fixedly connected with the baffle. The variable-distance straw cutting-off device has the advantages that the structure is simple; the variable-distance straw cutting-off device is applicable to various straw cutting-off; the cutting-off length is accurate and controllable.

Owner:四川点草成金科技有限责任公司

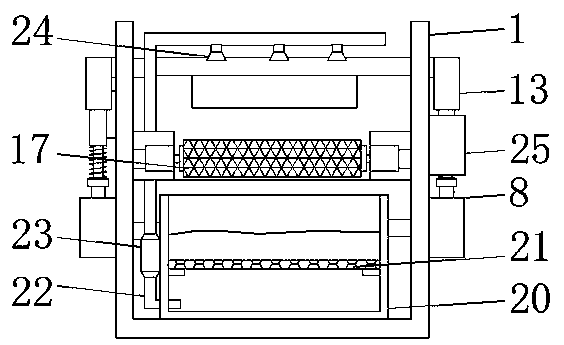

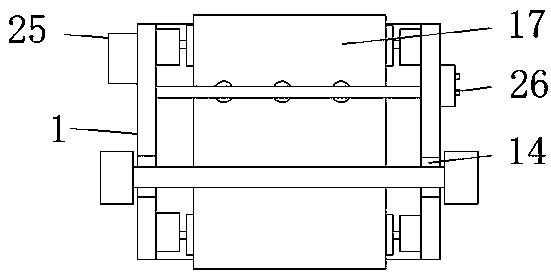

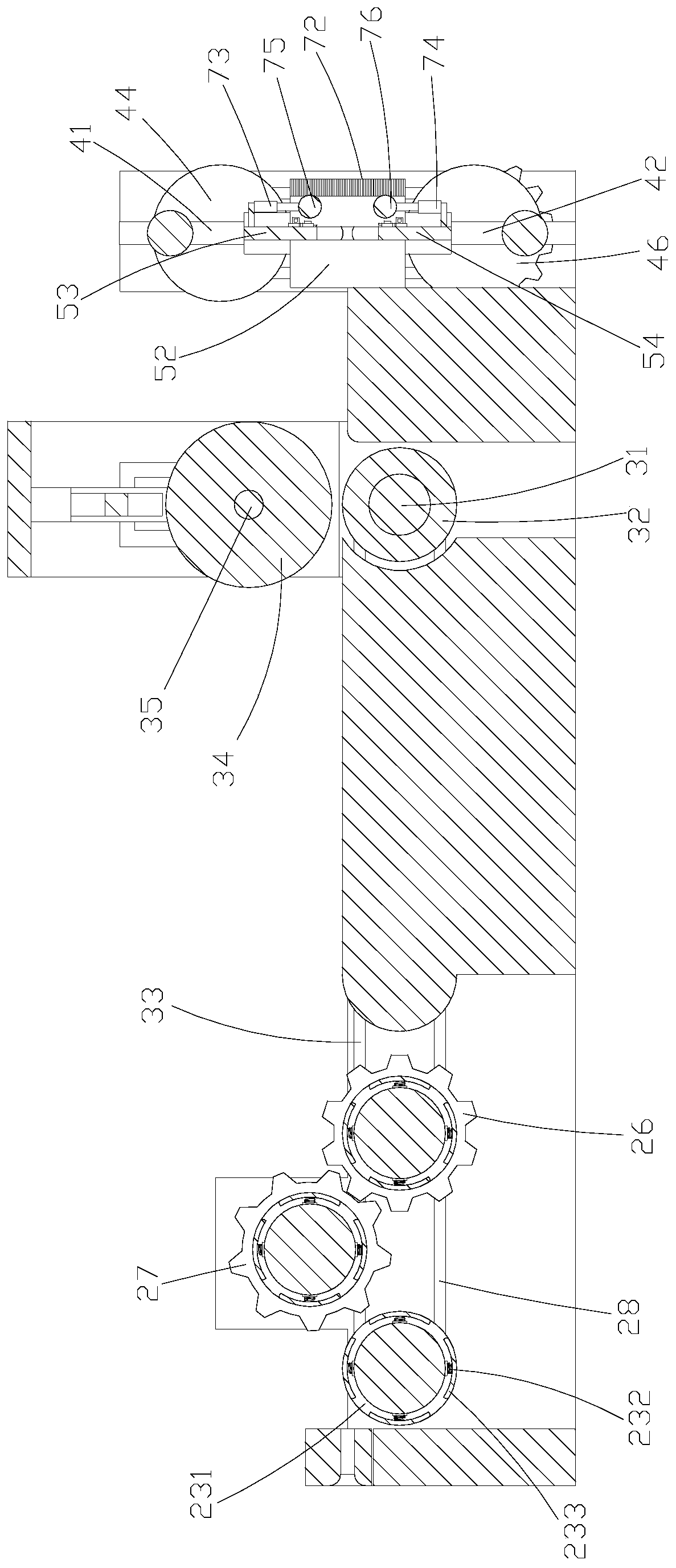

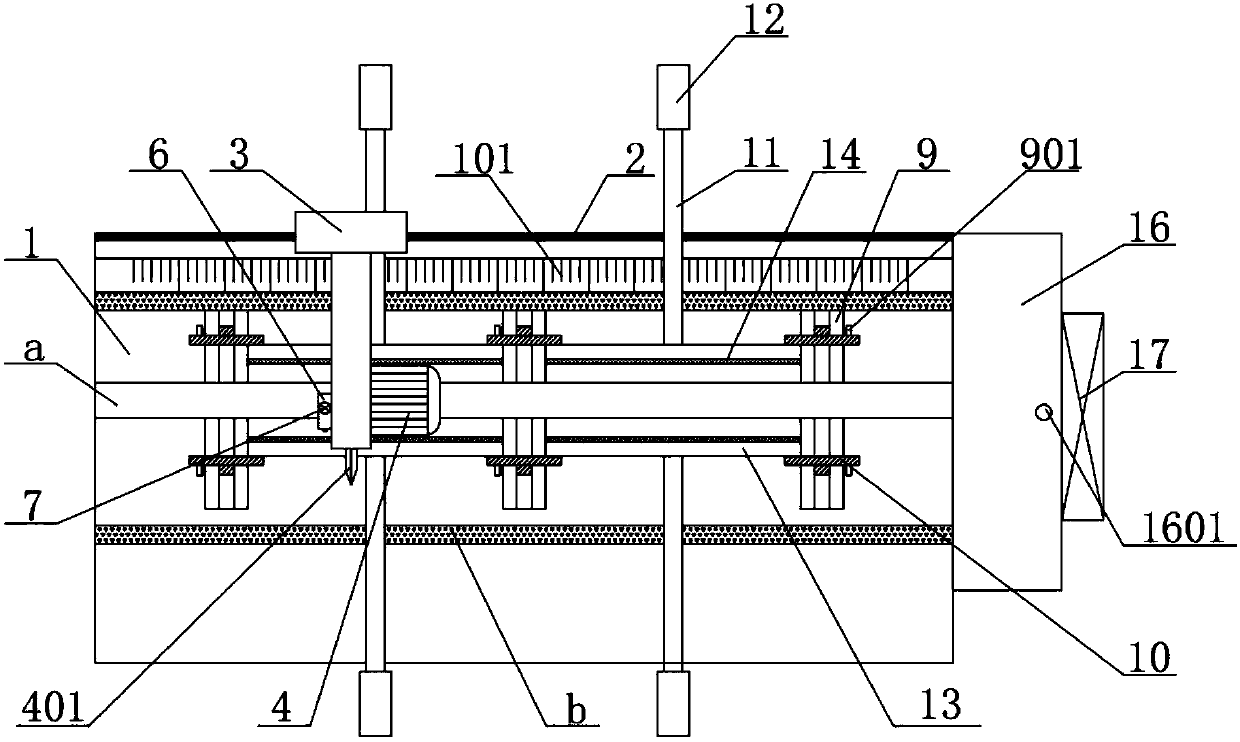

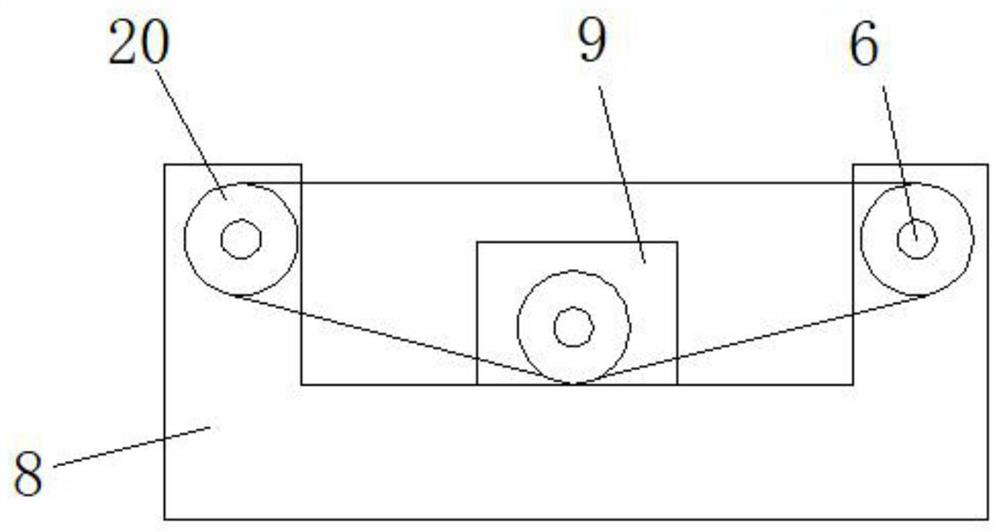

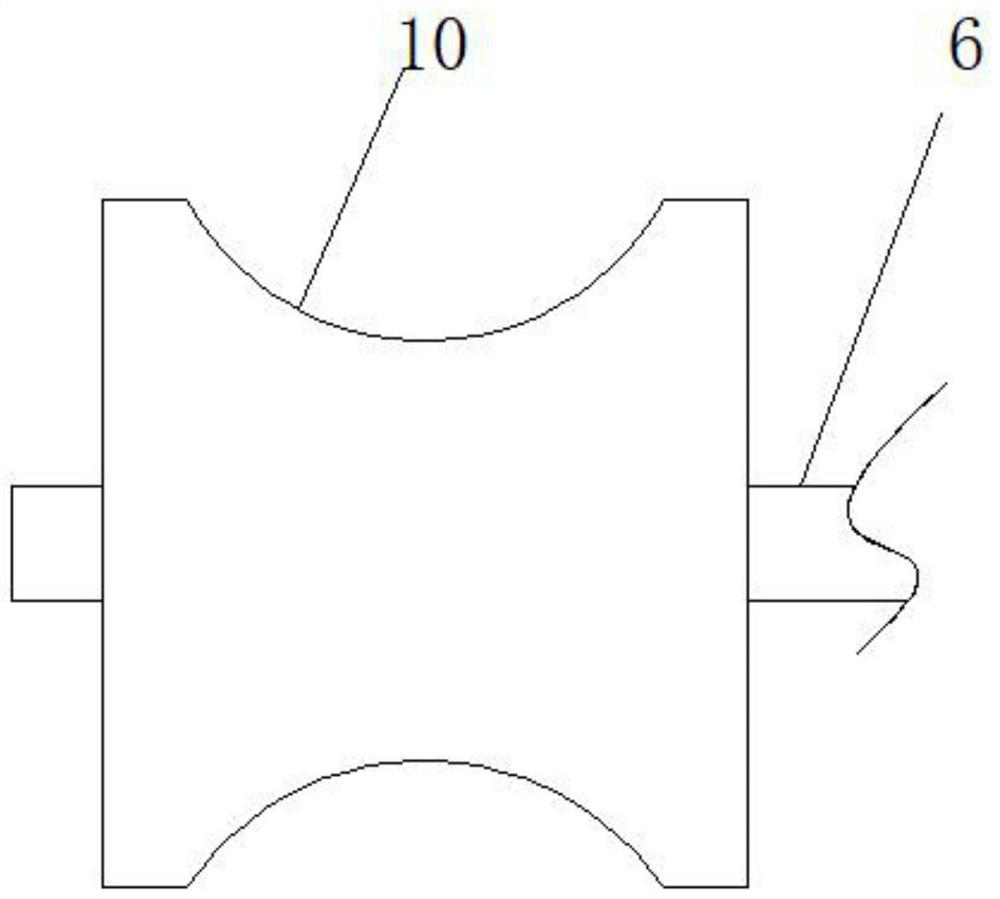

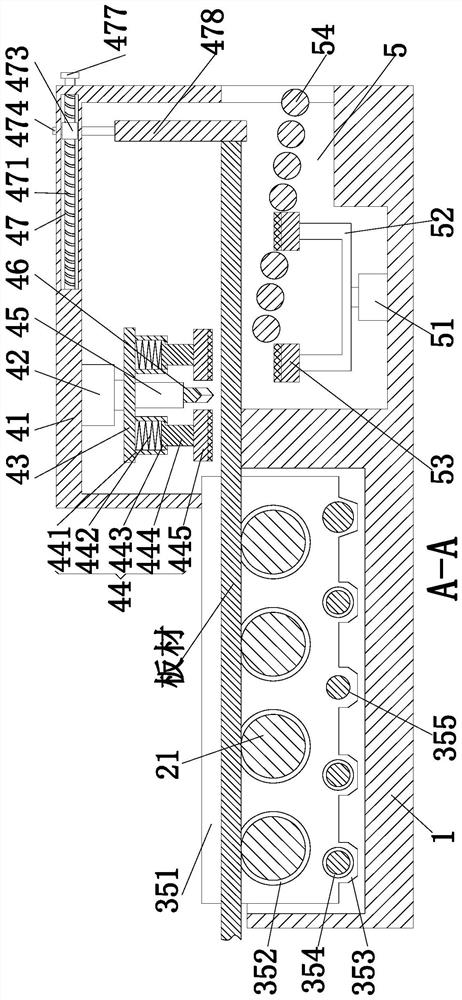

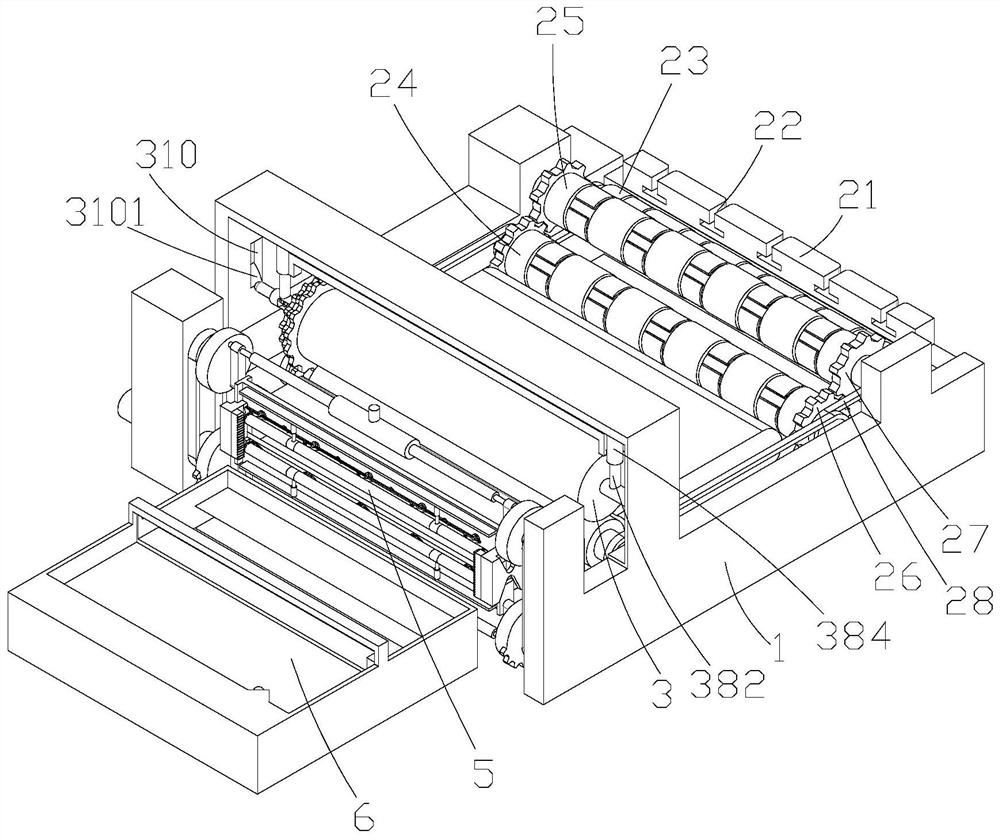

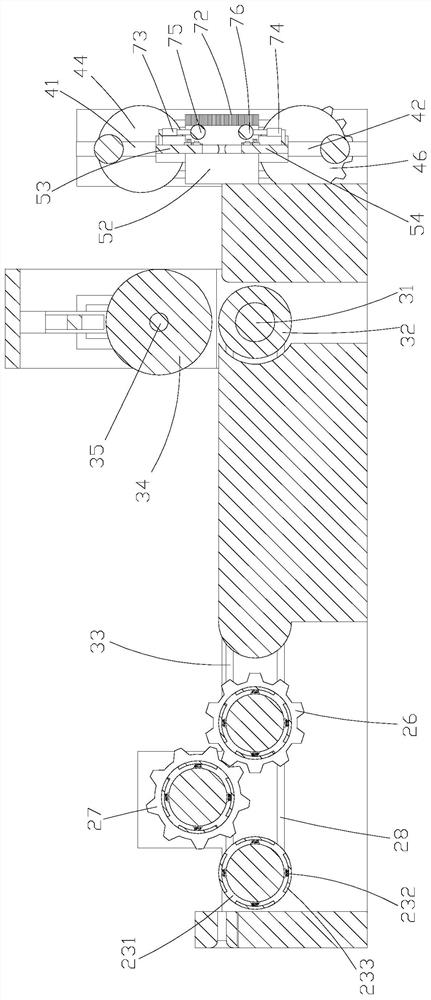

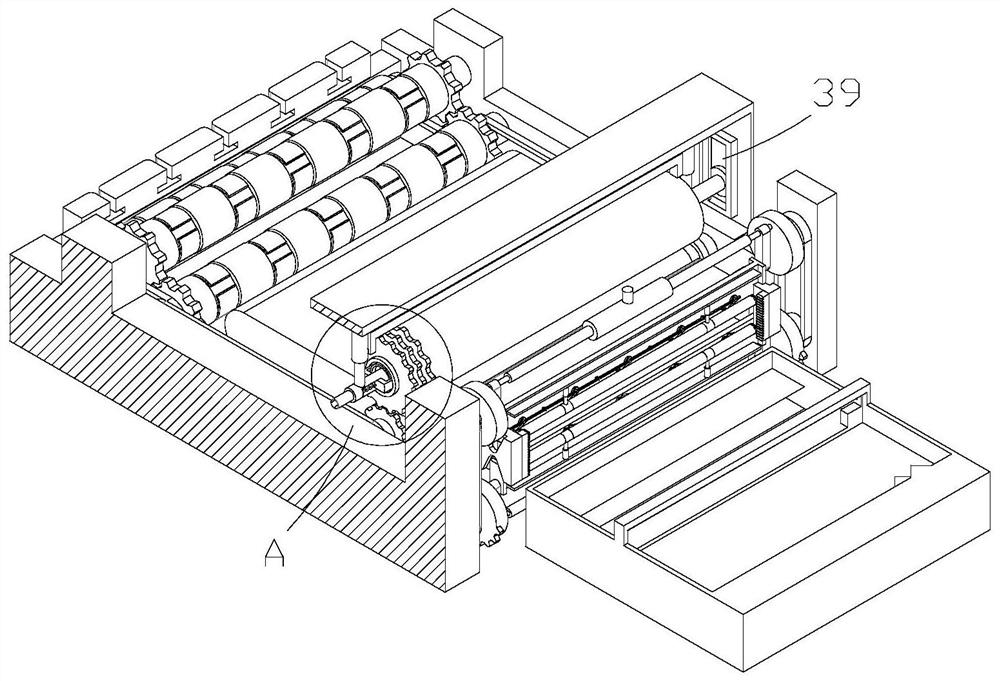

Photovoltaic system assembly production equipment

ActiveCN111036977ASecurity tensionControl cutting lengthShearing machinesShearing machine accessoriesStructural engineeringKnife blades

The invention discloses photovoltaic system assembly production equipment particularly used for slitting, producing and machining photovoltaic welding strips. The photovoltaic system assembly production equipment comprises a rack, a limiting mechanism set on the rack, a feeding mechanism, a transmission mechanism, a slitting mechanism and a bundling mechanism; a fixing block is arranged on the limiting mechanism, a plurality of T-shaped grooves are formed in the fixing block, and a first guide roller, a second guide roller and a third guide roller are arranged on the limiting mechanism; an upper feeding roller and a lower feeding roller are arranged on the feeding mechanism, and a variable gear set is arranged on the upper feeding roller; an upper pressing plate and a lower pressing plateare arranged on the slitting mechanism, an upper blade is arranged on the upper pressing plate, and a lower blade is arranged on the lower pressing plate. The problems of burrs and inclination at a notch of a solder strip are solved, the solder strip is prevented from swinging in the slitting process, the stability of a product is improved, the length of the solder strip can be controlled more accurately, and solder strips with different lengths can be machined according to requirements.

Owner:杭州首电能源科技有限公司

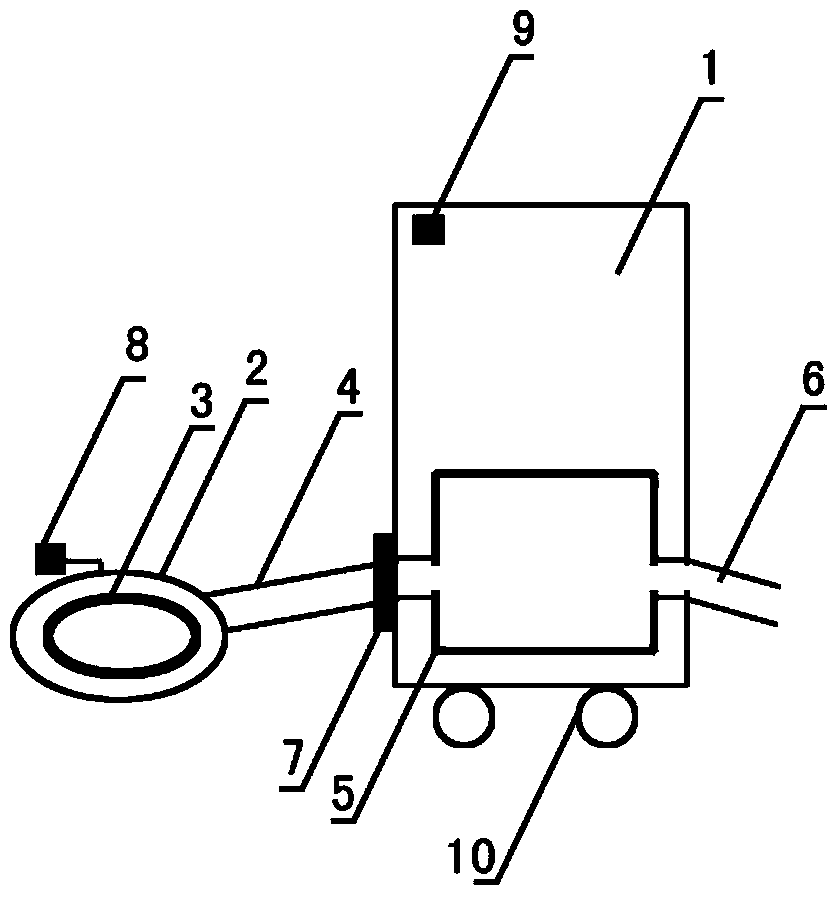

Rubber preforming device

InactiveCN112659512AAvoid cloggingQuality improvementMetal working apparatusCircular discEngineering

The invention belongs to the technical field of rubber manufacturing, and particularly relates to a rubber preforming device. The rubber preforming device comprises a bottom plate, a material cylinder and a cutting ring; a supporting frame is fixedly connected to the upper portion of the bottom plate; the side, away from the bottom plate, of the supporting frame is arc-shaped, and fixedly connected with the material cylinder; the material cylinder is of a cylindrical cavity type structure; a hopper is fixedly connected to the side, away from the supporting frame, of the material cylinder; the hopper communicates with the inner cavity of the material cylinder; one end, close to the hopper, of the material cylinder is fixedly connected with a power box; and the power box is designed in a disk shape. According to the rubber preforming device provided by the invention, by arranging an extension pipe, a supporting pipe and a transmission rod, the transmission rod is driven to rotate through rotation of a motor, thus the extension pipe is enabled to move at a constant speed through meshing between a connecting ring and a threaded groove in the transmission rod, and then extruded rubber strips are cooled for a period of time by virtue of support of the supporting pipe and the extension pipe; and in this way the rubber strips are primarily hardened and can be conveniently cut by the cutting ring.

Owner:ZHEJIANG TIANTAI XIANGHE IND CO LTD

Automatic clean wood sawing machine

InactiveCN107738322AReduce wasted timeImprove work efficiencyGripping devicesClamping devicesScrapElectric heating

The invention relates to the technical field of mechanical equipment, in particular to an automatic cleaning sawmill, comprising a fixed plate, and a horizontally arranged arc-shaped groove is provided at the central position of the end surface of the fixed plate, and the two sides of the arc-shaped groove are symmetrical A waste chute is provided, and a support plate is provided between the arc-shaped groove and the waste chute, and the support plates are arranged in pairs, clamping blocks are slidably connected between the support plates, and a second support plate is spirally connected to one side of the support plate. Two locking screws, in the present invention, through the set clamping block and the second locking screw, it is convenient to control the distance between the clamping blocks, and can clamp wood with different diameters, which has wide applicability and has a large market Foreground, at the same time, the waste chips can be cleaned through the cleaning device, which is convenient and quick to clean. At the same time, the cleaned wood chips can be directly pushed into the steam drying box, and dried and dried by fans and electric heating wires, which has huge economical advantages. Benefits and broad market prospects, it is worth popularizing and using.

Owner:WUXI AOTU AUTOMATION TECH CO LTD

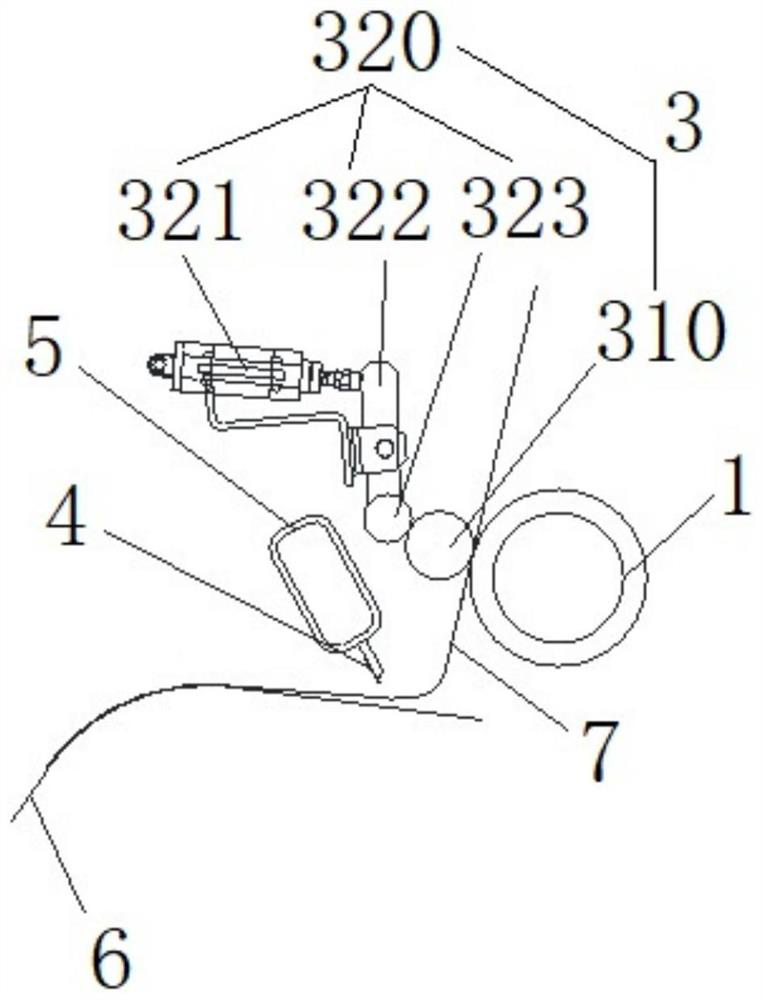

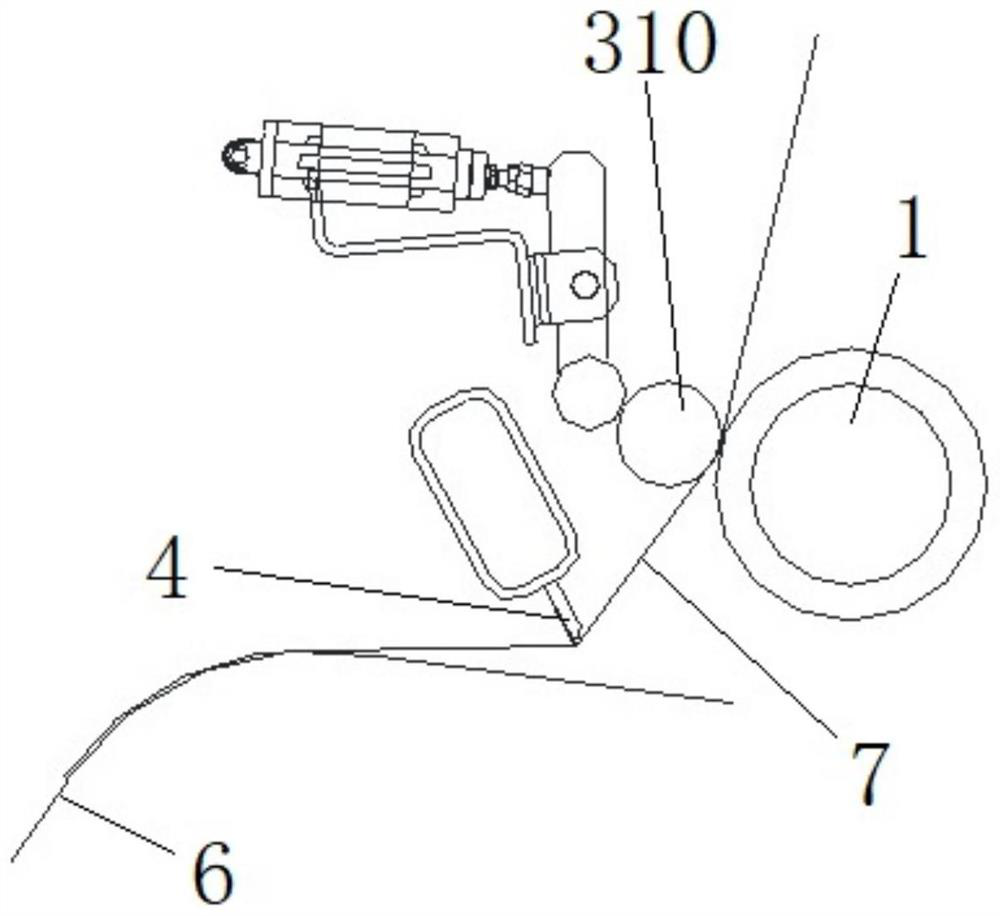

Straw crushing machine

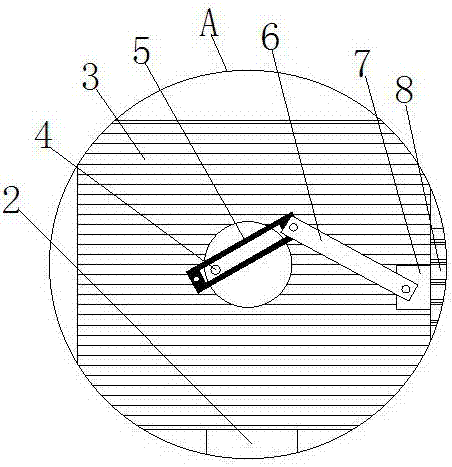

A straw crushing machine comprises a machine frame (1). A cutting winch (2) is arranged at the front end of the machine frame (1), a cutting blade (3) is arranged in the cutting winch (2), the cutting winch (2) is connected with the machine frame (1) through a conveying pipeline (4), a crushing device (5) is arranged in the machine frame (1) and used for crushing straws conveyed by the conveying pipeline (4), the crushed straws are discharged through a discharging port (6). An adjusting base (7) is arranged on the machine frame (1), the conveying pipeline (4) is fixed on the adjusting base (7), cutting height of the cutting winch (2) can be adjusted through the adjusting base (7) to adjust the length of cut straws, a video probe (8) is arranged at the position of the cutting winch (2), a monitoring device is arranged on a control table to dynamically observe a cutting state, cutting length is controlled when the cut straws are returned to the field, meanwhile the straws are effectively crushed, and efficiency is improved.

Owner:YINCHUAN BOJU IND PROD DESIGN

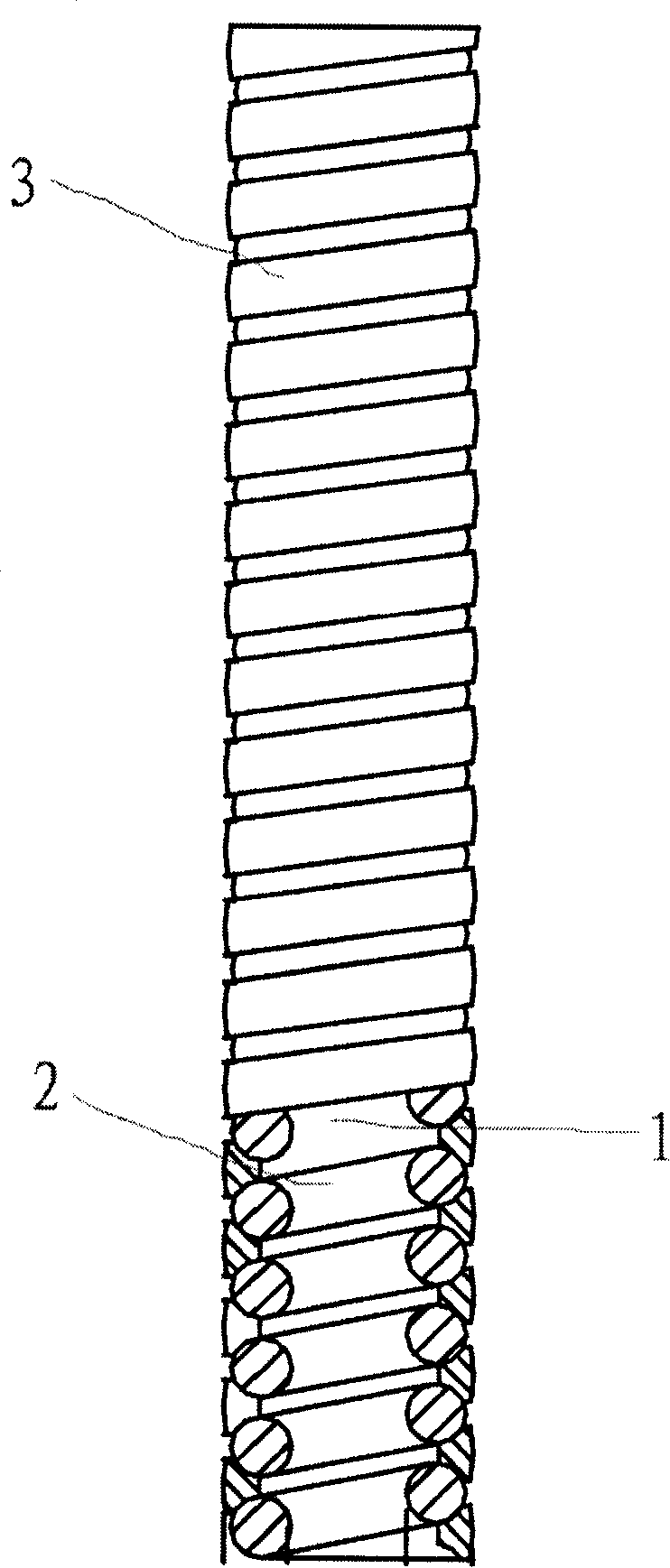

Metal tube for earphone microphone and its making method

InactiveCN101193456AControl cutting lengthIncrease softnessWire articlesEarpiece/earphone attachmentsCarbon steelCopper wire

The invention discloses a flexible metallic conduit for the microphone of an earphone which is used by matching a piece of metallic wire; a piece of high-carbon steel wire or stainless steel wire is coated outside the metallic wire, while a layer of steel wire or copper wire is again coated outside the high-carbon steel wire or stainless wire. The method for manufacturing the flexible conduit is as follows: firstly, the steel wire and iron wire are fed synchronously and formed by adopting a bilateral wire roller, and a wire pressing roller is installed at the wire roller part where the iron wire is fed, and the iron wire is pressed into a triangle; secondly, the steel wire is formed on the axis by a bended guide board of the mould, and meanwhile by using a pressing-in mould, the iron wire is pressed into the spring formed by the steel wire so as to form the flexible conduit; thirdly, when the forming length of the flexible conduit reaches the set length, an infrared sensor is triggered, and the flexible conduit is cut into a required length; the flexible conduct is convenient to use with good toughness; the technology can forms the flexible conduit once with precise control tolerance and flexible conduit cutting length; flexible conduits with outer diameter more than 2. 3mm can be manufactured via the new technology and device for the first time, which fills a gap at home and abroad.

Owner:胡旺龙

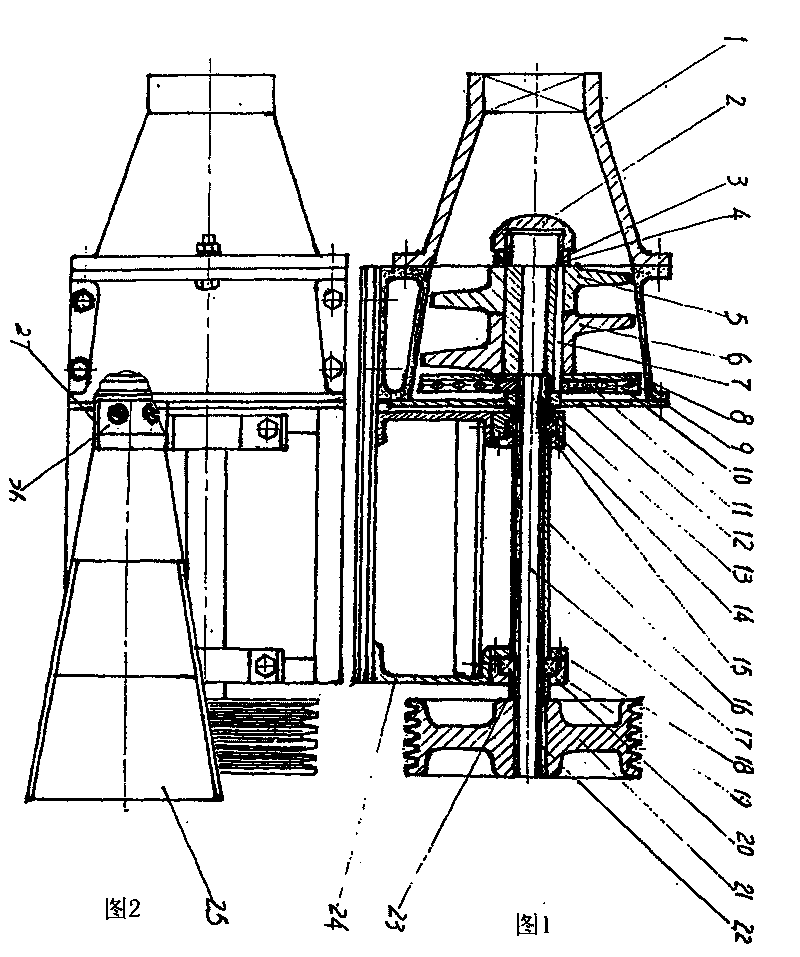

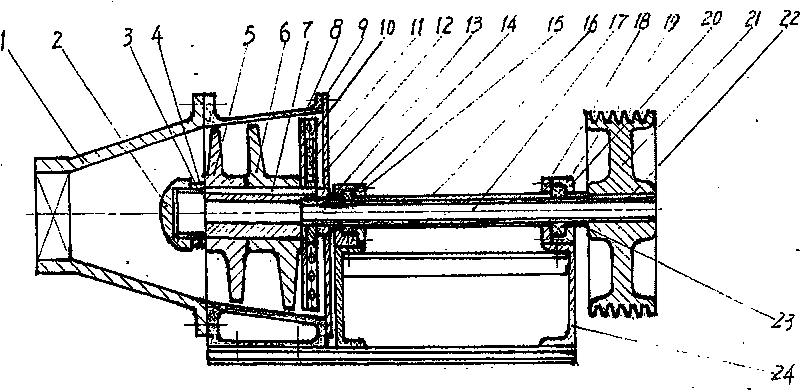

Particle cutting machine

InactiveCN105729541ASimple structureEasy to useMetal working apparatusEngineeringMechanical engineering

The invention relates to a particle cutting machine which comprises a bottom plate, a fly-cutter disc fixing seat and a fly-cutter disc, wherein the fly-cutter disc fixing seat and a fixed plate are vertically mounted on the upper end face of the bottom plate; the fixed plate is arranged vertical to the front end face of the fly-cutter disc fixing seat; a servo motor is mounted on the back end face of the fly-cutter disc fixing seat; a rotating shaft of the servo motor is connected with the fly-cutter disc parallel to the front end face of the fly-cutter disc fixing seat; a slicing knife fixture is mounted on the edge of the fly-cutter disc; a slicing knife is mounted inside the slicing knife fixture; a particle cutting mold is mounted in the position, above the fly-cutter disc, of the front end face of the fly-cutter disc fixing seat; a stepping motor is mounted on one side of the fixed plate; a rotating shaft of the stepping motor penetrates through the fixed plate to be connected with a driving wheel; and a driven wheel capable of being adjusted up and down is mounted in the position above the driving wheel, of the fixed plate. According to the particle cutting machine, the structure is simple, the utilization is convenient, the cutting speed is high, the working efficiency is high, the cutting length can be well controlled, and the cutting surface is quite smooth.

Owner:NINGBO MERRY ART GLOW TECH CO LTD

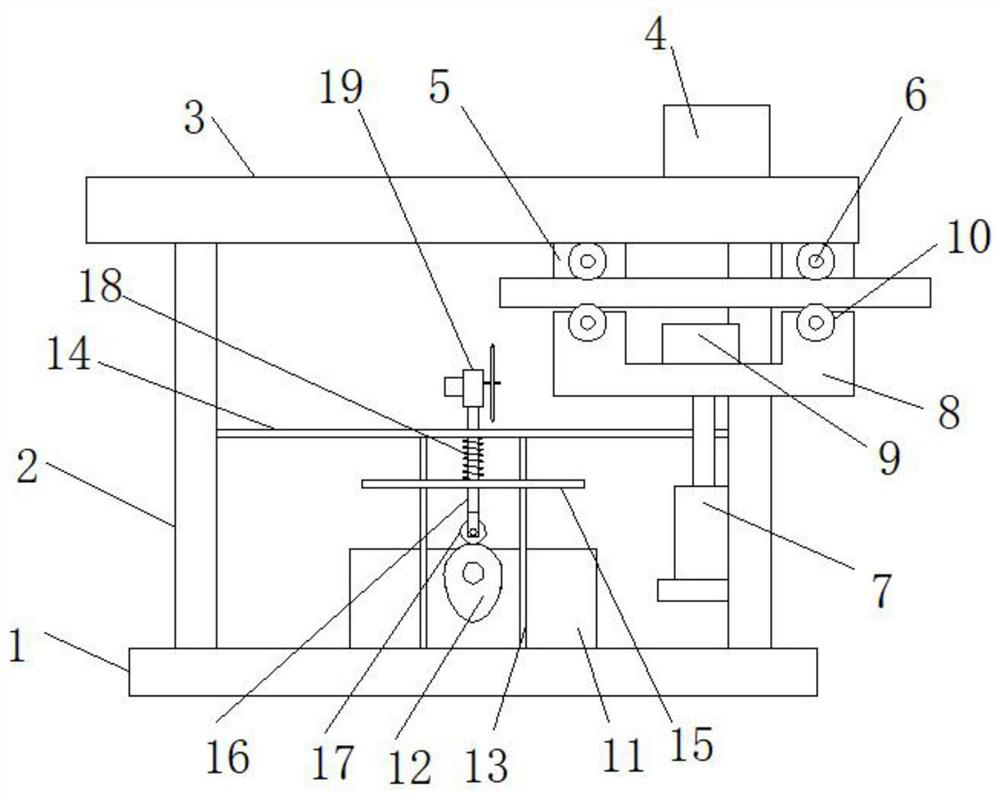

Cutter maching capable of adjusting cutting size

InactiveCN109746494AAdjustable cutting sizeAdjusting the position in the front-back directionLarge fixed membersMilling equipment detailsHydraulic cylinderMilling cutter

The invention discloses a cutter maching capable of adjusting the cutting size. The comprises a base, a first motor box, a cross beam, a second sliding chute, a first groove and a collecting box, wherein a first sliding chute is formed in the upper end face of the base; the first motor box is arranged on the rear end face of the base; the cross beam is arranged between movable brackets; a hydraulic cylinder box is arranged on the inner side of a movable block; a connecting column penetrates through the lower end of the hydraulic cylinder box; a second motor shaft is arranged on a second motor;a milling cutter is connected with the lower end of the second motor shaft; fixed rods are arranged between the second sliding chute; the first groove is formed in the upper end face of the base; a bearing plate is arranged in the second sliding chute; and the collecting box is arranged in the interior bottom of the base and is arranged in a second groove. The cutter maching adjusts the positionof two movable blocks at a first slideway; and when an operating column is moved on the first slideway, an expectant cutting length is not exceeded to realize the purpose of adjusting the cutting length.

Owner:江苏摩臣智联科技有限公司

Efficient optical fiber automatic cutting device

ActiveCN107088712ASimple structureEasy to operateCoupling light guidesLaser beam welding apparatusEngineeringMechanical engineering

The invention discloses an efficient optical fiber automatic cutting device which comprises a machine body and a supporting frame. The supporting frame is arranged on the machine body; the efficient optical fiber automatic cutting device is characterized in that the middle portion of the supporting frame is provided with a main sliding rail shaft transversely arranged on the supporting frame, a main sliding pair in sliding connection is arranged above the main sliding rail shaft, a laser focus device is connected to the position below the main sliding rail shaft, the positions, on the two sides of the main sliding rail shaft, of the supporting frame are each provided with a plurality of small air cylinders, and a plurality of auxiliary sliding rail shafts the same as the supporting frame are arranged in front of the small air cylinders; auxiliary sliding pairs are connected to the positions above the auxiliary sliding rail shafts in a sliding manner, air cylinder chambers are arranged at the lower ends of the auxiliary sliding rail shafts, and pistons which are in tight fit and can move vertically are arranged on the air cylinder chambers; and clamping hand mechanisms capable of retracting towards the center are connected to the positions below the positions, and the small air cylinders are connected with the air cylinder chamber through air guide pipes. According to the efficient optical fiber automatic cutting device, shortcomings in the prior art are overcome, and the device capable of achieving optical fiber automatic cutting is provided.

Owner:NEWPION PHOTONICS TECH CO LTD

Simple automatic paper cutting machine

InactiveCN104511926AEasy to replaceControl cutting lengthMetal working apparatusPulp and paper industryEngineering

The invention provides a simple automatic paper cutting machine. The simple automatic paper cutting machine comprises a transmission device, an adjusting device and a paper cutting device; the transmission device comprises two rollers; any one of the rollers is equipped with a base; the two rollers are connected through a chain; a conveyor belt is arranged at the outer side of the chain; one roller is connected with a first motor through a belt; a control panel is arranged on the first motor; the adjusting device comprises a flat plate; two baffles are arranged at two sides of the flat plate; any one of the baffles is movably connected with the flat plate; a cutter rack is arranged on the top part of the paper cutting device; a blade is arranged in the center of the top part of the cutter rack; a base plate is arranged at the bottom part of the cutter rack; a second motor is arranged on a cutter holder and is connected with the cutter rack through a line. The simple automatic paper cutting machine has the beneficial effects that the cost is low, the cutter head is conveniently replaced, the cutting length and direction of corrugated paper can be controlled well, and therefore, the production efficiency can be increased, and the production cost can be decreased.

Owner:天津滨海新区大港亨佳造纸厂

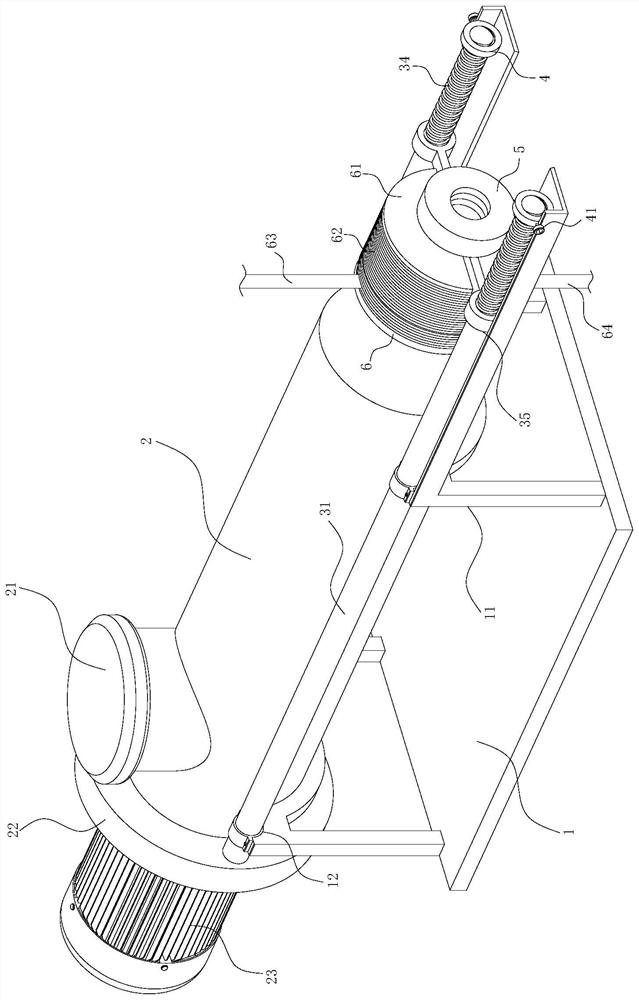

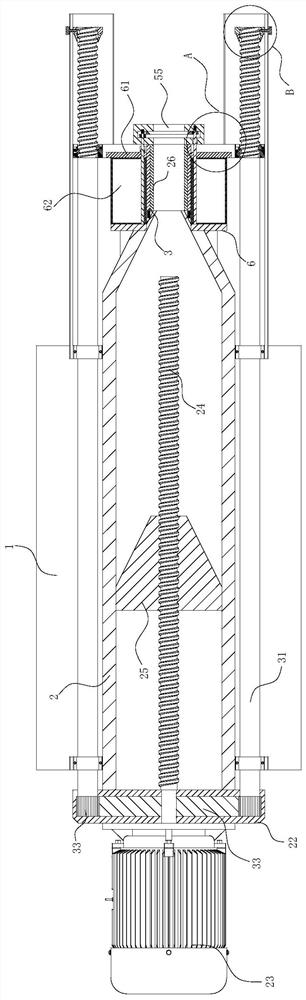

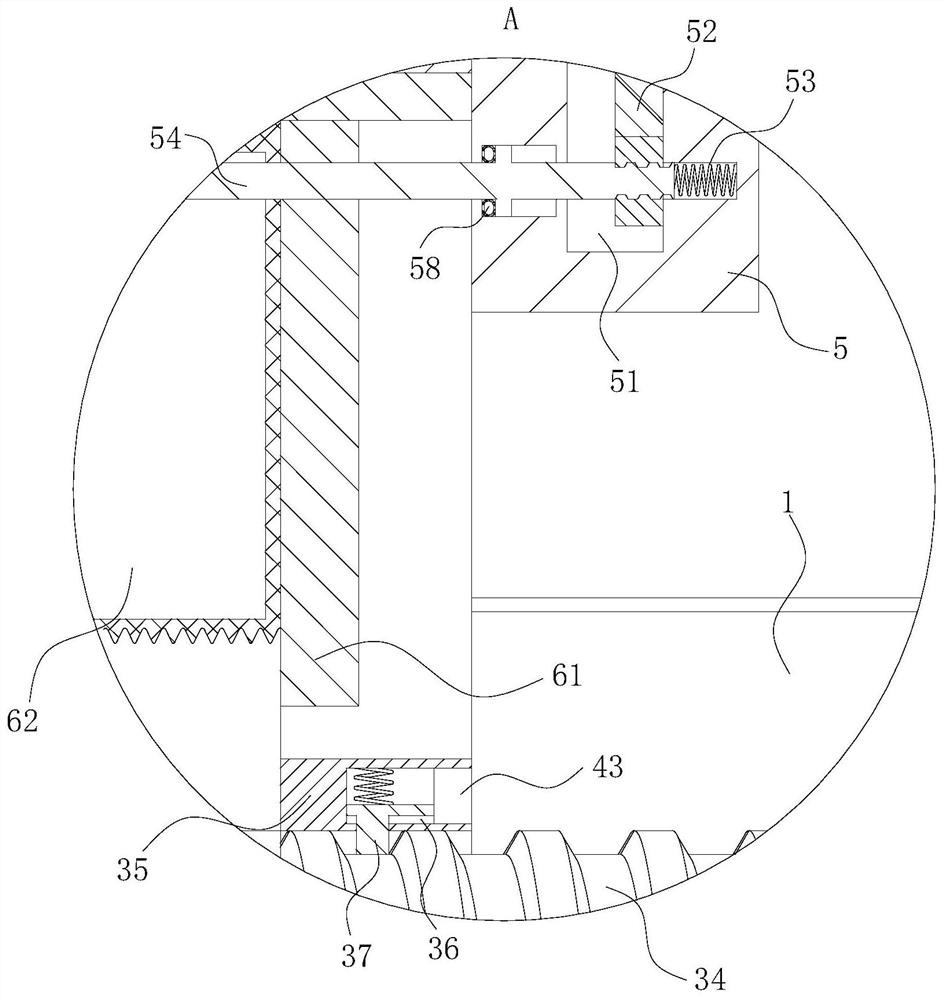

Cutting device of aluminum profiles

InactiveCN109396524AEasy to fixControl cutting lengthShearing machinesShearing machine accessoriesEngineeringMachining

The invention relates to the technical field of hardware machining, in particular to a cutting device of aluminum profiles. The cutting device of the aluminum profiles comprises a supporting frame. The supporting frame is a two-step-shaped square pipe frame, a rectangular square pipe connecting frame is further welded to the left end of the supporting frame, a cutting mechanism is mounted on the front face of an upper step of the supporting frame, a fixing plate is mounted on the front face of a lower step of the supporting frame through a nut, and a fixing mechanism is mounted on the fixing plate. The aluminum profiles are better fixed, and two aluminum profiles can be simultaneously cut.

Owner:嘉善敏达金属制品厂

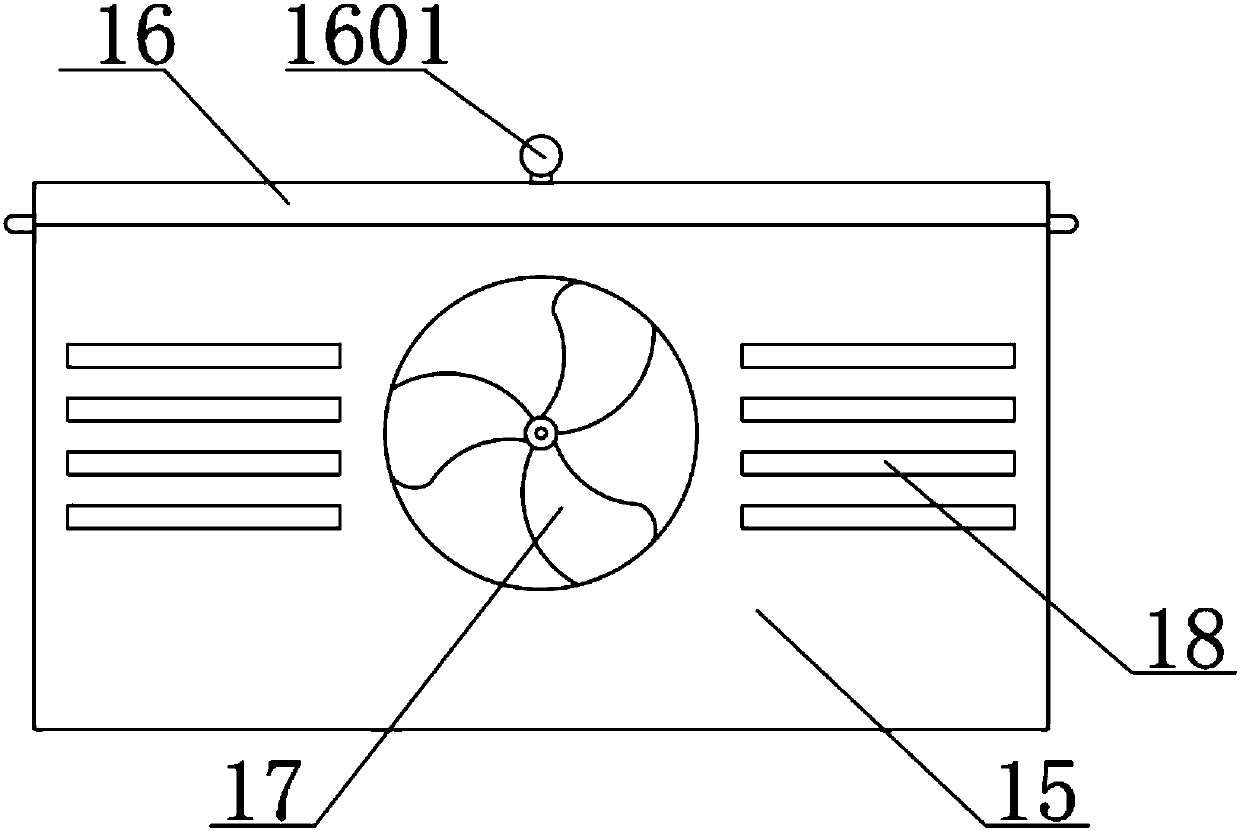

High-precision raw material cutting device for chopstick production

InactiveCN110919779AEasy to fixControl cutting lengthProfiling/shaping machinesBark-zones/chip/dust/waste removalElectric machineryFan blade

The invention relates to the technical field of chopstick production, and discloses a high-precision raw material cutting device for chopstick production. The high-precision raw material cutting device comprises a workbench; a controller is mounted on the front side of the workbench; a cover plate is arranged on one edge of the top end of the workbench; a fixed lapping frame is connected in the position, close to the cover plate, of the top end of the workbench; a moving lapping frame is connected at the top end of the workbench; two first square holes are formed in the top end of the workbench; a sliding groove is formed in the middle of the top end of the workbench; and a second motor is mounted on one edge of the inner side of the workbench. According to the high-precision raw materialcutting device, by the aid of a receiving hole, a receiving plate, a first motor, fan blades, a ventilation hole, an air draft casing, a wood dust collecting box and a sealing door, wood dust producedby cutting of raw materials can be collected conveniently and can be prevented from being distributed in a scattered manner during cutting of the raw materials, and the raw materials cut into sections can be collected conveniently, so that use by workers is facilitated.

Owner:陈雪军

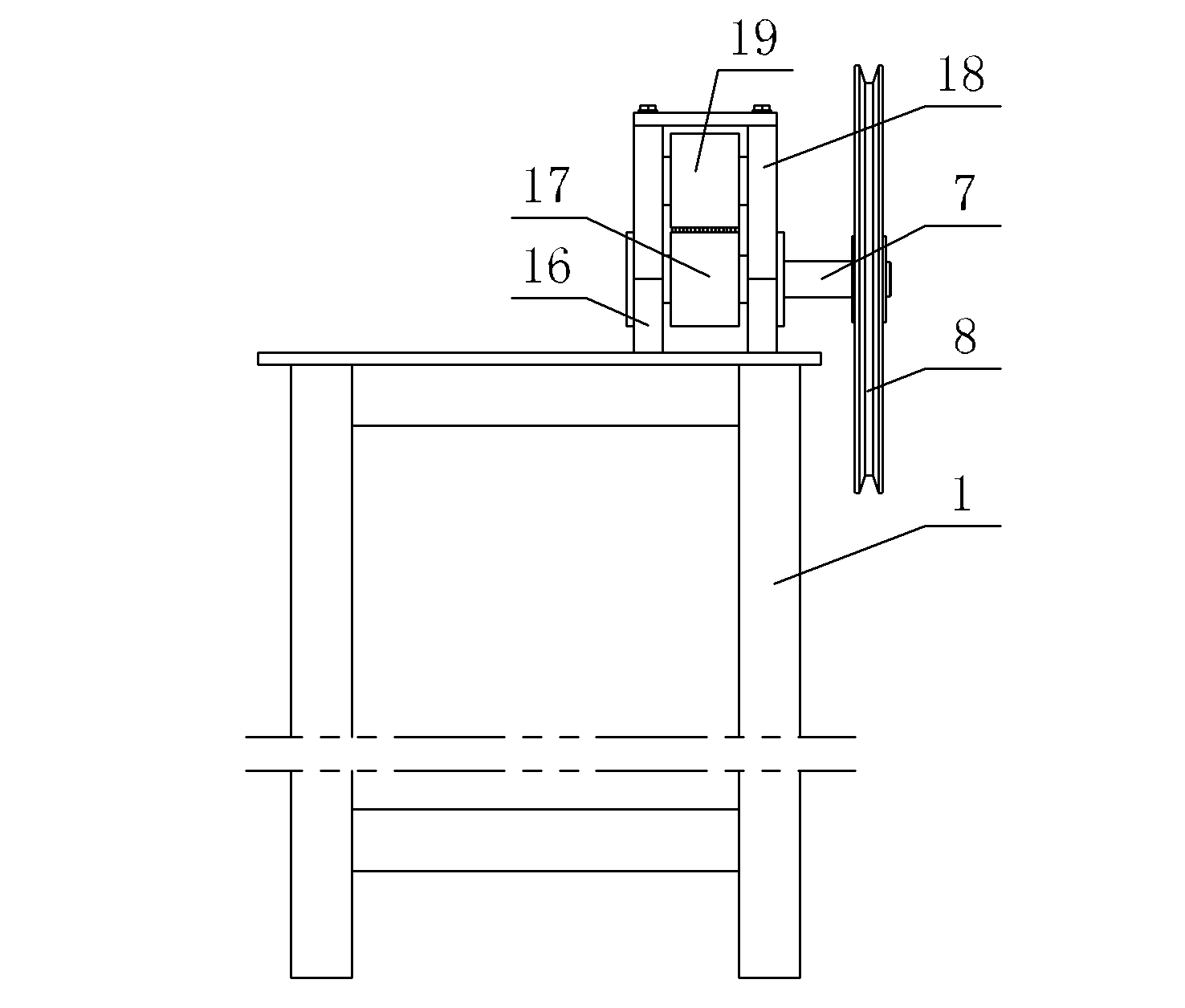

Pipe cutting machine for wiring engineering

InactiveCN112775481AEasy to moveControl cutting lengthTube shearing machinesShearing machine accessoriesElectric machineryEngineering

The invention discloses a pipe cutting machine for wiring engineering. The pipe cutting machine for the wiring engineering comprises a base plate, wherein supporting columns are welded to the top of the base plate, a cover plate is welded to the tops of the supporting columns, a first motor is fixedly arranged at the top of the cover plate, two supporting plates are welded to the bottom of the cover plate, a supporting frame is arranged below the supporting plates, rotating shafts are rotationally arranged on the supporting plates and the supporting frame, one ends of the rotating shafts are sleeved with rollers, an air cylinder is fixedly arranged on one side of one supporting column, a piston rod of the air cylinder is fixedly connected with the supporting frame, a second motor is fixedly arranged on the supporting frame, belt pulleys are arranged at the other ends of the rotating shafts and output shafts of the first motor and the second motor correspondingly, the belt pulleys are connected through a belt, a mounting plate is welded to the top of the base plate, a cam is rotatably arranged on the mounting plate, and a guide rod is welded to the top of the base plate. The pipe cutting machine achieves automatic cutting of pipes, can control the cutting length of the pipes, and is high in cutting efficiency, convenient to use and easy to popularize.

Owner:西安思途米环保科技有限公司

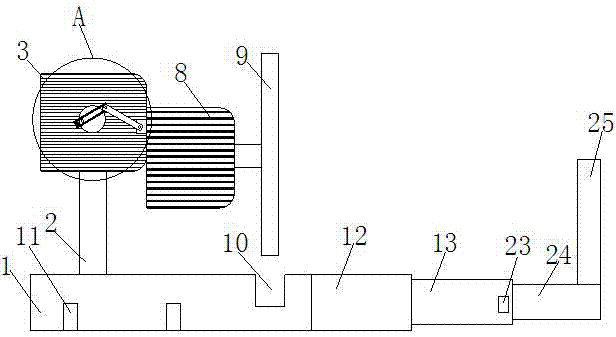

Paper cutting-off equipment for paper paving machine and cutting-off method

ActiveCN112850323AFast cutting speedMotion synchronizationStacking articlesUnfolding thin materialsTool bitIndustrial engineering

The invention provides paper cutting-off equipment for a paper paving machine and a cutting-off method. The paper cutting-off equipment comprises a first paper conveying device, a second paper conveying device, and a cutter fixed between the first paper conveying device and the second paper conveying device. Paper sequentially passes through the first paper conveying device and the second paper conveying device. When the first paper conveying device stops operating, the paper can be strained by the second paper conveying device and make contact with the cutter, and the cutter can cut off the paper. The paper cutting-off method comprises the steps that when the length of the paper output by the first paper conveying device reaches the set length, the first paper conveying device stops operating, the paper is strained by the second paper conveying device and makes contact with the cutter, and the cutter cuts off the paper. By the adoption of the paper cutting-off equipment for the paper paving machine, as the cutter is fixed, and does not need to move in the working process, working time for cutter head moving and cutting is saved, and thus paper cutting speed is increased.

Owner:CHINA TRIUMPH INT ENG

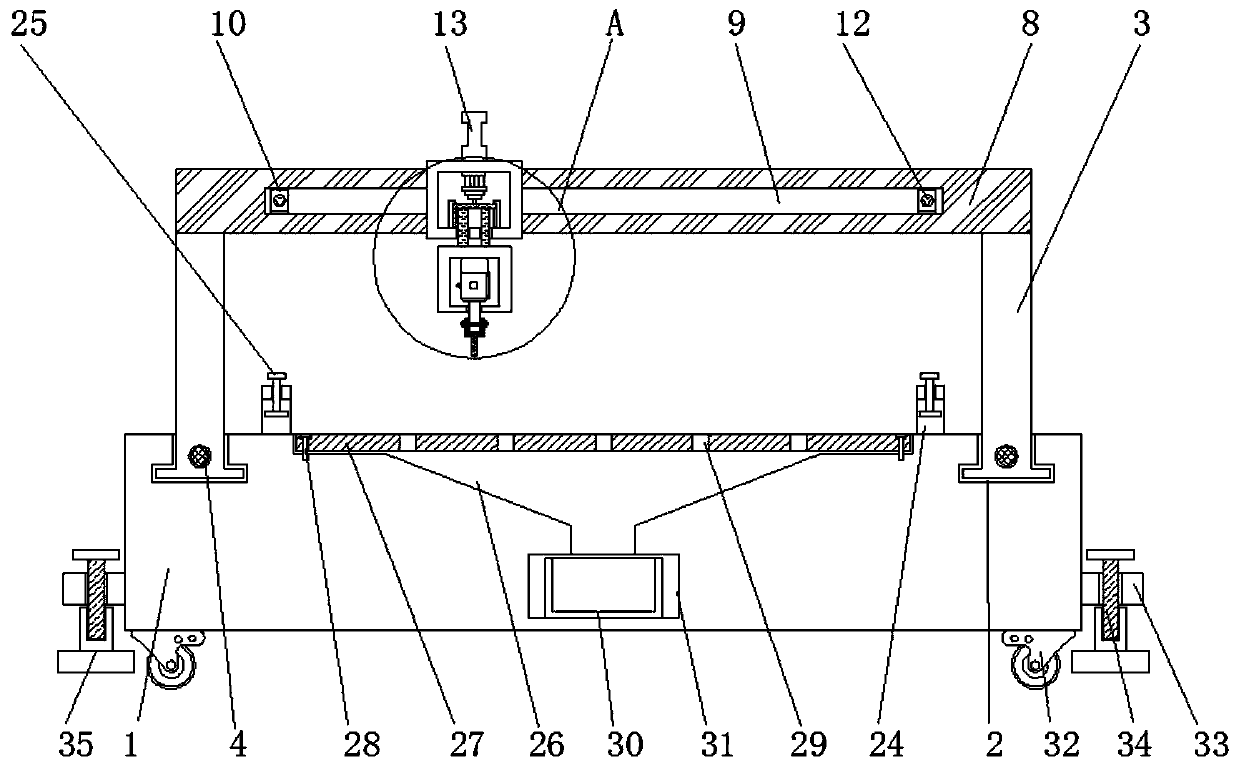

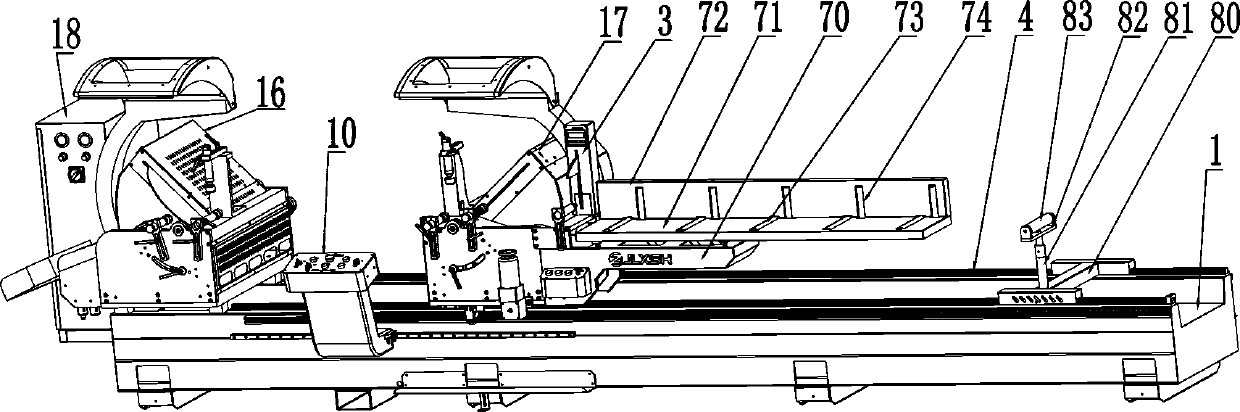

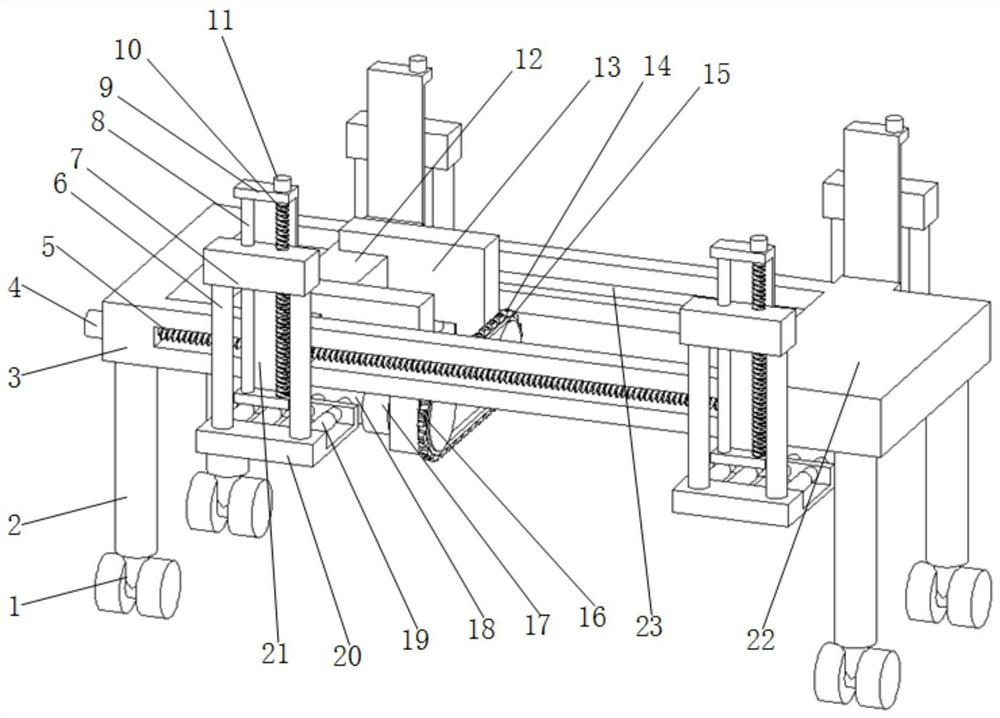

Double-end saw cutting machine with automatic locating function

PendingCN111360320AControl distanceControl cutting lengthMetal sawing devicesMetal sawing accessoriesStructural engineeringMachine

A double-end saw cutting machine with an automatic locating function comprises a horizontal rack arranged in a manner of extending in the left-and-right longitudinal direction, a fixed cutting unit fixedly arranged on the horizontal rack, a movable cutting unit movably arranged on the horizontal rack in the left-and-right longitudinal direction and an automatic controller. The fixed cutting unit and the movable cutting unit comprise metal round saw blades used for sawing correspondingly and are used for being controlled by the automatic controller to cut cut profiles through the metal round saw blades. The double-end saw cutting machine has the advantages that the cutting angles, lengths, heights and other parameter data of the cut profiles can be acquired through a data sampling device, and therefore the automatic controller can achieve automatic distance control and cut profile length control according to the parameter data, operation is automatically completed, efficiency is improved, and locating is accurate.

Owner:湖南金立星机械科技有限公司

Insulator core rod cutting device

InactiveCN110125783ARealize cut-to-lengthReduce labor intensityGrinding machinesGrinding feedersElectricityGrinding wheel

The invention relates to an insulator core rod cutting device, and belongs to the technical field of electrical processing. The insulator core rod cutting device specifically comprises a cutting grinding wheel, a conveying roller, a limiting device, a pressing device and a control device, wherein the control device comprises a speed sensor and a controller, the speed sensor is arranged on the conveying roller, the speed sensor is electrically connected with the controller, and the controller is electrically connected with the conveying roller, the limiting device and the pressing device correspondingly. The insulator core rod cutting device can accurately control the cutting length of an insulator core rod, is easy and convenient to operate and high in automation degree, and the productionefficiency is effectively improved.

Owner:襄阳银鼎电力设备有限责任公司

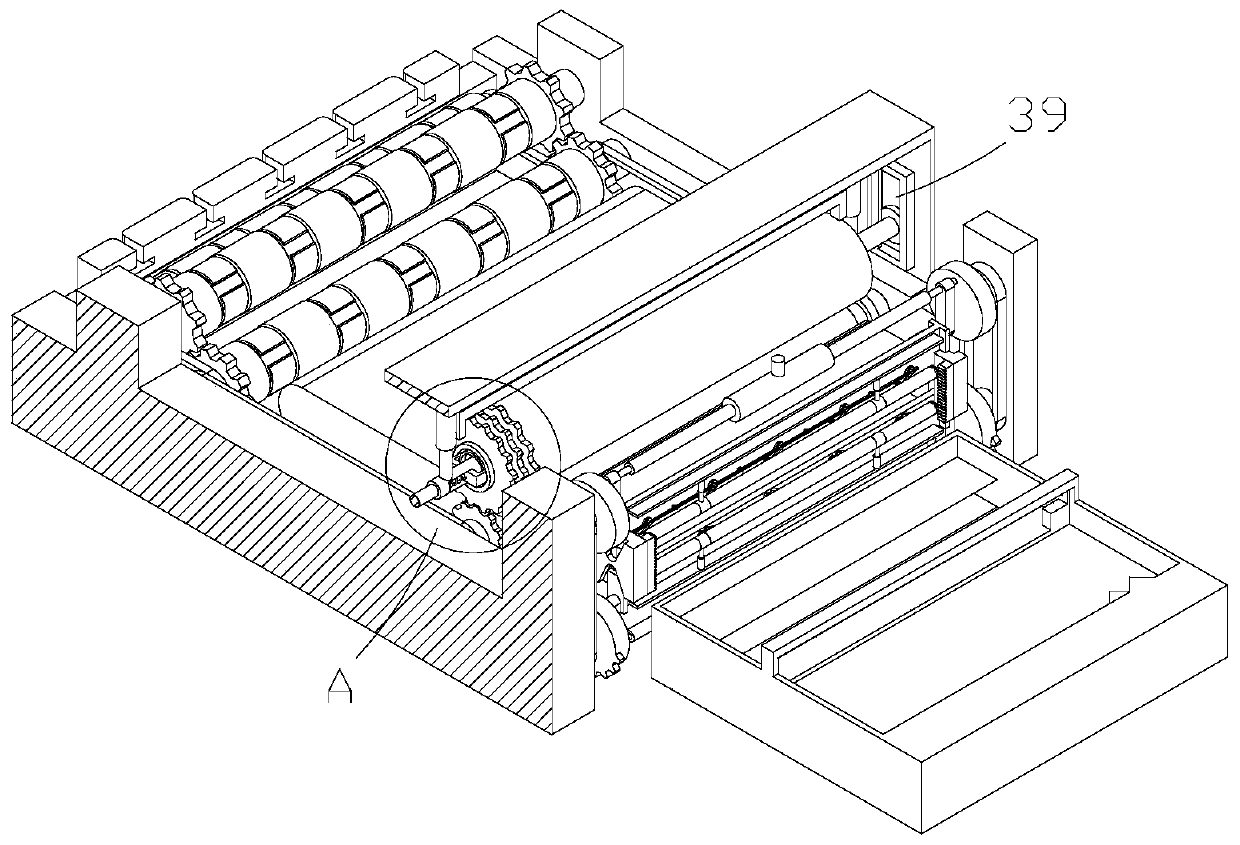

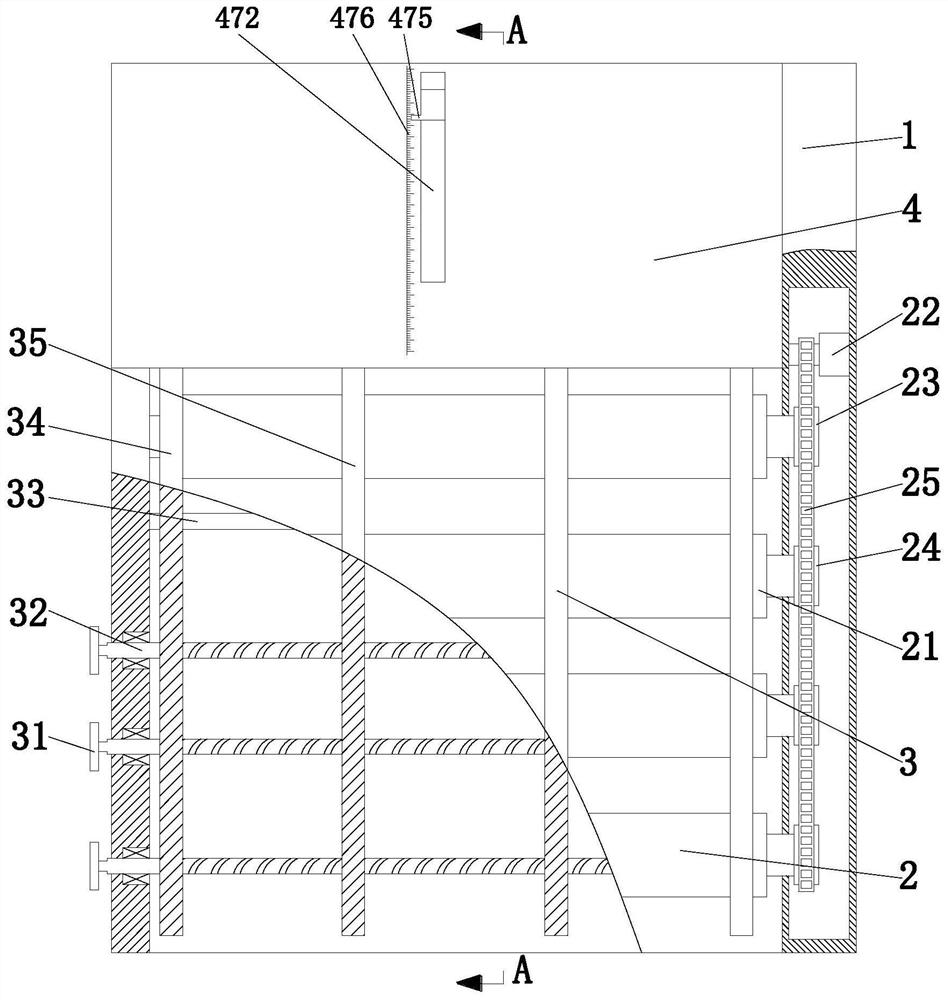

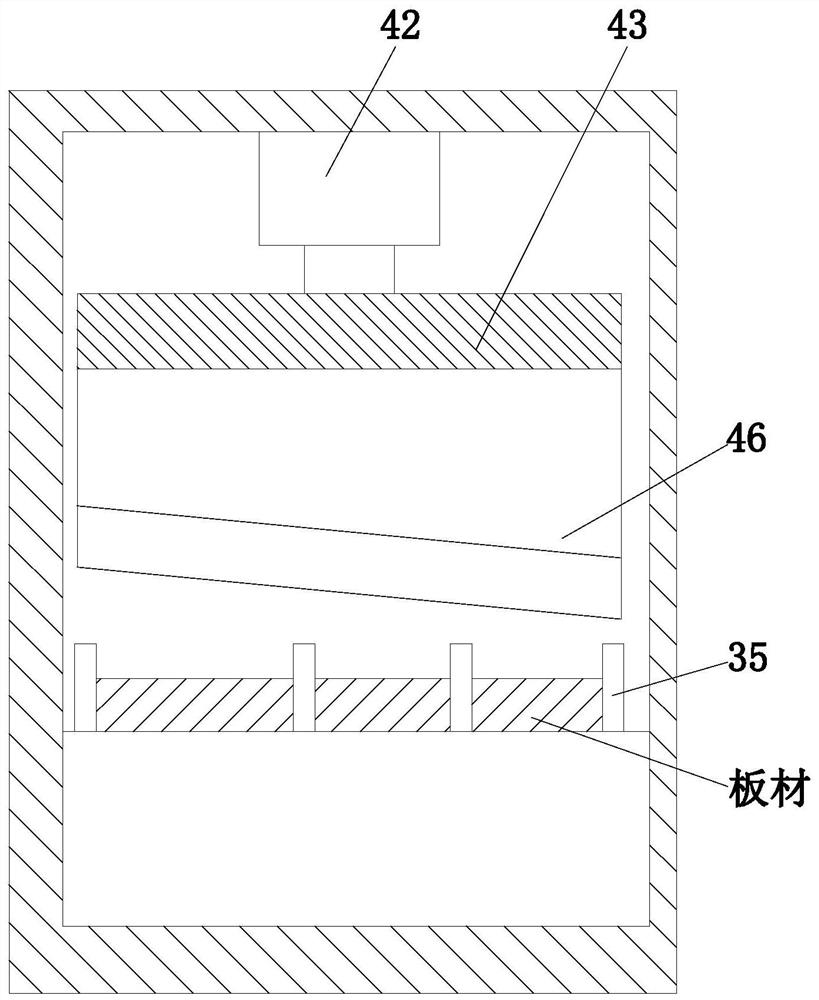

An automatic cutting machine for steel structure profile feeding and fixed length

ActiveCN110524056BControl cutting lengthIncreased labor intensity, etc.Feeding apparatusMetal working apparatusMachineAutonomation

The invention relates to a steel structure profile feeding fixed-length automatic cutting machine. The machine comprises a base, a feeding device, a material distributing device, a cutting device anda discharging device, a feeding cavity and a discharging cavity are formed in the front end of the base from bottom to top, the feeding device and the material distributing device are sequentially installed in the feeding cavity from top to bottom, the cutting device is installed on the upper side of the front end of the base, and the discharging device is installed in the discharging cavity; theadjustable material distributing plate is adopted, so that steel plates with different widths can be fed at the same time; by adjusting the position of the stop block, the steel plate cannot be fed after extending out by a specified length, and the cutting length of the steel plate is controlled; the two ends of the plate are prevented from tilting to influence the cutting precision in a mode of firstly fixing and then cutting; and through discharging of the plates, the conditions that the plates are accumulated on the working platform, efficiency is affected, and the labor intensity of workers is increased are prevented.

Owner:靖江市中元钢构有限公司

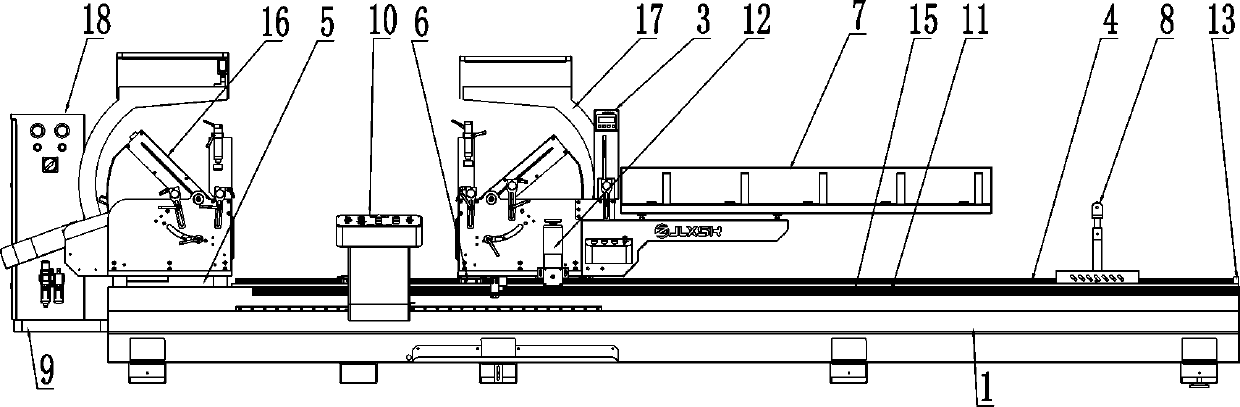

Pipe cutting equipment

InactiveCN105618847BControl cutting lengthHigh degree of automationMetal sawing devicesEngineeringPipe support

The invention discloses a pipe material blanking device, which comprises a pipe material support bracket. A pipe material conveying device and a pipe material cutting device are arranged on one side of the pipe material support bracket. The pipe material cutting device is suspended above the end of the pipe material to be cut. The conveying device includes a retractable clamping and feeding mechanism, which includes a movable slider, a driving part that drives the movable slider to move along the pipe axial direction, and is arranged on the movable slider to clamp and release the pipe. Open the first clamping manipulator. The invention can realize equal cutting, fixed-length cutting or end-to-end cutting of the pipe material, has high automation, fast cutting speed and easy control.

Owner:SHANDONG UNIV OF SCI & TECH

A multifunctional forestry wood cutting device

ActiveCN112677246BNeatly cut offControl cutting lengthSawing componentsBand sawsForest industryAgricultural engineering

The invention provides a multifunctional forestry wood cutting device, which includes a mobile platform, a support frame, a cutting device and two sets of clamping devices; the support frame is supported by the support device; the mobile platform passes through both sides of the support frame, and The drive moves along the length of the support frame; the cutting device includes a first motor and two synchronous pulleys; the two synchronous pulleys are respectively connected to the lower end of a first frame plate through a rotating shaft, and are synchronized by a metal belt; the metal belt A plurality of small sawtooths are evenly welded on the surface; each set of clamping devices includes two opposite jaws; the two clamping jaws of each set of clamping devices are respectively set Side; the installation platform is erected under the slide table through the lifting device, and is driven to move up and down by the lifting device; the curved splint is driven to expand and contract through the telescopic device. The device realizes the automatic cutting of wood, and can guarantee the stability and accuracy when cutting wood.

Owner:NANCHANG INST OF TECH

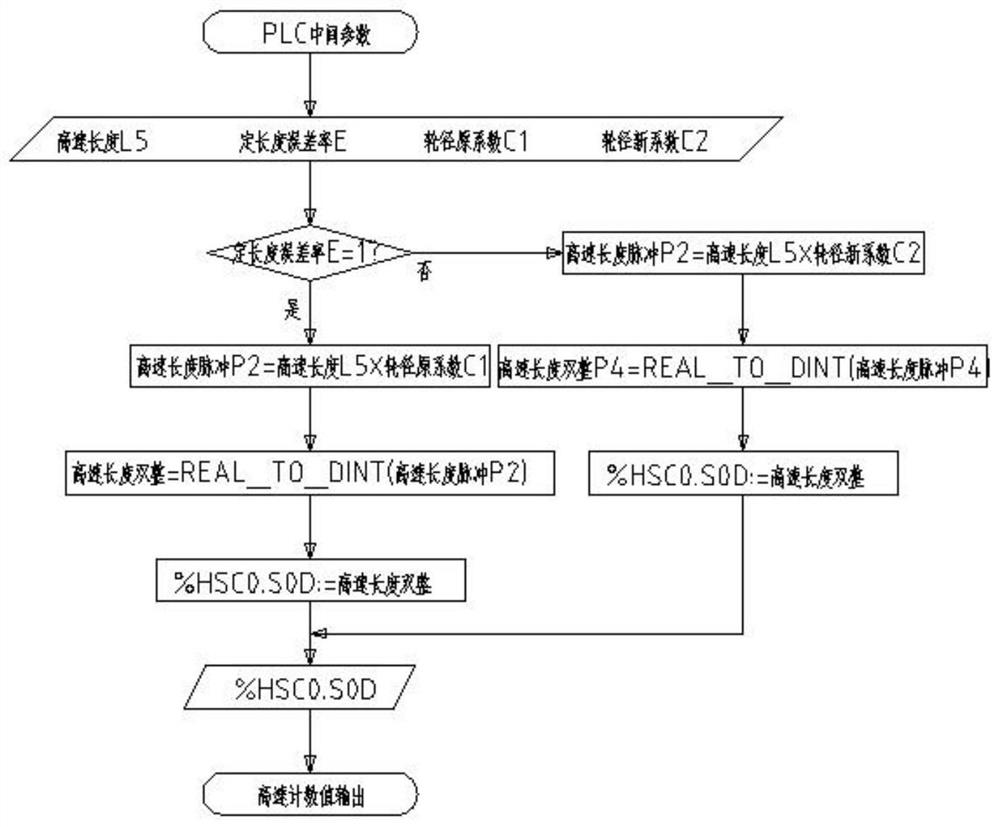

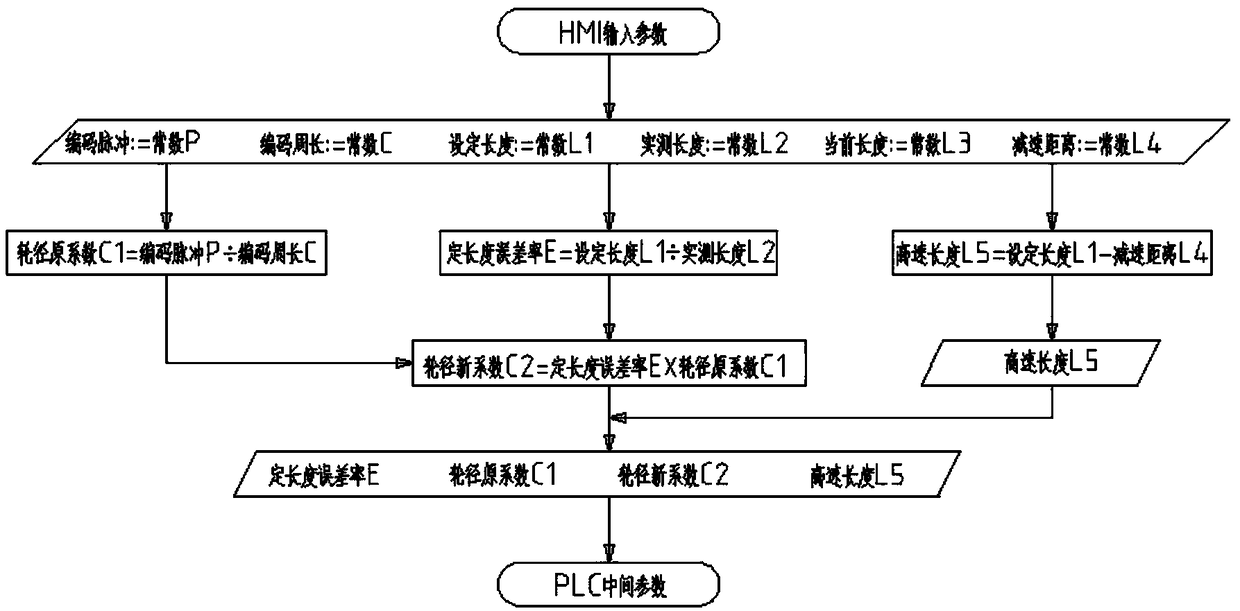

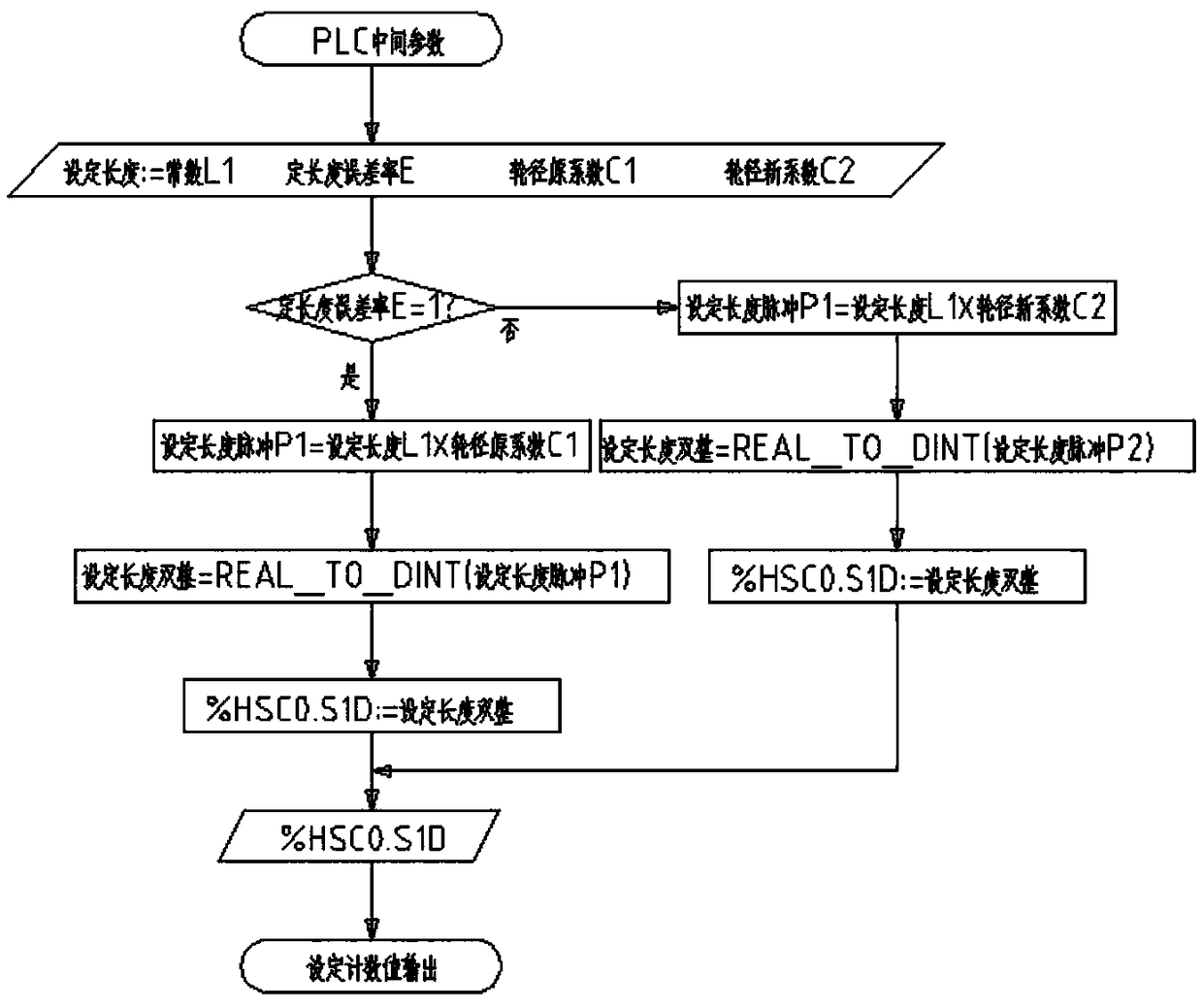

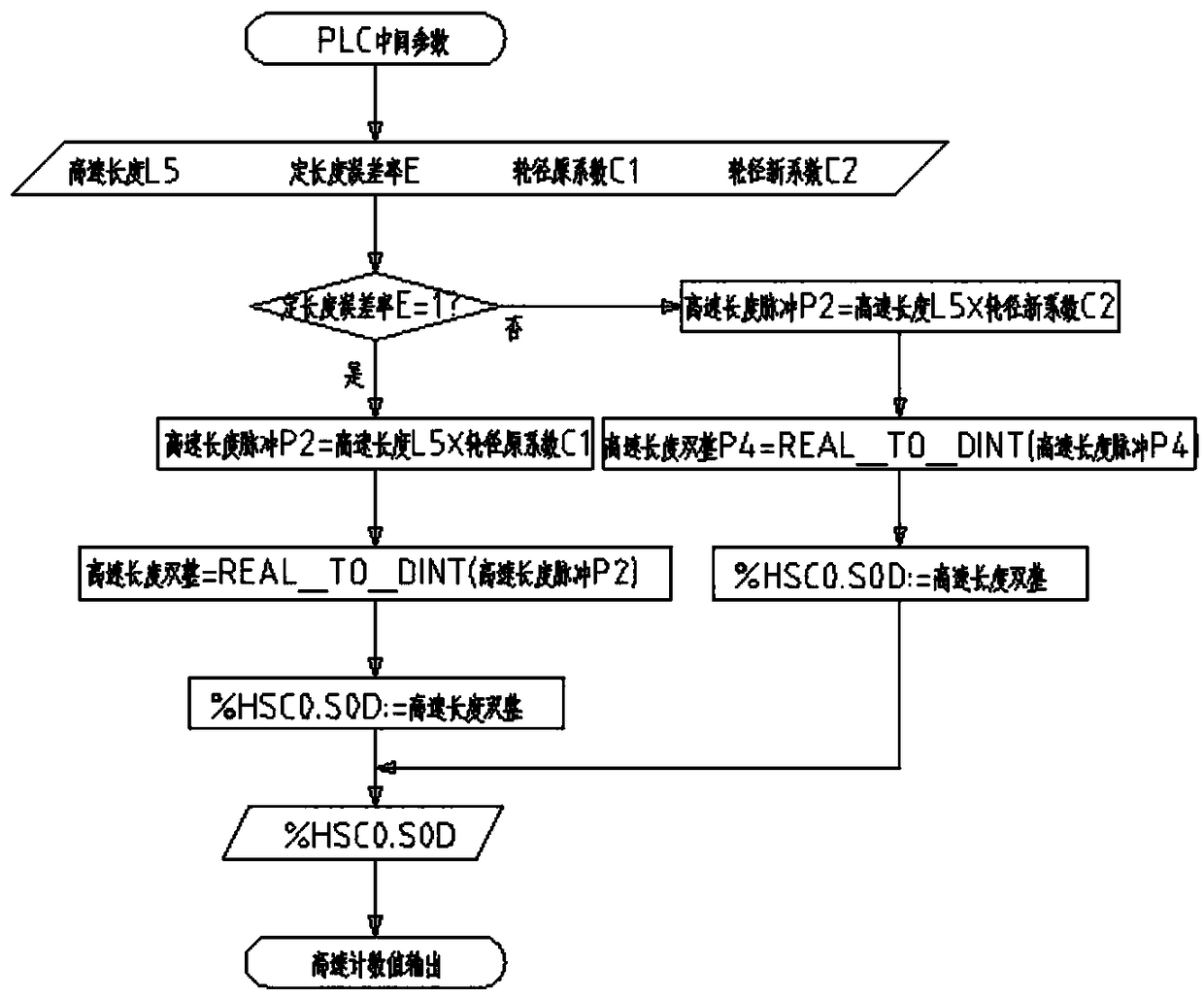

A fixed-length cutting algorithm for color steel tiles based on plc program control

ActiveCN108762185BControl cutting lengthControl precisionProgramme control in sequence/logic controllersHuman–machine interfaceAlgorithm

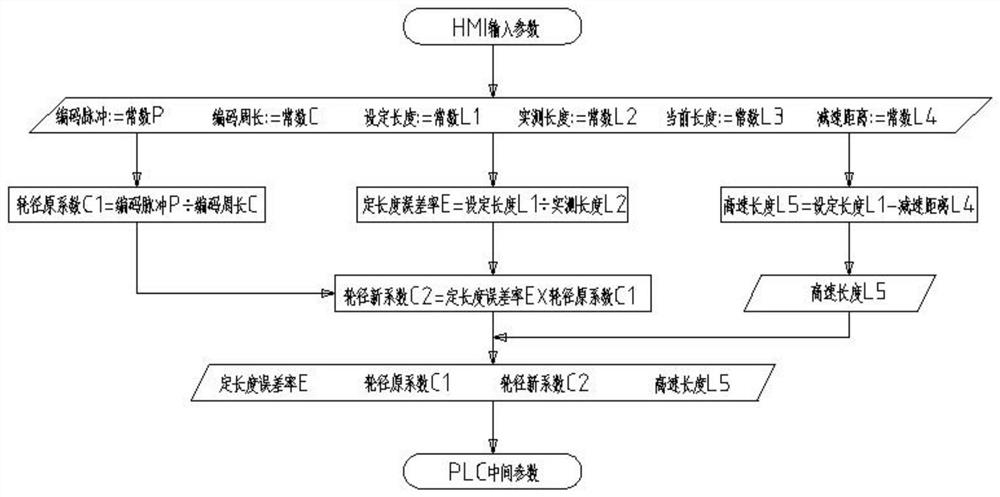

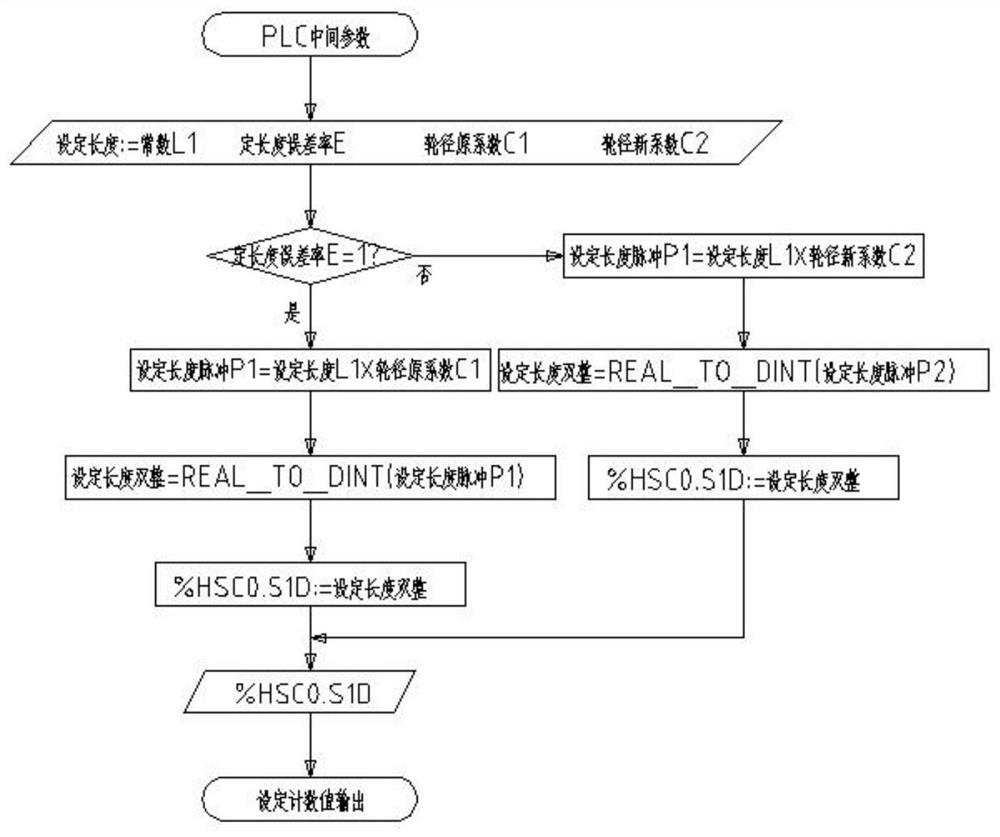

The invention discloses a color steel tile fixed-length cutting algorithm based on PLC program control, which collects high-speed pulse signals through a high-speed counter, performs high-speed calculation and interrupts output, can realize batch cutting production of color steel tiles with different lengths, and adopts fixed length The error rate method effectively solves the cumulative error in the color steel tile cutting process. Input the information such as the set length and the number of cut sheets through the man-machine interface. After actual testing and correction of the length, the stability of the continuous cutting of the color steel tile is guaranteed. It can effectively control the cutting length, number and precision of color steel tiles, and realize the accurate length-fixed batch cutting of roof color steel tiles of any length.

Owner:HENAN WEITE TRUCK CRANE

PLC program control based fixed length cutting algorithm for color steel tile

ActiveCN108762185AControl cutting lengthControl the number of sheetsProgramme control in sequence/logic controllersHuman–machine interfaceAgricultural engineering

The invention discloses a PLC program control based fixed length cutting algorithm for a color steel tile. The PLC program control based fixed length cutting algorithm acquires high-speed pulse signals through a high-speed counter, performs high-speed operation interrupt output, can realize batch cutting production of color steel tiles having different lengths, adopts the fixed length error rate method to effectively solve the cumulative error in the cutting process of the color steel tile, inputs information such as the set length and the number of cutting sheets through a man-machine interface, performs actual test and length correction to ensure the stability of continuous cutting of the color steel tile, can effectively control the cutting length, the number of sheets, and the precision of the color steel tiles, and can achieve precise fixed-length batch cutting of the arbitrary length of the roof color steel tile.

Owner:HENAN WEITE TRUCK CRANE

A photovoltaic system component production equipment

ActiveCN111036977BSecurity tensionControl cutting lengthShearing machinesShearing machine accessoriesKnife bladesIndustrial engineering

The invention discloses a production equipment for photovoltaic system components, in particular for the slitting production and processing of photovoltaic welding strips: comprising a frame, a limit mechanism arranged on the frame, a feeding mechanism, a transmission mechanism, a slitting mechanism and a bundling mechanism; The limiting mechanism is provided with a fixing block, the fixing block is provided with a plurality of T-shaped grooves, and the limiting mechanism is provided with a first guide roller, a second guide roller and a third guide roller; The feeding mechanism is provided with an upper feeding roller and a lower feeding roller, the upper feeding roller is provided with a speed change gear group; the slitting mechanism is provided with an upper pressing plate and a lower pressing plate, and the upper pressing plate is provided with an upper blade, so The lower platen is provided with a lower blade. The invention solves the problem of burrs and inclinations at the incision of the welding strip, avoids the welding strip swinging during the slitting process, improves the stability of the product, can control the welding strip length more accurately, and can process welding strips of different lengths according to requirements.

Owner:杭州首电能源科技有限公司

An automatic cutting machine for controlling cutting length

InactiveCN106001778BControl cutting lengthTo achieve the purpose of stretchingEngineeringRotating disc

Owner:无锡博成洋超声设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com