Diesel engine spiracle disassembling and assembling device

A diesel engine and door device technology, applied in the direction of hand-held tools, manufacturing tools, etc., can solve the problems of troublesome, time-consuming and labor-intensive, and low efficiency of diesel engine valve mechanism disassembly and assembly, and achieve convenient use, reduce manpower and time waste, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

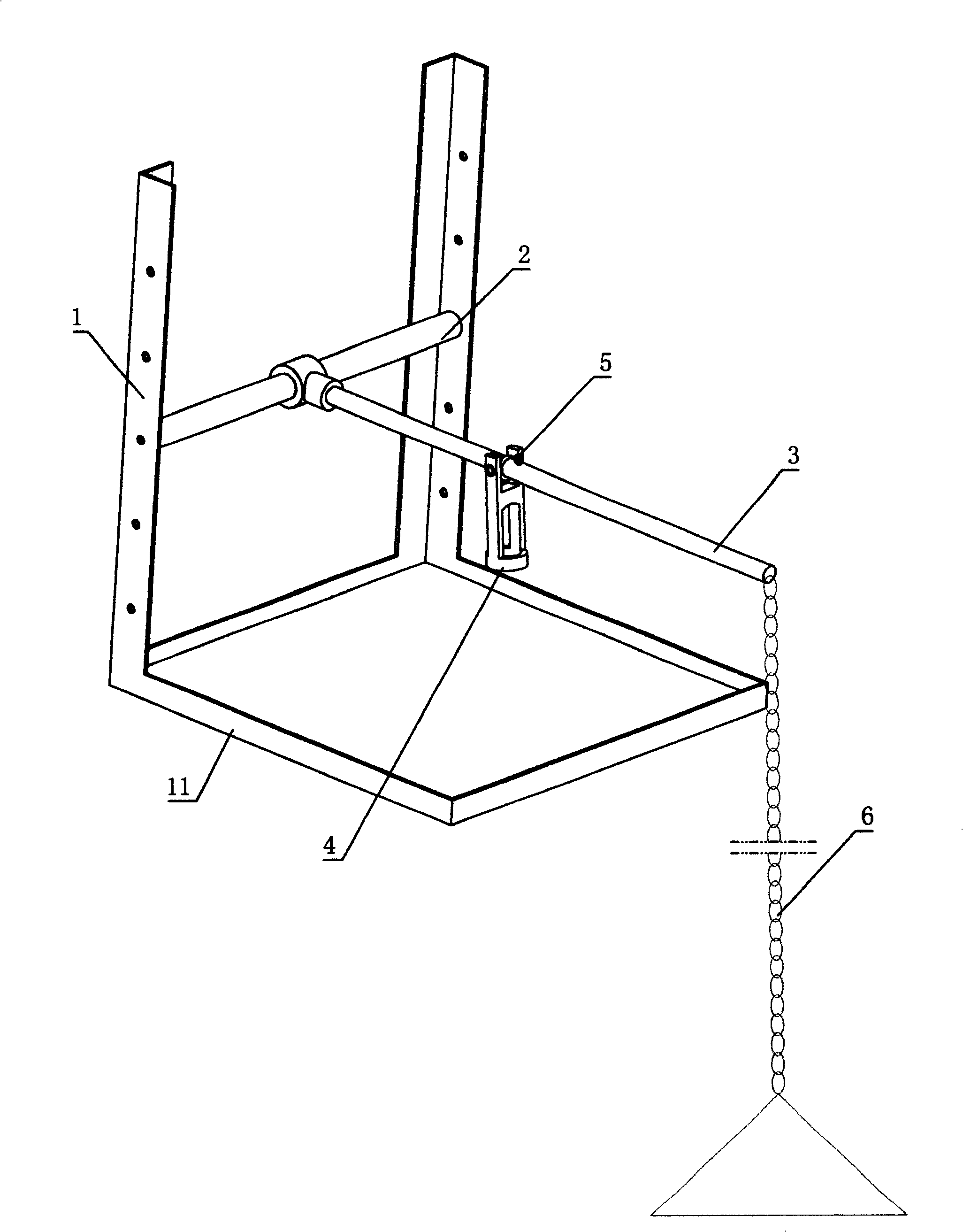

[0015] Such as figure 1 As shown, the diesel engine valve disassembly device includes a bracket 1. In order to facilitate the use of the device on the diesel engine cylinder head, the bracket 1 is provided with a base 11 that can place the valve disassembly device on the diesel engine cylinder head. There is a cross bar 2 on the top, the cross bar 2 can be fixed on the bracket 1 by bolts, and the height position of the cross bar 2 can be adjusted according to the needs of actual operation, one end of the pressure bar 3 is set on the cross bar 2 and the other end There is a force application device 6 that drives the pressure bar 3 to pivot on the cross bar 2, and the pressure bar 3 can slide on the cross bar 2 to facilitate adjustment when disassembling the valve mechanism, while the force application device 6 can A chain is provided at the end of the pressure rod 3, and a pedal is connected to the chain. When in use, the operator can step on the pedal to drive the pressure rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com