Particle cutting machine

A pellet machine and pellet technology, applied in metal processing and other directions, can solve the problems of poor control of cutting length, insufficient smooth cutting plane, slow cutting speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

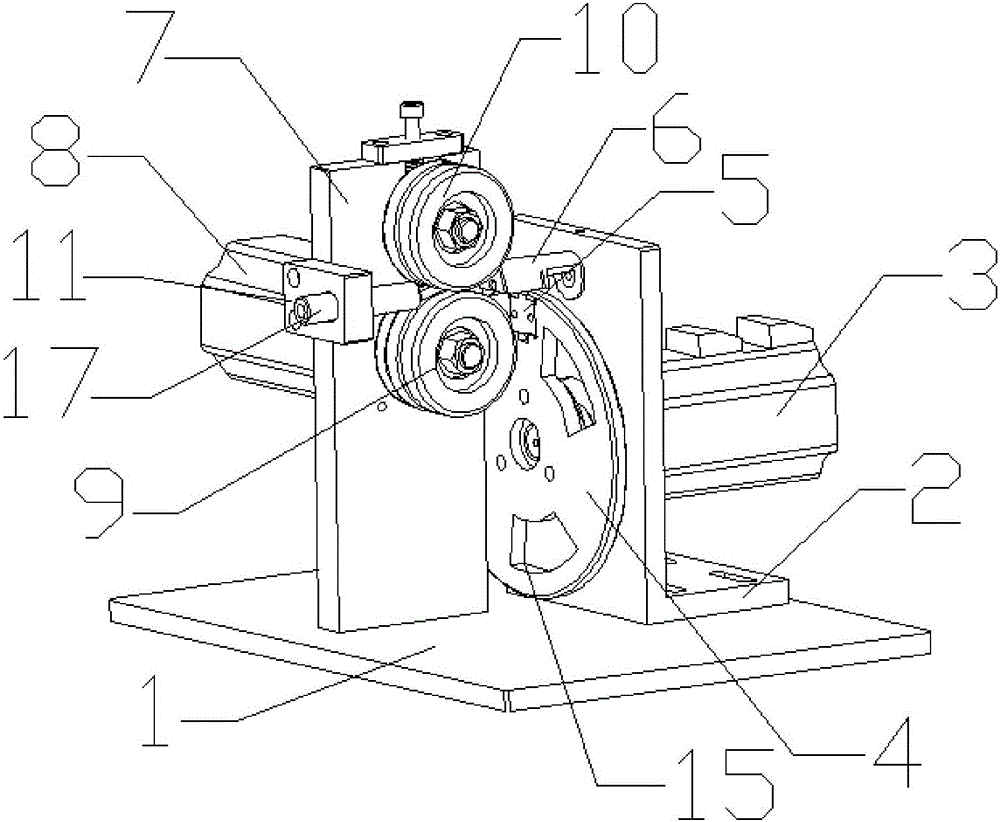

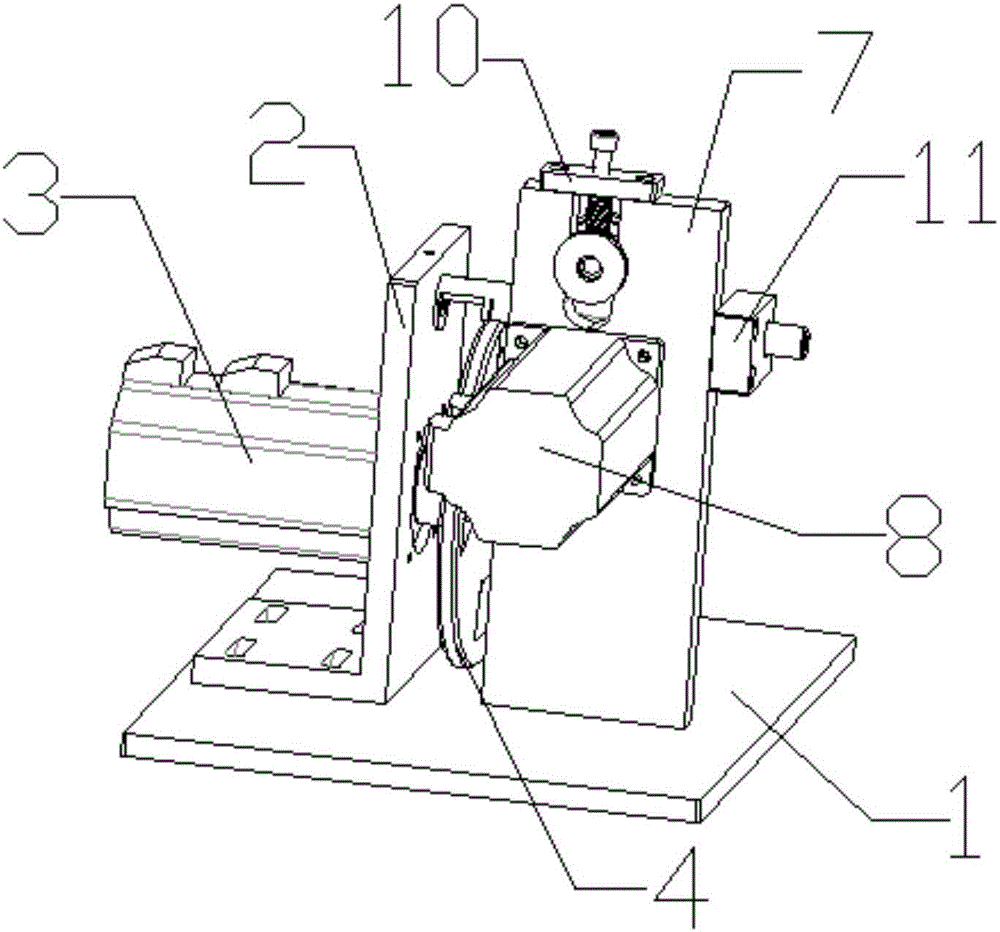

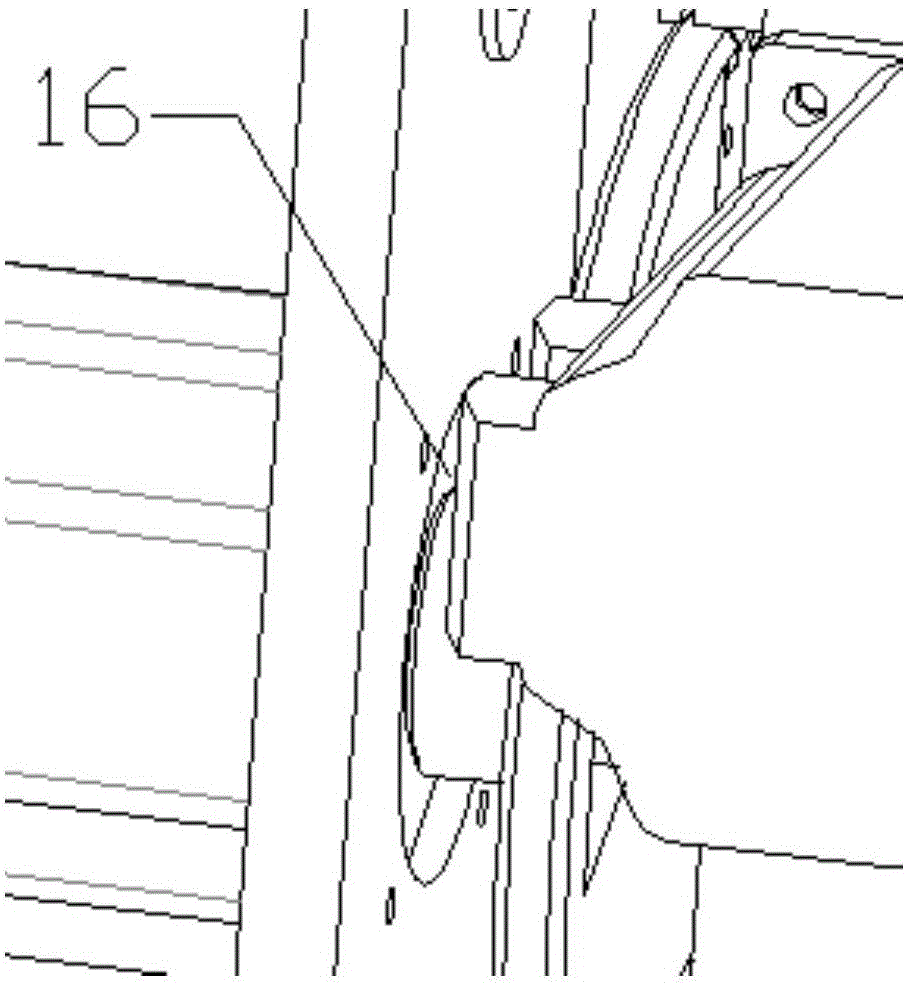

[0036] Pass the plastic rod of the fluorescent stick assembly to be cut through the guide tube 17 installed in the guide tube fixing seat 11, then pass through the gap between the driving wheel 9 and the driven wheel 10 and enter the particle cutting mold 6, and pass the adjusting screw 13 Adjust the upper and lower positions of the driven wheel 10 until the gap between the driving wheel 9 and the driven wheel 10 is adjusted to an appropriate size, and finally control the rotation speed of the servo motor 3 and the stepping motor 8 through the controller to obtain a corresponding length of fluorescent light. rod components. The invention is simple in structure, easy to use, fast in cutting speed and high in working efficiency. The cutting speed is controlled by controlling the rotating speed of the flying cutter disc through the servo motor, and the rotating speed of the driving wheel is controlled by the stepping motor, so that the cutting length can be well controlled. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com