Integrated forming device for plastic processing

A molding device and plastic technology, applied in metal processing, separating solids from solids with airflow, solid separation, etc., can solve problems such as dust and impurities treatment, and achieve the effect of controlling the feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

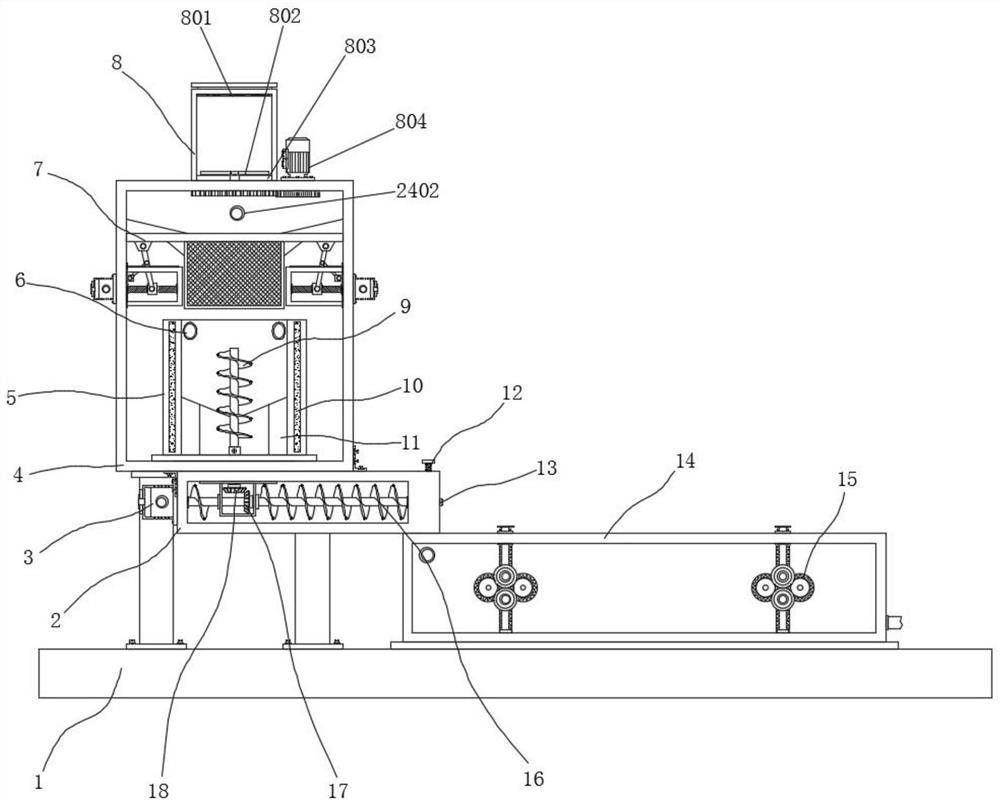

[0045] Example 1: See Figure 1-6 , an integrated molding device for plastic processing, including a base 1, a box body 2, a shell 4 and a water tank 14, one side of the top of the base 1 is fixedly connected with a shell 4, and the bottom end of the inside of the shell 4 is fixedly connected with a cylinder body 5, a heating block 10 is arranged on the inner side of the outside of the cylinder body 5, the bottom end of the cylinder body 5 is fixedly connected with a tapered groove 11, and the inside of the tapered groove 11 is movably connected with a vertical screw rod 9, and the bottom of the vertical screw rod 9 The end is fixedly connected with the second gear 18, the bottom outside the base 1 is fixedly connected with the box body 2, and the side outside the box body 2 is fixedly connected with the first motor 3, the model of the first motor 3 can be ECMA-C20401ES, the box The two sides inside the body 2 are movably connected with a horizontal screw rod 16, one side of t...

Embodiment 2

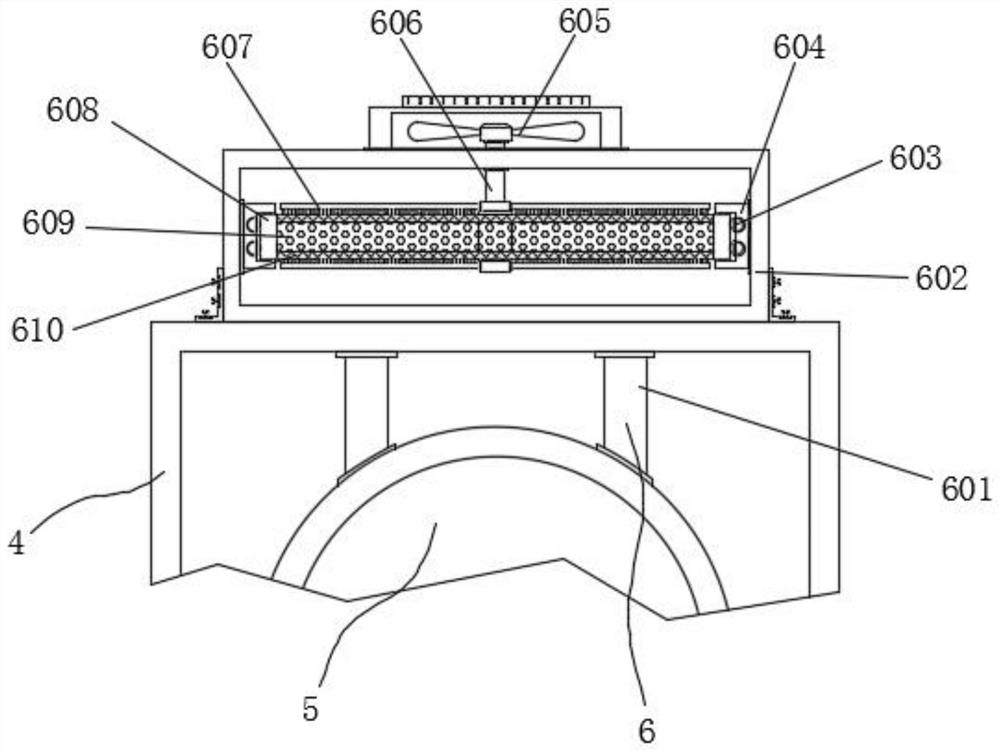

[0048] Embodiment 2: The filter mechanism 6 is composed of a connecting pipe 601, a gas collecting box 602, a sliding ball 603, a card slot 604, a negative pressure fan 605, a rotating shaft 606, a brush rod 607, a hollow plate 608, activated carbon particles 609 and a filter screen 610, The gas collection box 602 is fixedly connected to one end of the outer shell 4, the two sides between the gas collection box 602 and one end of the cylinder body 5 are respectively fixedly connected with connecting pipes 601, and the two sides inside the gas collection box 602 are respectively fixedly connected with card slots 604, two sets of sliding balls 603 are arranged on one side of the slot 604, and a hollow plate 608 is movably connected between one side of the slot 604, and filter screens 610 are respectively arranged at both ends of the hollow plate 608, and the hollow plate 608 There are activated carbon particles 609 inside, and a negative pressure fan 605 is fixedly connected to t...

Embodiment 3

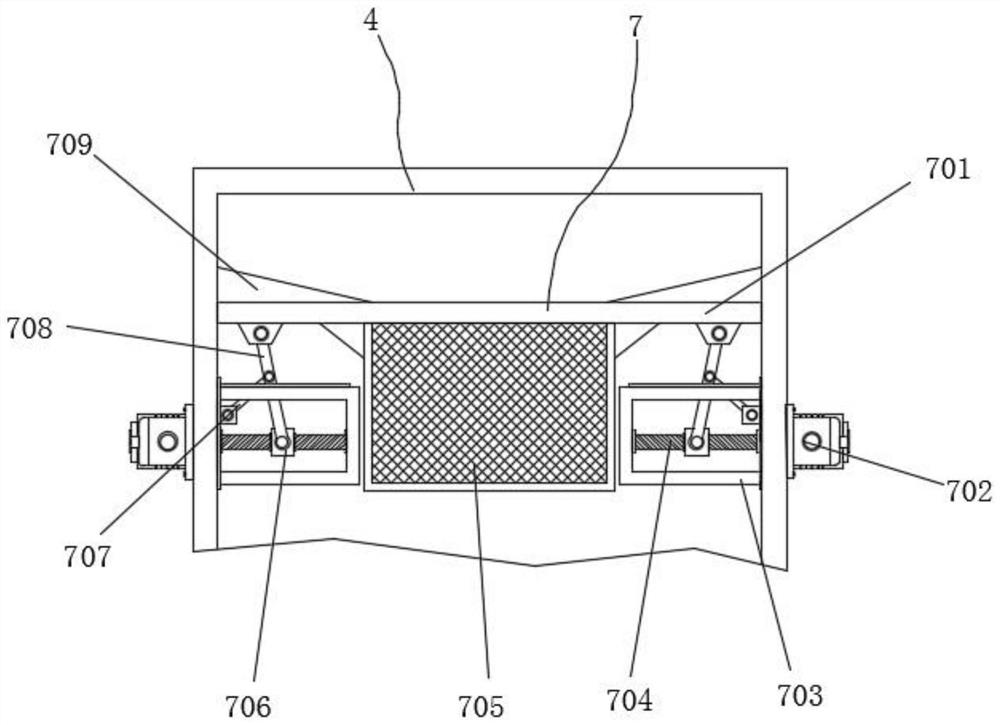

[0051] Embodiment 3: The screening mechanism 7 is composed of a horizontal plate 701, a second motor 702, an installation groove 703, a screw rod 704, a screen frame 705, a threaded block 706, a hinged rod 707, a support rod 708 and a magnet 709, and the installation grooves 703 are respectively fixed Connected to the top of both sides inside the housing 4, a screw 704 is movably connected between the two sides inside the installation groove 703, and one side of the screw 704 passes through the housing 4 and is fixedly connected to a second motor 702, the model of the second motor 702 It can be ECMA-C20804R7. The outer side of the screw rod 704 is movably connected with a threaded block 706, and the inside of the installation groove 703 is provided with a horizontal plate 701. The bottom end of the horizontal plate 701 is fixedly connected with a screen frame 705. Between the threaded block 706 and the horizontal plate 701 The two ends on both sides are respectively movably con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com