PLC program control based fixed length cutting algorithm for color steel tile

A cutting algorithm, color steel tile technology, applied in program control, electrical program control, program control in sequence/logic controllers, etc., can solve the problems of low production efficiency, high labor intensity, inconsistent length of color steel tiles, etc. Achieve the effect of ensuring stability and solving accumulated errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to deepen the understanding of the technical solutions of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

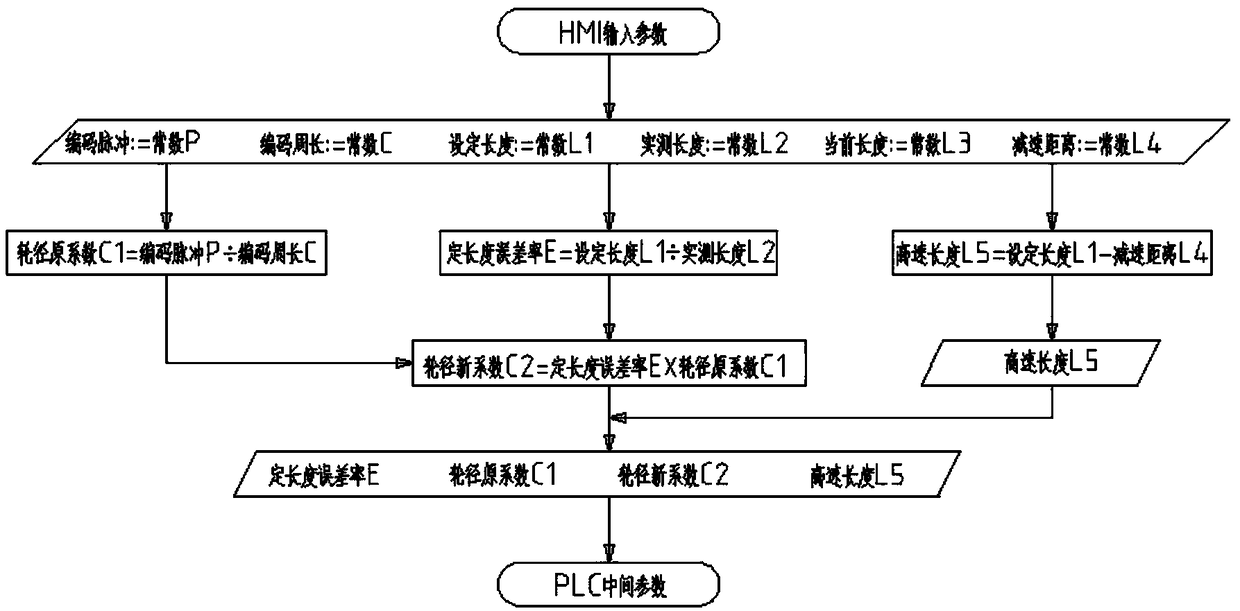

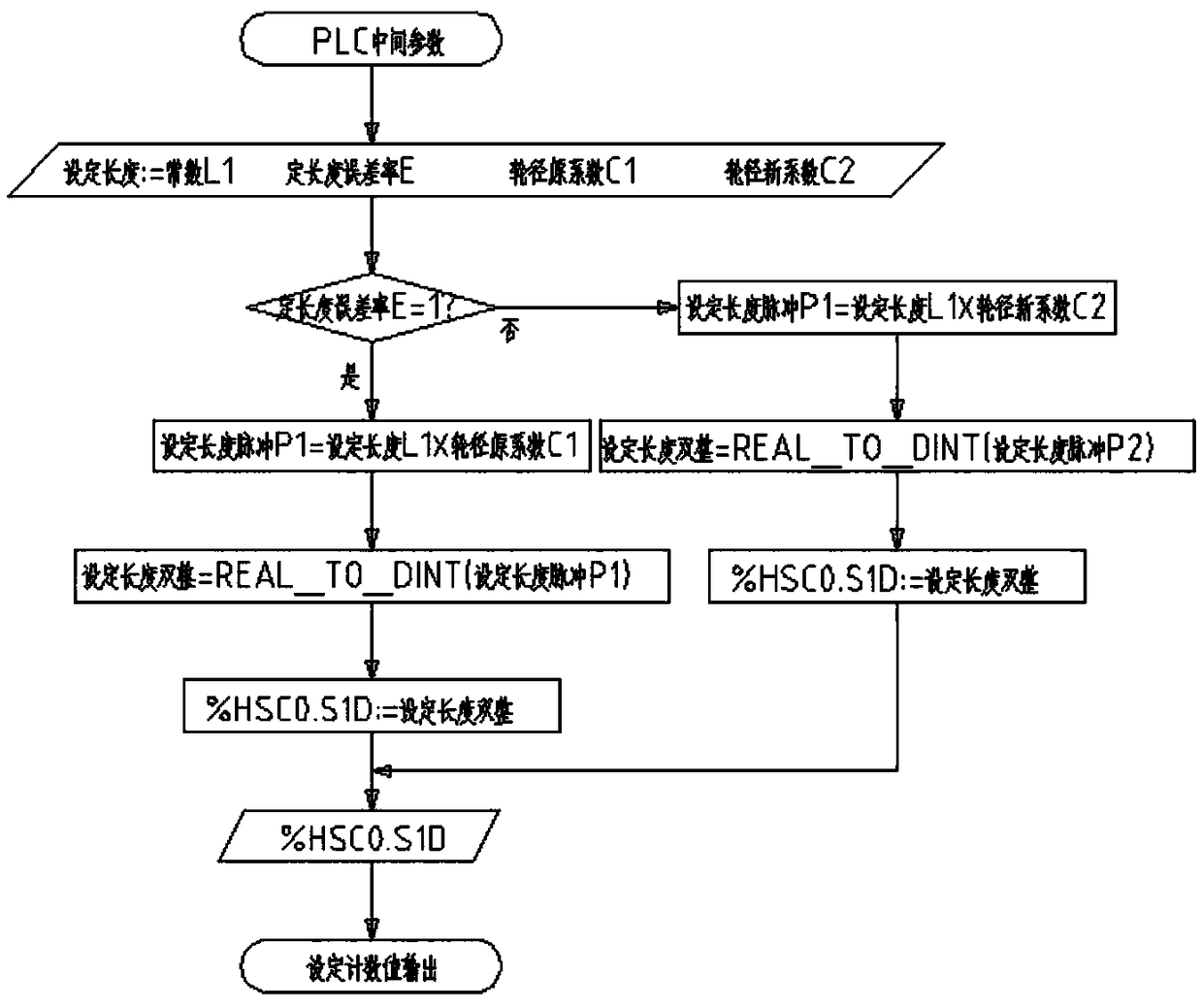

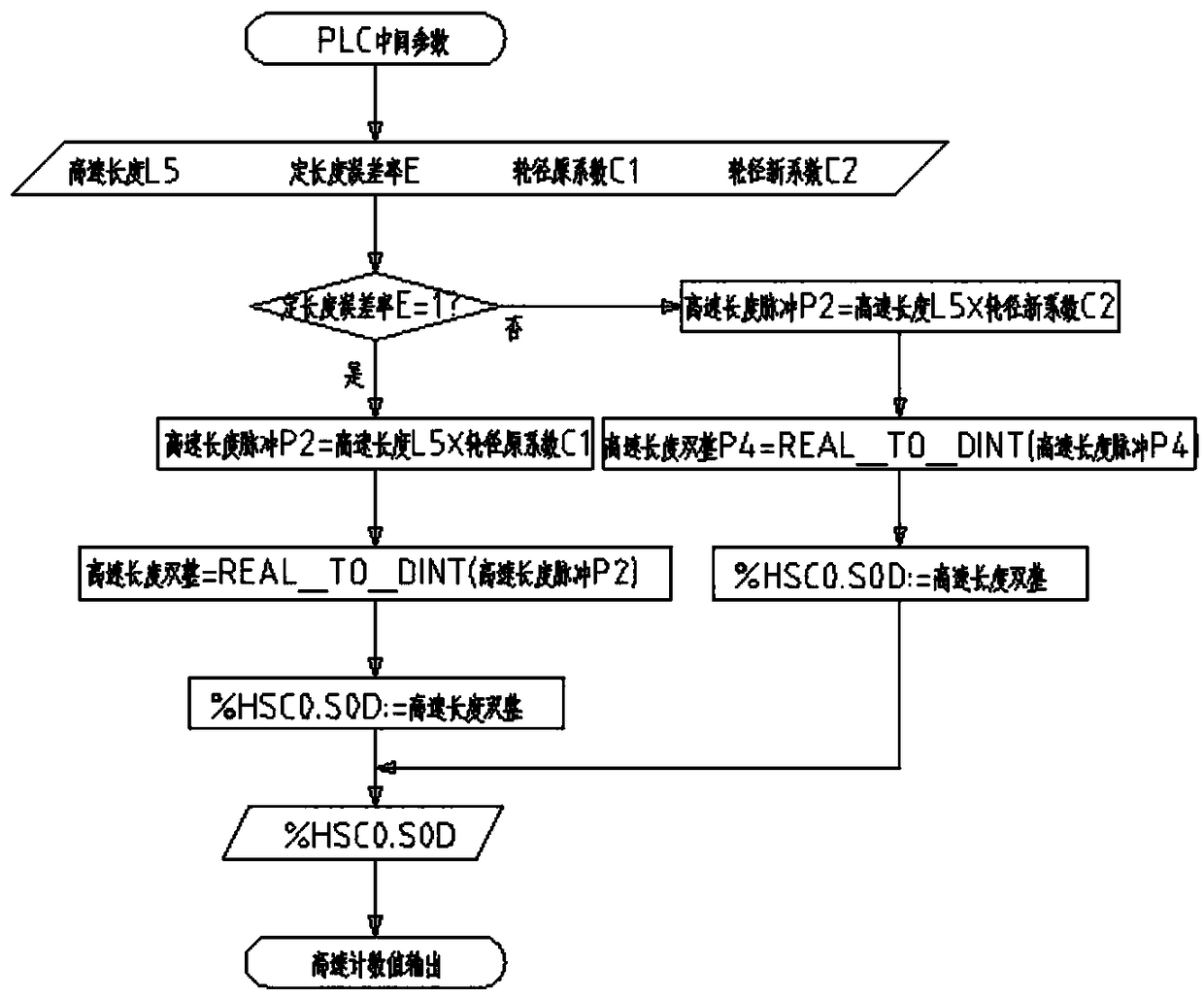

[0022] Such as Figure 1-5 As shown, the present invention provides a color steel tile fixed-length cutting algorithm based on PLC program control, including the following process:

[0023] 1) Calculation of PLC intermediate parameters: Calculate the original coefficient of wheel diameter C1=P / C and the length of high-speed section L5=L1 according to the encoder pulse P, coded circumference C, set length L1, measured length L2 and deceleration distance L4 -L4, fixed length error rate E=L1 / L2 and wheel diameter new coefficient C2=E*C1;

[0024] 2) Calculation of the set length pulse P1: when the fixed length error rate E=1, set the length pulse P1= L1*C1, convert the set length pulse into a double integer through REAL_TO_DINT, and then send it to the %HSC0 of the high-speed counte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com