Paracoccus sp. and culture application thereof

A paracoccus and liquid culture medium technology, applied in the field of environmental microorganisms, can solve the problems that Paracoccus does not have salt tolerance, is not suitable for high-salt wastewater treatment, and has high production costs, maintains growth characteristics and tolerance characteristics, and improves The effect of wastewater treatment and the effect of reducing cultivation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0028] Embodiment 2 screening and separation and purification

[0029] The activated sludge obtained from a petrochemical enterprise in Yueyang City, Hunan Province for the treatment of epichlorohydrin production wastewater was domesticated and cultivated for 15 days by gradually increasing the salt concentration in the culture medium.

[0030] The above-mentioned domesticated activated sludge was taken, and the method of dilution coating was used for preliminary separation in the enrichment medium, thereby obtaining 15 colonies with good growth status and different characters. The main components of the enrichment medium used are: 1000mg / L COD, 1000mg / L calcium ion concentration, 10000mg / L total salt, and 2.0% agar content in the solid medium used.

[0031] Then, the obtained colony was transferred by streaking on a plate, and transferred to a screening medium by streaking for further separation and screening. The main components of the screening medium used are: 1000mg / L CO...

Embodiment 3

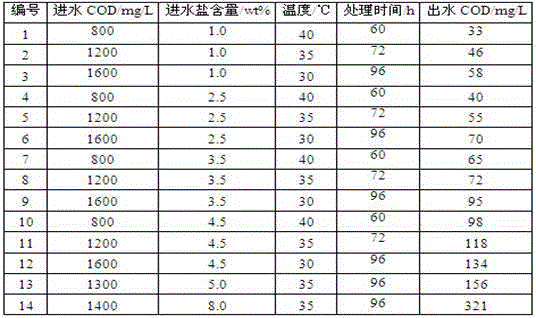

[0033] The investigation of embodiment 3 paracoccus FSTB-2 salt tolerance

[0034] The cultivation method of Paracoccus FSTB-2 of the present invention comprises: bacterial strain activation, liquid seed solution cultivation, aeration cultivation, concrete process is as follows:

[0035] (1) Strain activation: Paracoccus ( Paracoccus sp. ) FSTB-2 was inoculated into a plate containing FSTB solid medium, cultured at 35°C for 48 hours, and then stored in a refrigerator at 4°C until use. The FSTB solid medium is: FeSO 4 •7H 2 O 25mg / L, NH 4 NO 3 286mg / L, KCl 929mg / L, CaCl 2 2769mg / L, NaCl 21008mg / L, beef extract 5g / L, peptone 10g / L, agar 20g / L, pH 7.8.

[0036] (2) Liquid seed liquid culture: Prepare FSTB liquid medium, divide it into Erlenmeyer flasks, sterilize and cool to room temperature, use an inoculation loop to pick the activated strains on the plate and inoculate them into Erlenmeyer flasks under a sterile environment. Incubate at 35°C for 48 hours. The FSTB ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com