Patents

Literature

260results about How to "Reduce wasted time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

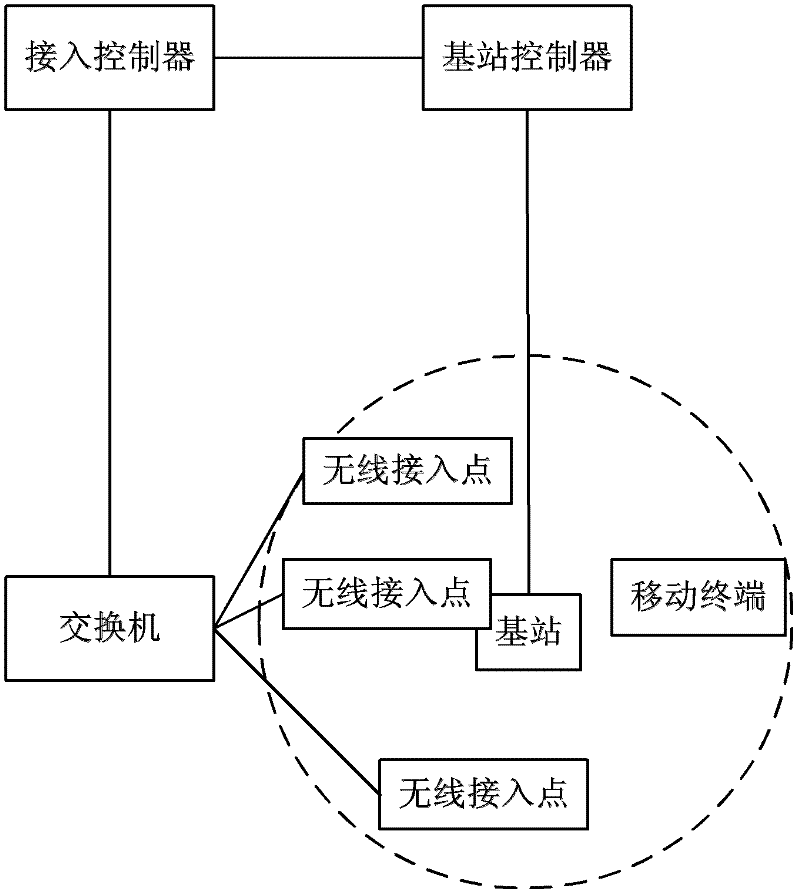

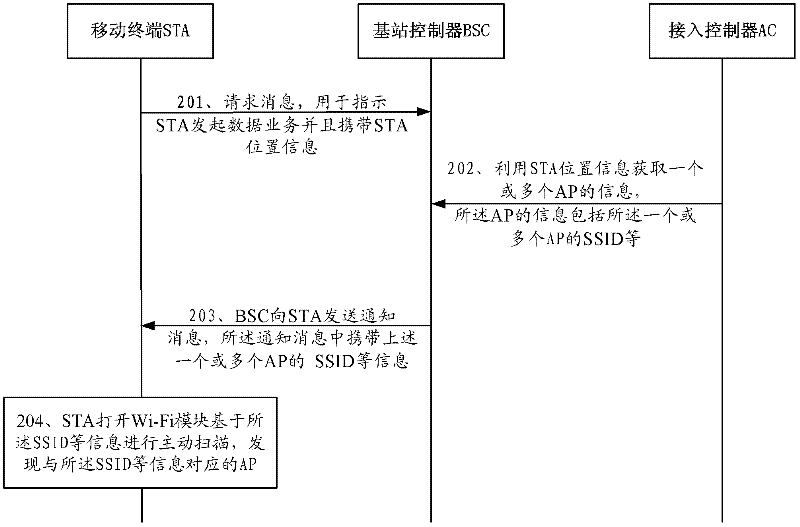

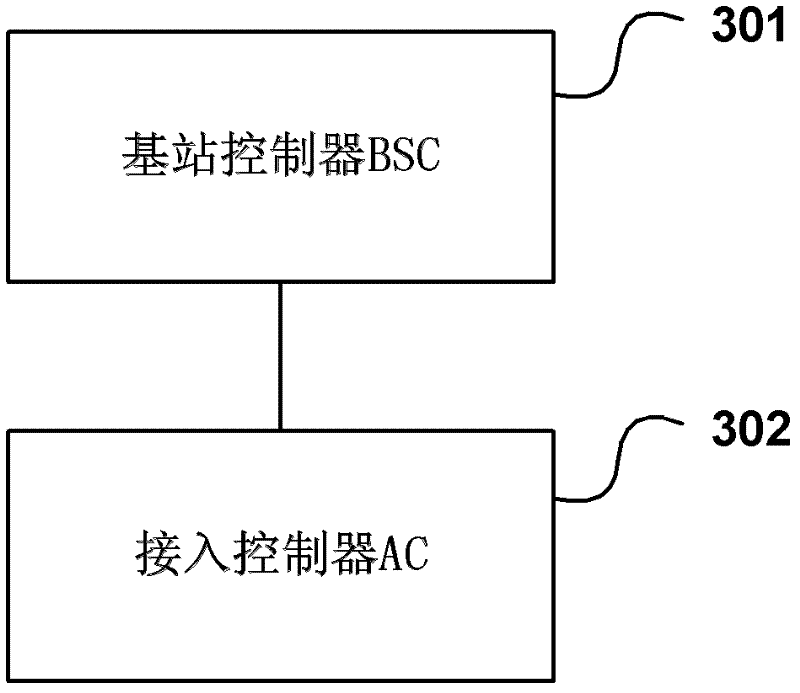

Method, device and system for finding out wireless access point

InactiveCN102421166AImprove resource utilizationReduce wasted timeEnergy efficient ICTAssess restrictionComputer terminalWireless access point

The embodiment of the invention provides a method, device and system for finding out a wireless access point, aiming to achieve the purposes of rapidly finding out an available access point and saving the electric quantity for a mobile terminal STA (station). In the method, a base station controller (BSC) receivers a request message sent by the mobile terminal STA, acquires one or more AP (Access Point) information nearby the STA from an access controller (AC), and sends a notice message to the STA so as to make the STA actively scan and find out the corresponding AP based on a service set identifier (SSID).

Owner:HUAWEI TECH CO LTD

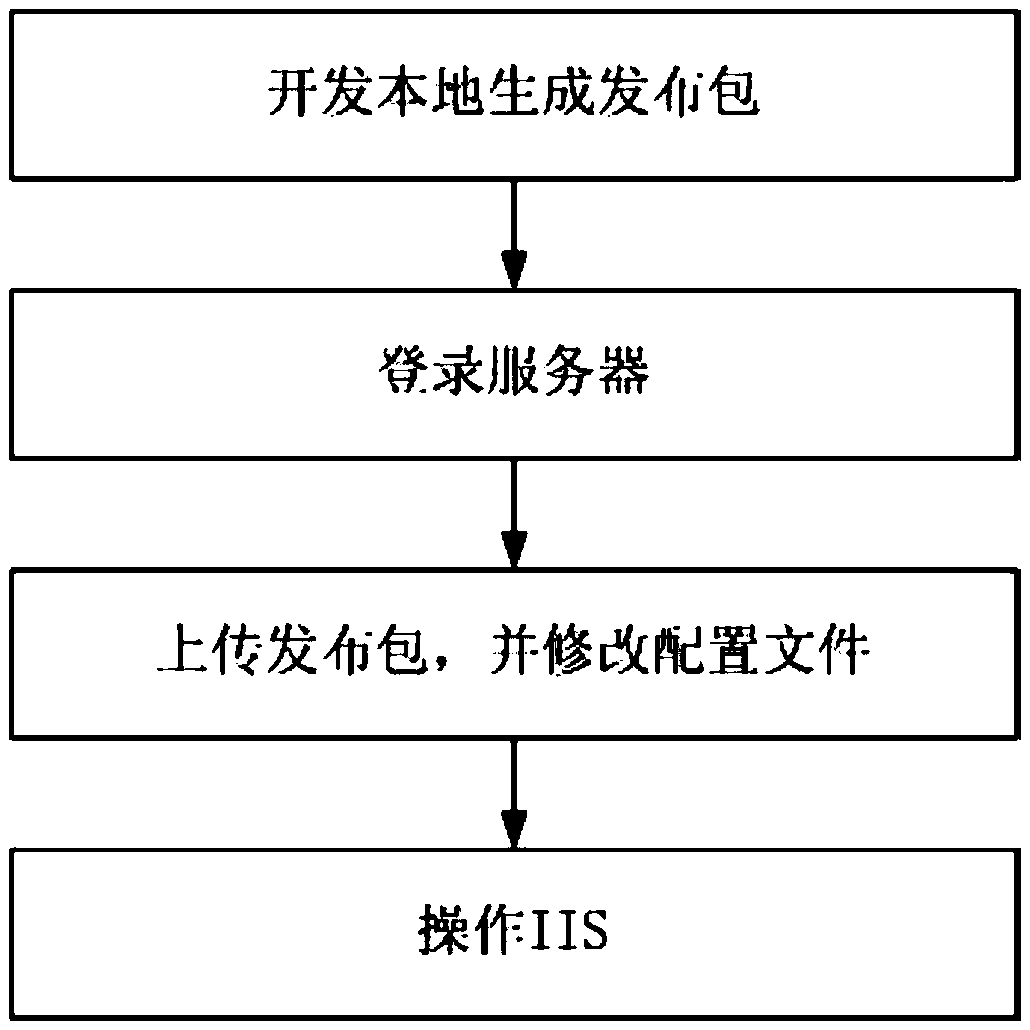

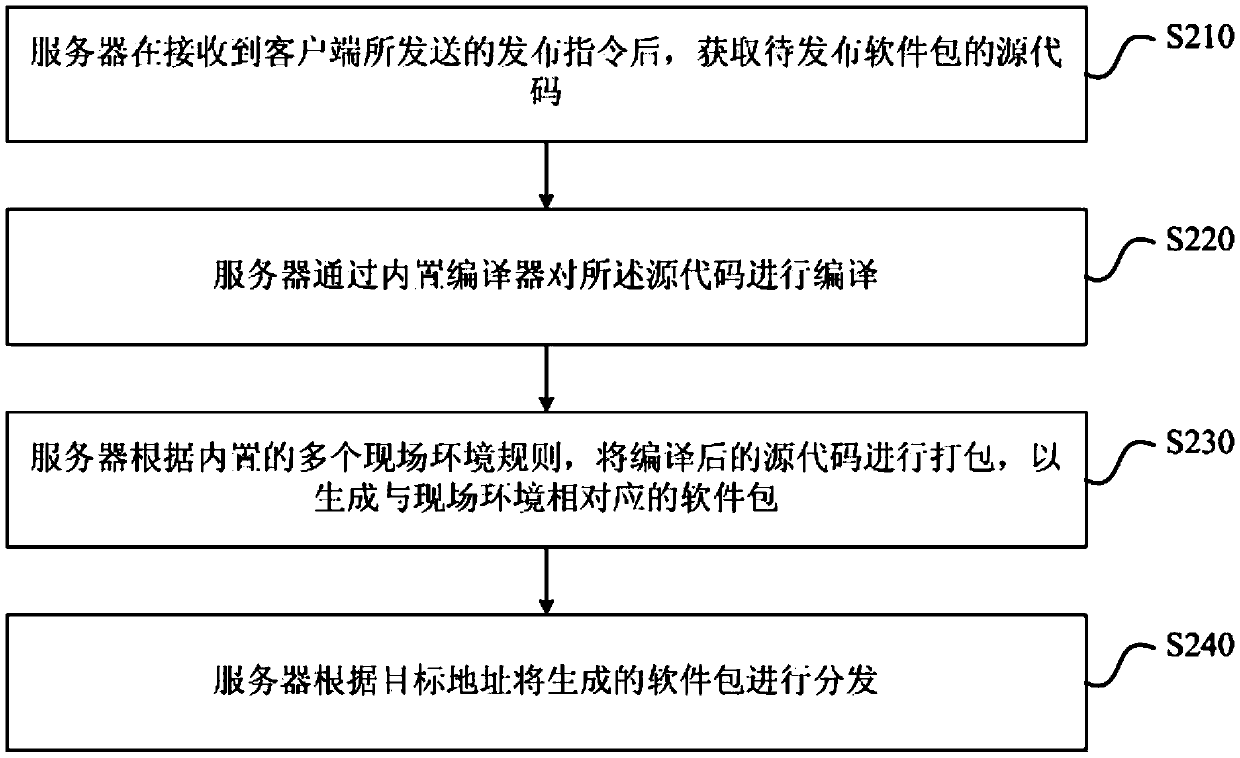

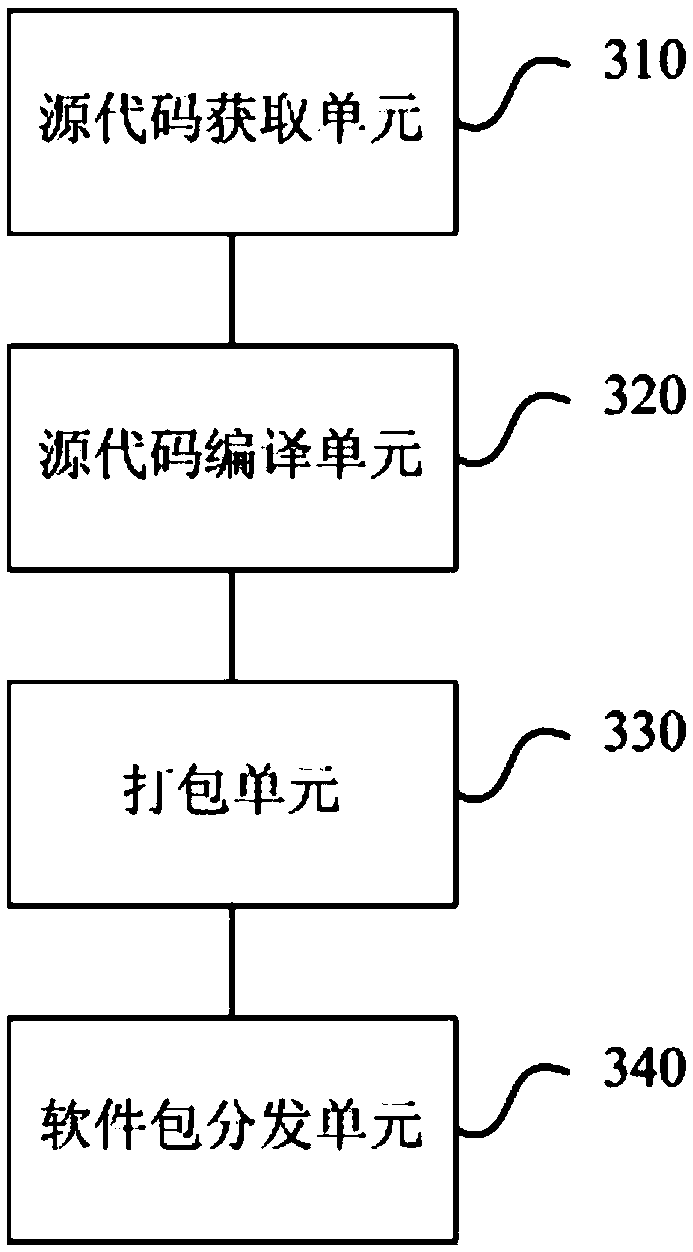

Method and system for automatically releasing software package

ActiveCN105373401AImprove post qualityImprove publishing efficiencyProgram loading/initiatingSoftware deploymentSoftware engineeringSoftware development

The present invention provides a method and a system for automatically releasing a software package. The method comprises the following steps: (1) after receiving a publishing instruction sent by a client, a server obtains source code of a software package to be released; (2) the server compiles the source code with a built-in compiler; (3) the server packages the compiled source code according to a plurality of built-in site environmental rules, to generate the software package corresponding to a site environment; and (4) the server distributes the generated software package according to a destination address. According to the present invention, not only a repeated and reliable release process can be established to improve the release quality of the software package, but also the entire release process can be automated to improve the release efficiency of the entire software package, and furthermore, multiple developers can participate at the same time to increase the transparency of software development.

Owner:SHANGHAI GANGFU E COMMERCE

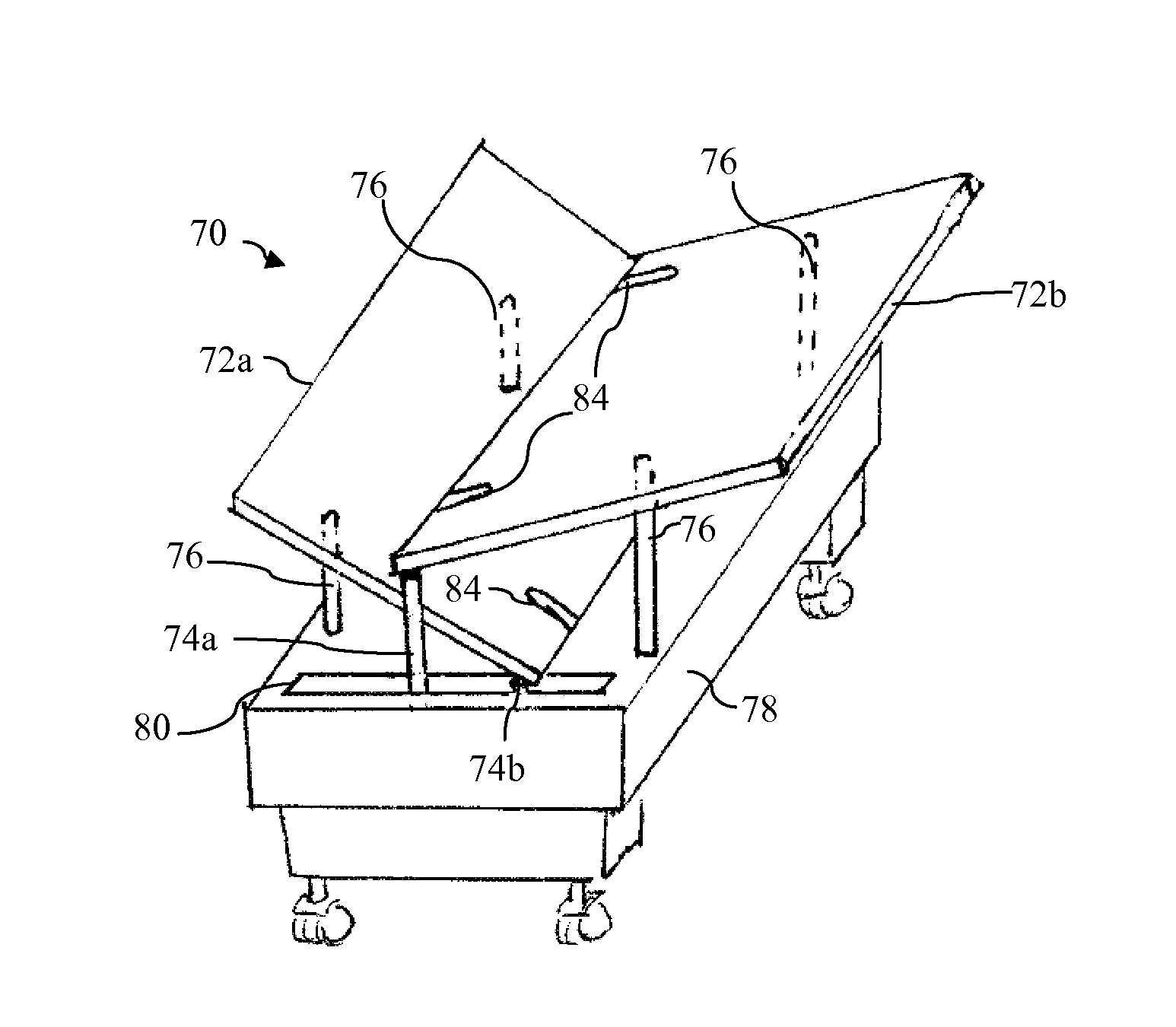

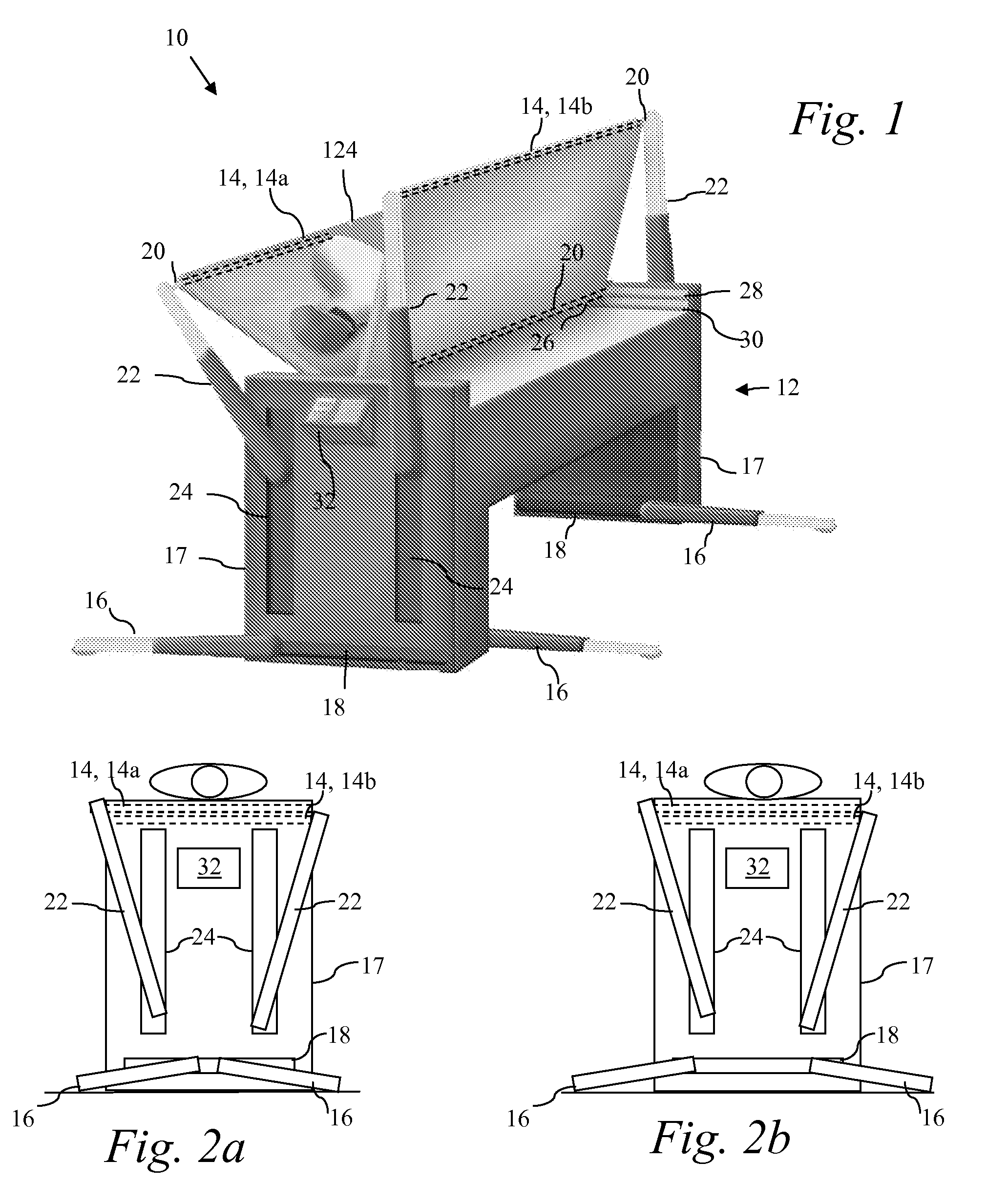

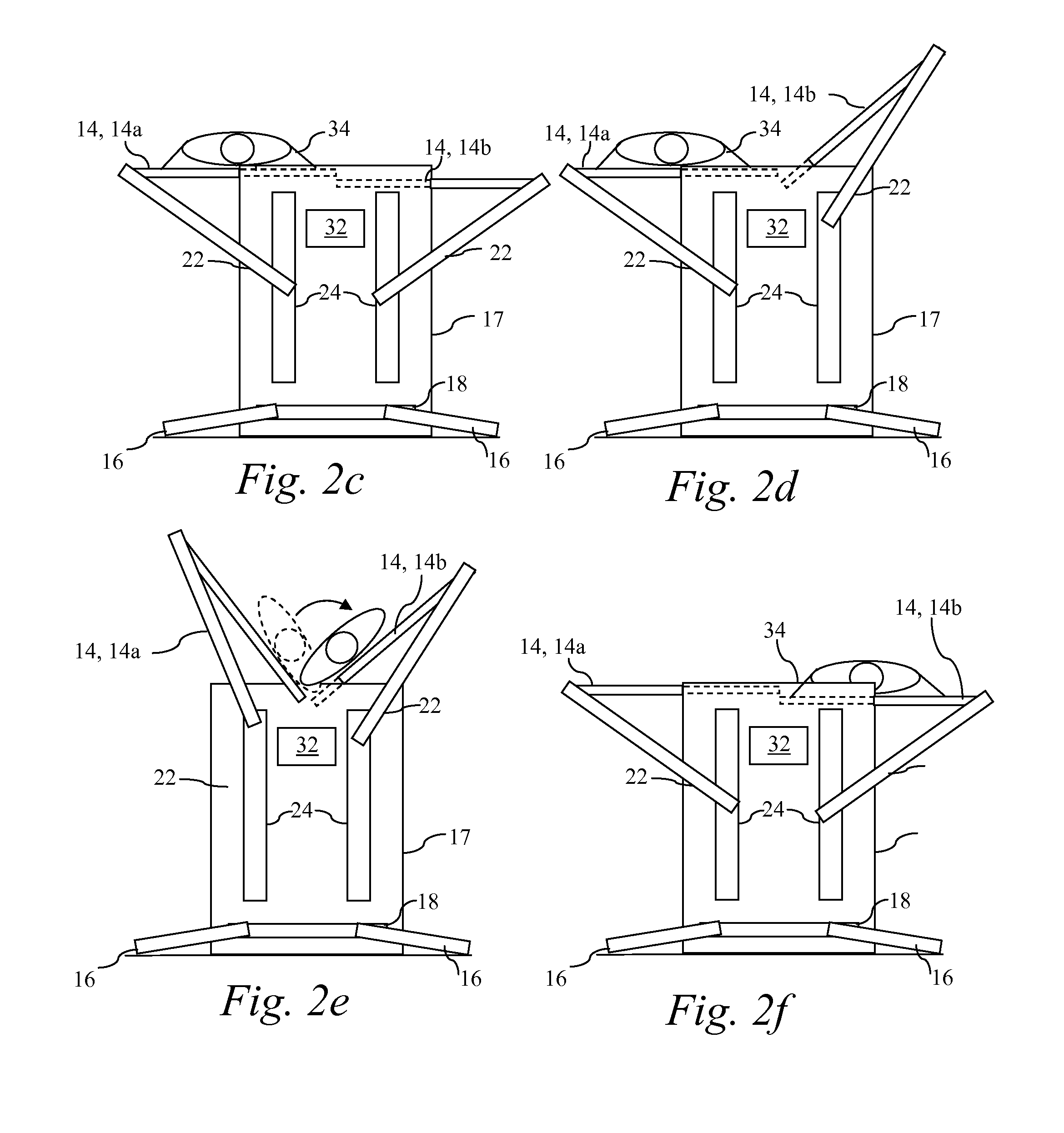

Rotational operating table

InactiveUS8042208B2Safely and quickly turnedMinimizing chanceOperating tablesWheelchairs/patient conveyancePatient needEngineering

An operating table has first bed platforms, each which can rotate. In an operating configuration, the patient lies on one of the bed platforms in a prone or supine position with the bed platform centered over the base. When the patient needs to be turned, the other table extends outwardly, and both tables are rotated to position the patient for turning. Once the patient is turned, the table on which the patient lies is returned to its operating position over the base and the other table is returned to its storage position.

Owner:GILBERT JAN +4

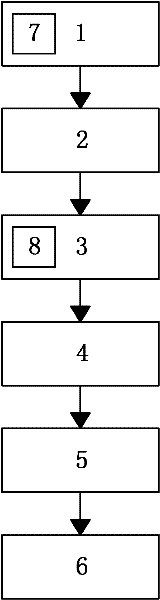

Method and system for displaying FLASH downloading progress on webpage in real time

The invention discloses a method and system for displaying a FLASH downloading progress on a webpage in real time. The method comprises the following steps: S1. a client side obtains a loading address and sends a loading request to a web server; S2. the web server downloads the loading resource corresponding to the loading address to the client side; S3. the client side obtains the FLASH address and sends a FLASH downloading request to the web server; S4. the web server downloads the FLASH resource corresponding to the FLASH address to the client side; S5. the client side computes the downloading progress of the FLASH; and S6. the client side loads the downloading progress of the FLASH in loading and displays the downloading progress. The method and system for displaying the FLASH downloading progress can be used for displaying the downloading progress of FLASH in real time and enabling users to know the FLASH downloading progress in real time, thereby saving the time of users for waiting the FLASH to be downloaded.

Owner:BEIJING PEOPLE HAPPY INFORMATION TECH

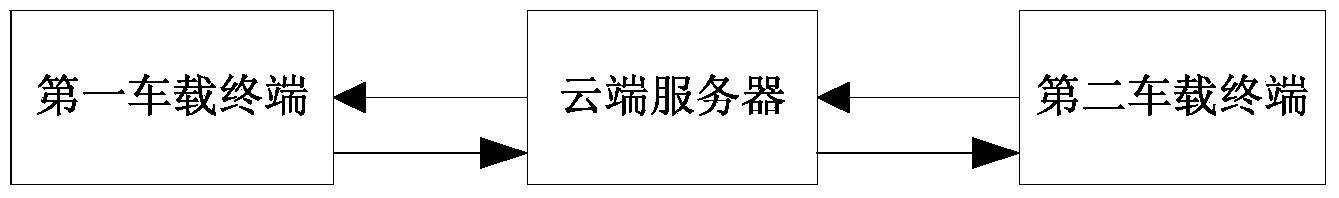

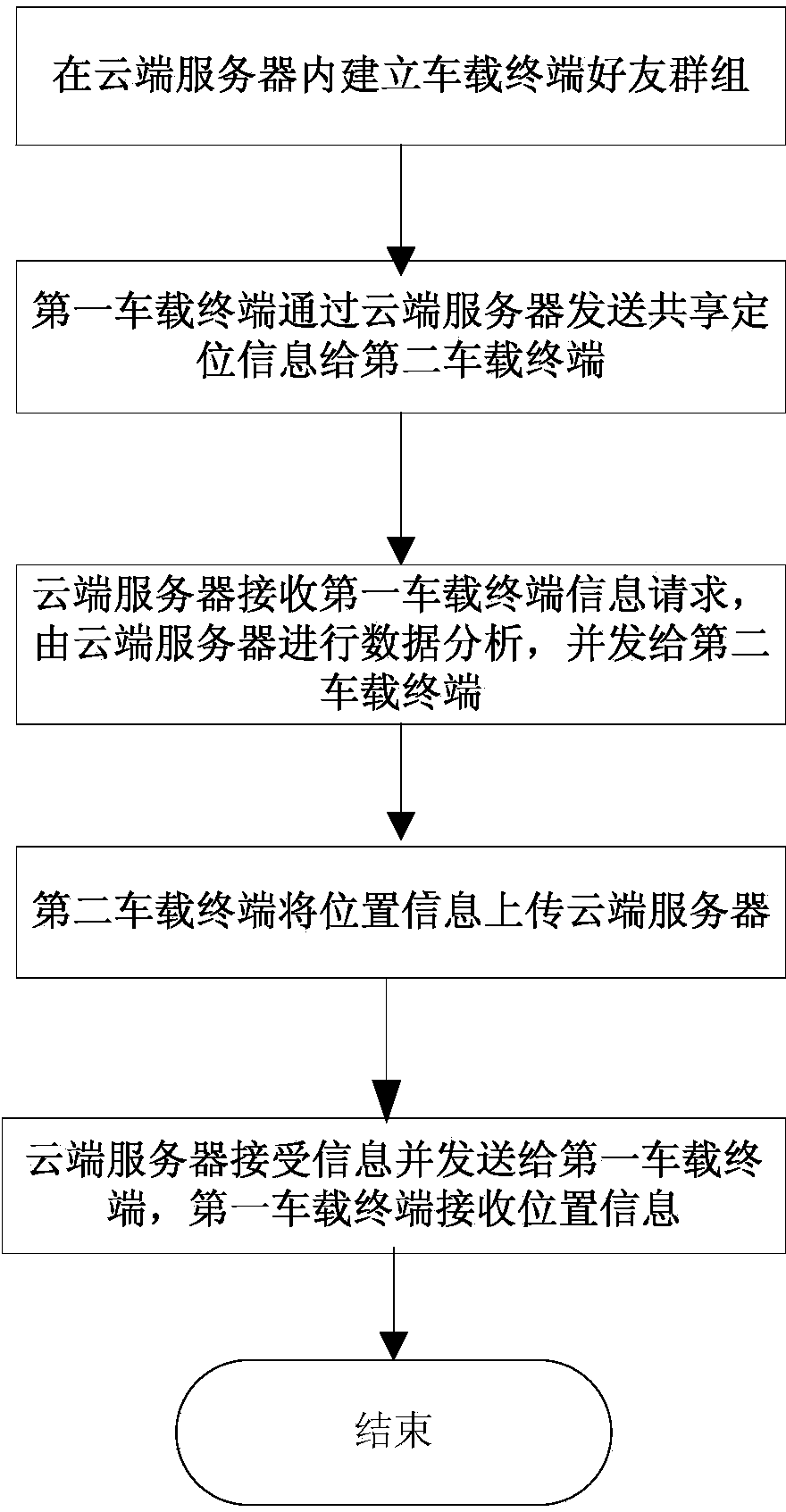

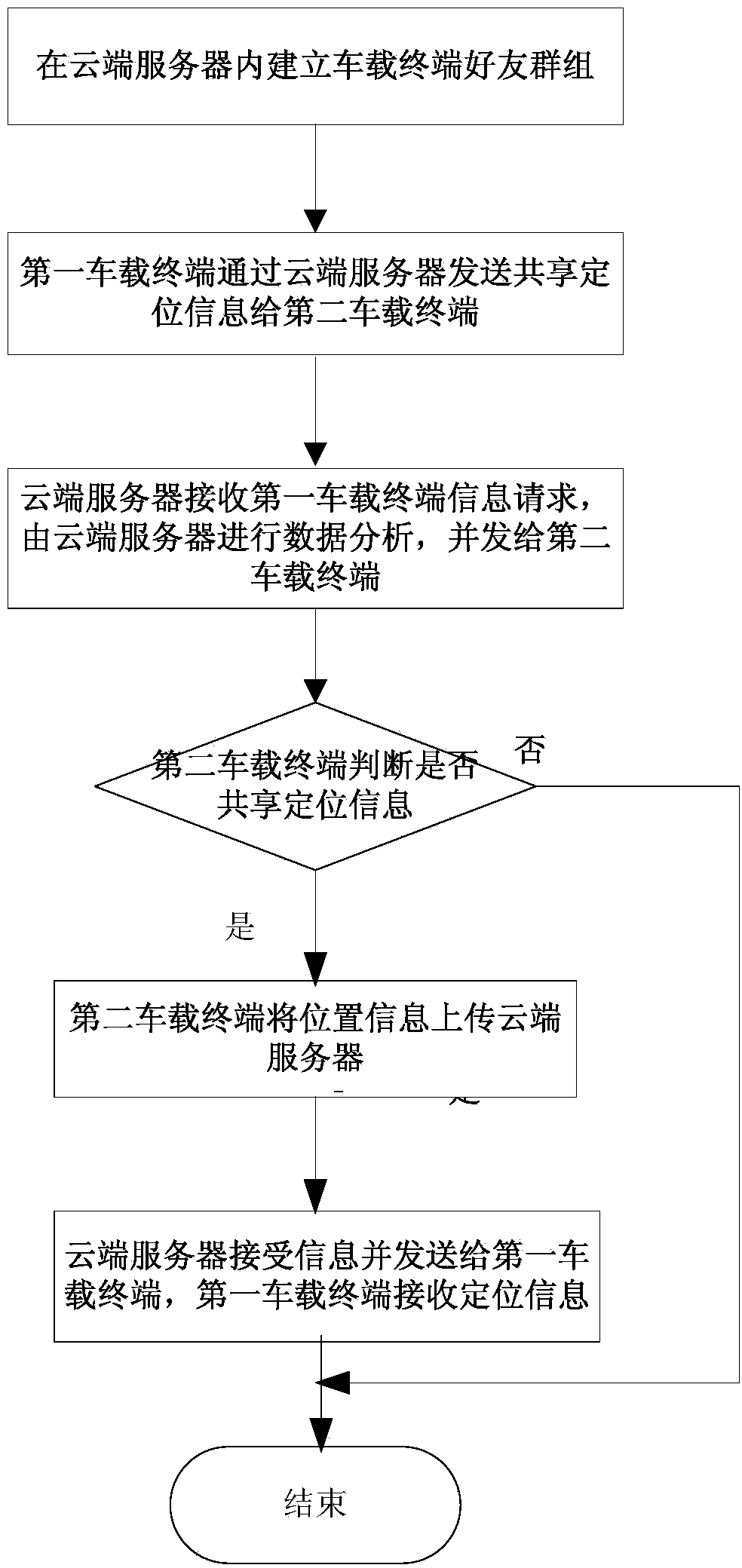

Vehicle position sharing method

InactiveCN103914991AAchieve sharingPrevent separationRoad vehicles traffic controlLocation sharingTerminal server

The invention discloses a vehicle position sharing method based on a vehicle-mounted terminal and a cloud terminal server. The vehicle-mounted terminal and the cloud terminal server are connected, a user sends a positioning request to the cloud terminal server through the vehicle-mounted terminal, the cloud terminal server receives the request to process data to found out the information of a positioned user and sends a position obtaining request to a positioned user vehicle-mounted terminal, and after the positioned user vehicle-mounted terminal receives the request, the cloud terminal server returns the position information to the request vehicle-mounted terminal. According to the vehicle position sharing method, positioning and sharing of different positions are achieved, the navigation functions and applications are enriched, and the specific requirements of users are met.

Owner:NANJING IOT SENSOR TECH

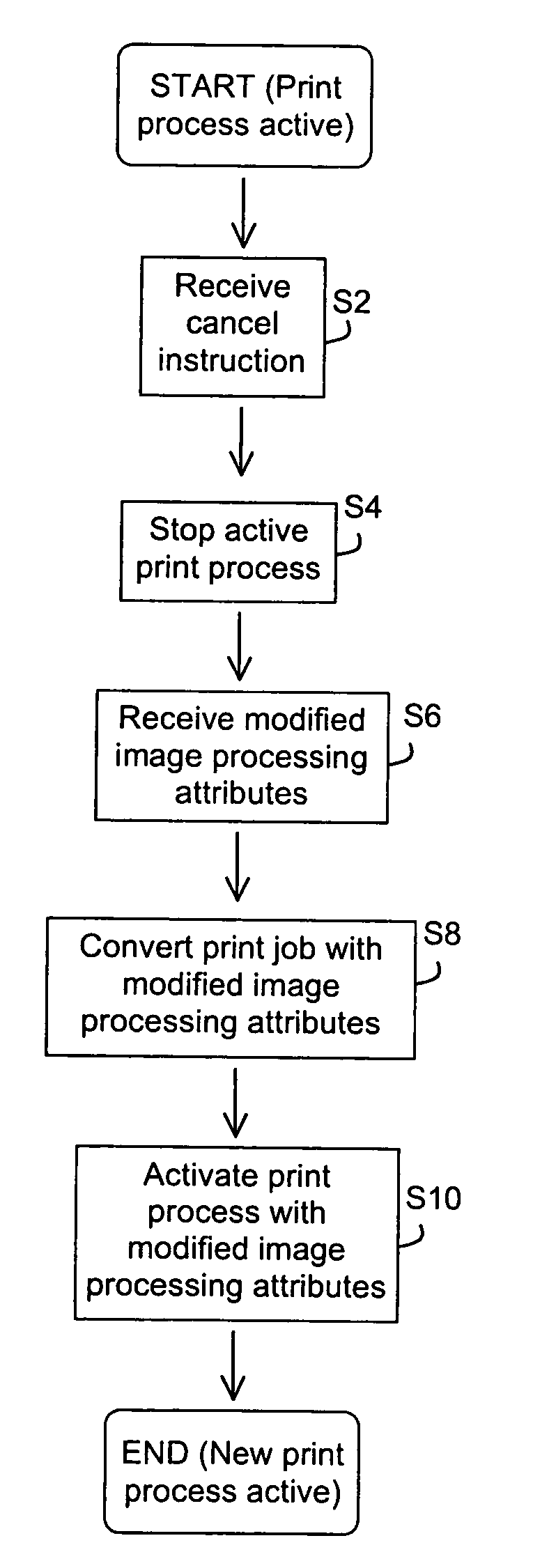

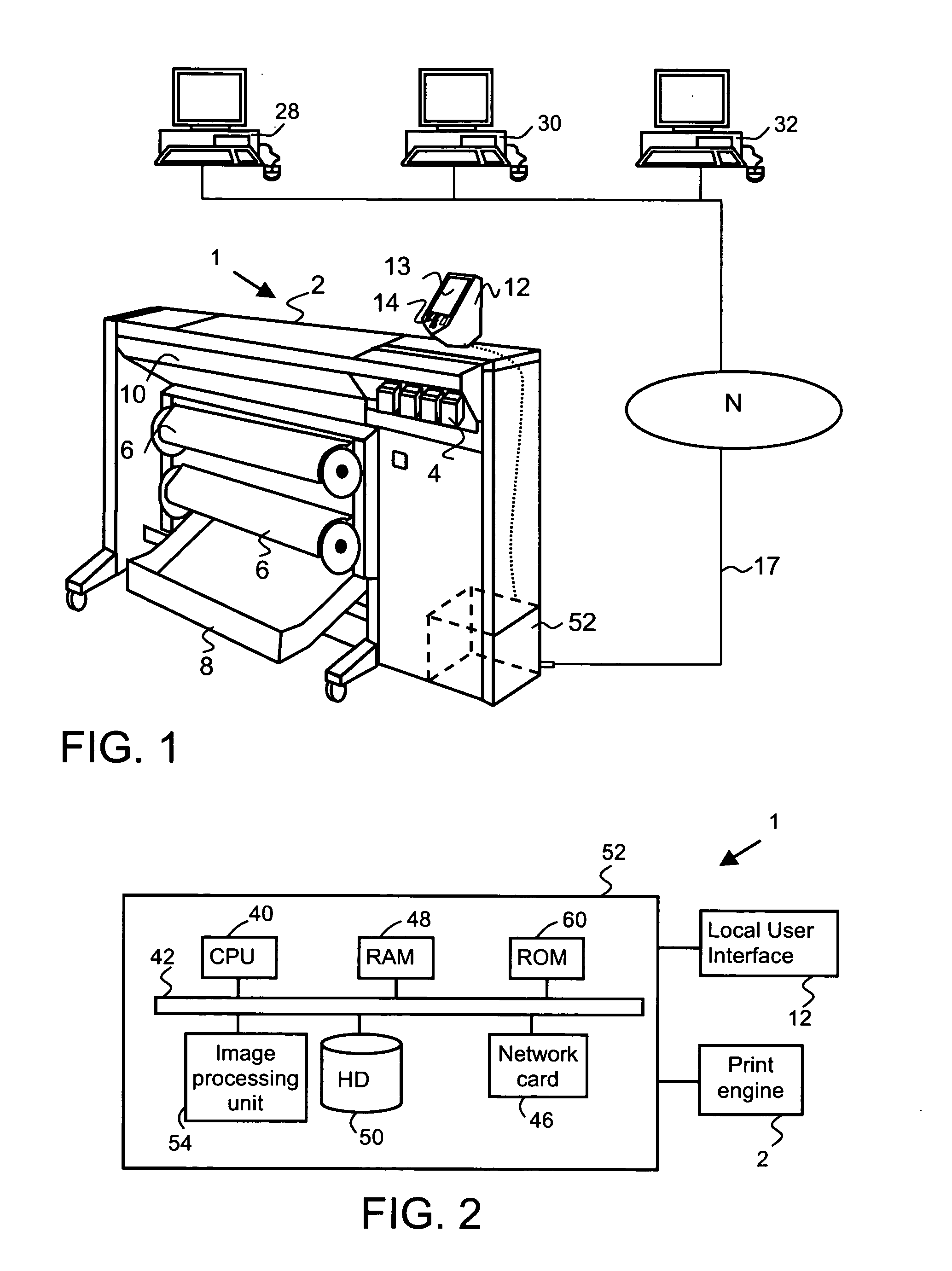

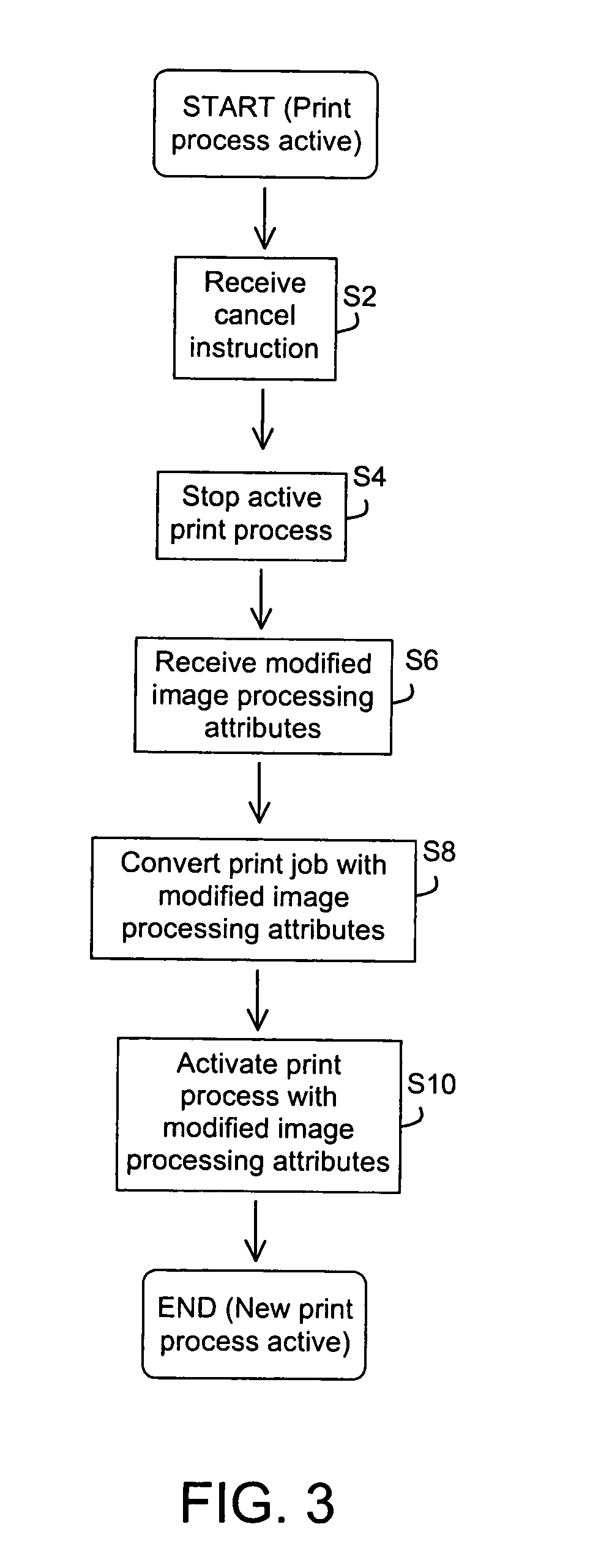

Method, apparatus and computer program product for modifying attributes of a cancelled print job

InactiveUS20080055622A1Simple methodReduce wasted timeElectrographic process apparatusDigital output to print unitsImaging processingUser interface

A method for executing a print process on a printing apparatus that is provided with a print engine, a local user interface unit and a control unit includes receiving a cancel instruction via the local user interface unit and cancelling an active print process of a print job executed according to image-processing attributes. The method further includes receiving an instruction via the local user interface unit to modify the image-processing attributes of the print job, converting the print job according the modified image-processing attributes into a raster image and activating a print process of the print job according to the modified image-processing attributes. A printing apparatus for performing the method includes a print engine, a local user interface and a control unit.

Owner:OCE TECH

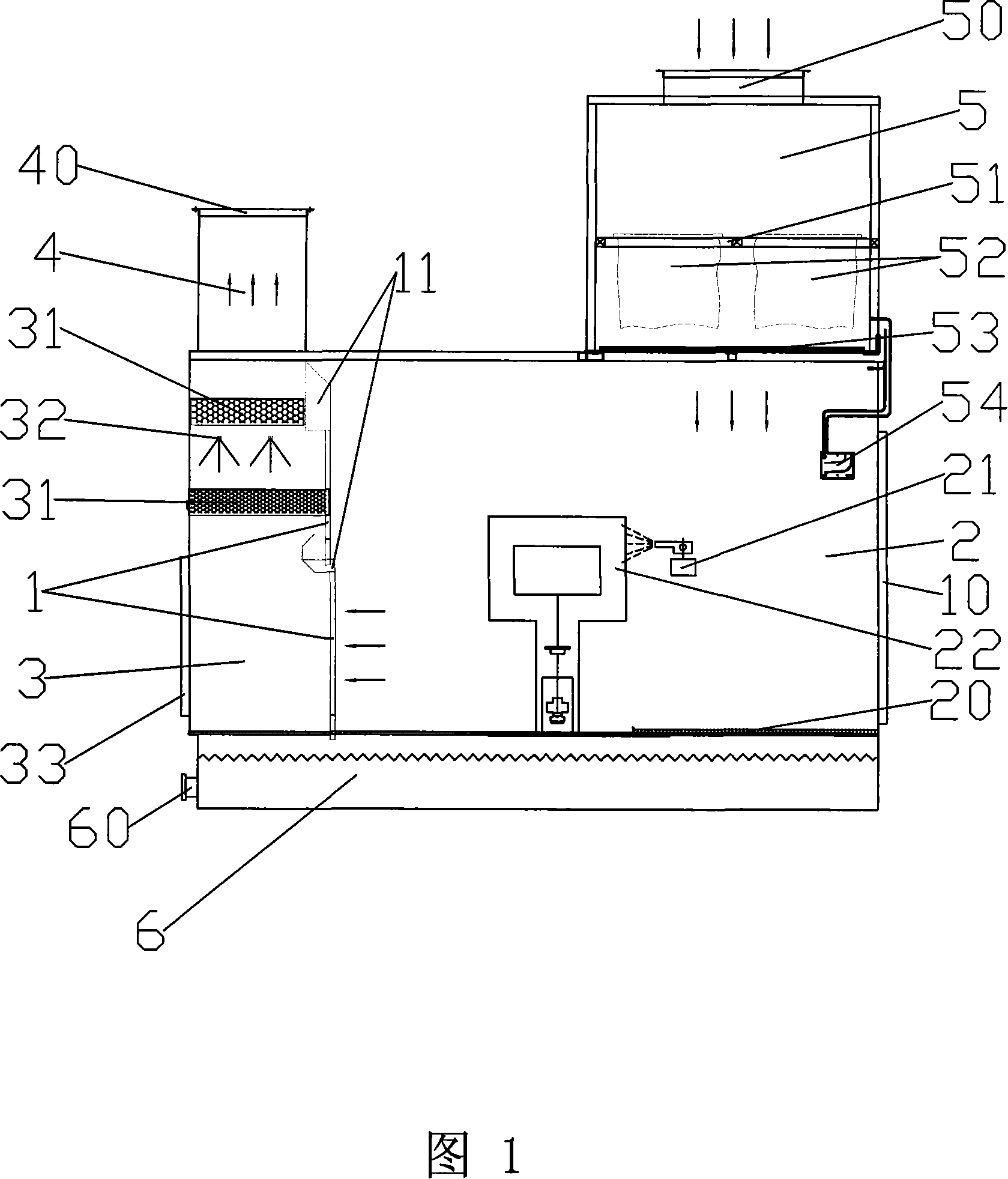

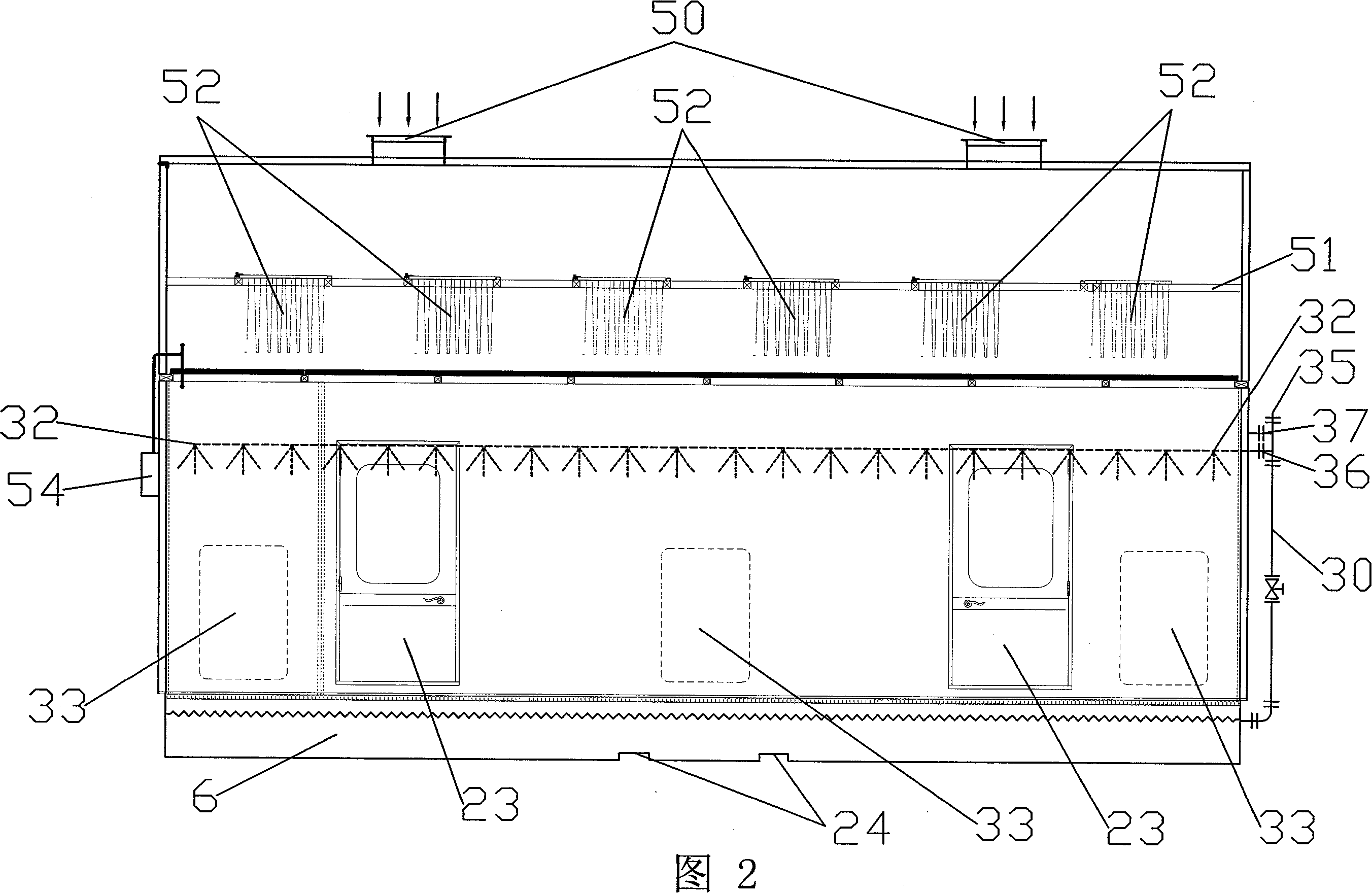

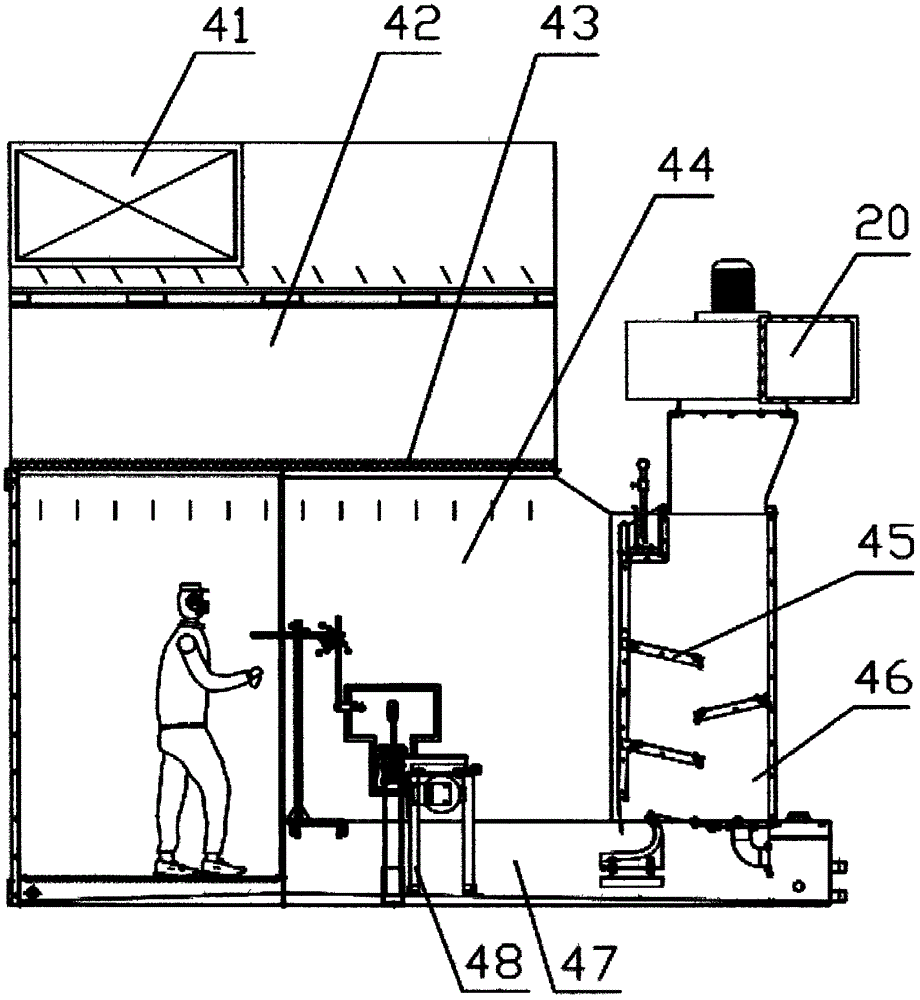

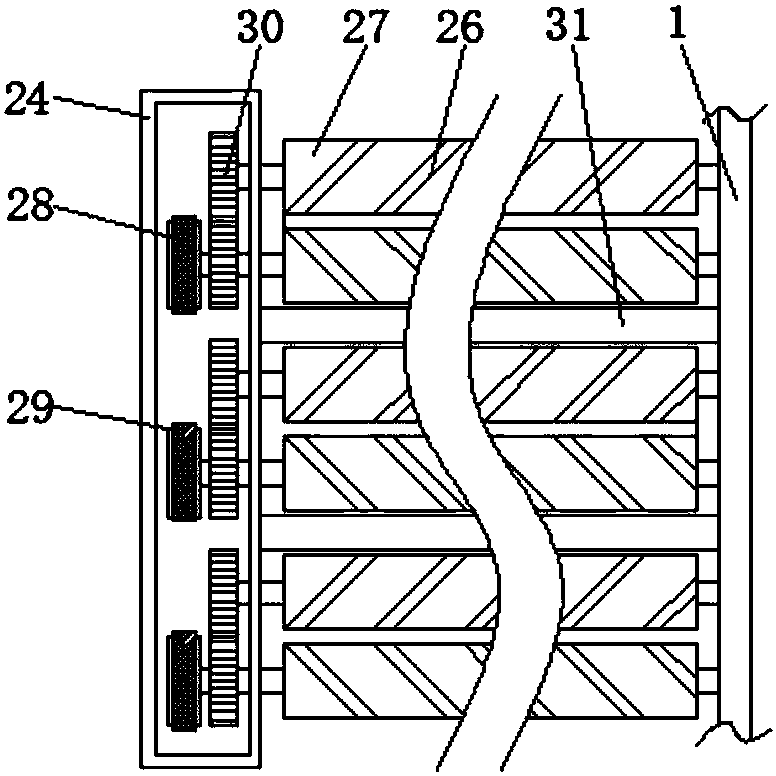

Multi-layer type water curtain spraying chamber

InactiveCN101125319AGood processing effectLow costLiquid surface applicatorsSpraying apparatusLacquerAirflow

The present invention discloses a multi-layer type water screen spray room, whose inside is provided with a water screen plate, and the inside of the spray room is divided into the front spray painting operating area and the back painting mist processing area. The bottom of the whole spray room is provided with a water tank, and an air flow channel is formed between the water tank and the water screen plate. The upper part of the painting mist processing area is provided with an air exit, and the upper part of the spray painting operating area is provided with a uniform compression chamber. The uniform compression chamber is connected with the central wind supplying system to make the dissipated paint mist in the whole spray painting operating area can be fully absorbed to the painting mist processing area for processing, moreover, the invention can reduce the energy consumption of the whole system and is convenient for the maintenance of the system. The inside of the painting mist processing area is provided with a glue flower layer, and a plurality of water spray nozzles, and the glue flower layer further absorbs the residual paint mist to ensure the processing effect of paint mist. The water screen plate comprises the upper and lower layer water screen plates, and the upper and lower water screen plates are all provided with water tanks. The invention makes the spray room provide different spray painting environments according to the spray coating requirement of the working piece by choosing to start the water screen plate.

Owner:东莞丰裕电机有限公司

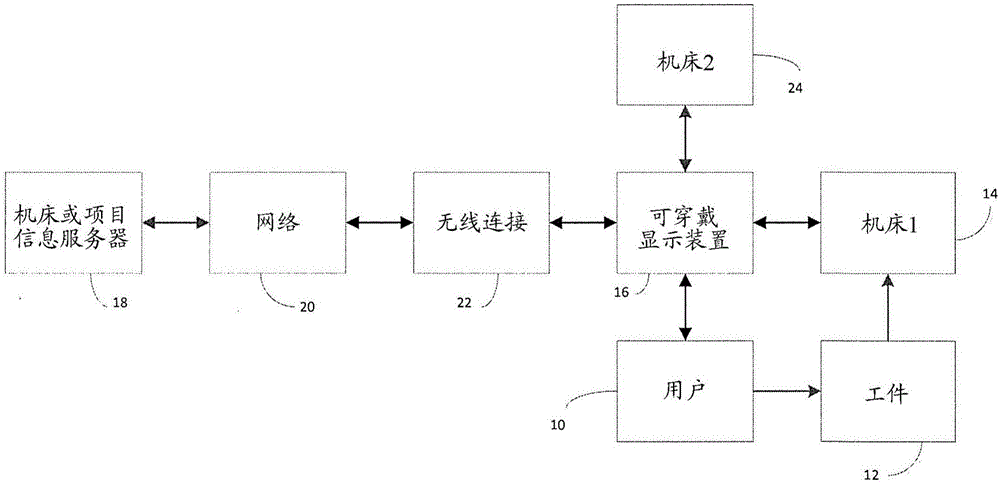

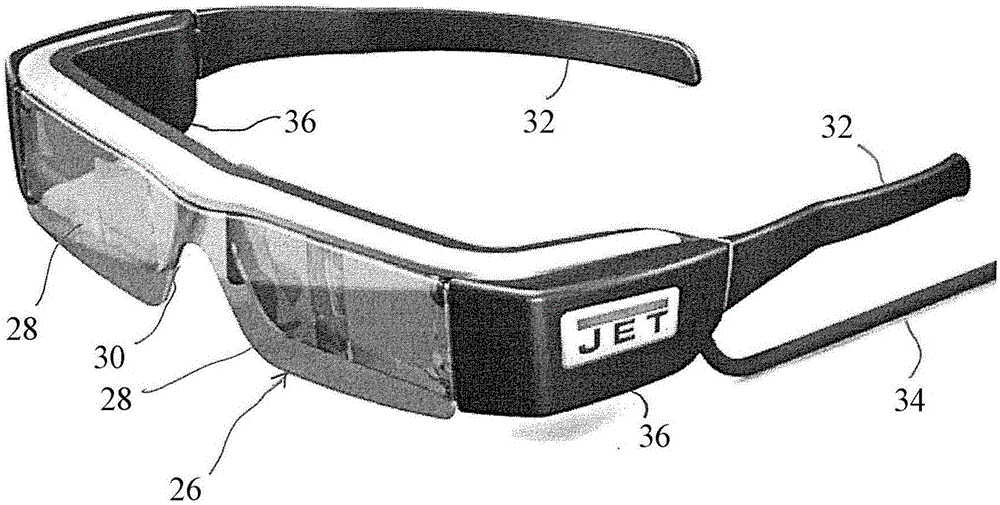

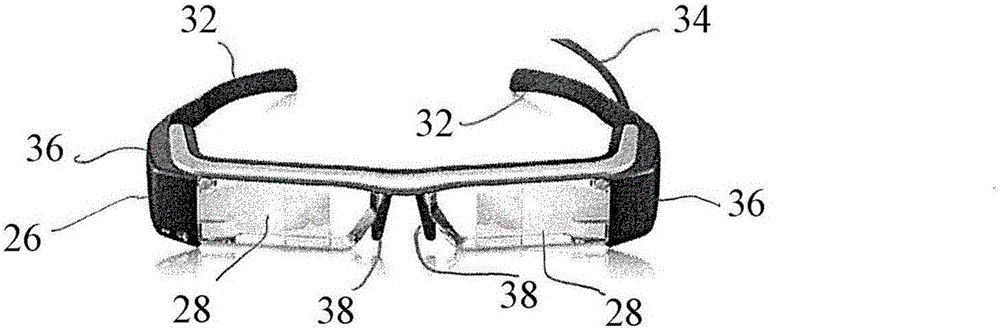

Wearable display for use with machine tool

InactiveCN106066633AReduce wasteImprove processing qualityProgramme controlMetal sawing accessoriesVirtual controlWork zone

A wearable augmented reality overlay device for use with a machine tool displays information to a user relating to the status or operation of the machine tool, to the forming of a work piece for a project, or to safety information related to the tool. The displayed information may include a highlight projected onto a portion of the machine tool, onto a wearer's body part, or onto a work piece. The displayed information may include a virtual control for the machine tool or another machine tool, an operating manual, or a maintenance, assembly or operating guide. The wearable display permits the user to control the tool and potentially other tools in the work shop. The display may instead include a projector to project adjustment information as a machine tool is adjusted. A virtual image of a tool may be projected to locating a machine tool in a work area.

Owner:JPW IND

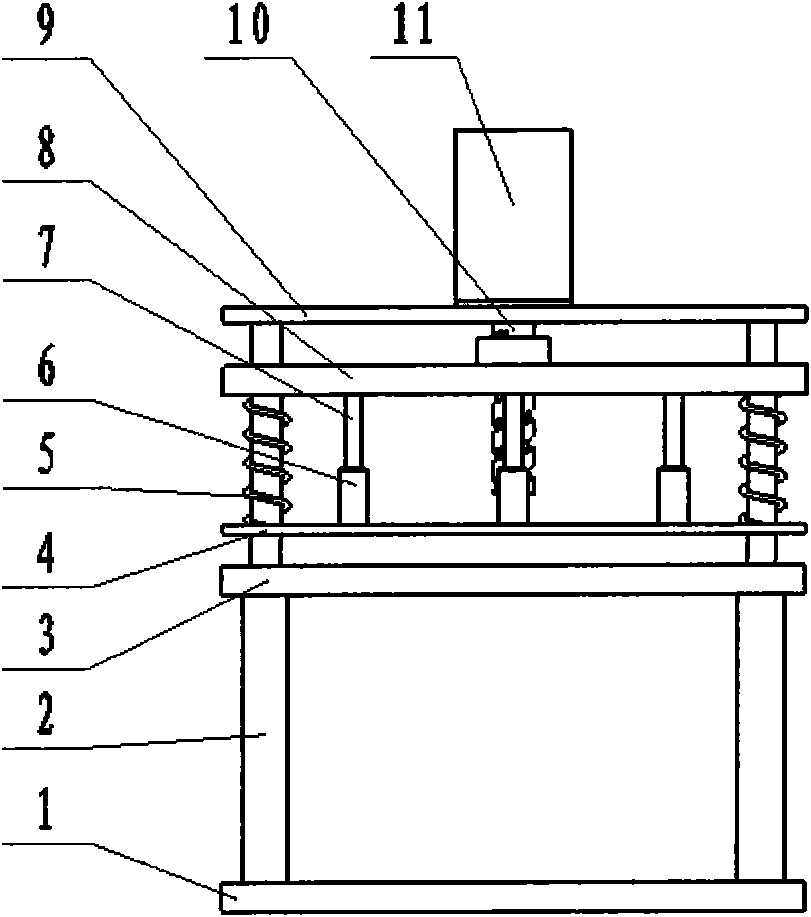

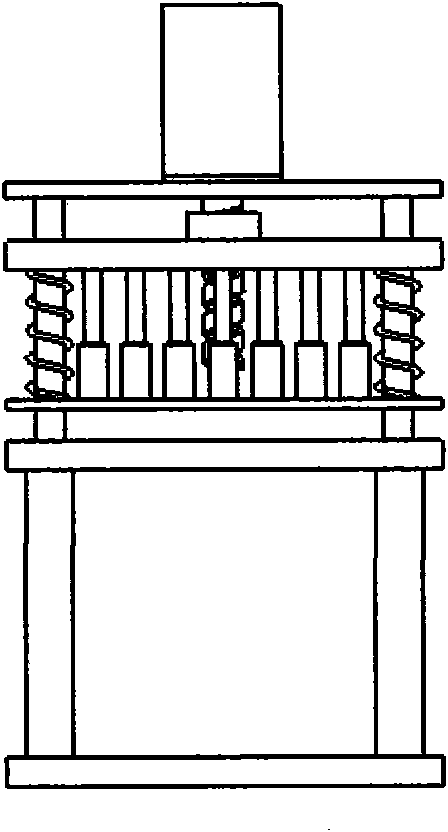

Cloth blanking equipment

InactiveCN101555662AProtect your healthReduced physical fitnessPreparing sample for investigationSevering textilesWorking environmentEngineering

The invention relates to cloth blanking equipment which comprises a machine frame and a clamping mechanism that is used for clamping cloth and includes a lower clamping plate, an upper clamping plate and a puller spring, wherein the lower clamping plate is fixedly arranged on the machine frame, the upper clamping plate is arranged over the lower clamping plate, and the upper clamping plate is arranged on the machine frame and can slide up and down; a cutting board is arranged over the upper clamping plate, the cutting board is arranged on the machine frame and can slide up and down, both ends of the puller spring are respectively fixed on the cutting board and the upper clamping plate; a knife group is arranged below the cutting board, the upper clamping plate is provided with a cutting hole, a charging hole is arranged on the lower clamping plate, the cutting hole and the charging hole are respectively arranged under each knife of the knife group, the cutting board is connected with a drive mechanism used for controlling the cutting board to lift up and down, and the drive mechanism is arranged on the machine frame. The cloth blanking equipment effectively prevents polluting the work environment and improves the reliability of the test results.

Owner:ZHEJIANG UNIV OF TECH

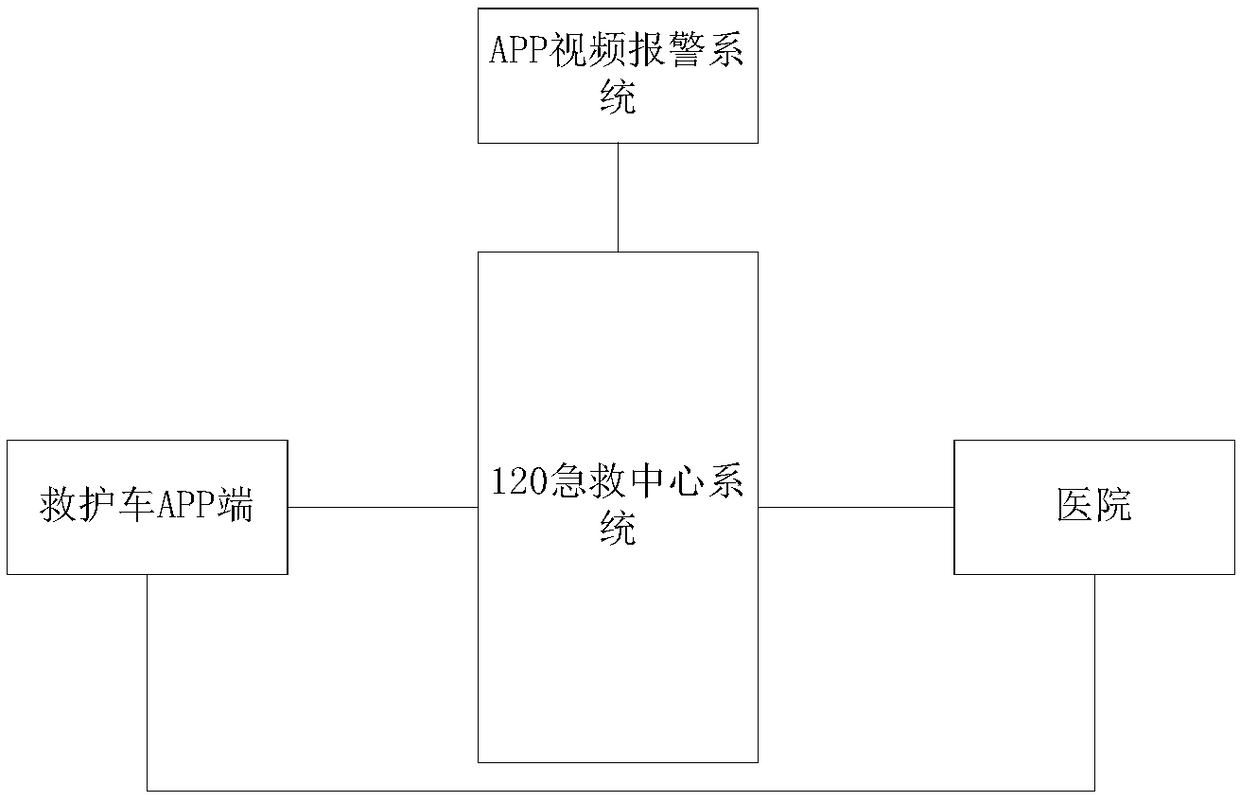

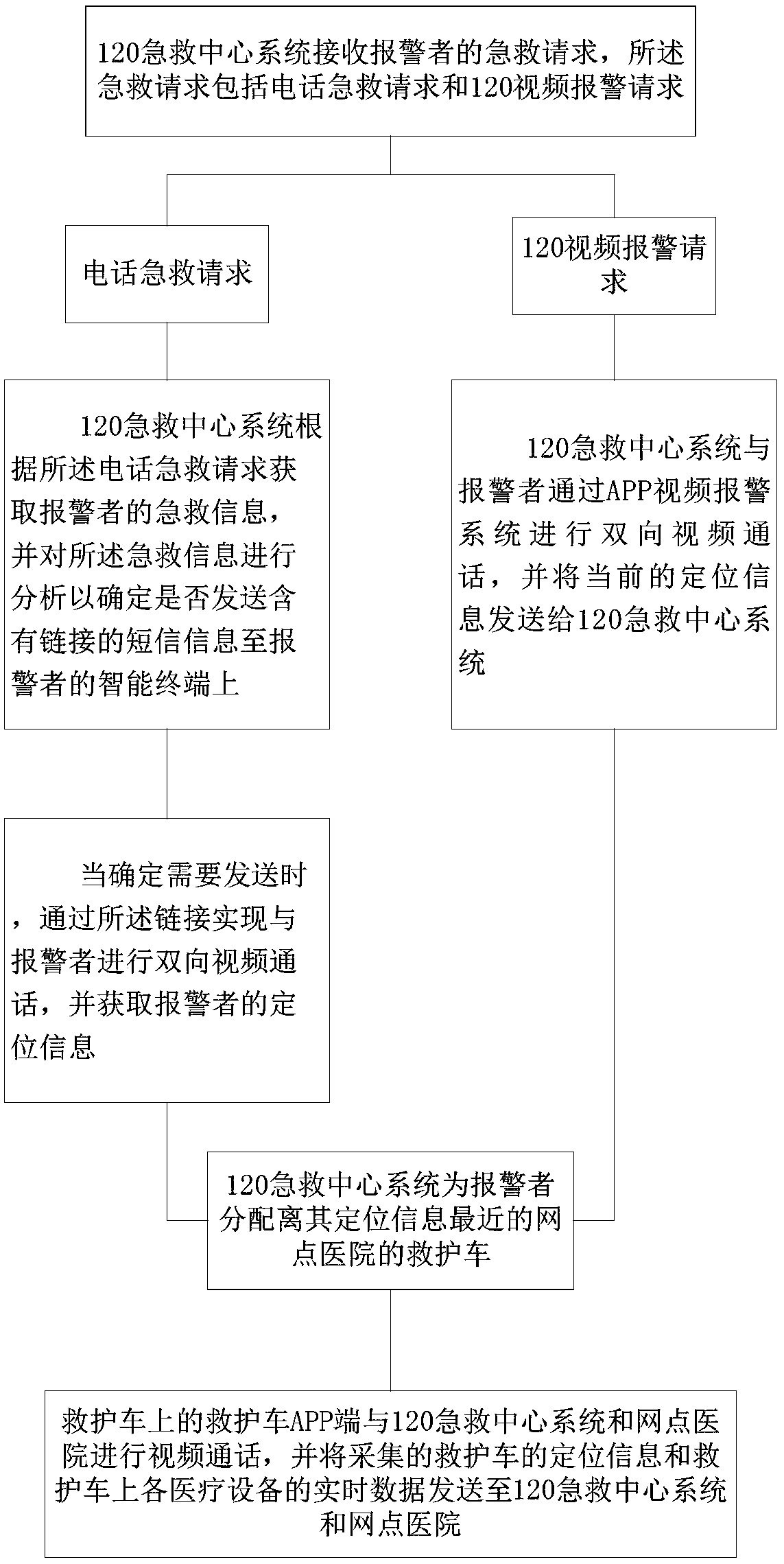

Remote video emergency system and emergency method

ActiveCN109087488AMeet usage habitsFacilitate communicationTwo-way working systemsAlarmsReal-time dataMedical device

The invention discloses a remote video emergency system and emergency method. The system comprises a 120 emergency center system, an APP video alarm system and an ambulance APP terminal; the 120 emergency center system receives the telephone emergency request of an alarming person to acquire emergency information of the alarming person, and analyzes the emergency information to determine whether to send the short message containing the link to the intelligent terminal of the alarming person to realize the video communication between the alarming person and the emergency center system, and obtains the positioning information of the alarming person and distributes the ambulance for the alarming person; the APP video alarm system is used for the alarm person to initiate a 120 video alarm request directly through an APP key, conduct two-way video communication with the 120 emergency center system, and send the current positioning information to the 120 emergency center system; the ambulance APP terminal is used for carrying out video communication with the 120 emergency center system and the hospital, and sending the acquired positioning information of the ambulance and the real-time data of the medical equipment on the ambulance to the 120 emergency center system and the hospital. The remote video emergency system and emergency method has the effect of improving the rescue efficiency by means of video emergency guidance.

Owner:重庆急视飞救科技发展有限公司

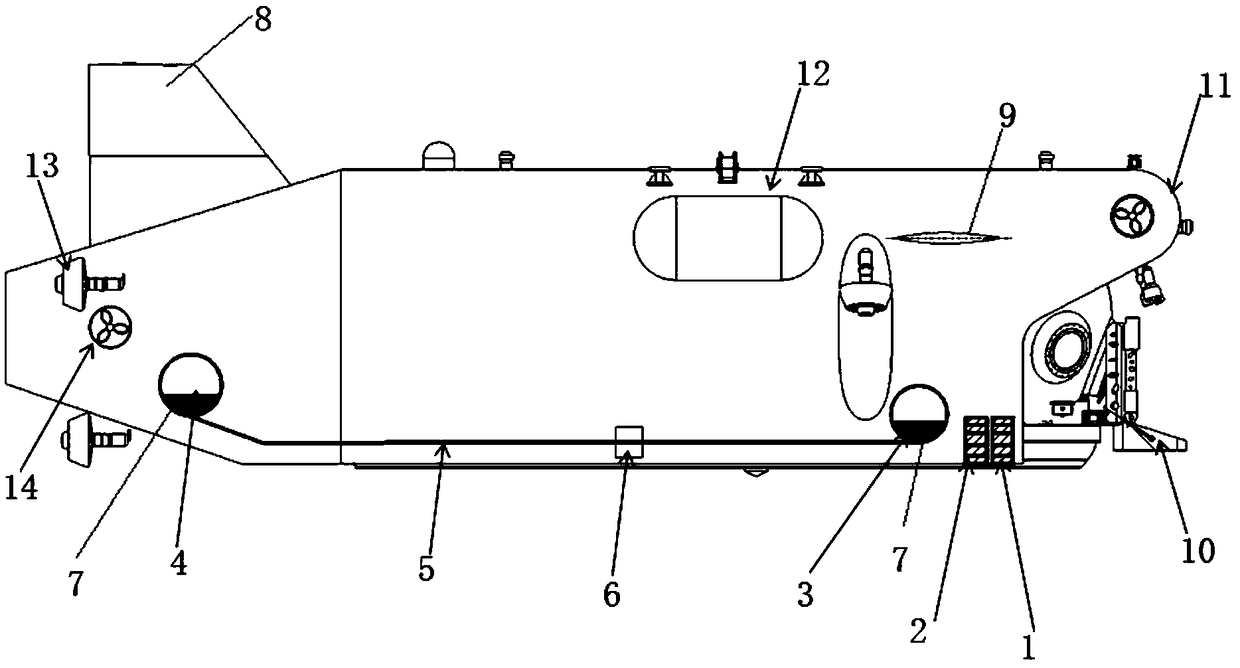

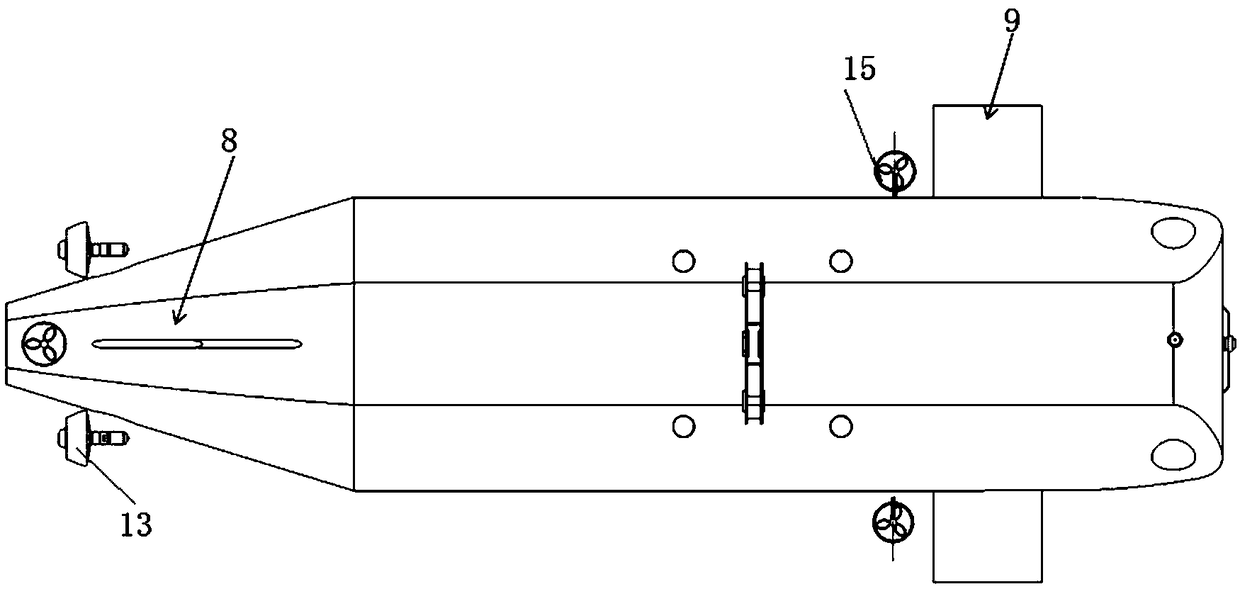

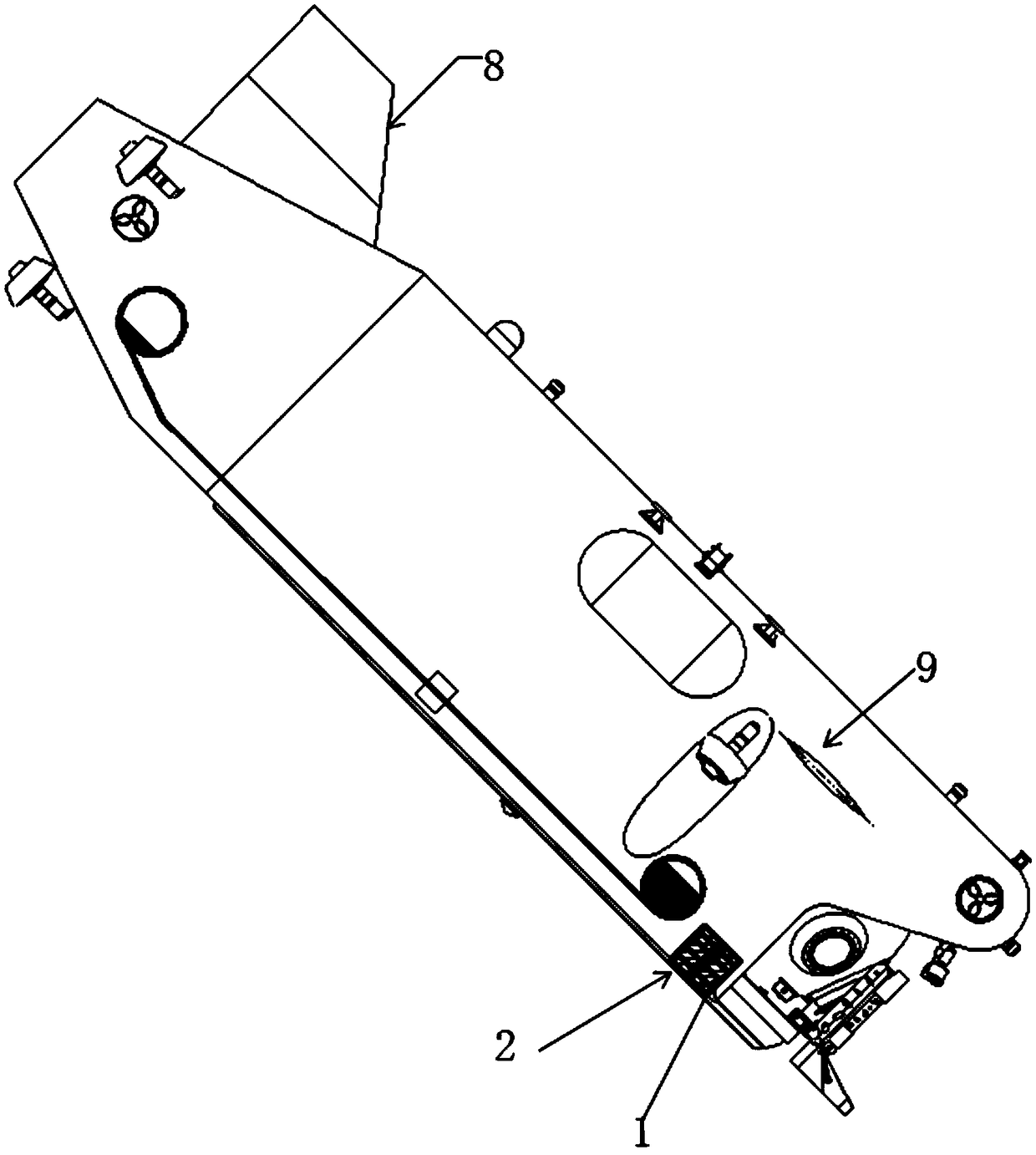

Unpowered dive floating motion method and system applied to large depth submersible

InactiveCN109466728ALong underwater working timeReduce visco-pressure resistanceUnderwater vesselsUnderwater equipmentHabitRudder

The invention belongs to the technical field of underwater motion control of deep water submersibles, and discloses an unpowered dive floating motion method and system applied to a large depth submersible. The method comprehensively uses a horizontal rudder, a vertical rudder, a dive ballast, a floating ballast, a vertical tilting adjustment system and the like, so that the submersible dives or floats at a certain pitch angle, so that the submersible is more streamlined in the moving direction during the dive or floating process, a water body is reduced in pressure when flowing through the outer surface of the submersible and presents a graded state, the sticking resistance is effectively reduced, and the total resistance is reduced. The method improves the speed of the dive and floating,so that the submersible has a longer underwater effective working time; the method is generally based on the basic components of the conventional submersible, improves the diving and floating speed ofthe submersible by means of function expansion, position adjustment, combined application and the like, reduces non-working time, and has a comprehensive advantage in terms of economy, operating habits and construction experience.

Owner:SHANGHAI OCEAN UNIV

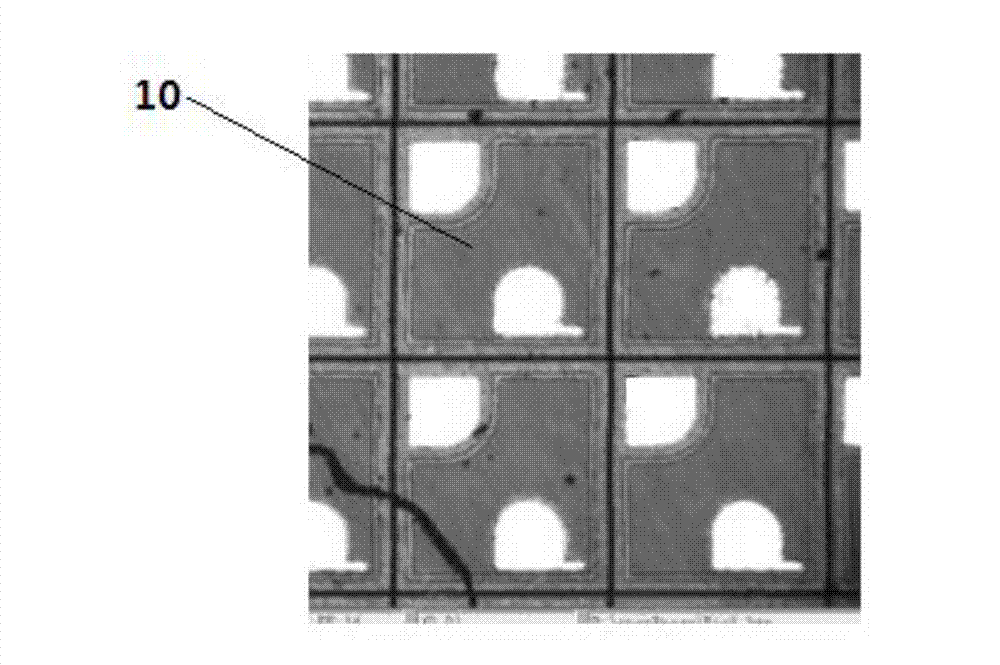

Planning method of motion path of wafer cutting machine tool

ActiveCN103111763AReduce wasted timeShorten the timeLaser beam welding apparatusEngineeringLaser beams

The invention discloses a planning method of a motion path of a wafer cutting machine tool. The method comprises the following steps: (1) a wafer is driven by a Y shaft motor moving platform to conduct line cutting motion along the vertical direction; (2) when the wafer reaches the end portion of the cutting line of the wafer along the vertical direction, a circular interpolation module is started, an X shaft motor moving platform is in linkage with the Y shaft motor moving platform so as to drive the wafer to conduct circular motion; (3) circular interpolation is finished, the wafer reaches the end portion of the cutting line along the adjacent vertical direction so as to conduct cutting to another cutting line of the vertical direction; (4) the above steps are repeated so as to finish all line cutting of the vertical direction; and (5) all cutting of transverse cutting lines is conducted by utilizing similar operation. According to the planning method of the motion path of the wafer cutting machine tool, the cutting path of the wafer is planned reasonably, time waste caused by excessive miscut when laser beams are at two ends of the wafer is reduced; meanwhile, the X shaft motor moving platform and the Y shaft motor moving platform operate simultaneously in the circular motion of a miscut area, a large amount of time is saved, and working efficiency is improved.

Owner:福建省威诺数控有限公司

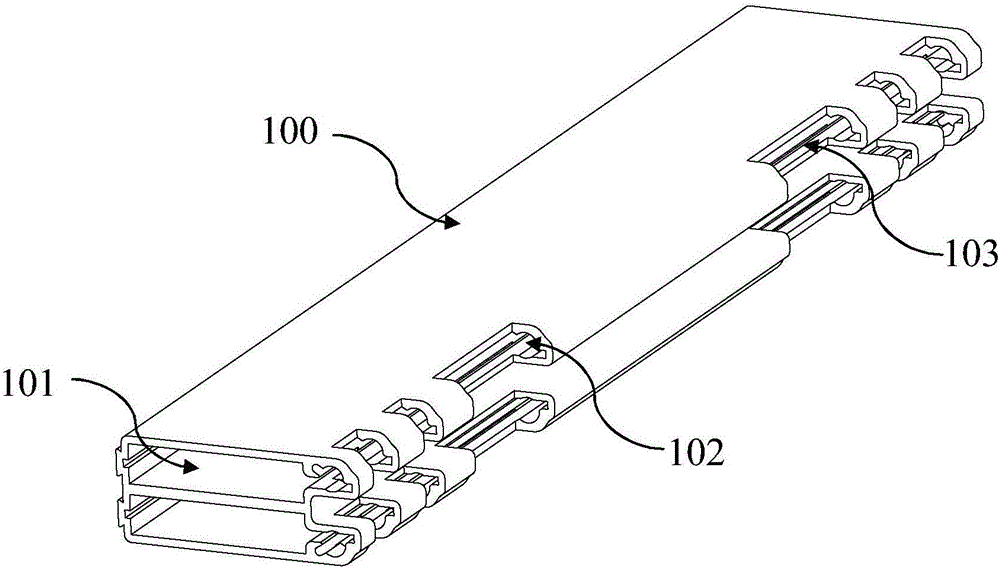

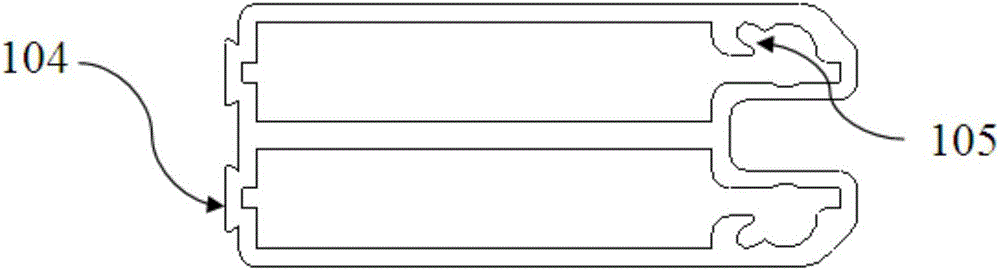

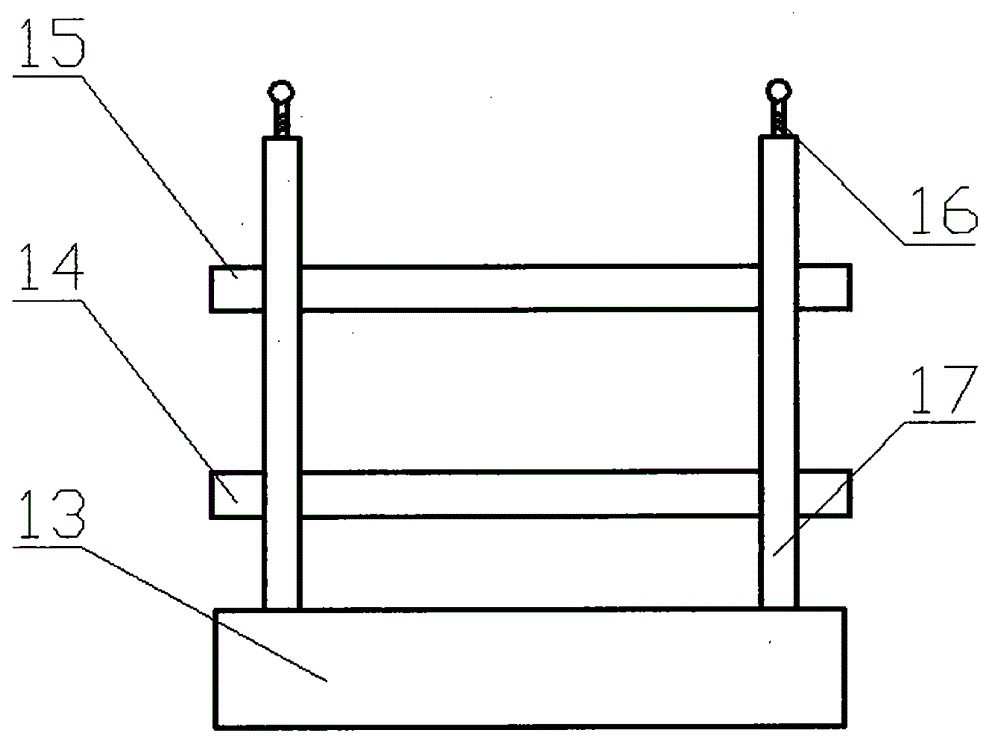

Dielectric phase shifter with novel conducting cavities

ActiveCN106067577AReduce the number of partsSave assembly timeWaveguide type devicesAntennasDistortionEngineering

The invention discloses a dielectric phase shifter with novel conducting cavities. The dielectric phase shifter includes an outer shell, dielectric sheets, a circuit board and coaxial cables; two rectangular cavities are formed in the outer shell; one conducting cavity is formed at one side of each cavity, wherein the conducting cavity is connected with the cavity; each conducting cavity is hollow and is a circular hole of which the diameter is 3.6 mm, and a small groove of which the width is 1.2 mm formed at one side of the hole; in each conducting cavity 4, a portion with a reserved width is maintained to be original at a position where the outer conductor of a corresponding coaxial cable is welded to the conducting cavity 4, and a portion of which the width is 15mm is machined downwards so as to be removed, and therefore, the coaxial cable can extend into the conducting cavity so as to be welded to the conducting cavity; the circuit board is designed into a rectangle with four grooves formed at one side; and the four grooves are corresponding to the edges of circuit board pads for welding the inner conductors of the coaxial cables. When welding is carried out, only one-time clamping is required, and therefore, a welding technique is better, and the economical efficiency of welding is improved; and the conducting cavities are utilized to excellently wrap the outer conductors of the coaxial cables, distortion can be avoided, bending stress of the coaxial cables can be avoided, the risk that welding spots and the circuit board are damaged can be lowered, and hidden hazard points in intermodulation can be decreased.

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

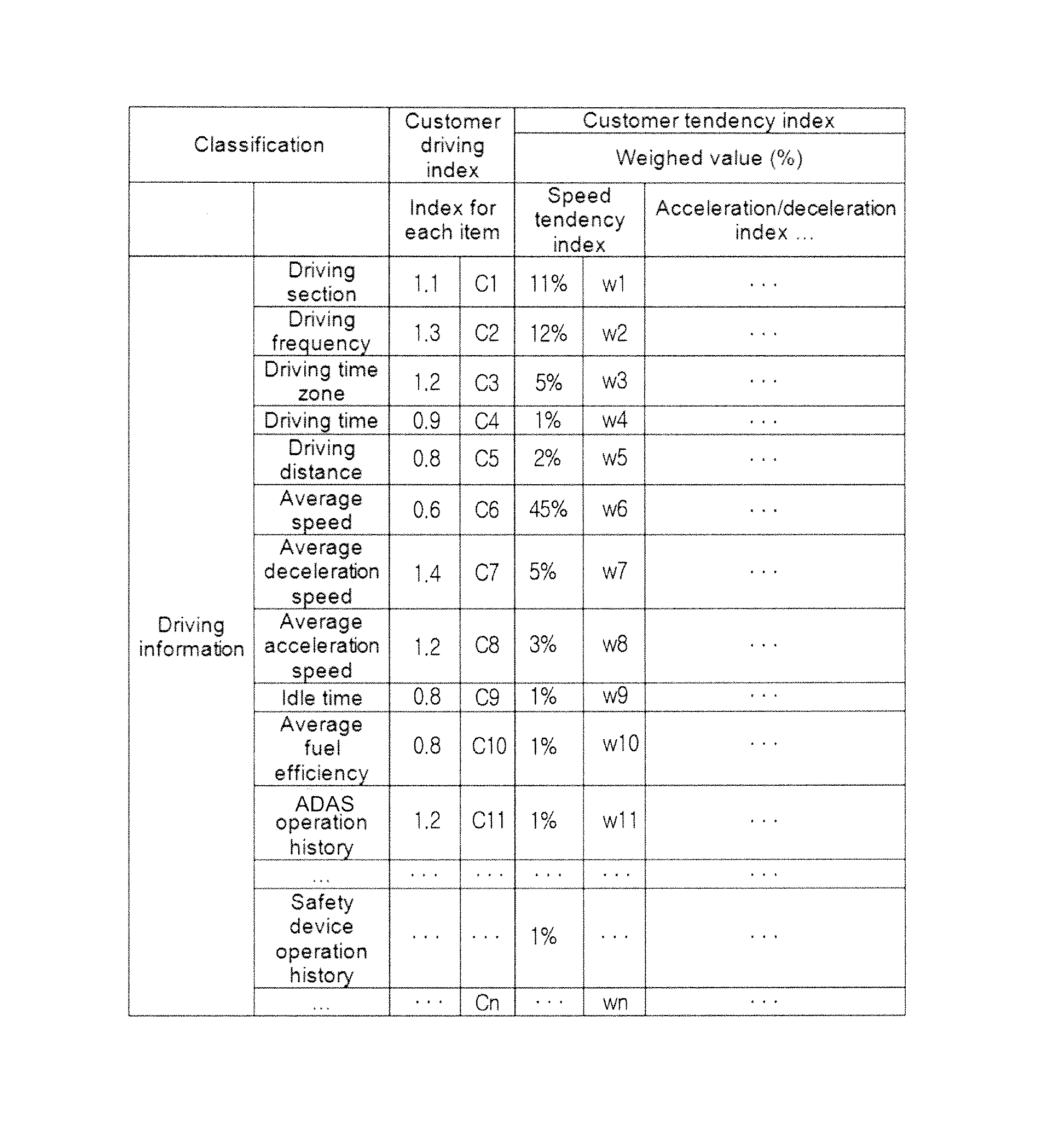

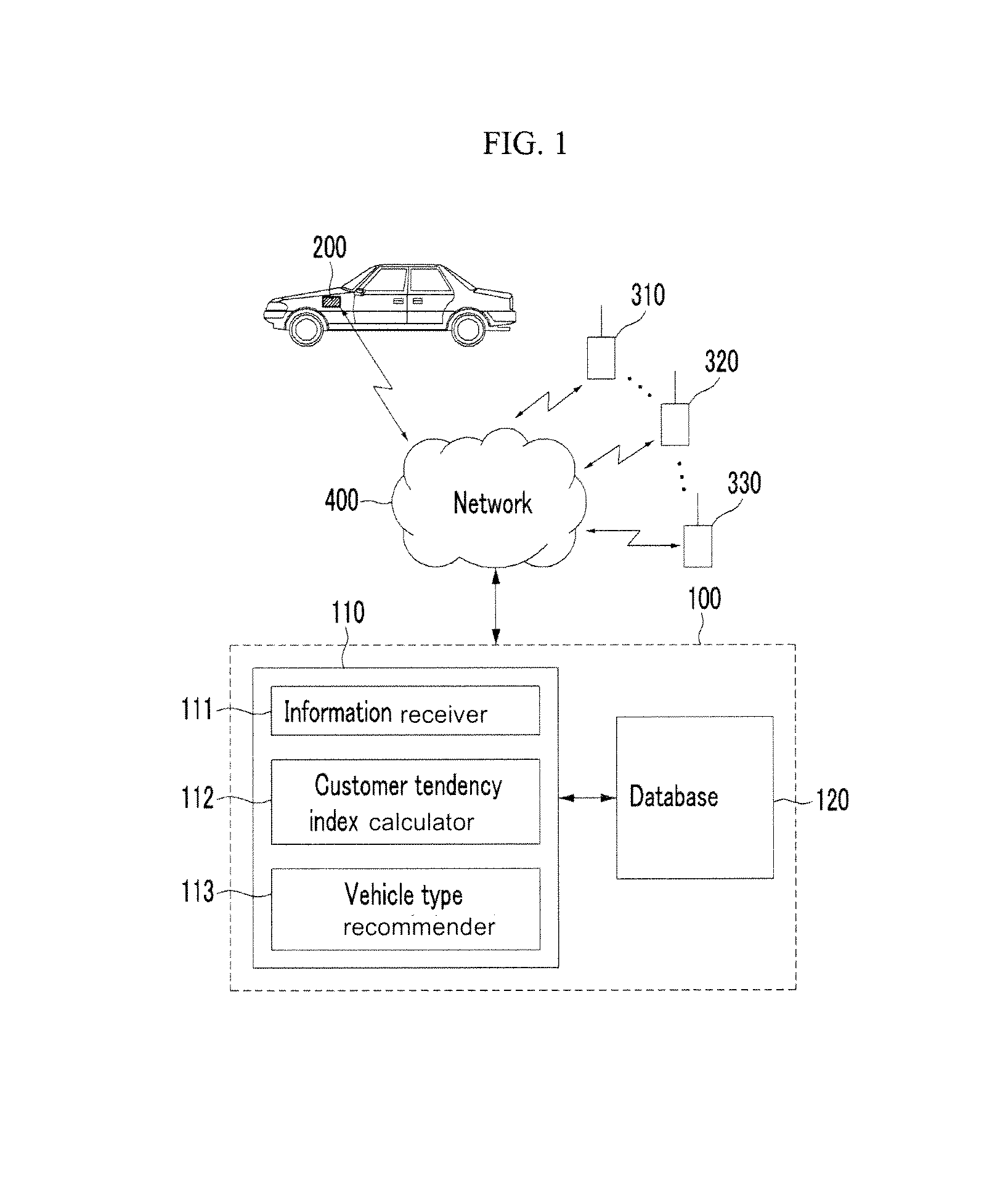

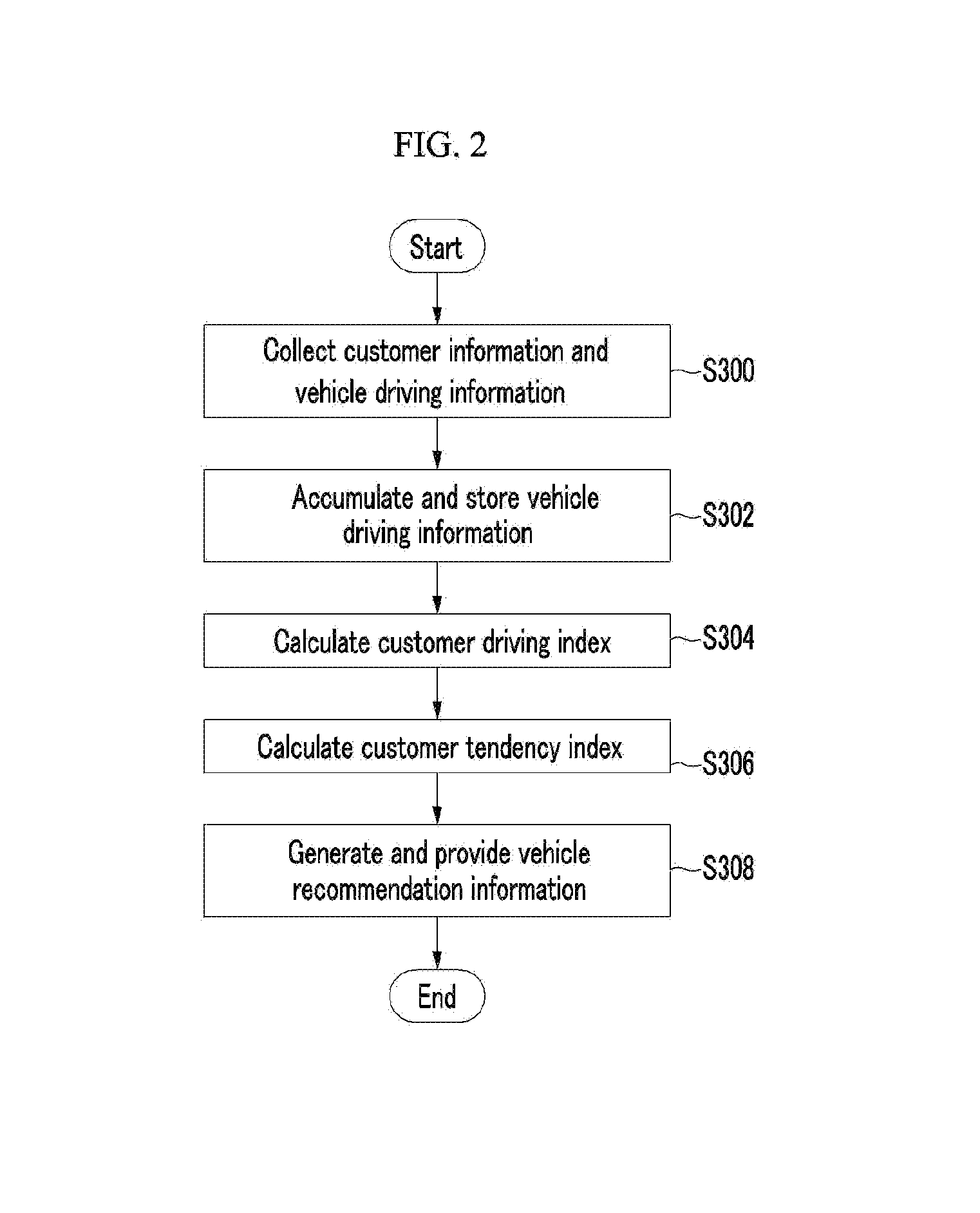

System and method of recommending type of vehicle based on customer use information and vehicle state

InactiveUS20150170253A1Reduce waste and waste of timeImprove abilitiesBuying/selling/leasing transactionsCustomer informationData mining

A server receives customer information and driving information about a vehicle and accumulates and stores the received customer information and driving information in a database when driving of the vehicle ends. The server calculates a statistical average value of the driving information about the customer stored in the database based on the customer information and the vehicle information, compares the statistical average value of the driving information about the customer and a statistical average value of driving information about a plurality of general customers, and calculates a customer driving index for each item as a normal distribution based probability value. A customer tendency index is generated by multiplying a weight and the customer driving index of each item and adding the values.

Owner:HYUNDAI MOTOR CO LTD

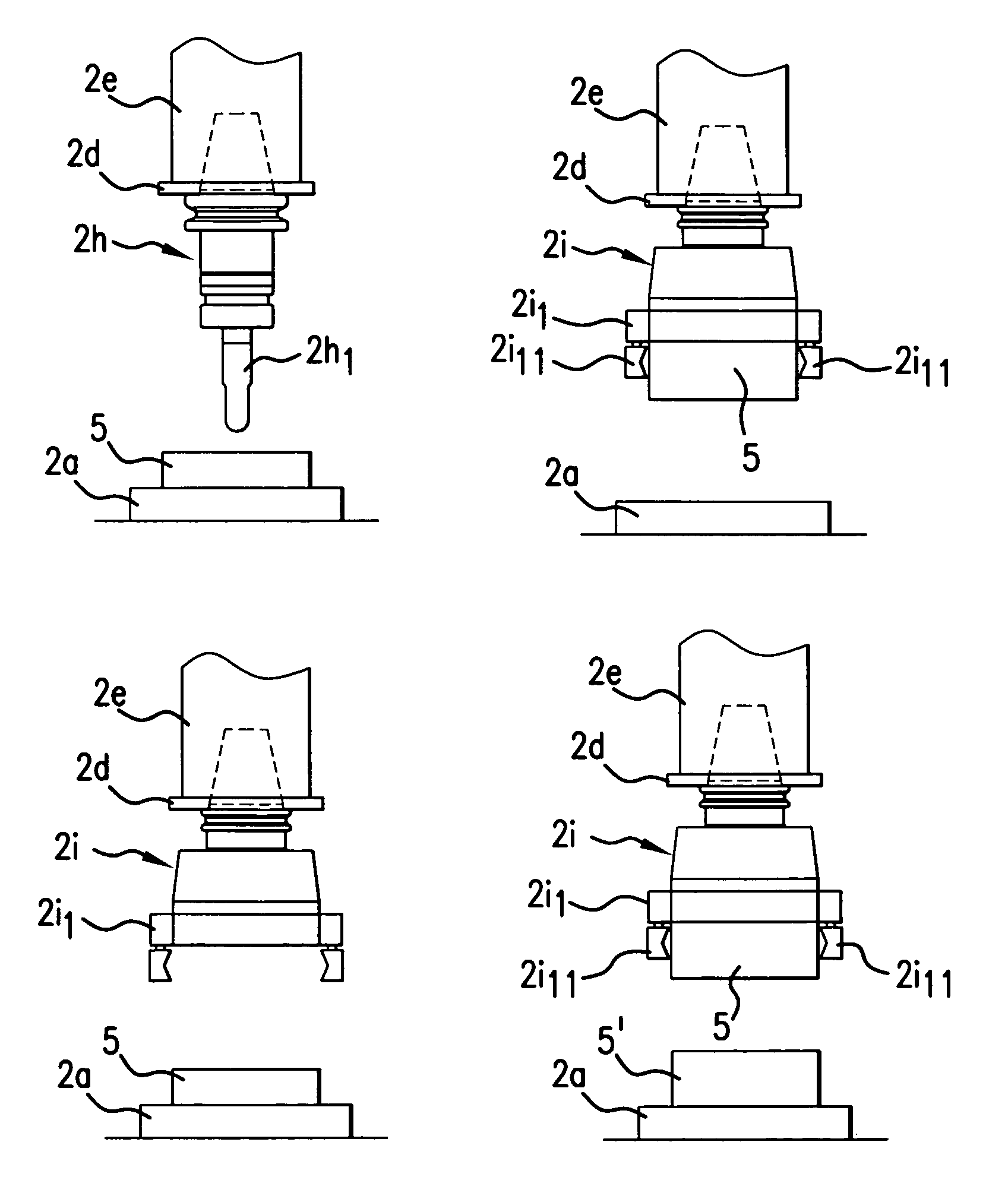

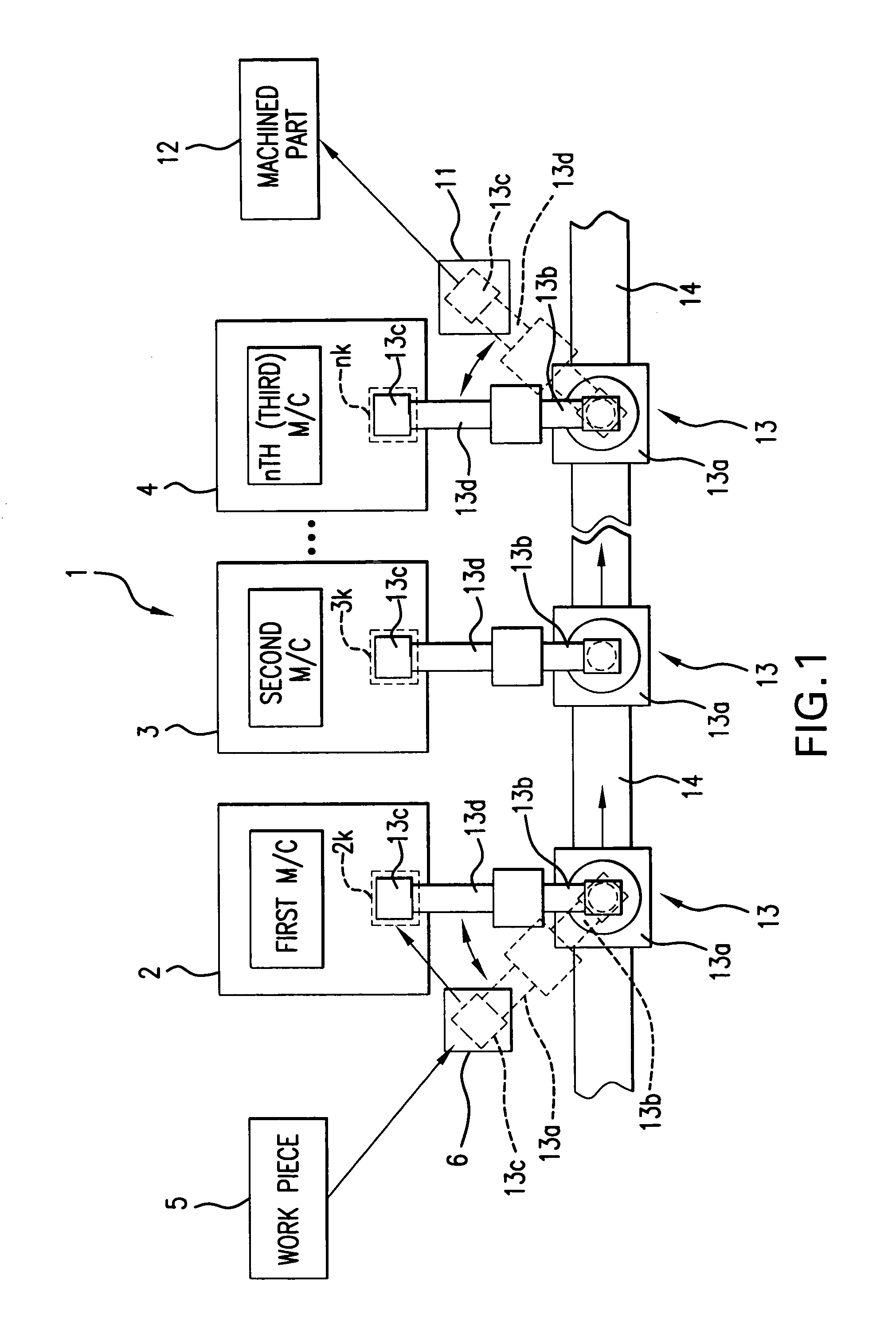

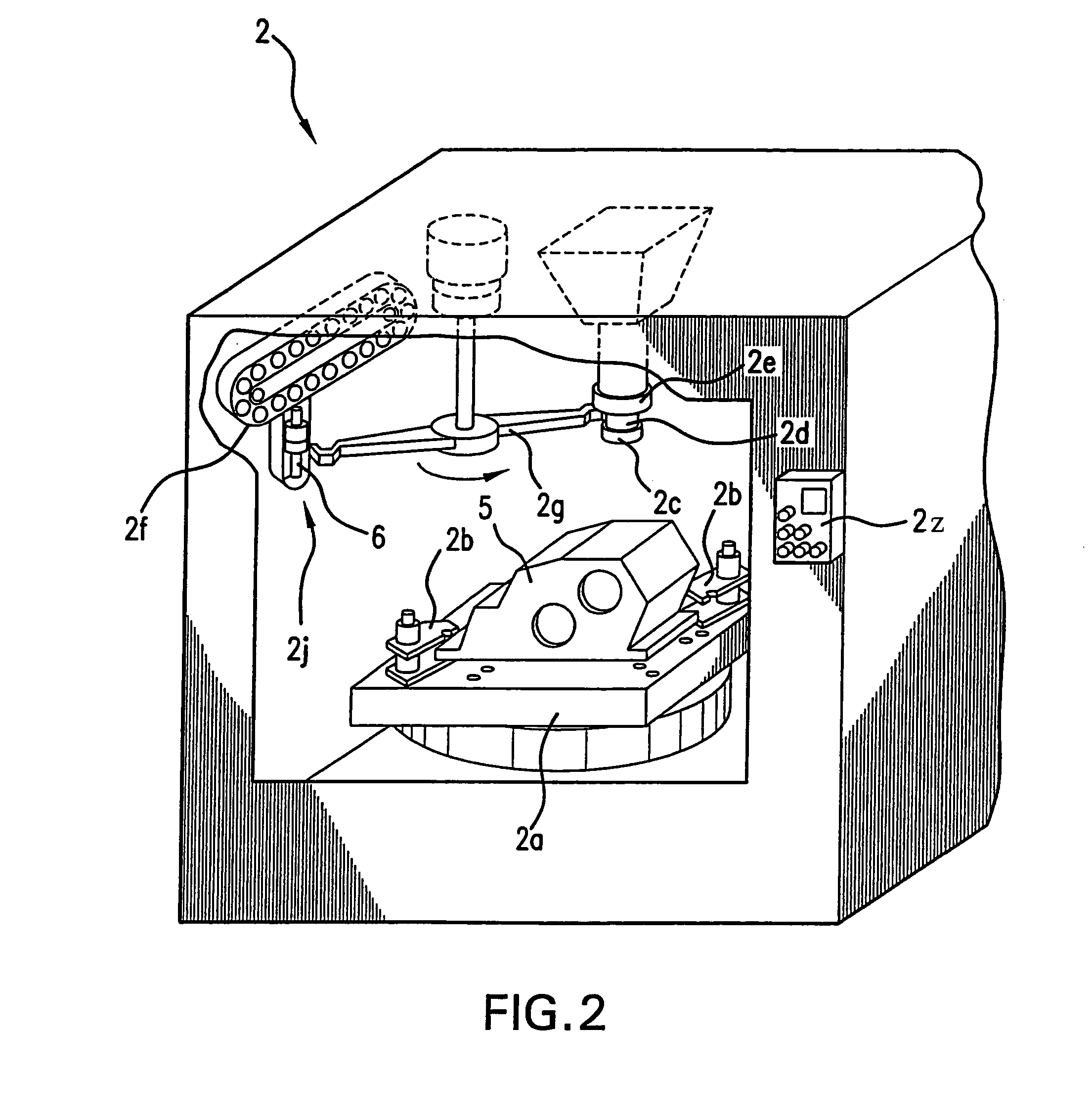

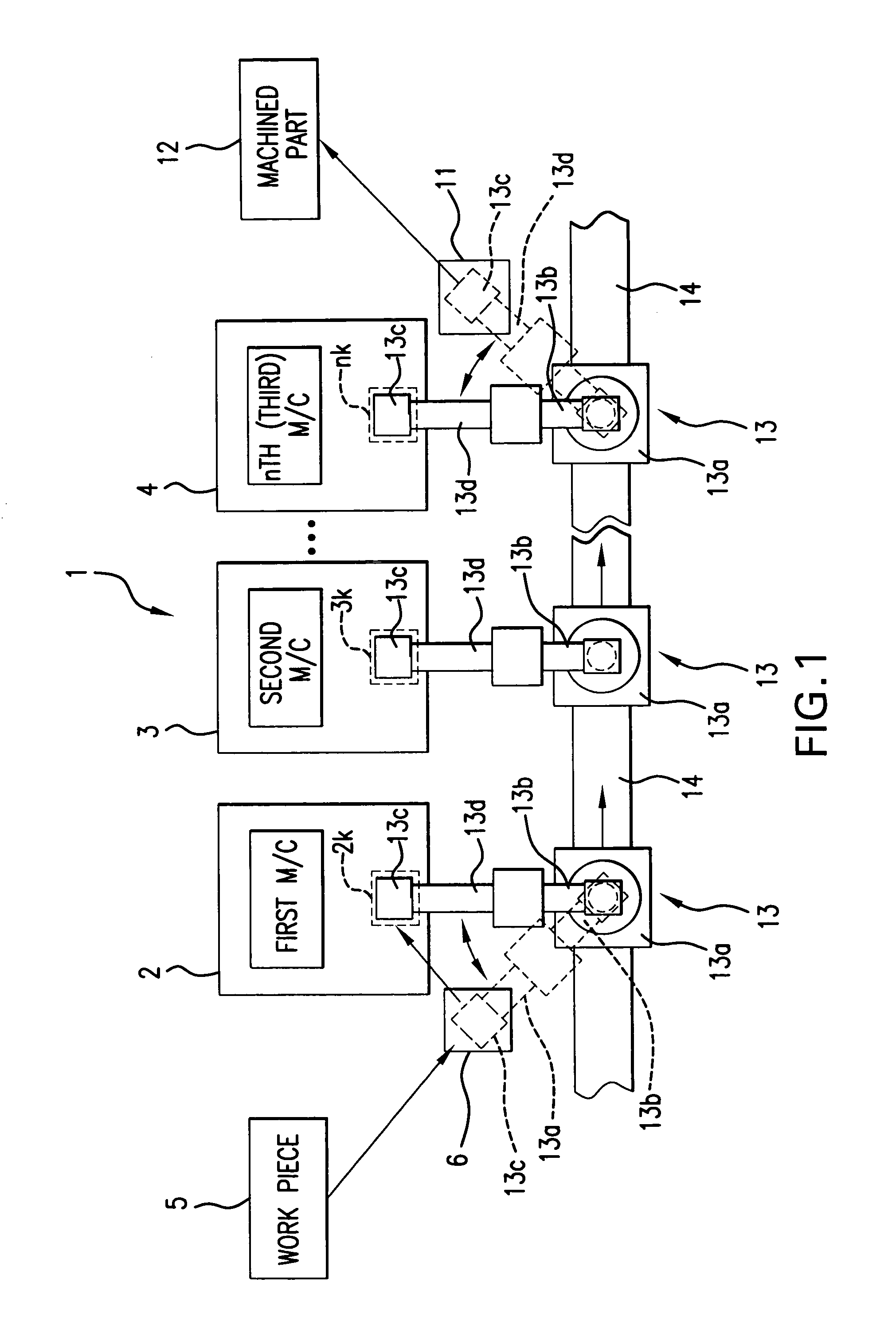

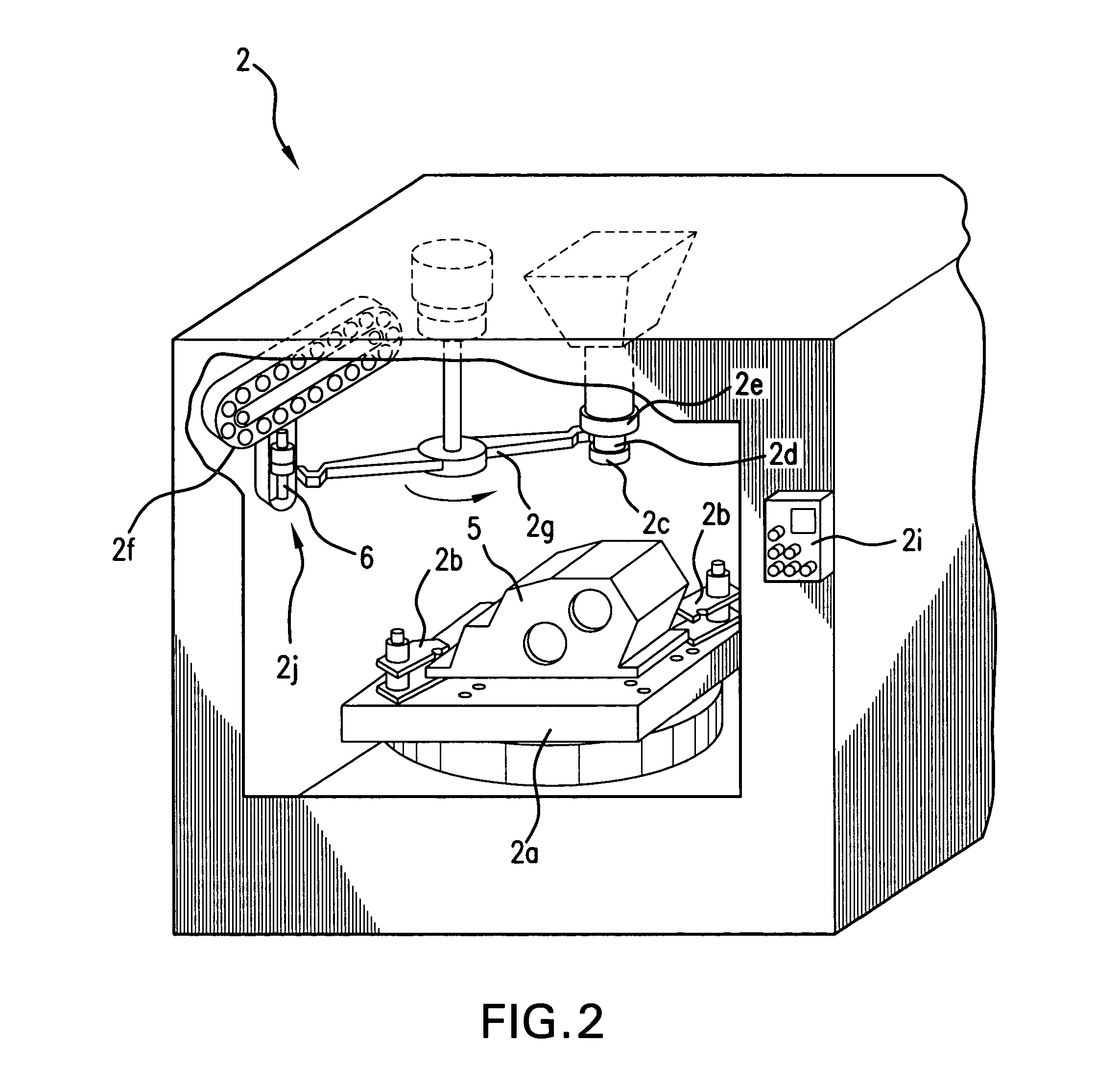

Machining apparatus and machining line provided with same

InactiveUS7103955B2Easy to operateEfficient executionMetal-working feeding devicesGripping headsEngineeringDrill bit

A drill fitted to an adapter is used to drill a hole in a workpiece fixed on a table of a machining center. When the hole drilling is finished, the drill is removed from the adapter, and a workpiece holding jig is fitted to the adapter. Then, the adapter is lowered, and the workpiece holding jig takes the workpiece for which the hole drilling operation has been finished. Following this, the adapter is raised, and the workpiece is temporarily held in the machining center. Then, in this state, the next workpiece is mounted on the table of the machining center. Accordingly, by temporarily holding the workpiece, for which the hole drilling operation has been finished, in the machining center, mounting of the next workpiece is simplified.

Owner:AISIN AW CO LTD

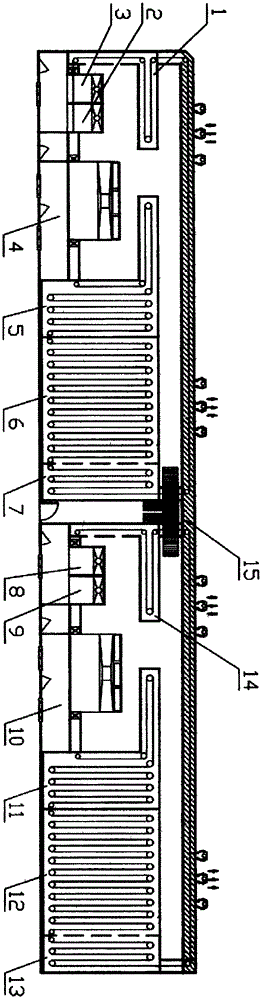

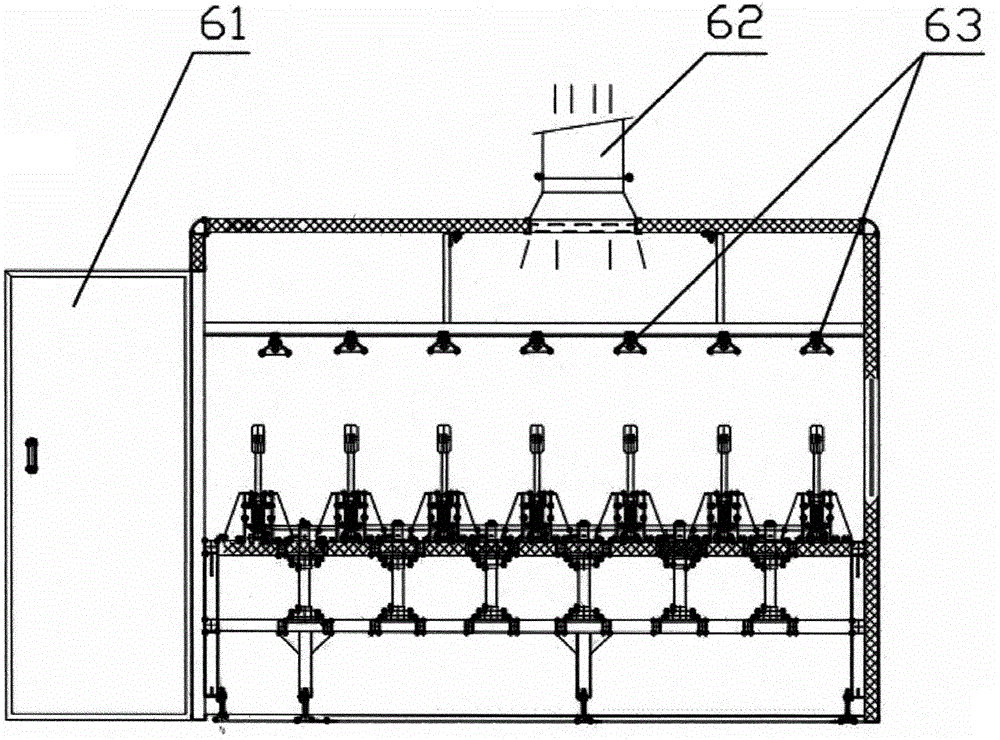

A metal surface automatic coating production line and a metal surface automatic coating production process

InactiveCN106031910AReduce pollutionResidue reductionPretreated surfacesCoatingsProduction lineEngineering

The invention provides a metal surface automatic coating production line comprising a first coating area and a second coating area. Each of the first coating area and the second coating area is provided with a dehumidification device, a dust removal system, an automatic paint spray device, a leveling area, a baking area and a cooling area successively; to-be-coated objects are transferred in the first coating area, in the second coating area and between the first coating area and the second coating area via a conveyor; the coating production line is arranged in a dust-free workshop. A metal surface automatic coating production process comprises the successive steps of assembly and work piece feeding, preheating and dehumidifying, manual electrostatic dust removal, automatic electrostatic dust removal, priming paint spray, primary leveling, primary baking, primary cooling, offline vacuum coating, loading to the line, dehumidification, dust removal, finish paint automatic spray, secondary leveling, secondary baking, secondary cooling, and discharging. The metal surface automatic coating production line and the metal surface automatic coating production process have the advantages of environmental production, high efficiency and low production cost and can replace traditional electroplating.

Owner:浙江京禾纳米科技有限公司

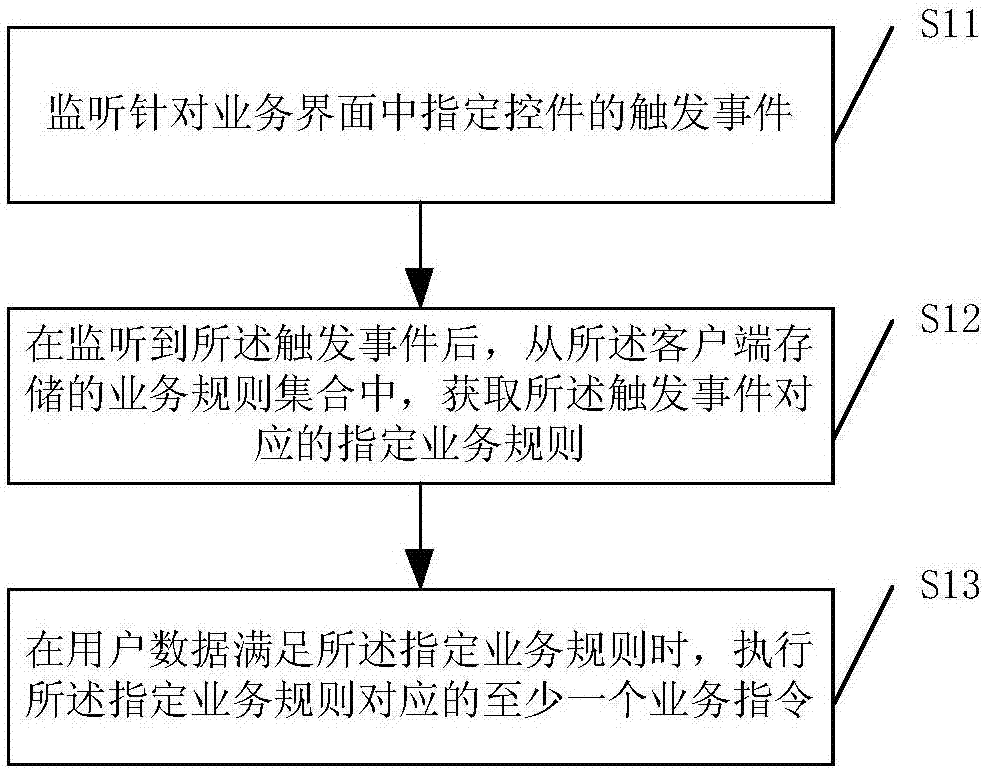

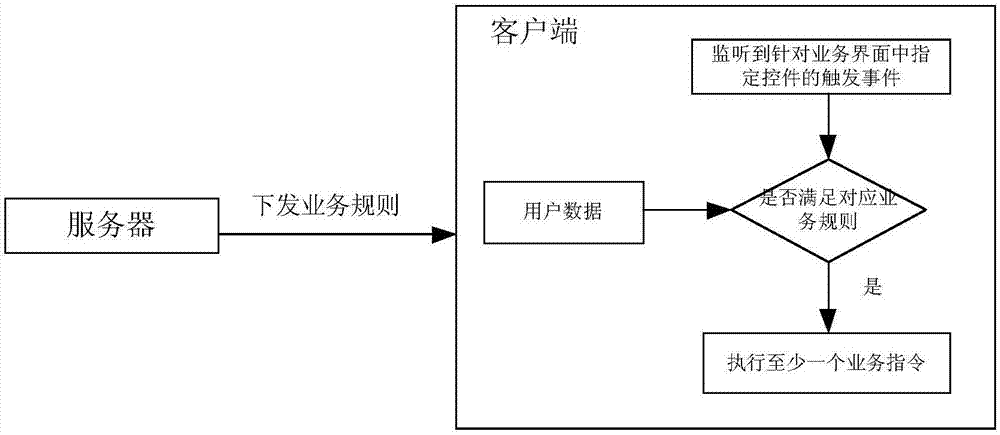

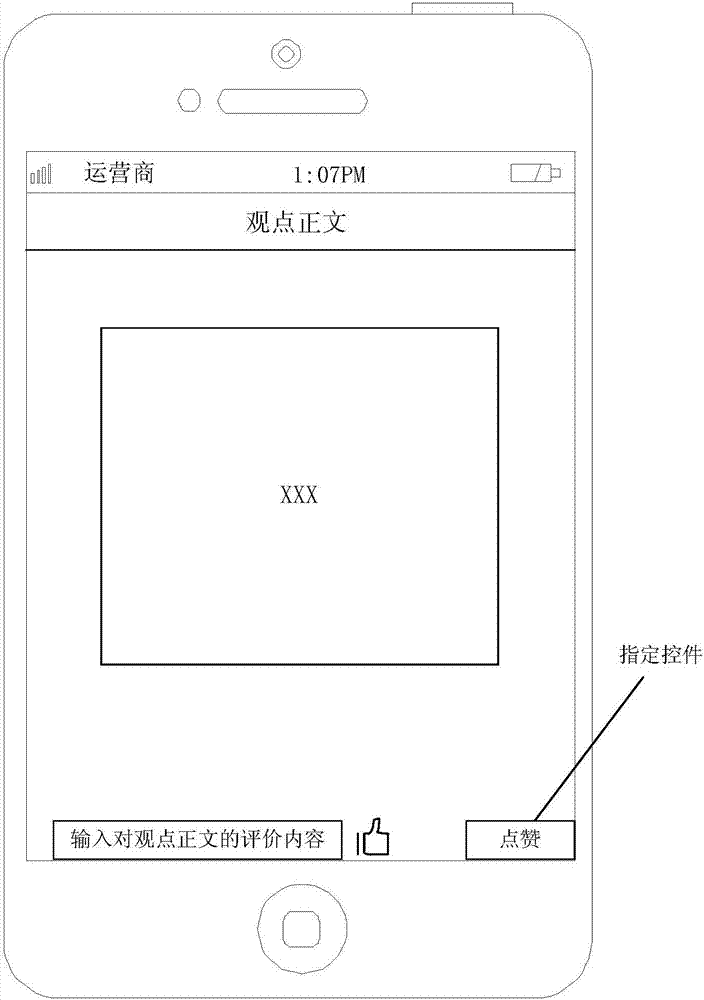

Service instruction execution method, client and storage medium

ActiveCN107390983AEasy to adjustAvoid repostingInput/output processes for data processingClient-side

The embodiment of the invention discloses a service instruction execution method, a client and a storage medium. The method is applied to the client. The client can send a service rule acquisition request to a server and receive and store a service rule set fed back by the server, wherein the service rule set includes at least one service rule; each service rule is associated with a data category and corresponds to at least one service instruction. The method comprises the steps of monitoring a triggering event for a specified control in a service interface; after monitoring the triggering event, acquiring a specified service rule corresponding to the triggering event from the service rule set stored in the client; and when user data satisfies the specified service rule, executing at least one service instruction corresponding to the specified service rule, wherein the data category of the user data is the data category associated with the specified service rule.

Owner:ADVANCED NEW TECH CO LTD

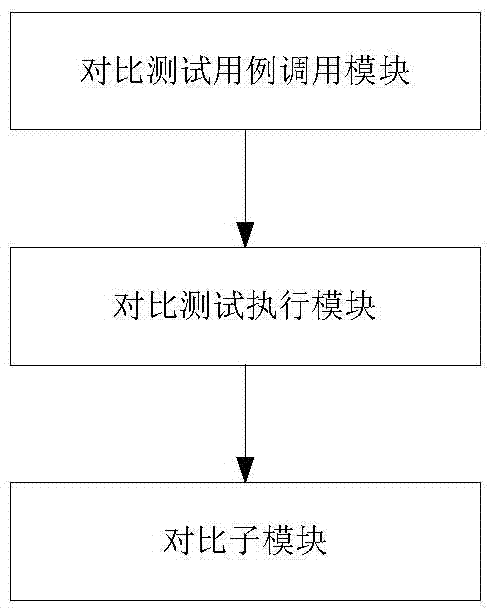

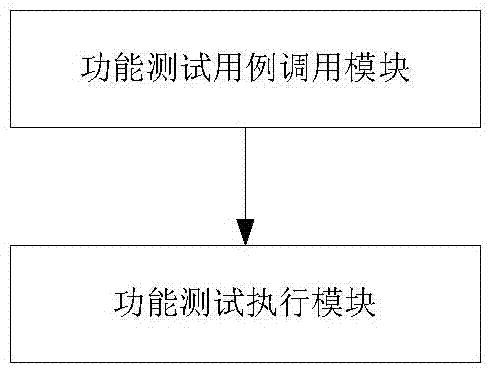

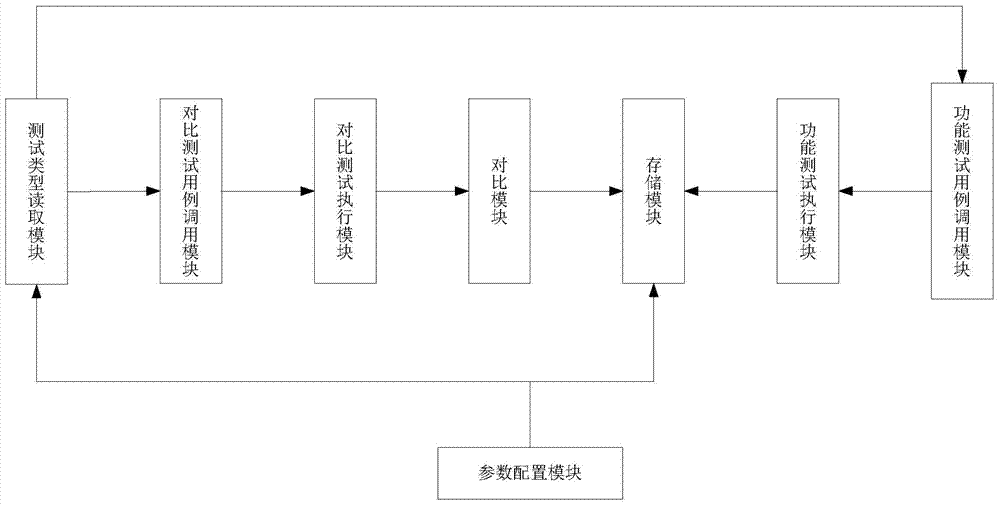

Automated testing system and method

InactiveCN104516809AImprove test efficiencyImprove test accuracySoftware testing/debuggingFunctional testingSystem monitor

The invention relates to an automated testing system and method. Testing types, testing cases, testing result storage addresses and the like are configured by a control panel, a background establishes Http Connection with an interface according to the configuration, the testing cases are called, an interface return result is acquired and then analyzed, two results are compared by calling a comparison algorithm, and the testing result and a comparison result are stored in corresponding paths. Both functional testing and comparison testing can be performed, testers do not need to test the testing cases one by one, the system can acquire results of all the testing cases once, the testers do not need to manually compare the results, the comparison algorithm is used for intelligent comparison, the system has a downloading function, the function testing result and the comparison testing result can be easily downloaded into various formats by the control panel, the system monitors testing progress and testing states in real time through the control panel, a user can stop testing at any time, and the system is easily operated through interfaces.

Owner:FOUNDER BROADBAND NETWORK SERVICE

Water proof comprehensive treatment construction method for construction roof

InactiveCN101392601AImprove waterproof performanceSimple processBuilding repairsSlurryFilm-coated tablet

The invention provides a construction method for waterproof comprehensive treatment on building roofing, which relates to the technical field of constructional engineering, in particular to the technical field of roofing waterproof system. The construction method comprises the following steps: cleaning leaking and penetrating parts; densifying the leaking and penetrating parts by a chemical slurry injecting method; densifying the clearance on the other surface of a structural layer by the chemical slurry injecting method after leak stoppage materials are completely solidified; brushing concave parts of the structural layer to be level by structural mortar; and brushing polyurethane film coating or spreading SBS coiled materials after the structural layer is dried. The construction method combines the self structural waterproof action and the waterproof action outside the structure for treatment, thereby achieving better waterproof effect. In addition, the construction method has the advantages of having simple working procedures, convenient construction and material fetching, bringing convenience to application, greatly reducing the probability of reworking and later maintenance, and reducing unnecessary loss and time waste.

Owner:JIANGSU XINGSHA CONSTR ENG GRP

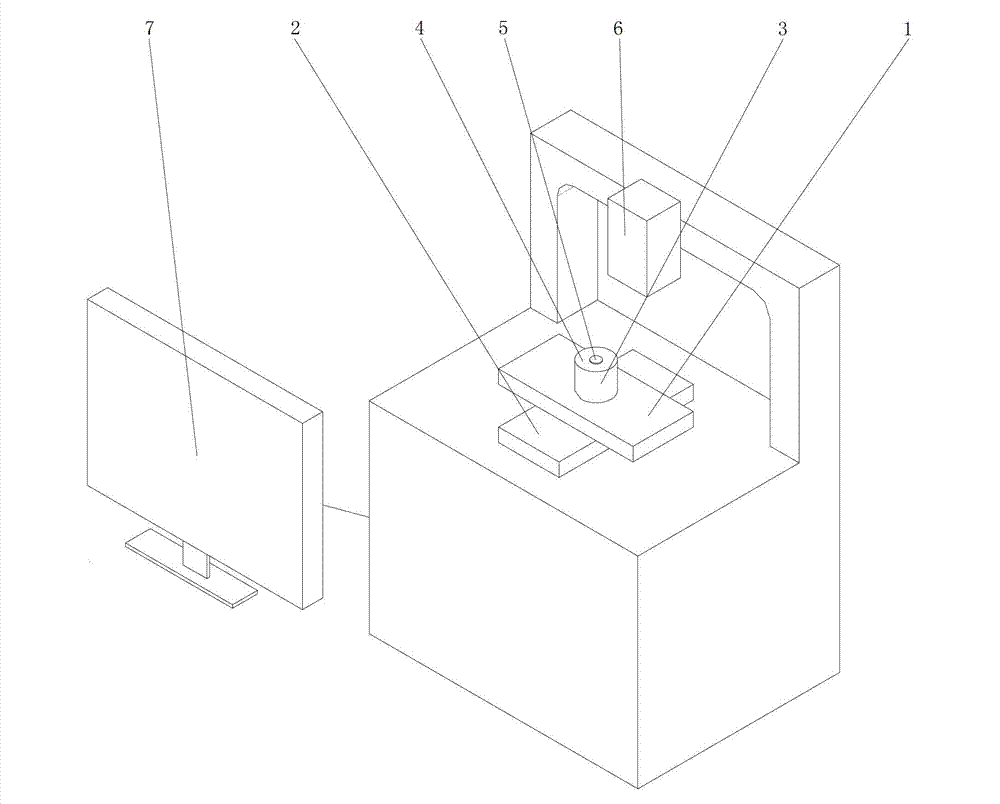

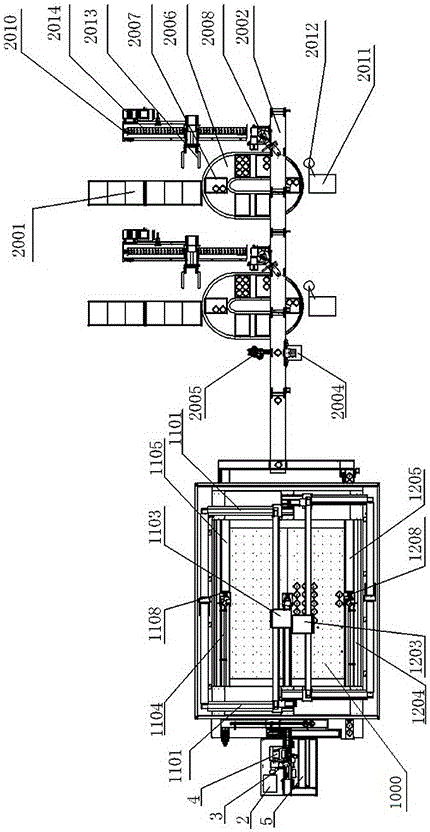

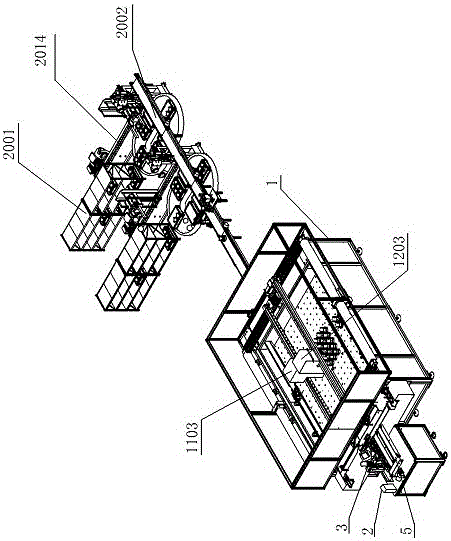

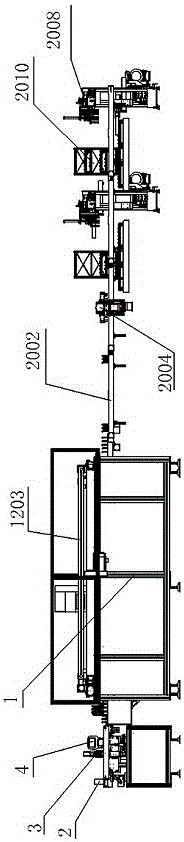

Fully-automatic lens detection, sorting and classified storage system

The invention discloses a fully-automatic lens detection, sorting and classified storage system, and belongs to the technical field of lens sorting. The fully-automatic lens detection, sorting and classified storage system comprises a rack (1), wherein a control device (2) and a lens sorting device are arranged on the rack (1); a lens detection device is arranged at one side of the lens sorting device; a lens classified storage device is arranged at the other side of the lens sorting device; the lens sorting device comprises a sorting platform (1000); and two groups of longitudinal guide rails are arranged at the two sides of the sorting platform (1000) respectively. The fully-automatic lens detection, sorting and classified storage system disclosed by the invention is capable of rapidly sorting lenses, thus increasing the lens sorting efficiency; and the classified storage device is more reasonable in arrangement, thus lens storage is further optimized, and a warehousing space is saved.

Owner:LINHAI JINZHENG MACHINERY

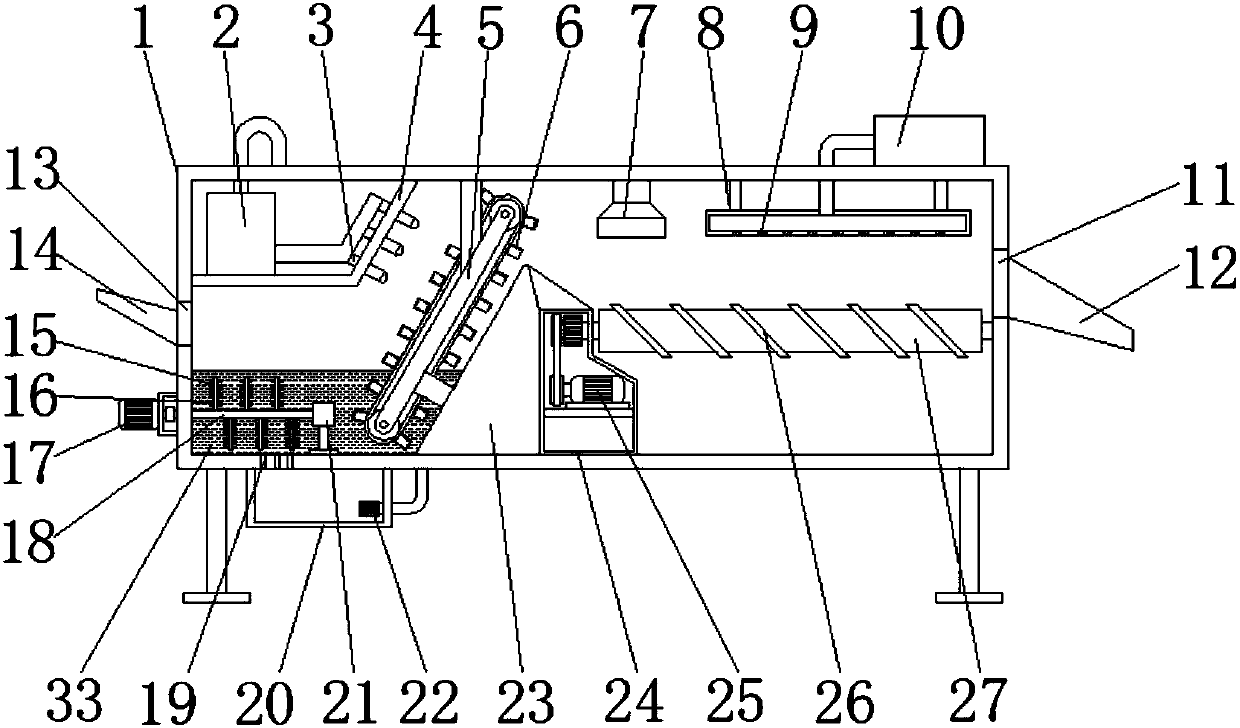

Cleaning, disinfection and drying all-in-one machine for agricultural product deep processing

InactiveCN107824513AReduce labor intensityTo achieve the purpose of secondary cleaningDrying gas arrangementsDrying solid materialsEngineeringAir blower

The invention relates to the technical field of agricultural product processing, in particular to a cleaning, disinfection and drying all-in-one machine for agricultural product deep processing. The cleaning, disinfection and drying all-in-one machine comprises a machine body. An installing block is arranged in the machine body. A cleaning pool is arranged on one side of the installing block and is internally provided with a cleaning mechanism. A conveying belt is arranged on the part, on one side of the installing block, in the cleaning pool and is provided with a plurality of support hoppers. A spraying mechanism is arranged on the side, away from the installing block, of the conveying belt and at the top of the machine body. A second shell is arranged on the side, away from the conveying belt, of the installing block. A conveying mechanism comprises two rollers. One ends of the rollers are movably connected with the inner wall of the machine body. The outer sides of the rollers aresleeved with soft cotton. The outer side of the soft cotton is sleeved with spiral strips. Boxes are arranged above the rollers and at the top of the machine body. A plurality of air outlets are formed in the bottoms of the boxes at equal intervals. A hot air blower is arranged above the machine body. Through the cleaning, disinfection and drying all-in-one machine, wasted time caused by transportis reduced, work efficiency is improved, meanwhile, labor intensity of staff can be further lowered, and manpower is saved.

Owner:惠州市鸿卓网络传媒有限公司

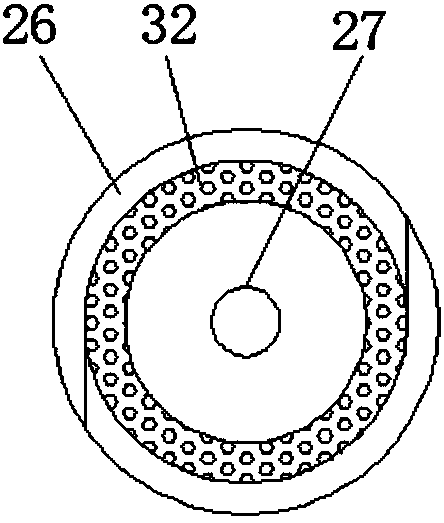

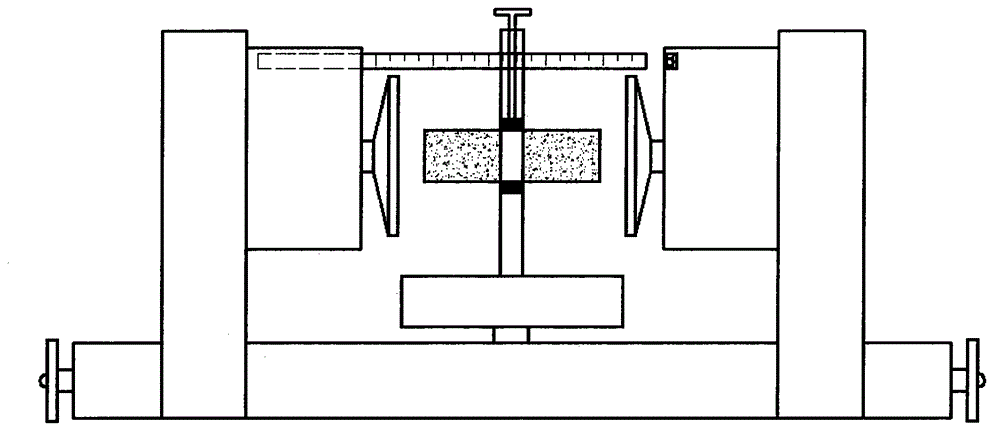

Rock sample double-end surface grinder

InactiveCN105527146AImprove grinding efficiencyPrecise and reliable length controlPreparing sample for investigationEngineeringRock sample

The invention discloses a rock sample double-end surface grinder. The rock sample double-end surface grinder comprises a base, frames, electrical cabinets and a clamping bench. The base is rectangular and is arranged at the bottom of the rock sample double-end surface grinder. The two frames are movably connected to the base through driving elements, are respectively located at left and right ends of the base and are perpendicular to the base. The two electrical cabinets are respectively arranged at left and right sides of the upper parts of the two frames. Two ends of the inner sides of the two electrical cabinets are respectively and symmetrically provided with two circular polishing discs. The clamping bench is slidingly connected to the base through a sliding rail installed above the base. The sliding rail is located at the axisymmetric center of the base. A rock sample is polished simultaneously through double end surfaces so that artificial measurement-caused errors are avoided and repeated processes of rock sample loading and unloading and time waste are avoided. The rock sample double-end surface grinder has the advantages of high polishing efficiency, accurate and reliable length control and operation convenience.

Owner:WUHAN UNIV OF SCI & TECH

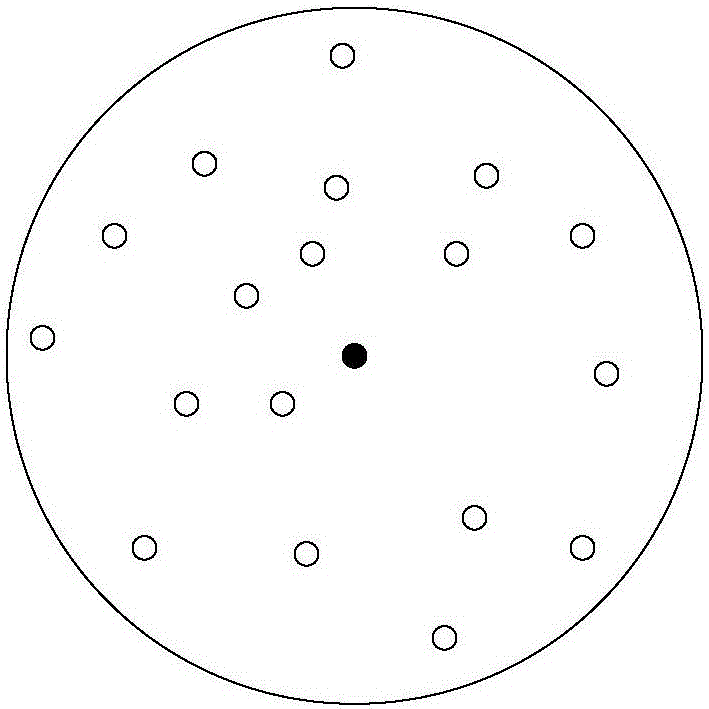

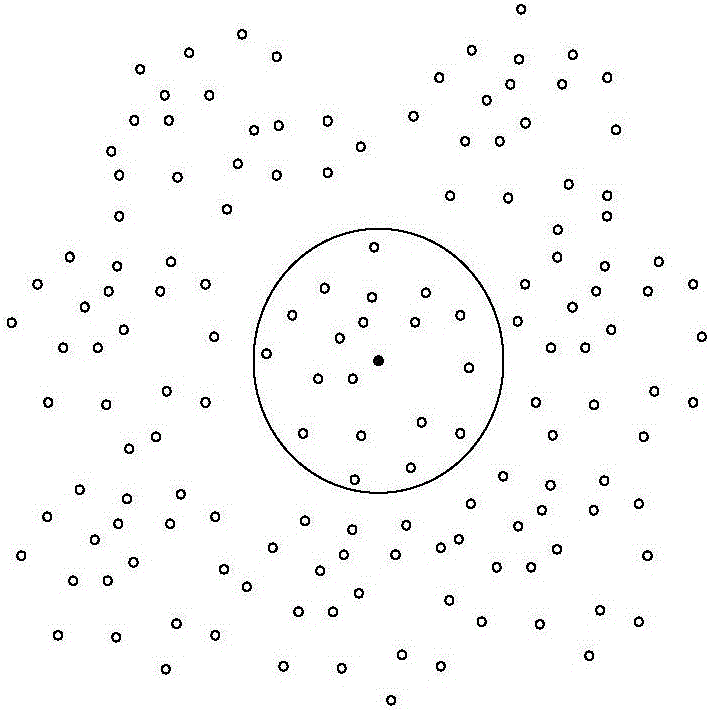

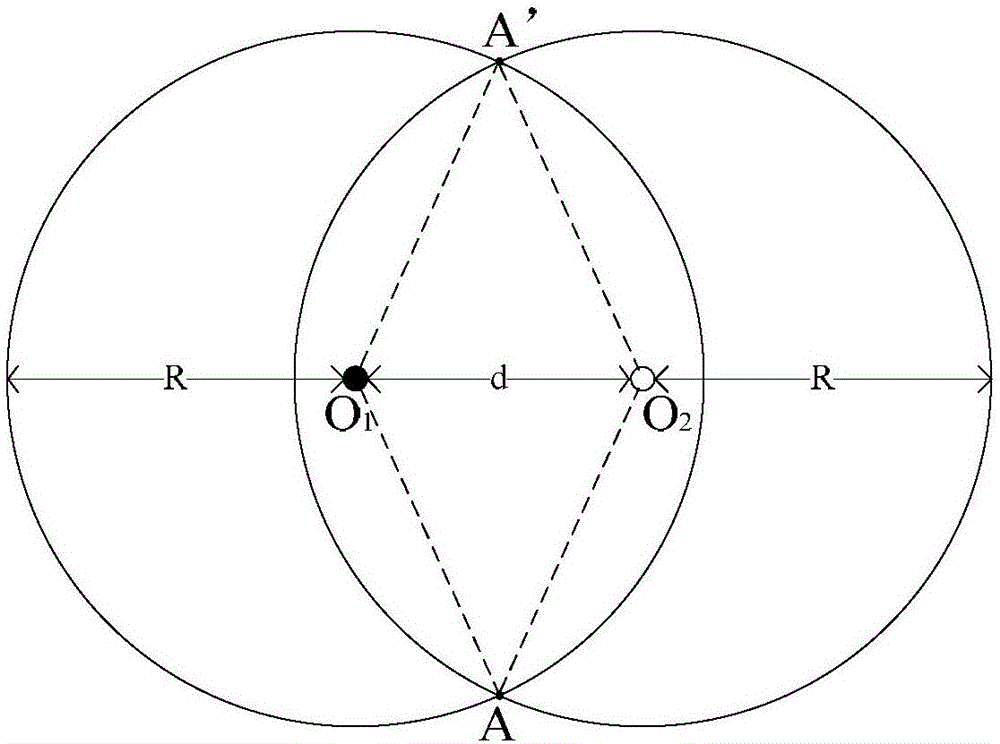

V2V multi-hop warning broadcasting method for VANETs

ActiveCN106851590AIncrease coverageReduce the numberNetwork traffic/resource managementNetwork topologiesAccidents vehicleBroadcasting

The invention relates to a V2V multi-hop warning broadcasting method for VANETs, aiming to solve the problem that the existing multi-hop broadcasting cannot simultaneously adapt to a variety of urban and suburban traffic environments. The specific process of the method comprises the following steps: I, determining the Nth forwarding node broadcast by an accident vehicle; if a neighbor node exists in a convex hull point set, executing step II; and otherwise, executing step IV; II, determining the (N+1)th forwarding node broadcast by the accident vehicle by taking the determined forwarding node as a source node; III, iterating the steps I and II to determine the (N+i)th forwarding node broadcast by the accident vehicle, and stopping broadcasting at the neighbor node in the convex hull point set until the convex hull point set is an empty set; and IV, obtaining the (N+j)th forwarding node, and stopping broadcasting at the neighbor node in the convex hull point set until the convex hull point set is the empty set. The V2V multi-hop warning broadcasting method disclosed by the invention is applied to the field of multi-hop warning broadcasting for VANETs.

Owner:HARBIN INST OF TECH

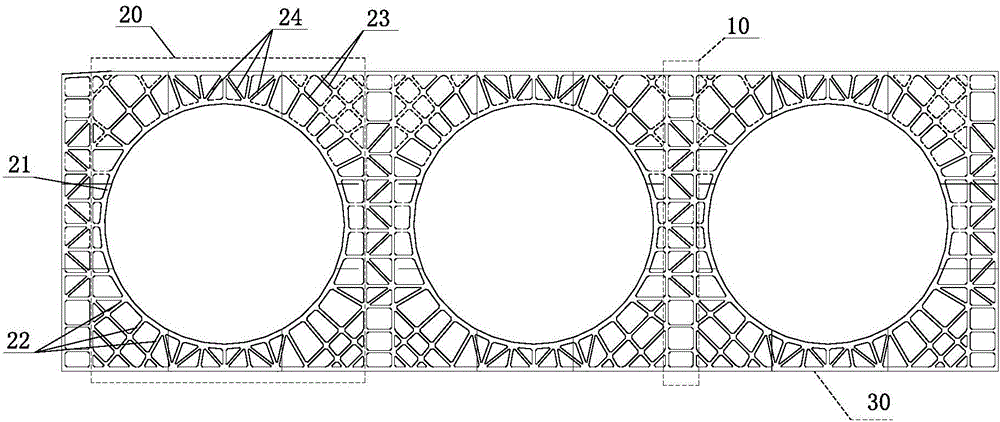

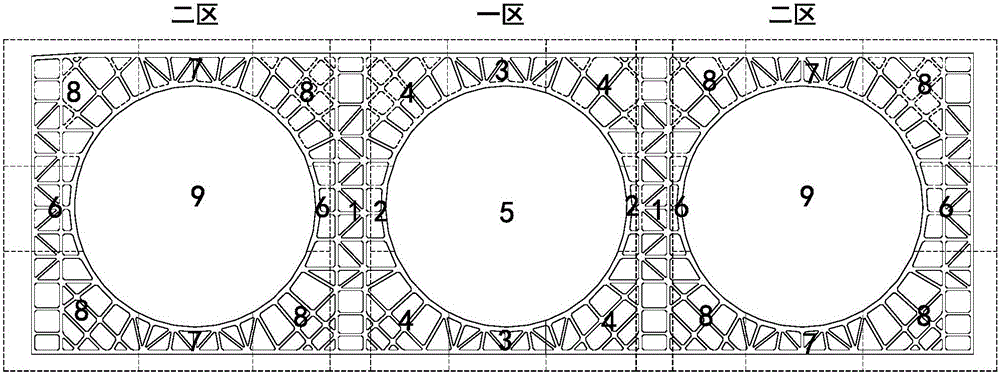

Partitioning supporting structure and method for large, long and deep foundation pit

InactiveCN106013167AImprove construction progressAvoid Staging Wall DemolitionExcavationsTowerBasement floor

The invention discloses a segmented support structure and a support method for long and deep foundation pits. The structure includes a plurality of partition supports that divide the foundation pit into several partitions, and a ring brace is fixed in each partition, and the ring The inner edge of the brace is rounded, and the outer edge of the ring brace matches the edge of the partition in which it is placed. It can realize the one-time excavation of super long and super large foundation pits, which greatly speeds up the construction speed, reduces the waste of labor, materials and time, and meets the development requirements of green construction. And it can effectively reduce the number of internal supports, so that the tower can avoid the construction of the supporting structure. When the basement floor is completed, the tower can be constructed, which speeds up the overall construction progress. Different construction sequences will have an important impact on the deformation of the ring brace and the distribution of internal forces, and the poor control of the roundness of the ring brace will affect the safety of the foundation pit project. , effectively controlling the roundness of the ring brace, thereby improving the safety of the foundation pit project.

Owner:SHANGHAI CONSTR NO 1 GRP

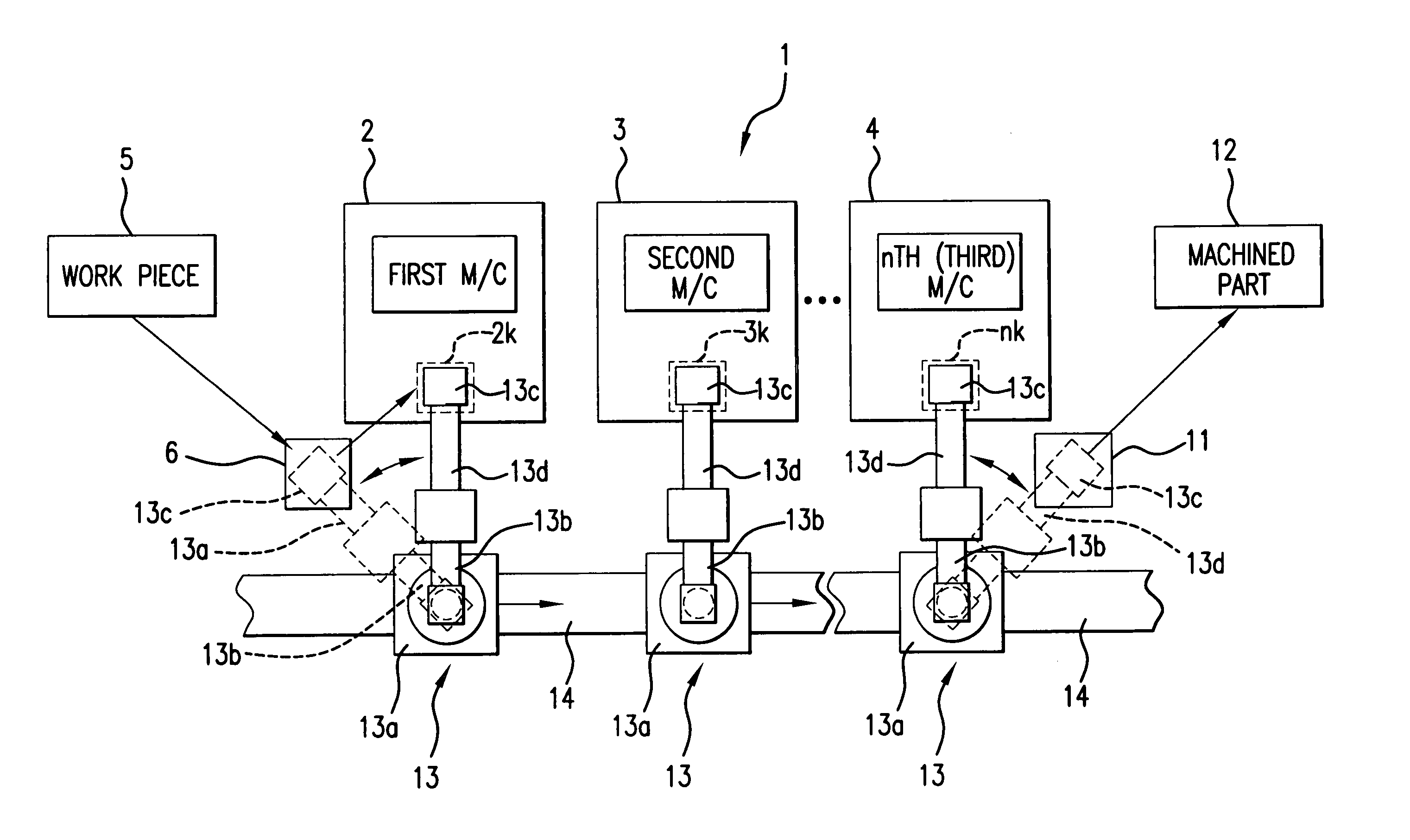

Machining apparatus and machining line provided with same

InactiveUS20050059538A1Efficient executionImprove efficiencyTool changing apparatusMetal working apparatusDrill bitEngineering

A drill fitted to an adapter is used to drill a hole in a workpiece fixed on a table of a machining center. When the hole drilling is finished, the drill is removed from the adapter, and a workpiece holding jig is fitted to the adapter. Then, the adapter is lowered, and the workpiece holding jig takes the workpiece for which the hole drilling operation has been finished. Following this, the adapter is raised, and the workpiece is temporarily held in the machining center. Then, in this state, the next workpiece is mounted on the table of the machining center. Accordingly, by temporarily holding the workpiece, for which the hole drilling operation has been finished, in the machining center, mounting of the next workpiece is simplified.

Owner:AISIN AW CO LTD

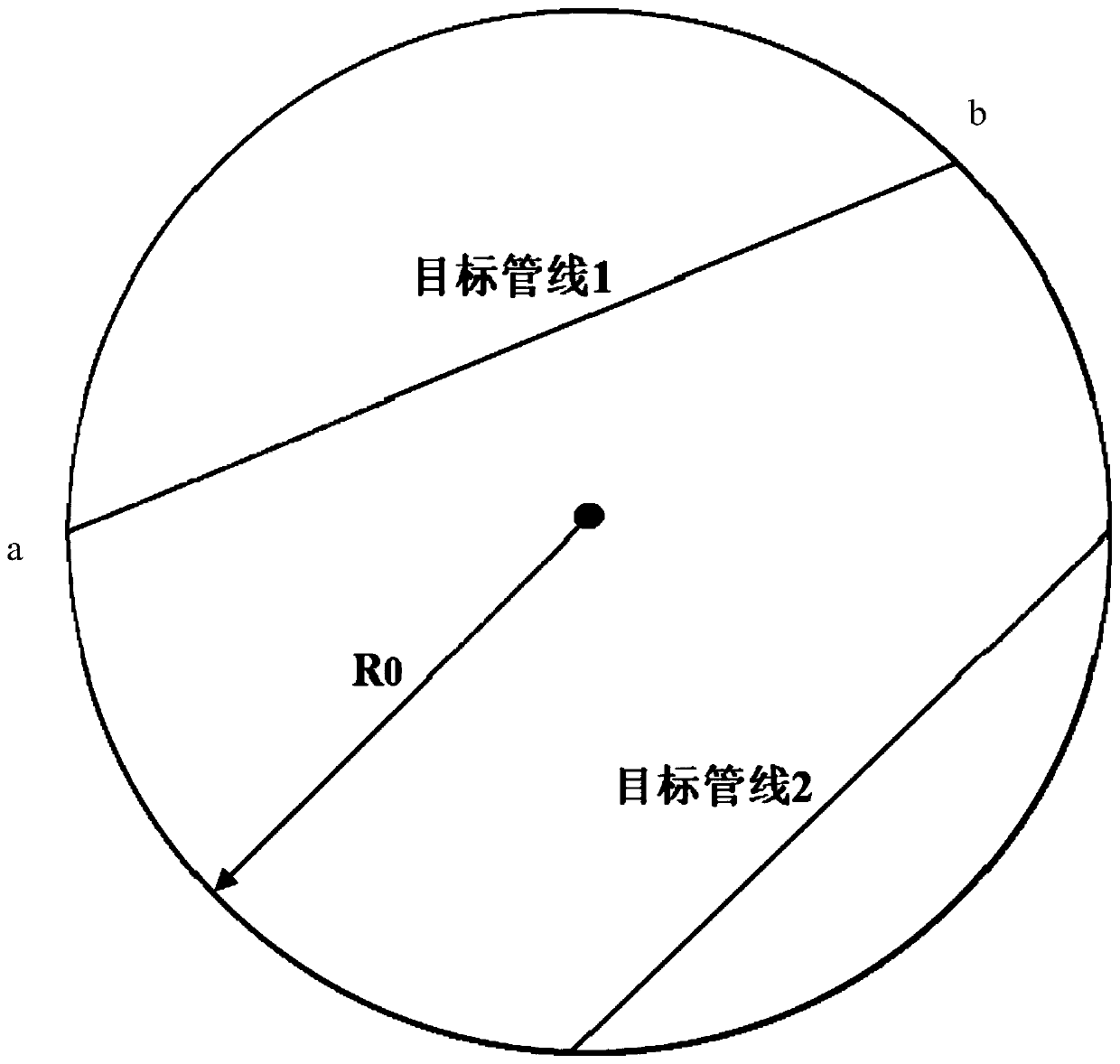

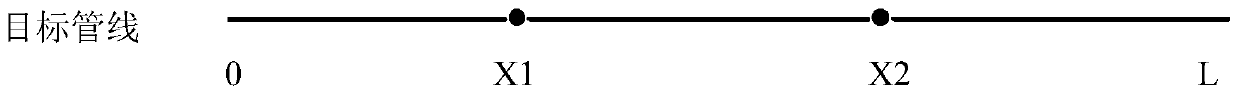

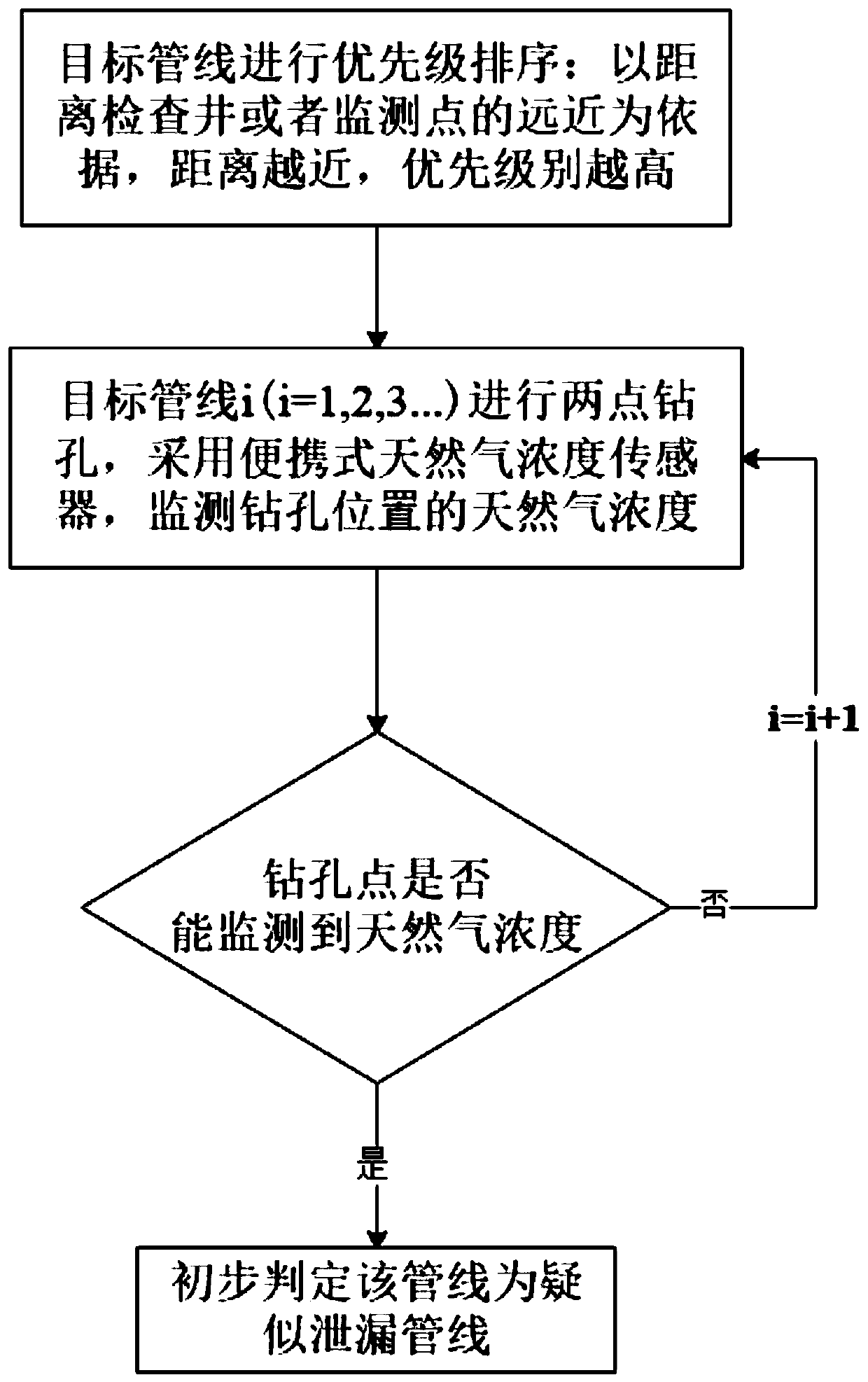

Fuel gas direct-buried pipeline leakage point positioning method based on two-point optimizing tracing

ActiveCN110043806AReduce the number of soil boreholesHigh precisionPipeline systemsProcess engineeringMaterial resources

The invention discloses a fuel gas direct-buried pipeline leakage point positioning method based on two-point optimizing tracing, relates to a fuel gas direct-buried pipeline leakage point positioningmethod and aims to solve the problems that through existing fuel gas pipeline detecting methods, excavation needs to be repeatedly performed on a direct-buried fuel gas pipeline for looking for leakage points, and consequently high manpower and material resources and large economic losses are caused. The process of the fuel gas direct-buried pipeline leakage two-point optimizing tracing positioning method includes the steps that (1) target pipelines which possibly have leakages are determined; (2) the target pipelines which possibly have leakages are screened, and the leakage pipelines are determined; (3) hole drilling and excavation are performed on the ground above the leakage pipelines in sequence through a two-point method; (4) a concentration diffusion mathematical model of leakage of the leakage pipelines is established, and solving is performed; and (5) gradual two-point optimizing is performed on the leakage pipelines for positioning leakage points. The fuel gas direct-buriedpipeline leakage point positioning method based on two-point optimizing tracing is used for the field of fuel gas direct-buried pipeline leakage point positioning.

Owner:HARBIN INST OF TECH

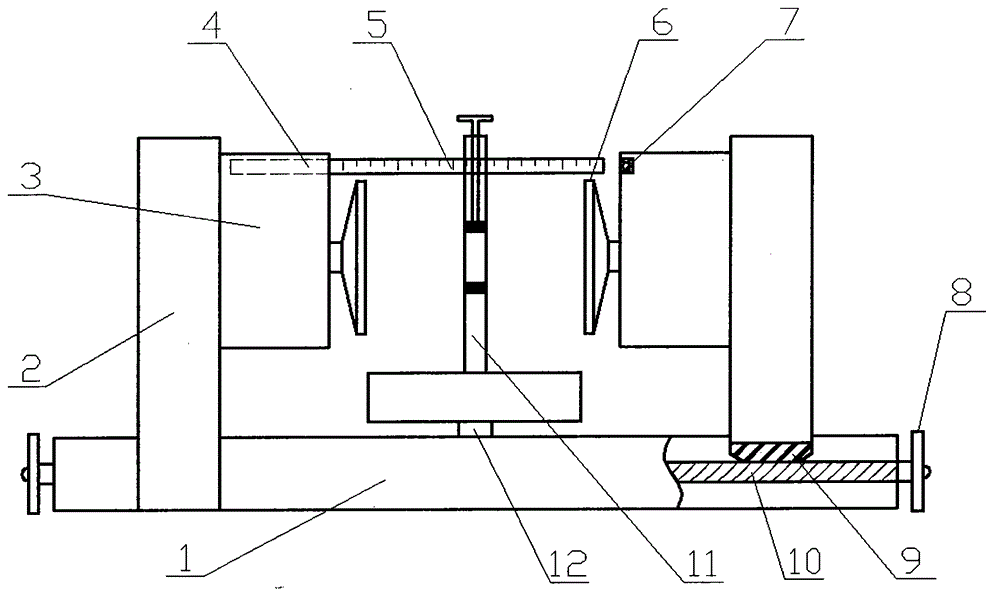

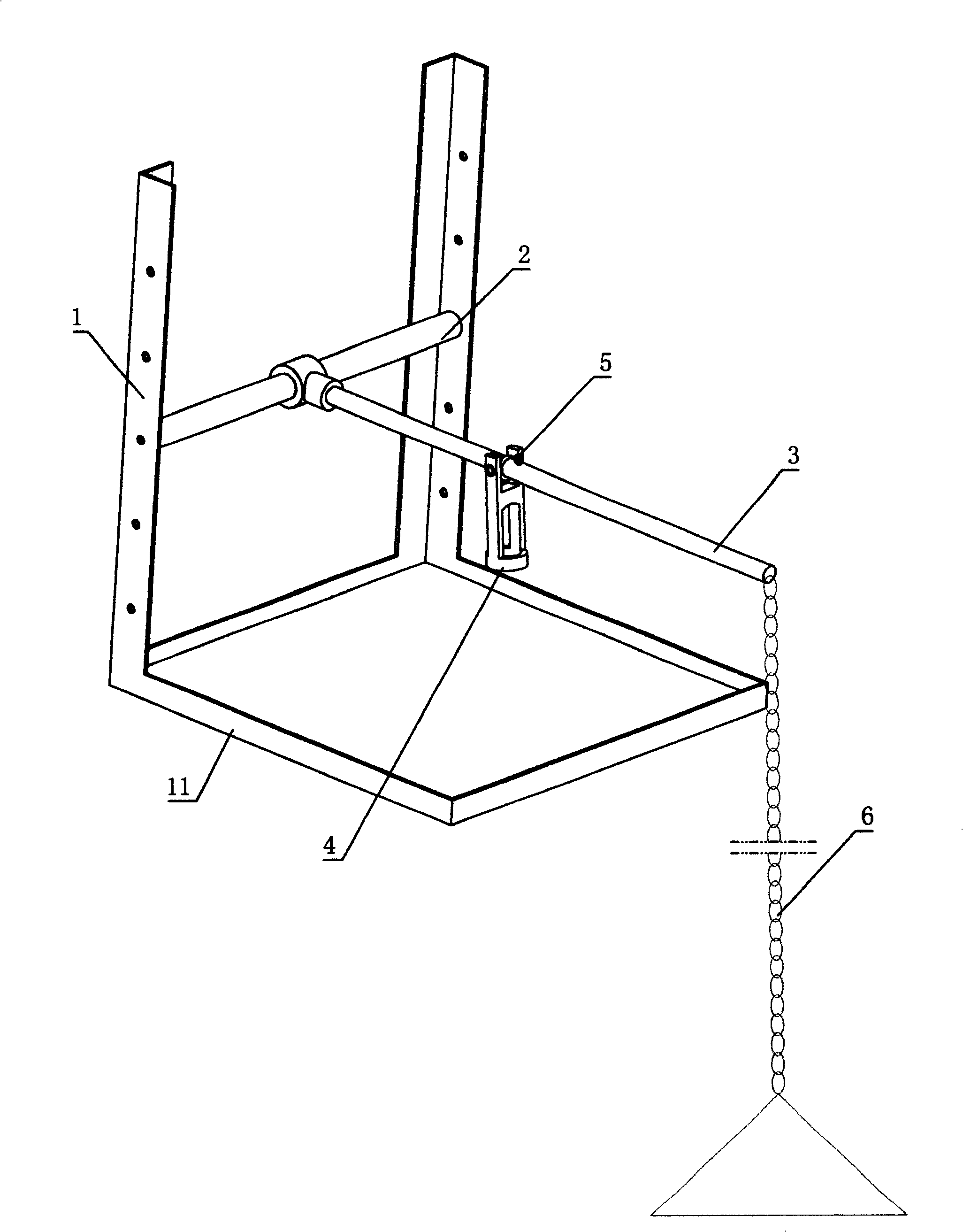

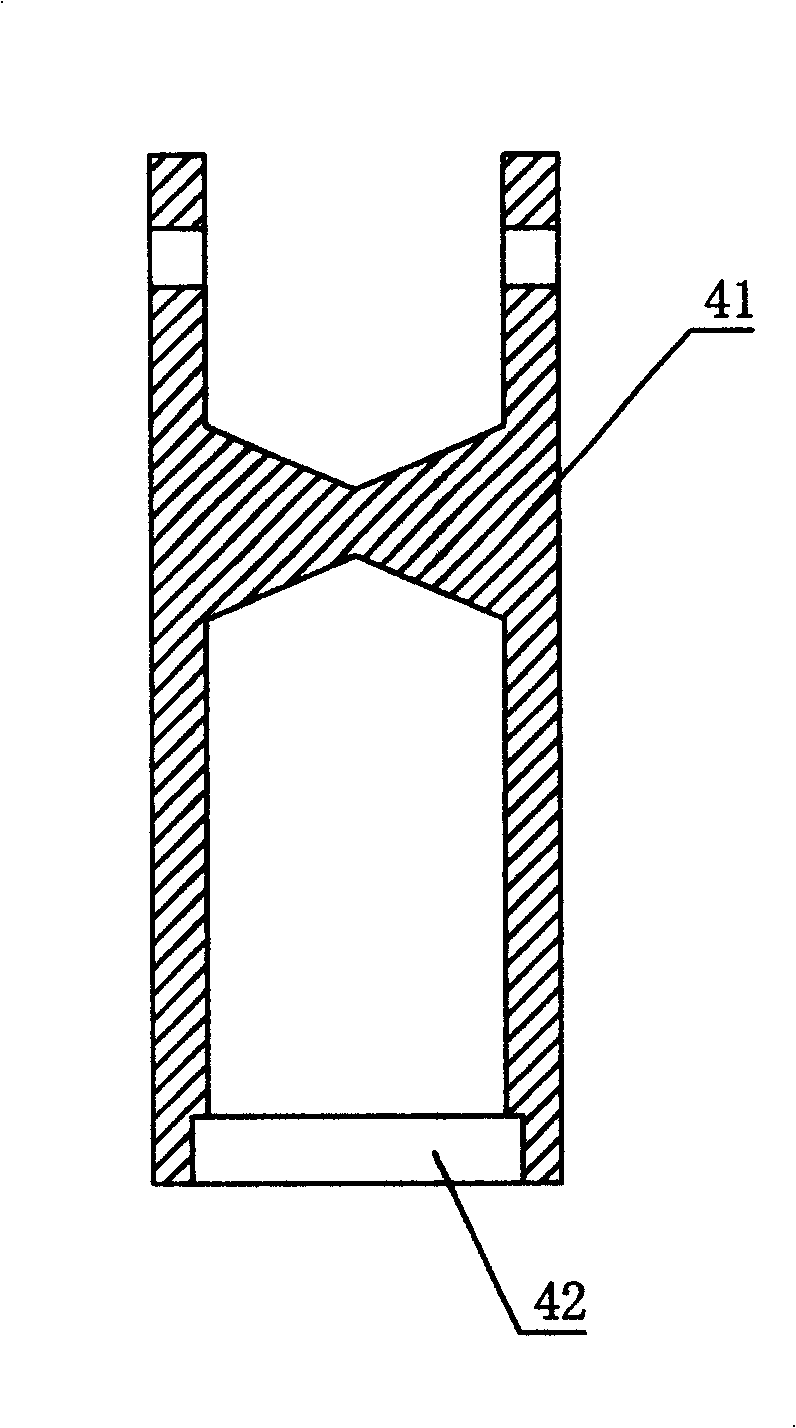

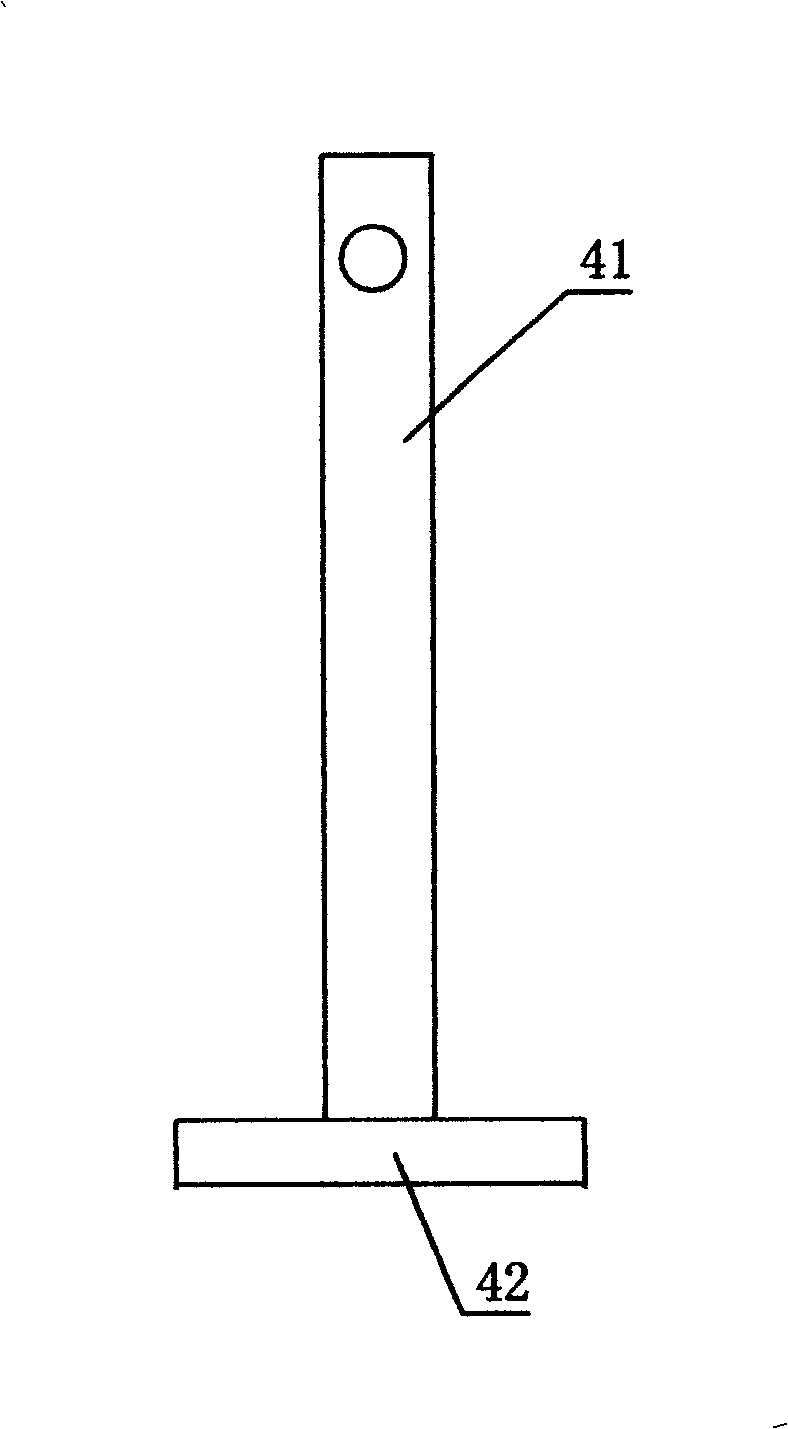

Diesel engine spiracle disassembling and assembling device

InactiveCN101244548AHigh and low position adjustableAvoid displacementMetal-working hand toolsEngineeringMechanical engineering

The invention discloses an assembling and disassembling device of diesel engine valve, comprising a support, the support is provided with a cross rod, on end of a compression bar is arranged on a drive compression bar which is a force application apparatus and rotates by the cross rod as the pivot, the compression bar is provided with a sleeve, the sleeve is articulated with a pressure valve device which can be arranged on the diesel engine valve to compress the valve spring. The assembling and disassembling device of diesel engine valve has the advantages of flexible movement, convenient operation and reducing the waste of manpower and time, improving the efficiency of assembling and disassembling.

Owner:WEICHAI POWER CO LTD

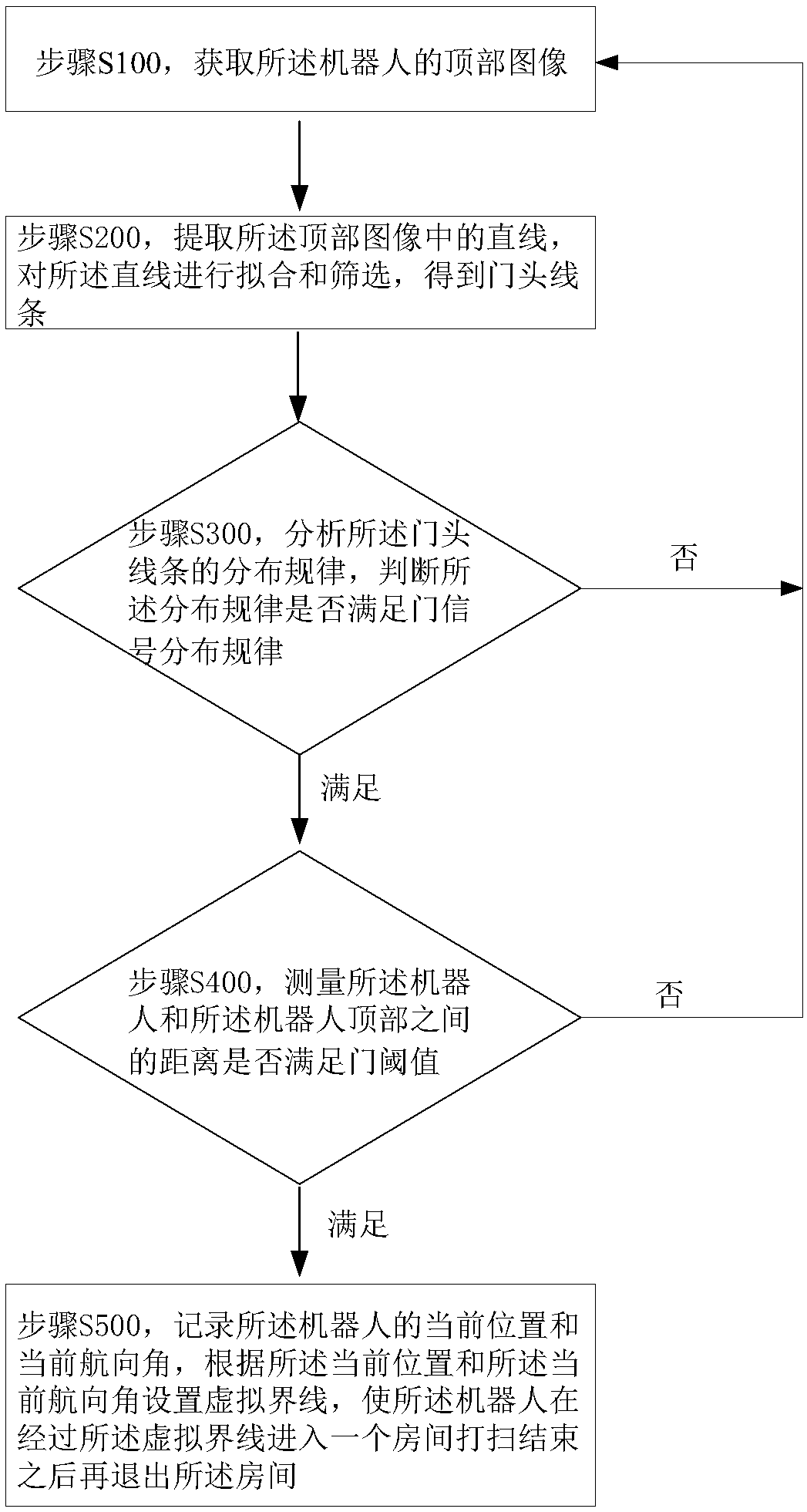

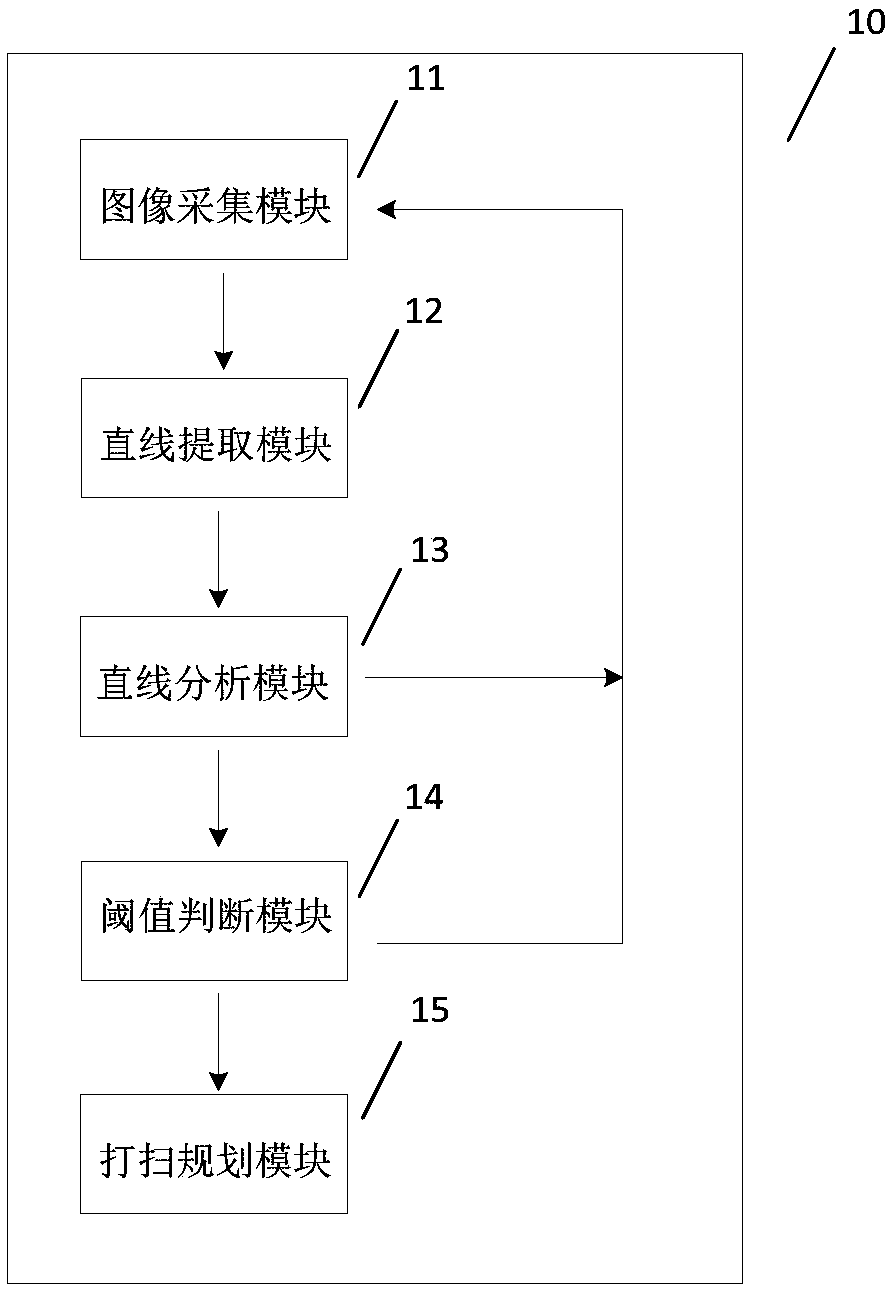

A sweeping robot and the sweeping method

The invention discloses a sweeping robot and the sweeping method. By utilizing the image processing method, the robot is capable of determining whether the door can be passed or not. Combining the measured distance between the robot and the door, the robot is capable of determining comprehensively whether it is being passing through a door currently. When the robot is passing through the door, itis capable of cleaning the second room after the cleaning of the first room through the setting of the virtual boundary, thus saving the wasted traveling time to and from different rooms while cleaning. In addition, the invention also discloses a sweeping robot.

Owner:厦门领贝机器人有限公司

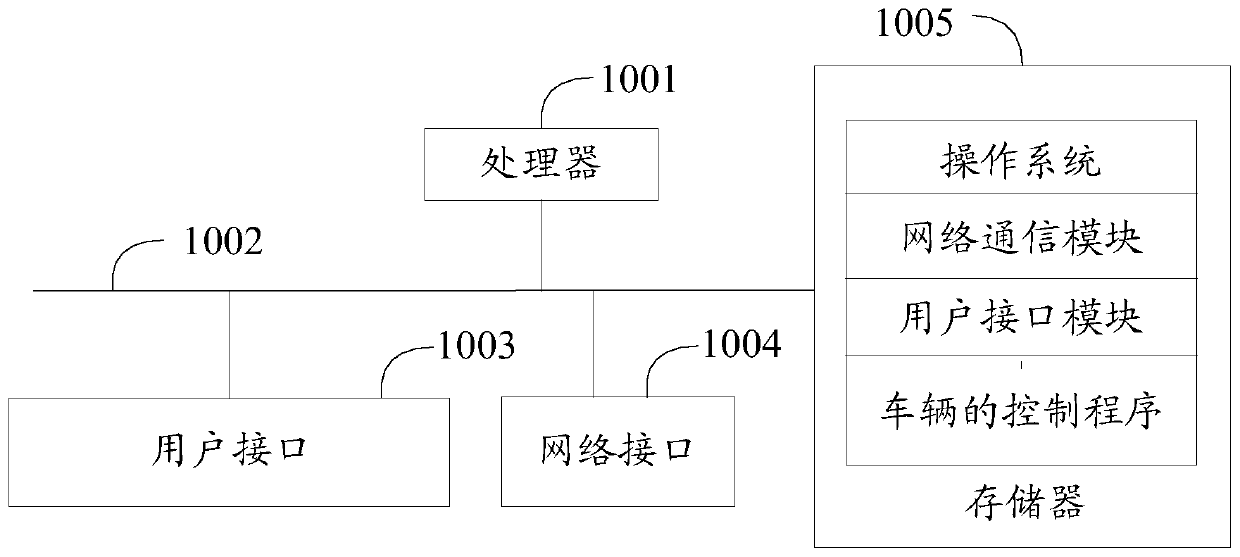

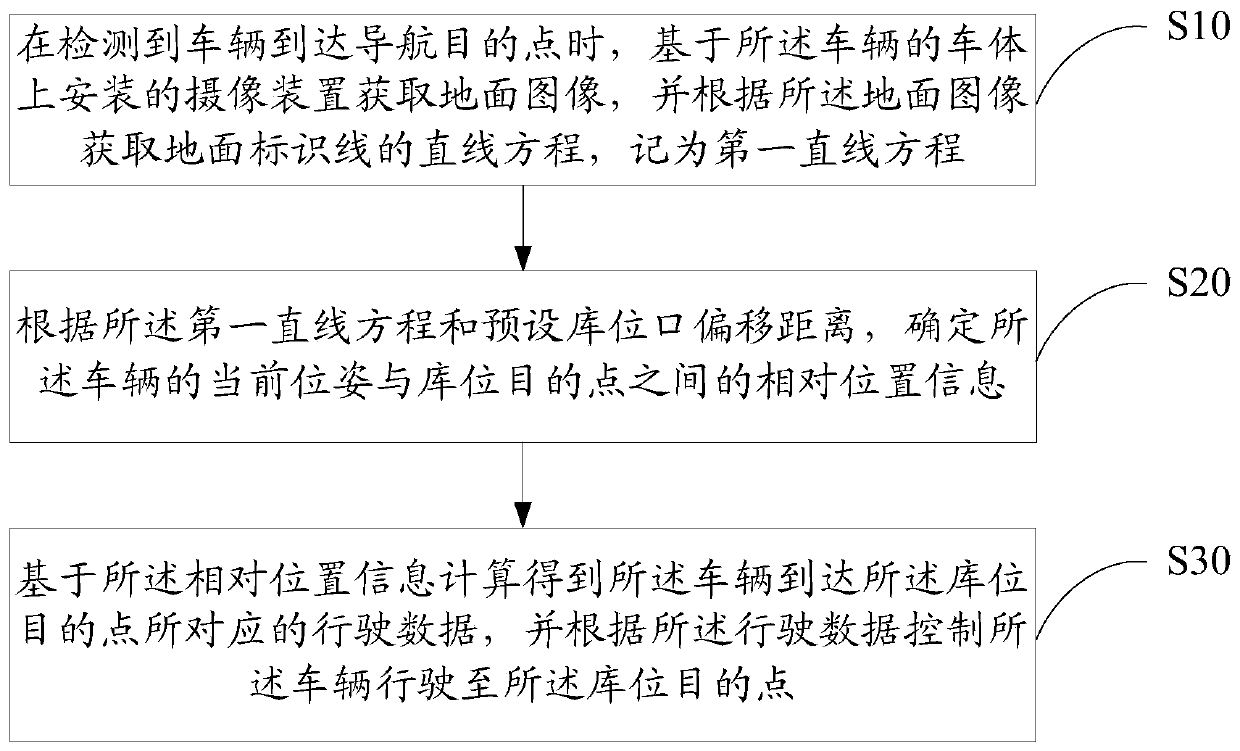

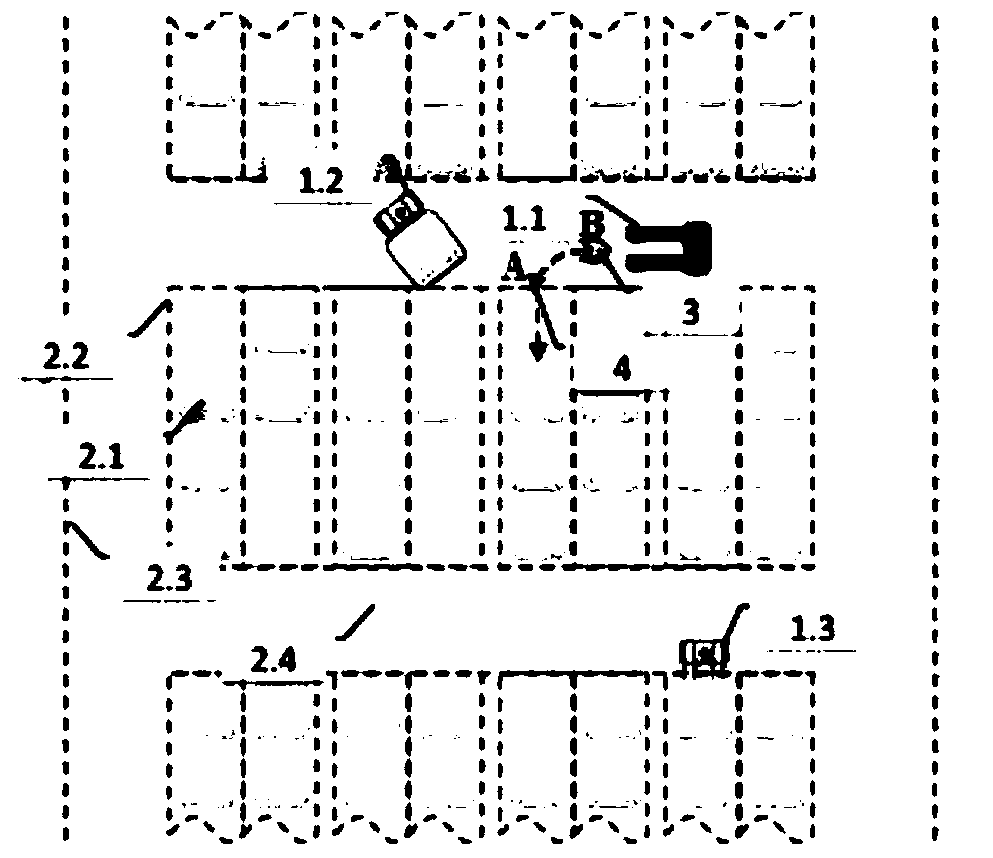

Vehicle control method and device and computer readable storage medium

ActiveCN110789529AImprove work efficiencyHigh precisionInstruments for road network navigationControl devicesData controlComputer science

The invention discloses a vehicle control method. The vehicle control method includes the steps of obtaining a ground image on the basis of a photographing device installed on a vehicle body of a vehicle when it is detected that the vehicle arrives as a navigation destination, obtaining a linear equation of ground marking lines as the first linear equation according to the ground image, determining the relative position information between the current position and orientation of the vehicle and a storage location destination point according to the first linear equation and a preset storage location hole deviation distance, calculating corresponding driving data when the vehicle arrives at the storage location destination point on the basis of the relative position information, and controlling the vehicle to be driven to the storage location destination point according to the driving data. The invention further discloses a vehicle control device and a computer readable storage medium. The problems that the positioning precision of a destination point in existing SLAM positioning is poor and a vehicle cannot be accurately parked can be solved.

Owner:SHENZHEN SKYWORTH DIGITAL TECH CO LTD

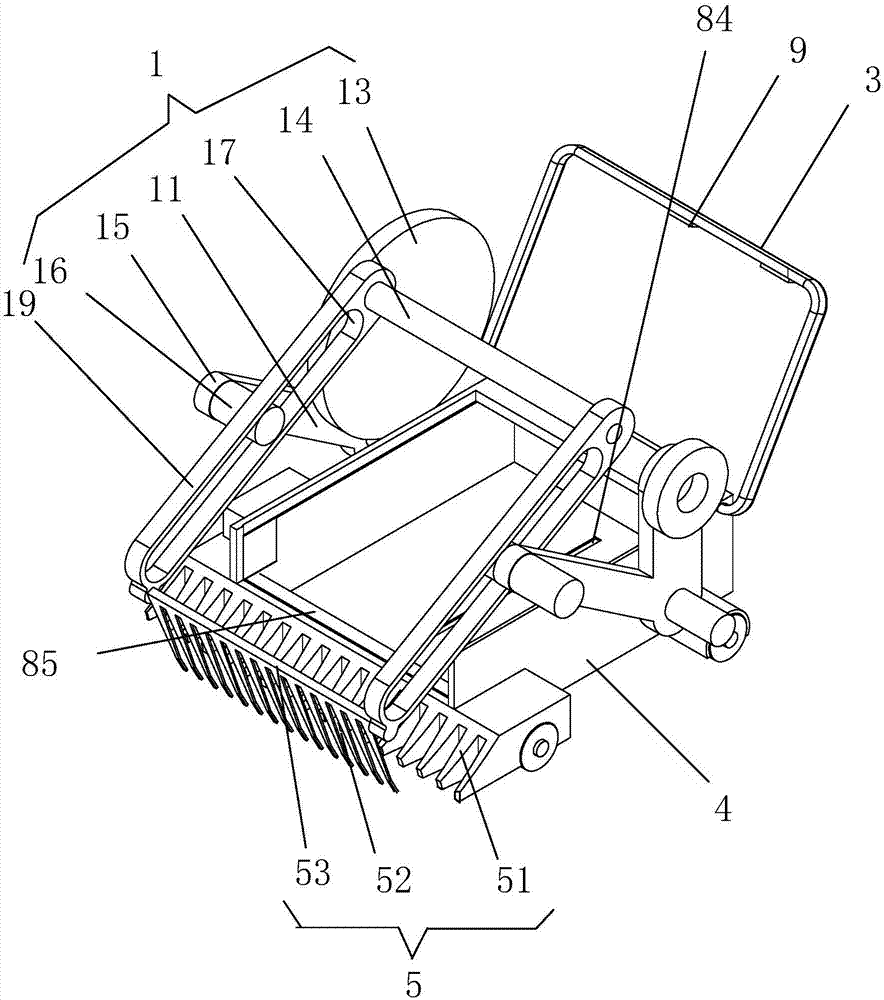

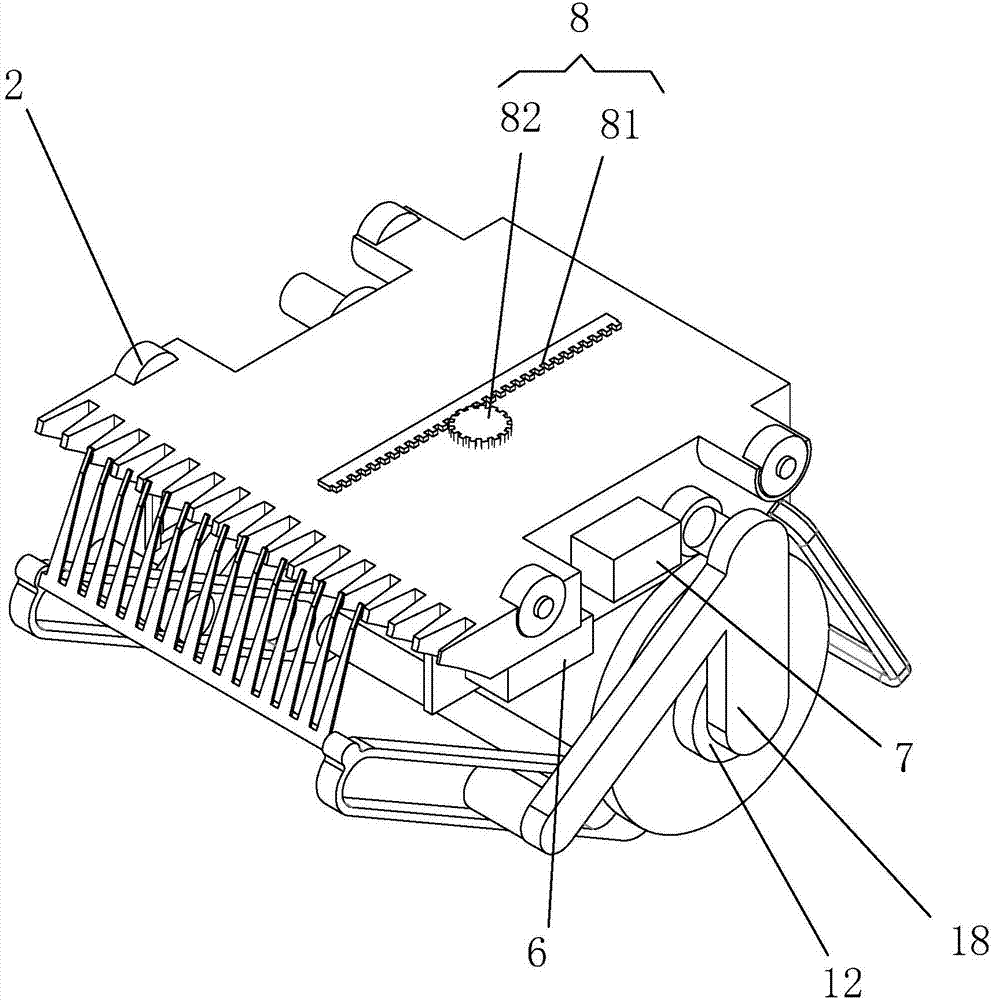

Garden falling leaf sweeping machine

The invention discloses a garden falling leaf sweeping machine comprising a leaf collection carriage. A plurality of moving wheels are arranged on the lower surface of the leaf collection carriage. Anoperation handle is connected to the rear wall face of the leaf collection carriage. The garden falling leaf sweeping machine is characterized in that power devices are arranged on the two sides of the leaf collection carriage; a sweeping device is connected to the front ends of the power devices; and a compressing device is arranged in the leaf collection carriage. The garden falling leaf sweeping machine can complete sweeping work automatically, so that time and labor force waste of sanitation personnel is reduced; falling leaves can be squeezed automatically after being collected, so thatthe collection capacity for the falling leaves is increased; and the garden falling leaf sweeping machine is simple in structure and convenient to use.

Owner:ZHONGSHAN NUODUN SCI RES TECH SERVICE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com