Shearing type at-sea laver harvester

A cutting-type harvester technology, which is applied to harvesters, agricultural machinery and implements, applications, etc., can solve the problems of laver no longer growing, not satisfying users, reducing production, etc., to achieve high rigidity, simple structure, and mechanical gain high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

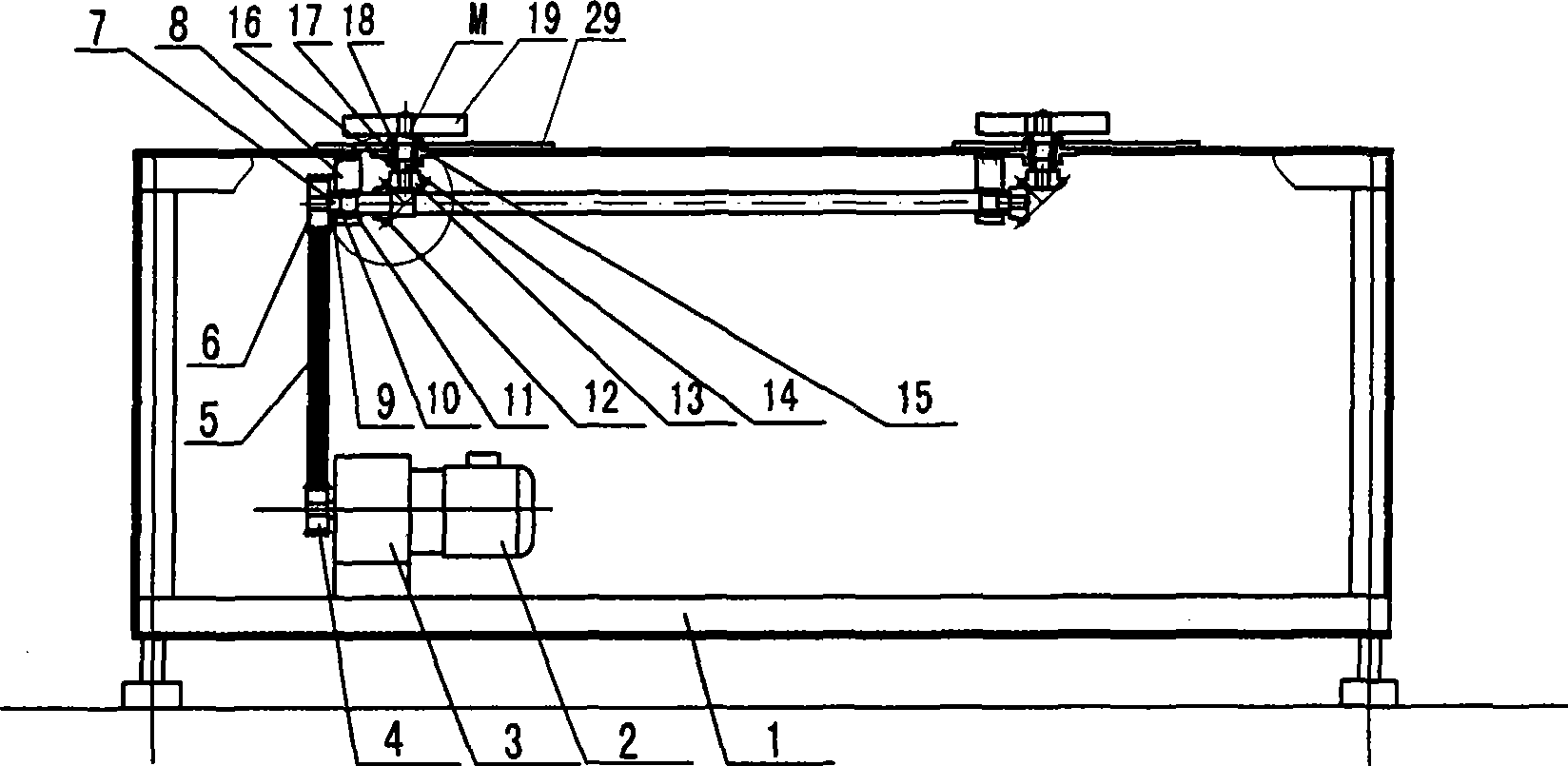

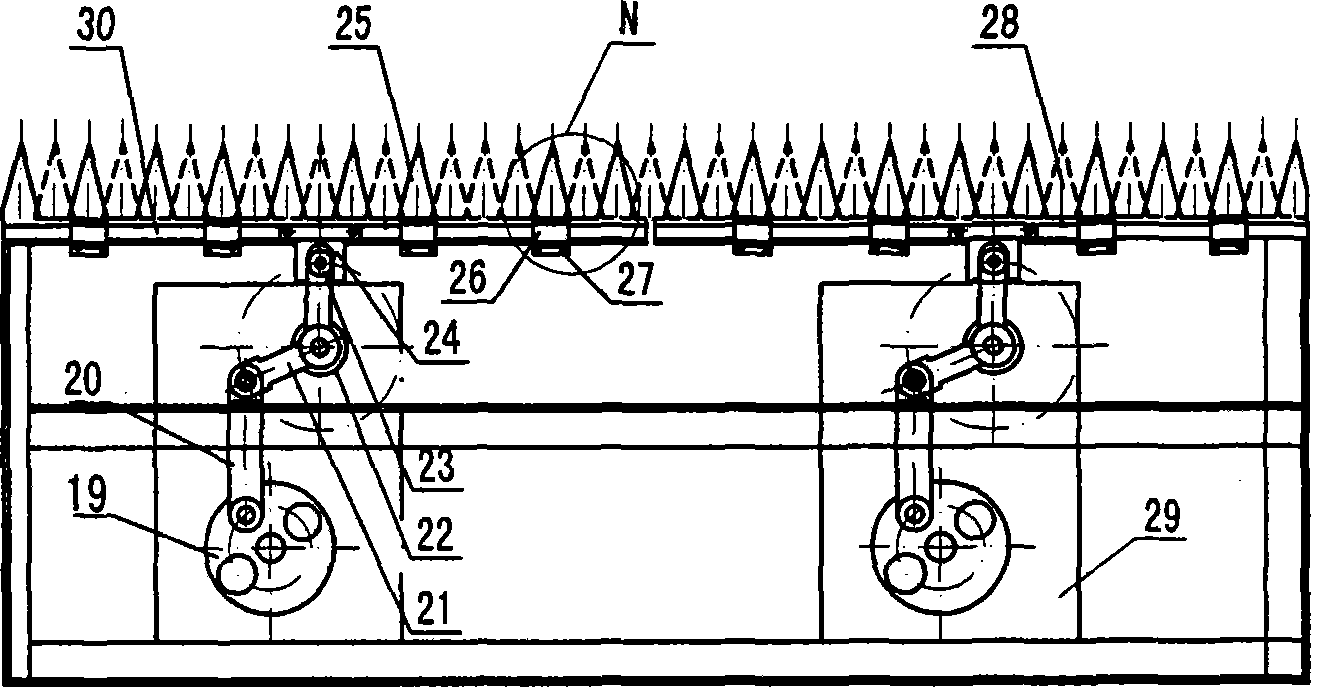

[0017] The present invention and its advantages will be further described below in conjunction with the accompanying drawings and embodiments.

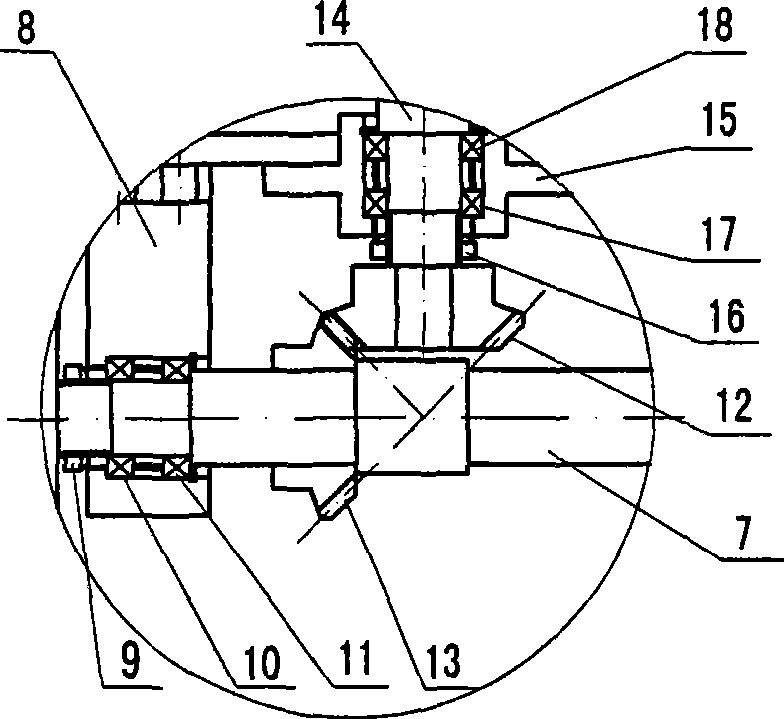

[0018] control figure 1 , figure 2 , the harvester of the present embodiment mainly consists of frame 1, diesel engine 2, reduction box 3, transmission shaft 7, rotating disk 19, moving knife row 25, fixed knife row 28, belt drive chain, bevel gear transmission mechanism and Crank connecting rod transmission mechanism. Its belt drive chain adopts the transmission structure of V-belt pulley and V-belt, and it is made up of driving V-belt pulley 4, and driven V-belt pulley 6 and V-belt 5. Certainly also can adopt the belt-type transmission chain structure that is made up of main and driven chain theory and chain. The bevel gear transmission mechanism is composed of a pair of driving bevel gears 12 , a driven bevel gear 13 and a rotating shaft 14 whose rotation directions are perpendicular to each other and meshed with each other. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com