Spiral briquetting machine

A briquetting machine and screw extrusion technology, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problems of waste of resources, high product prices, high prices, etc., to achieve convenient installation and maintenance, good grass cutting The effect of length, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

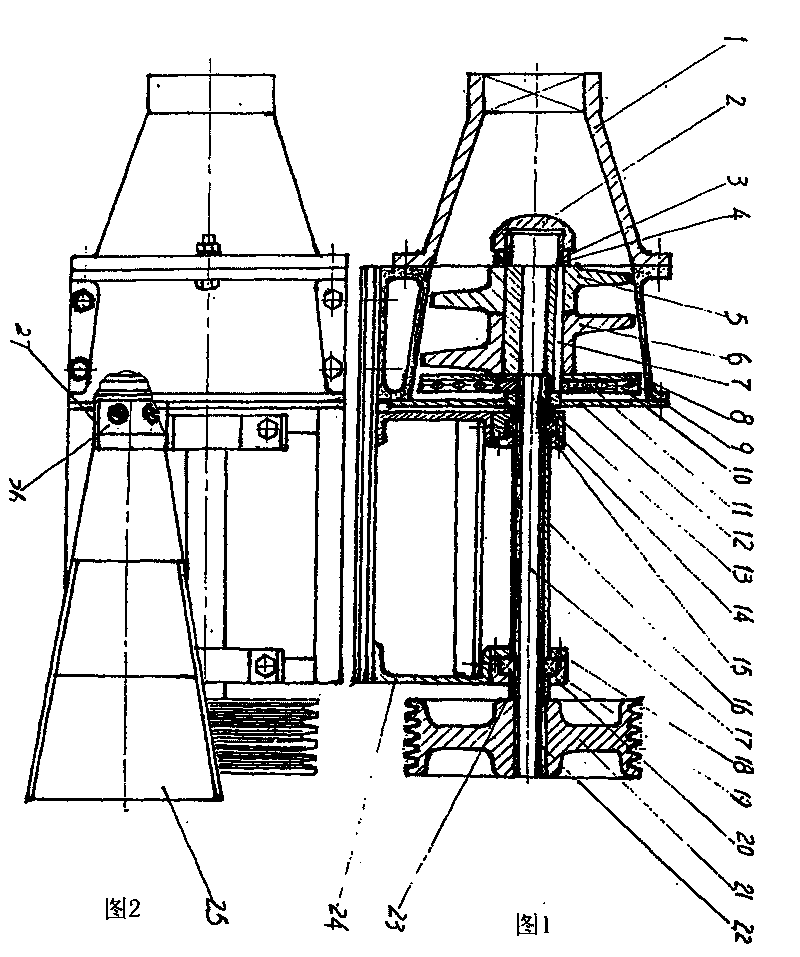

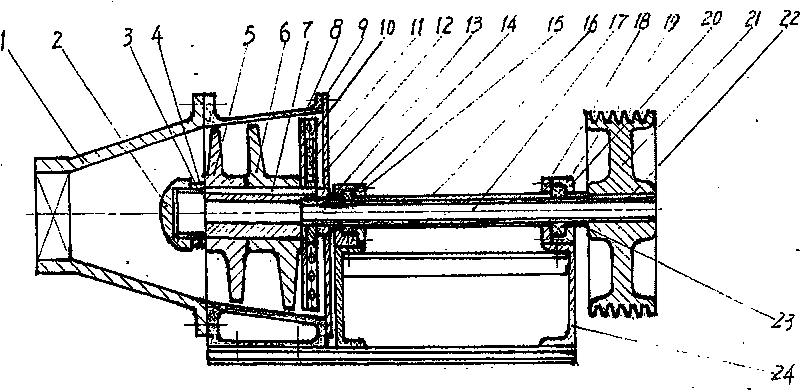

[0007] Below, the details and working conditions of the specific structure proposed according to the present invention will be described in detail in conjunction with the accompanying drawings.

[0008] The present invention mainly consists of a tapered briquetting die (1), a screw compression cavity (8), a screw extrusion shaft (2) (3) (4) (5) (6) (7) (9) (10 )(11)(12)(13)(14)(15)(16)(17)(18)(19)(20)(21)(22)(23)(26), frame welding(24 ), feeding hopper (25) and other parts. As shown in the attached figure, the tapered briquetting die is composed of a cone and a square body. The spiral chamber (8) is a conical chamber. Shaft (17), on the right side of the screw compression chamber cover (12), install the bearing seat (13), bearing (14), bearing cover (15) respectively, and use the bolt seat (20) and fix the bearing cover (18) with bolts On the bearing seat (20), then the bearing fixed cover (23), the V-shaped tape wheel (21) is packed into and with chain (22), is fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com