Multi-layer type water curtain spraying chamber

A multi-layer, spray booth technology, applied in the direction of coating, spraying device, device for coating liquid on the surface, etc., can solve problems such as adhesion, inconvenient maintenance, loose structure, etc., achieve good treatment effect, convenient maintenance, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

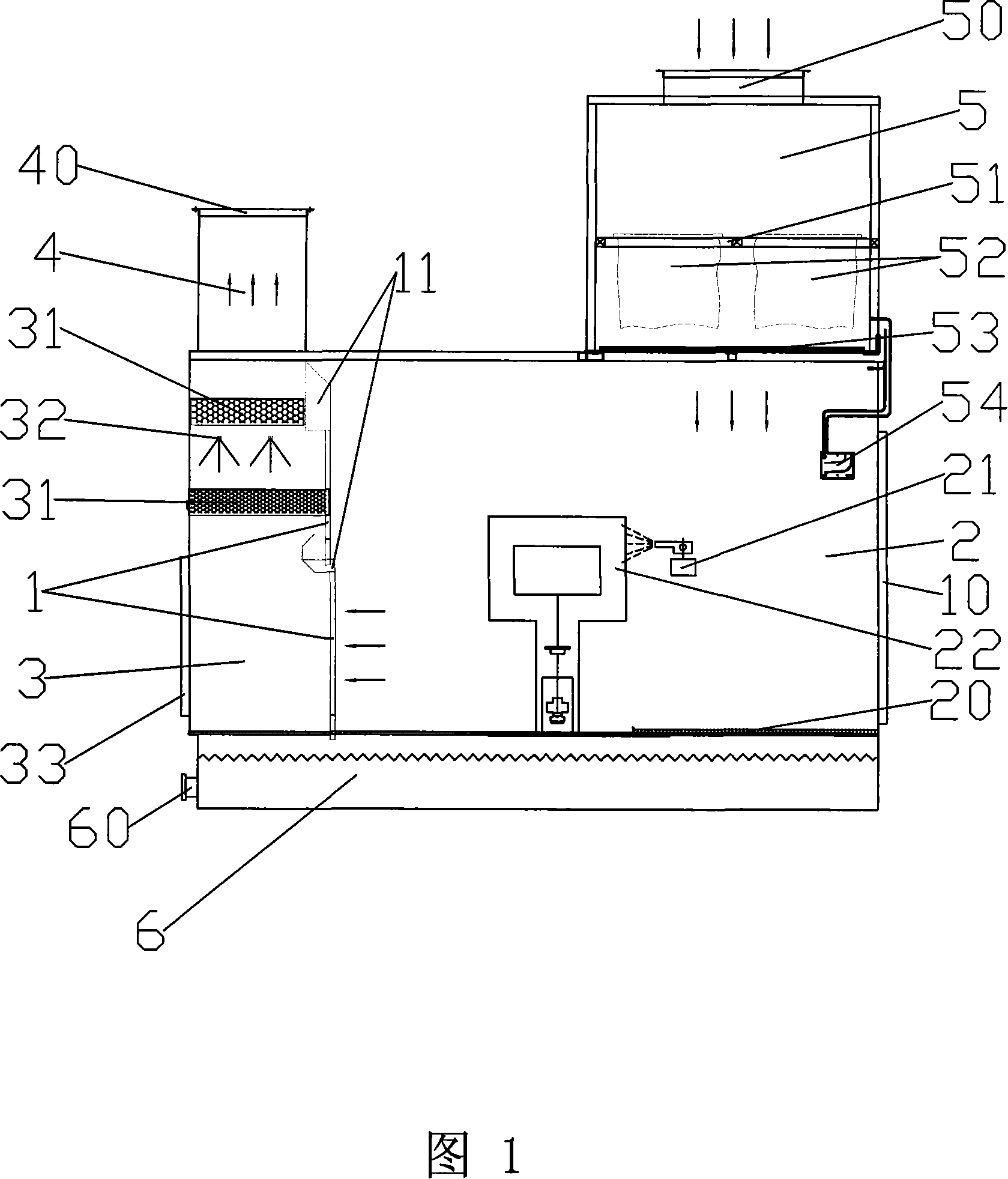

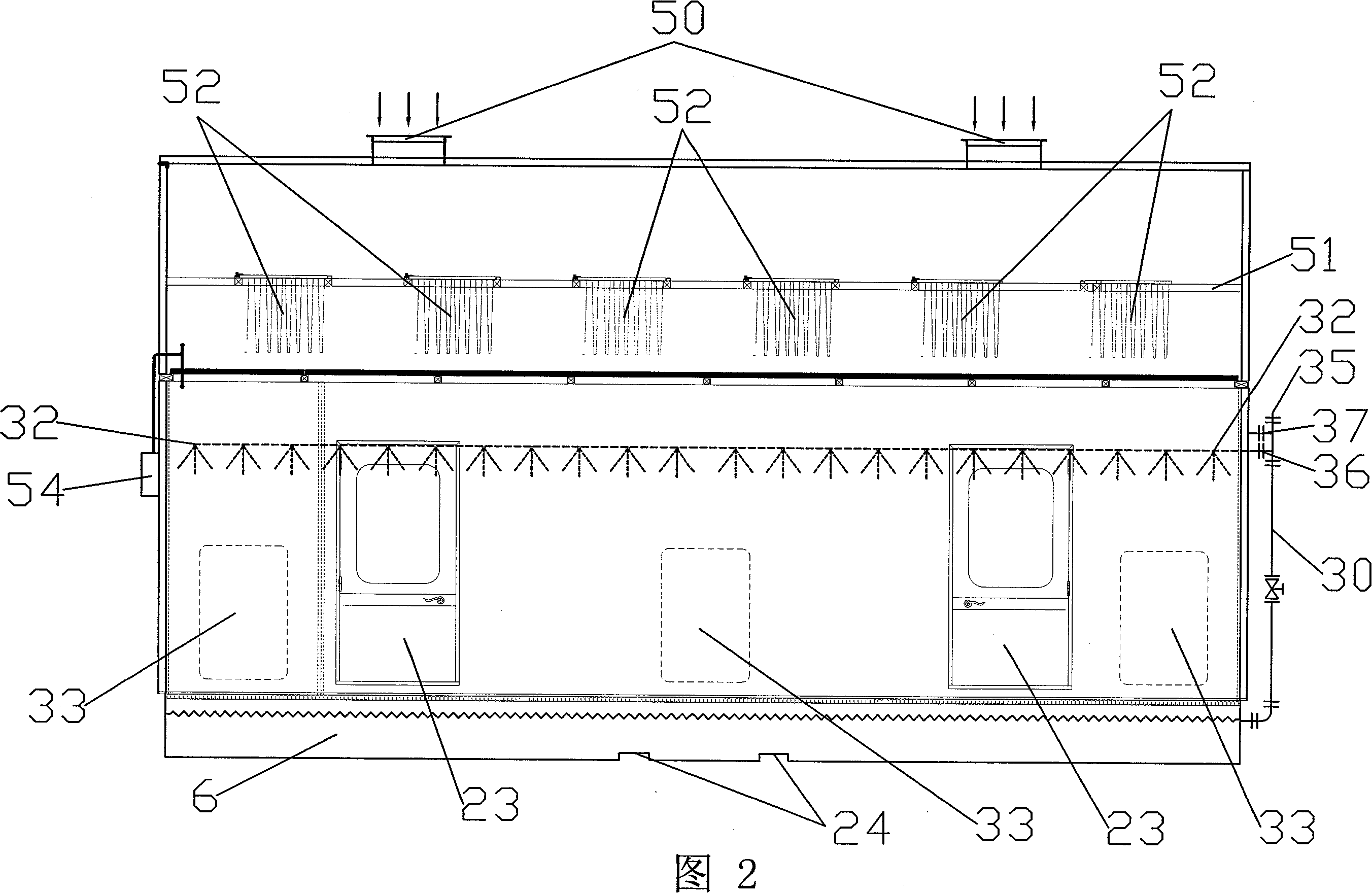

[0017] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, the present invention provides a kind of multi-layer water curtain spray booth, and described spray booth comprises that the spray booth is divided into the front spray operation area and the rear paint mist treatment area with the water curtain plate as the boundary, the whole A water tank is installed at the bottom of the spray booth, and an air outlet is provided on the upper part of the paint mist treatment area. The paint mist treatment area adopts glue filter and sprinkler nozzles to treat the paint mist, and separates the particles in the scattered paint mist from water and air. , so that the exhaust gas in the exhaust port contains less polluting impurities, so the spray booth paint mist treatment device has high dust removal efficiency and good effect, and the whole spray booth is low in cost, si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com