Processing method for back cover, back cover and electronic equipment

A processing method and technology for semi-finished products, which are applied in metal processing equipment, chassis/cabinet/drawer parts, metal casings, etc. effect, cost saving, effect of reducing processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

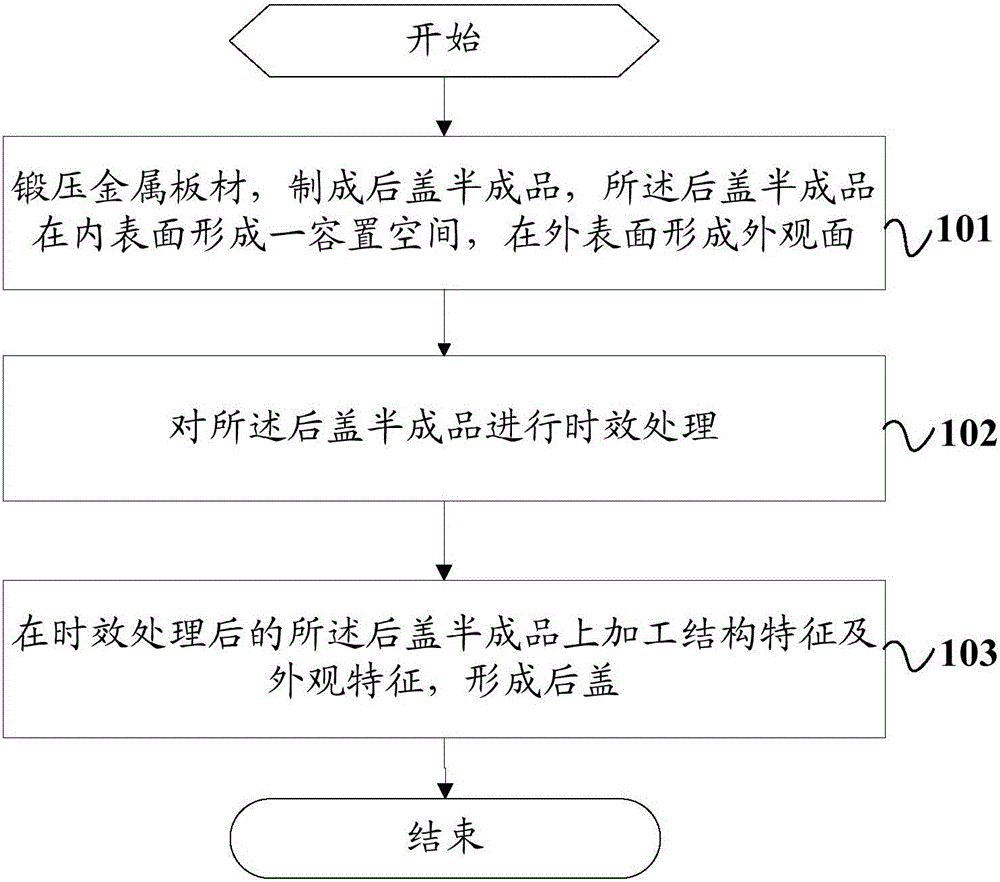

[0022] An embodiment of the present invention provides a method for processing a rear cover, combining figure 1 As shown, the processing method includes:

[0023] Step 101: Forging and pressing the metal plate to make a semi-finished back cover, the semi-finished back cover forms an accommodating space on the inner surface, and forms an appearance surface on the outer surface.

[0024] Wherein, the metal plate is made by extruding the metal blank. The metal sheet is preferably an aluminum alloy sheet. First, the metal sheet is forged and drawn according to the preset size to form the internal cavity size required by the rear cover, so as to form an accommodating space on the inner surface that can accommodate other components for installation and externally. The surface forms the exterior surface of the back cover semi-finished product.

[0025] Wherein, the manufacturing and forming process of the metal sheet is as follows: extruding the metal profile embryo to form a metal...

no. 2 example

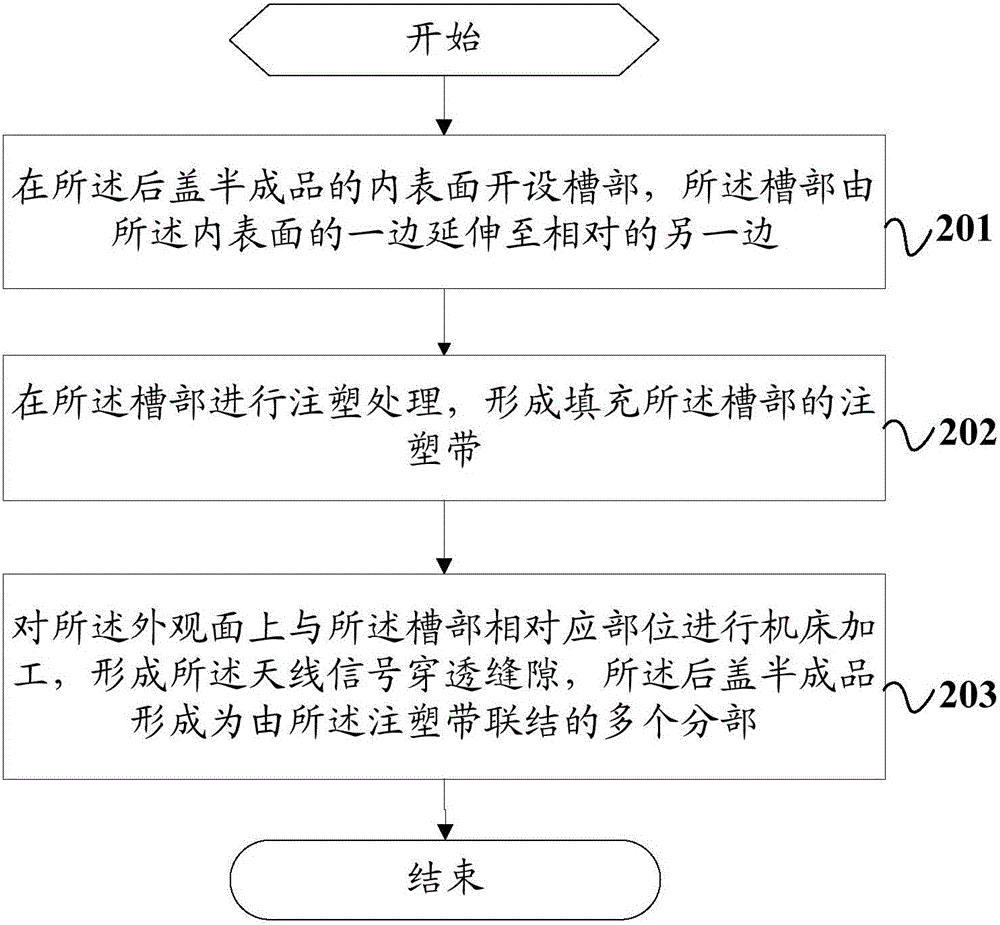

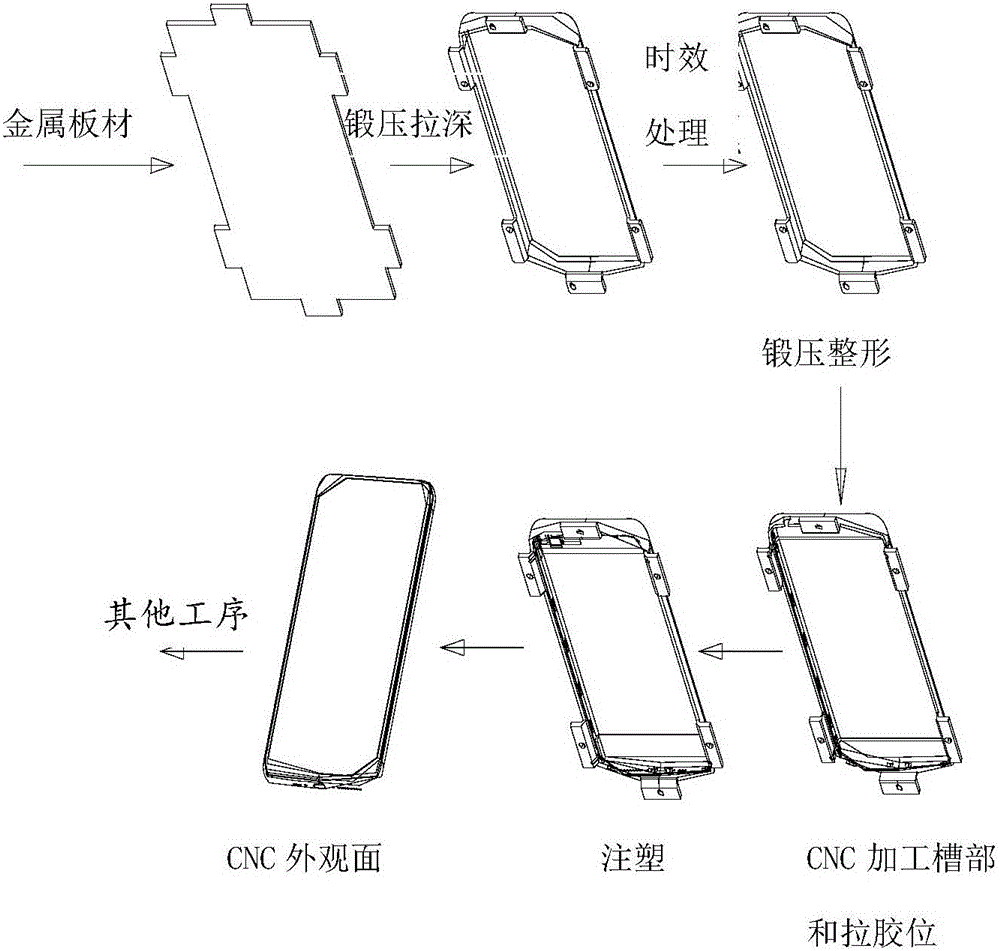

[0033] Further, combine image 3 As shown, a kind of processing method of back cover is provided in the present embodiment, and this method comprises:

[0034] Forging a metal plate to make a semi-finished back cover, the semi-finished back cover forms an accommodating space on the inner surface, and forms an appearance surface on the outer surface, wherein the metal plate is made by extruding a metal blank; The semi-finished back cover is subjected to aging treatment; the structural features and appearance features are processed on the semi-finished back cover after the aging treatment to form the back cover.

[0035] In the following, further descriptions will be made on the implementation steps further involved in the above method, and preferred implementation manners in the related steps.

[0036] Specifically, the structural features include antenna signal penetration slots for cooperating with the antenna installation and functioning. The back cover usually made of met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com