Planning method of motion path of wafer cutting machine tool

A technology for cutting machine tools and motion paths, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of wasting deceleration and restarting time, low work efficiency, etc., saving time, improving efficiency, and reducing waste. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

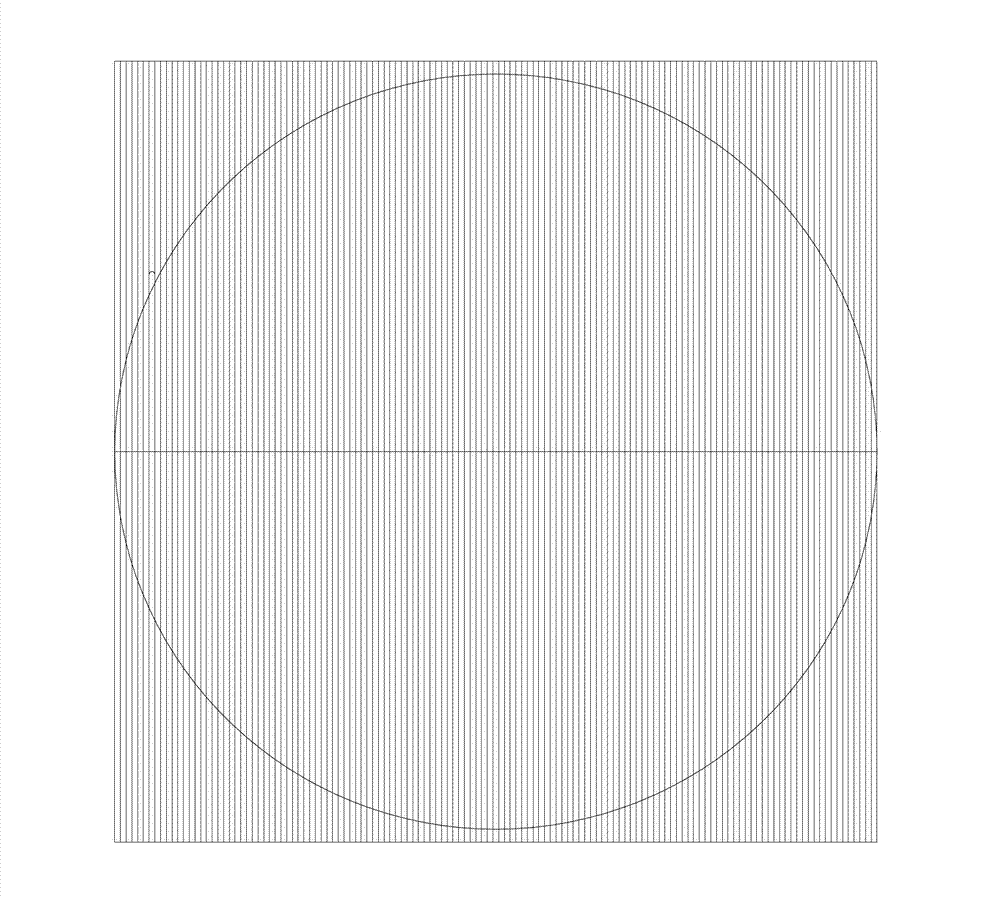

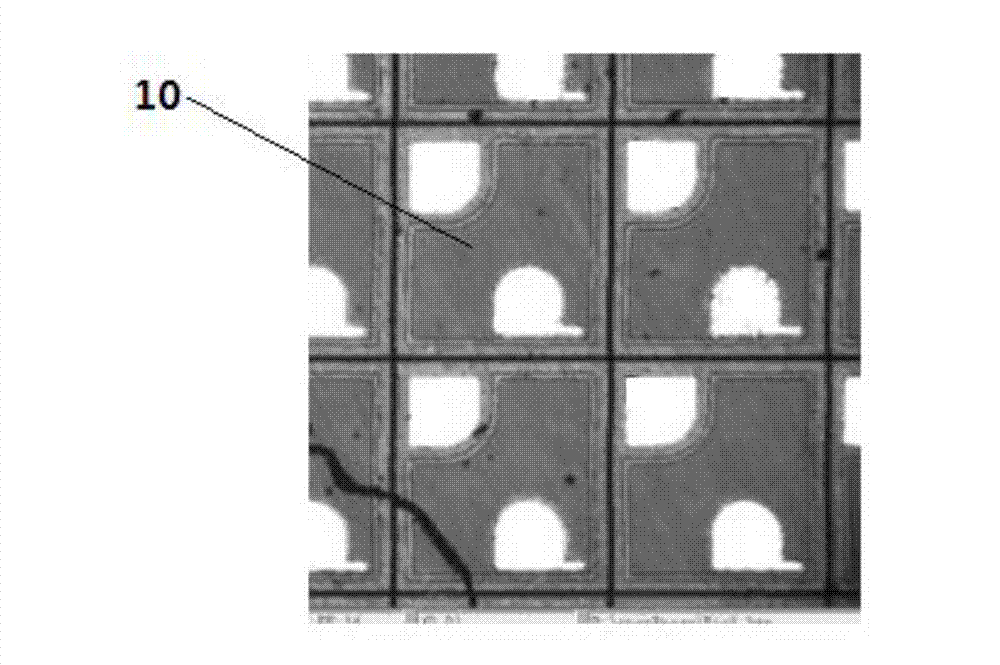

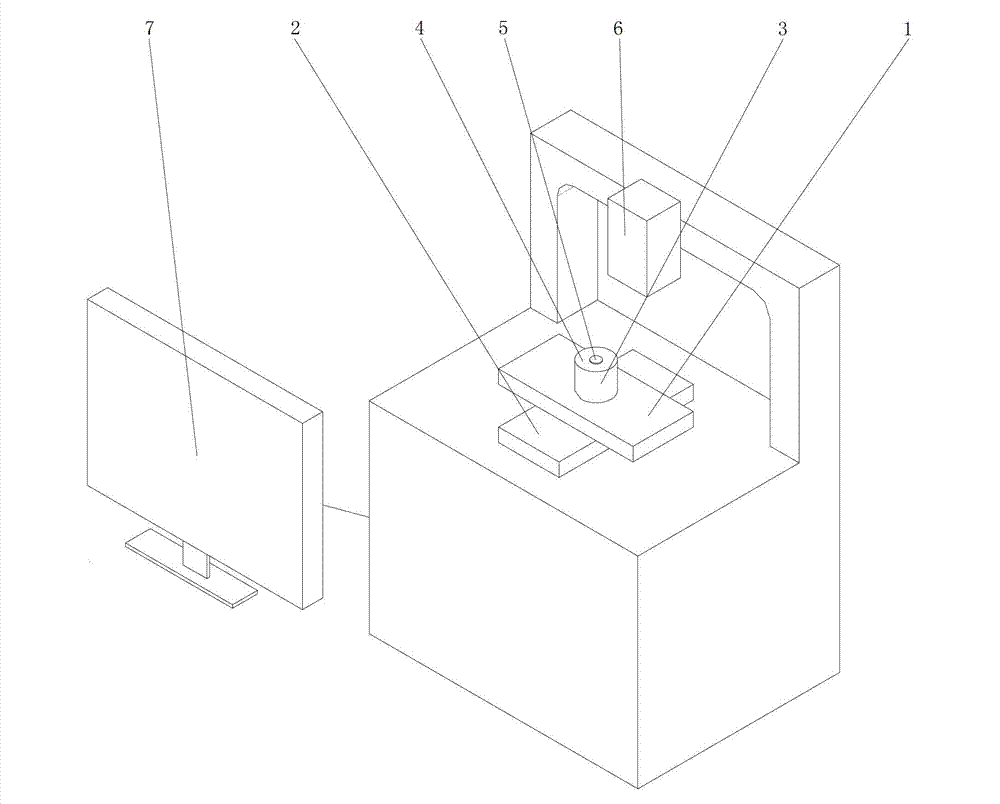

[0031] Such as Figure 3-7 As shown, a method for planning the movement path of a wafer cutting machine tool in the present invention, the wafer cutting machine tool used in the planning method includes X, Y axis motor motion platforms 1, 2, X, Y axis motor motion platforms 1, 2 A rotating motor platform 3 is provided, and a worktable 4 is arranged on the rotating motor platform 3. The wafer 5 is fixed on the workbench 4. A fixed laser 6 is arranged above the workbench 4. The laser beam emitted by the laser 6 is The wafer 5 on the quasi-workbench, the wafer cutting machine tool also includes a controller 7 with a CPU, the controller 7 is electrically connected to the X and Y axis motor movement platforms 1, 2, and the rotating motor platform 3 respectively, and the controller 7. Wafer processing parameters are pre-stored in it;

[0032] The planning method of the present invention comprises the following steps:

[0033] 1) When the wafer 5 is cut, input the processing parame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com