Insulator core rod cutting device

A technology of cutting device and insulator, which is applied in the direction of grinding feed motion, grinding workpiece support, grinding machine, etc., can solve the problems of easy error in manual measurement, high technical requirements of workers, uneven cutting interface, etc., so as to improve the cutting quality. and cutting efficiency, reduce labor intensity, and smooth the cutting interface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

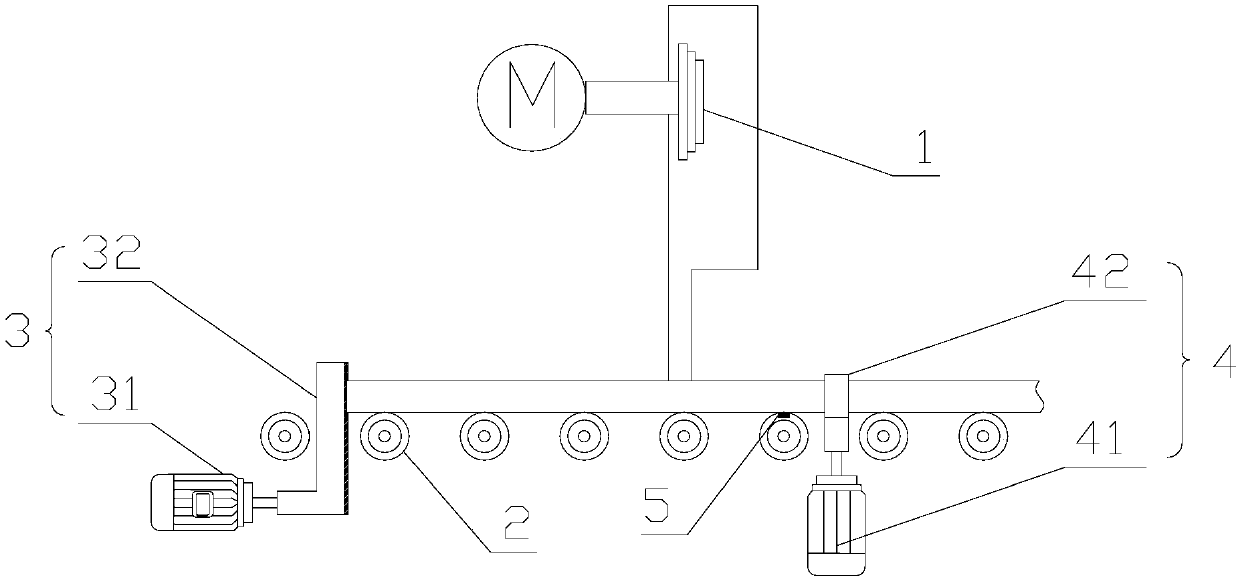

[0023] Such as figure 1 As shown, an insulator mandrel cutting device includes a cutting wheel 1, a conveying roller 2, a limiting device 3, a pressing device 4 and a control device, and the control device includes a speed sensor 5 and a controller (not shown in the figure) ), the speed sensor 5 is installed on the conveying roller 2, the speed sensor 5 is electrically connected to the controller, and the controller is electrically connected to the conveying roller 2, the limiting device 3 and the pressing device 4 respectively. The speed sensor 5 transmits the detected rotation speed of the conveying roller 2 to the controller, and calculates the conveying distance within a period of time; when the preset length is reached, the controller issues an instruction, and the conveying roller 2 stops conveying, and at the same time controls the limit The device 3 and the pressing device 4 act to prepare for cutting. When the cutting action is completed, the controller controls the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com