Double-end saw cutting machine with automatic locating function

A sawing machine and automatic positioning technology, which is applied to metal sawing equipment, sawing machine devices, manufacturing tools, etc., can solve the problems of large error fluctuation, low efficiency, and easy misreading, and achieve the effect of improving efficiency and accurate positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention and its beneficial technical effects will be described in further detail below in conjunction with the accompanying drawings and preferred implementation methods. The descriptions of orientation and position in the text are only relative positions for convenience of description, not absolute positions.

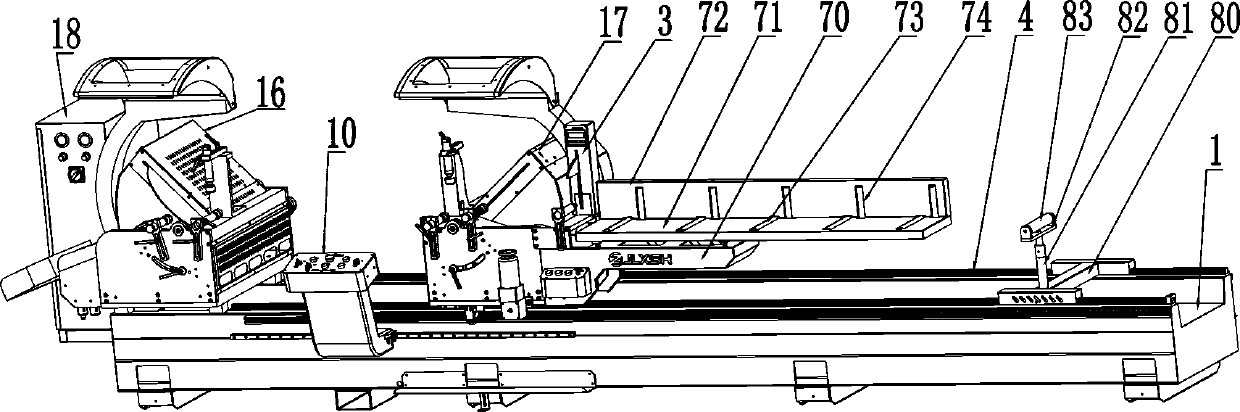

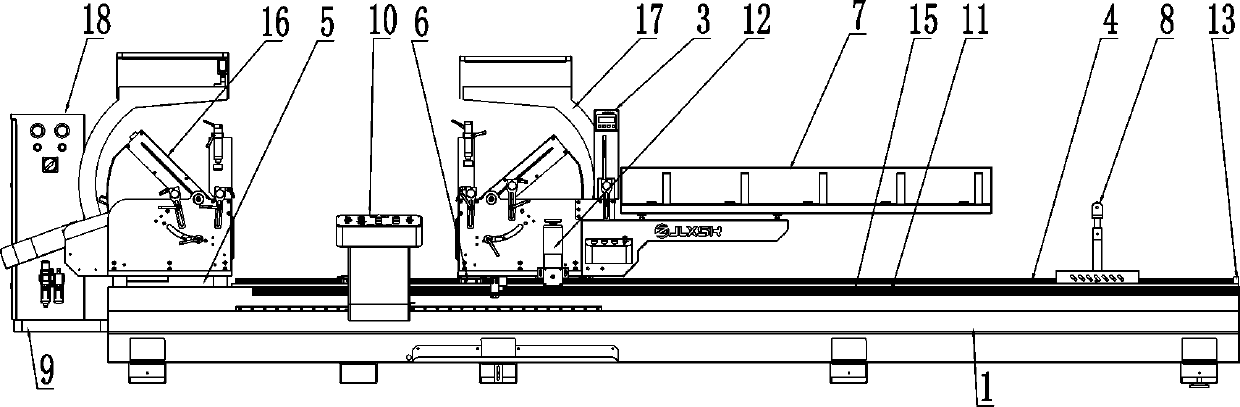

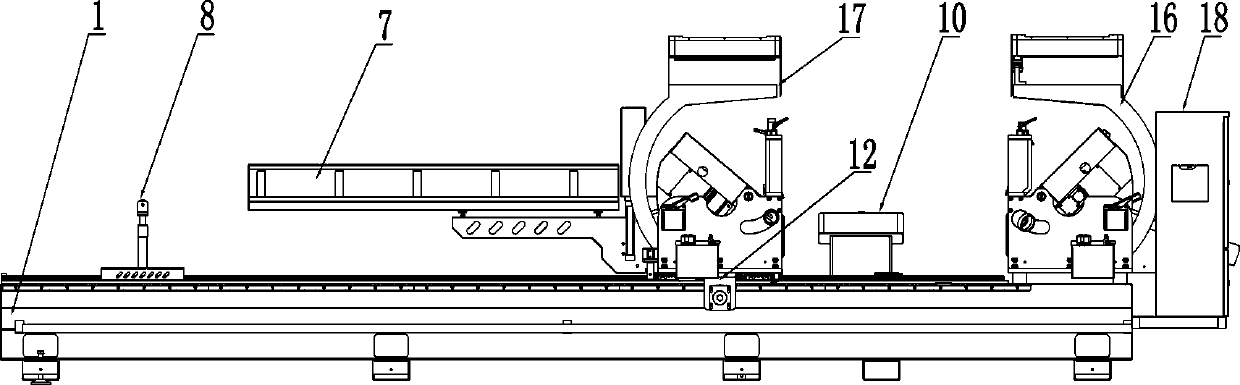

[0059] see Figure 1 to Figure 4 , a double-head saw cutting machine assembly, which includes a horizontal frame 1 arranged longitudinally extending from left to right, 2 sets of saw blade cutting units 2, a material height measuring device 3, and a horizontal frame arranged on the horizontal frame 1 2 linear horizontal rails 4, fixed seat 5, sliding seat 6, material support frame 7, movable material rack 8, electric cabinet frame 9, control box 10, automatic controller, transmission frame 11, drive the sliding seat 6 to slide and receive Controlled by the driving device 12 of the automatic controller. Wherein the automatic controller (also known ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com