Rock sample double-end surface grinder

A double-end, grinding machine technology, applied in the field of rock mechanics testing, can solve the problems of time-consuming and labor-consuming, low efficiency, low precision, etc., and achieve the effects of avoiding errors, convenient operation and high grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

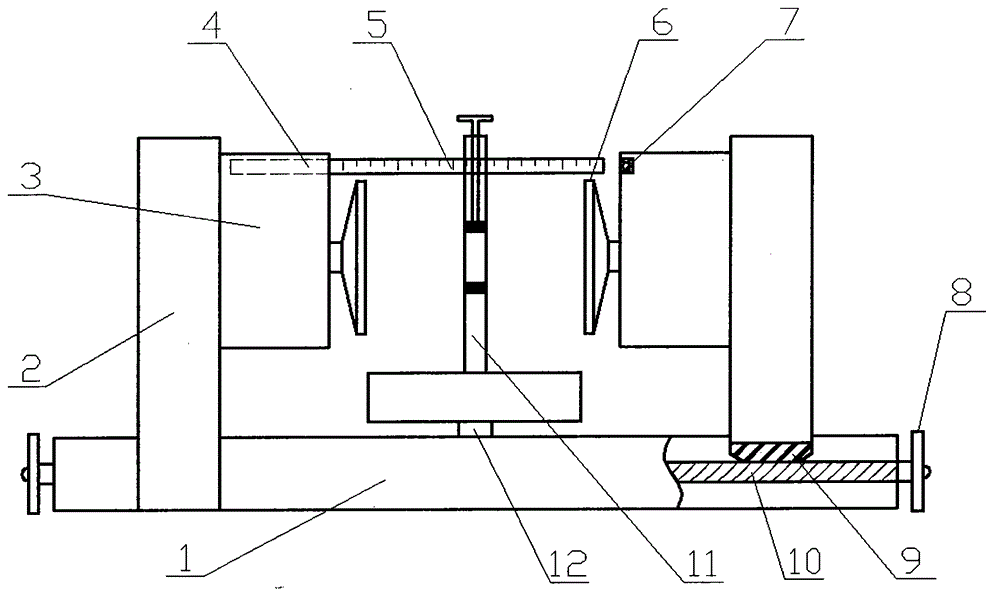

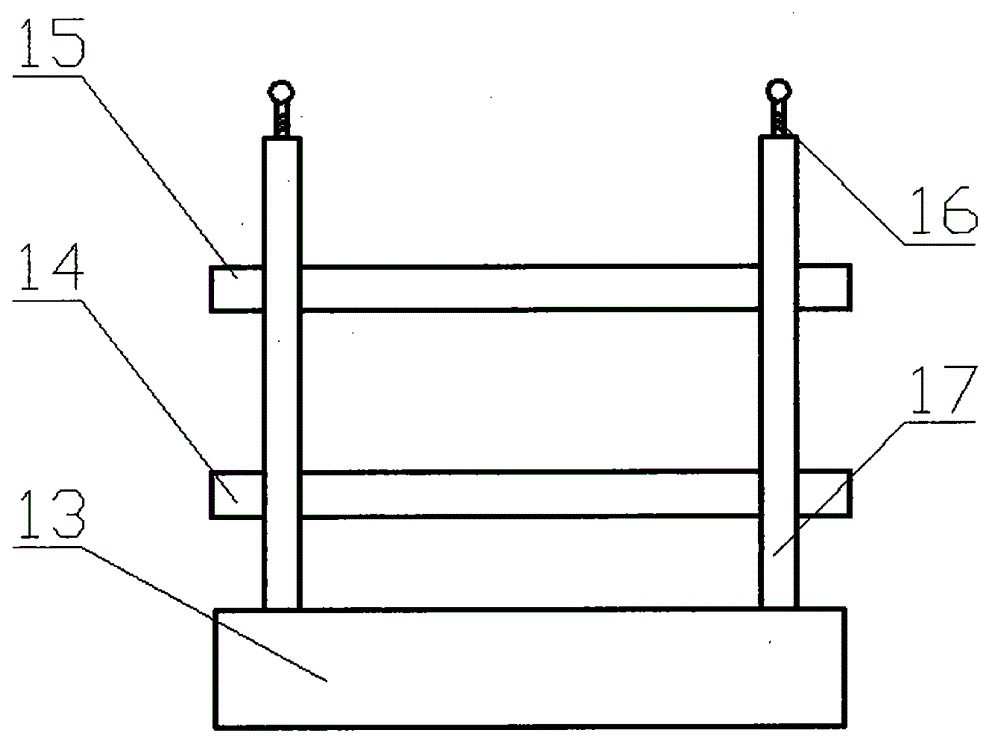

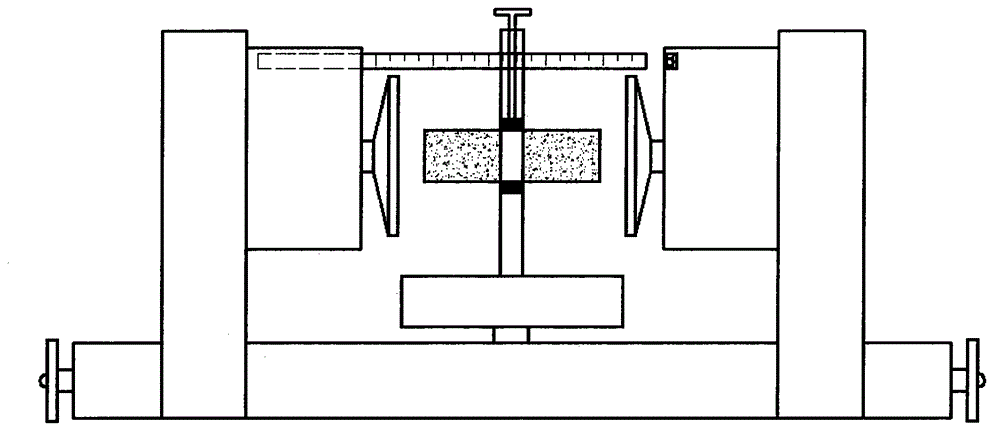

[0019] A rock sample double-end grinding machine provided by the present invention has specific working steps as follows:

[0020] Step 1: Place the rock sample to be polished horizontally between the upper and lower compression rods, and tighten the adjusting bolts so that the rock sample is fixed by the compression rod. Through the final retained rock sample length L 0 The distance from the end face of the grinding disc on both sides to the inner end face of the electric control cabinet is 2L 1 sum to determine the scale value L of the length control ruler 2 (ie: L 2 =L 0 +2L 1 ), extend the length control ruler out of the ruler slot to the scale value L 2 .

[0021] Step 2: Start the grinding machine, the clamping table is fed back and forth through the slide rails, and the two electric control cabinets control the racks on both sides to automatically approach the rock sample. Manually, it is realized by rotating the rings on both sides, and the grinding disc starts t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com