High-precision raw material cutting device for chopstick production

A cutting device, high-precision technology, applied in special forming/shaping machines, forming/shaping machines, wood processing equipment, etc., can solve the problems that wood chips cannot be collected conveniently, and the length of cutting raw materials cannot be accurately controlled, so as to improve Practicality, improved work efficiency, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

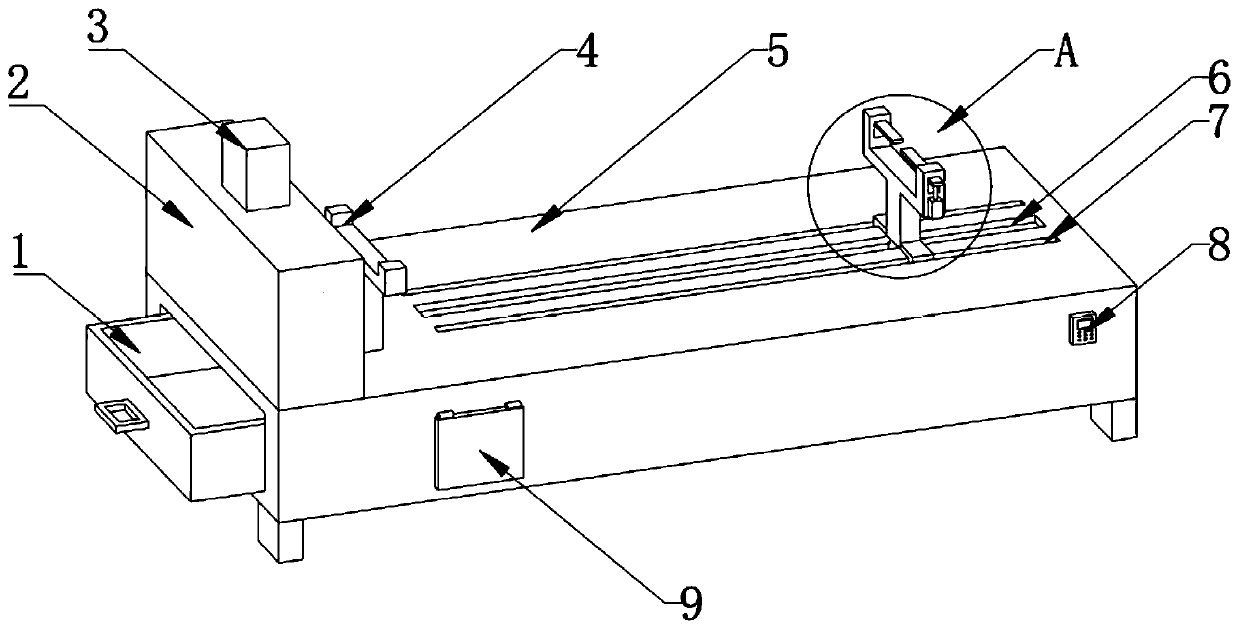

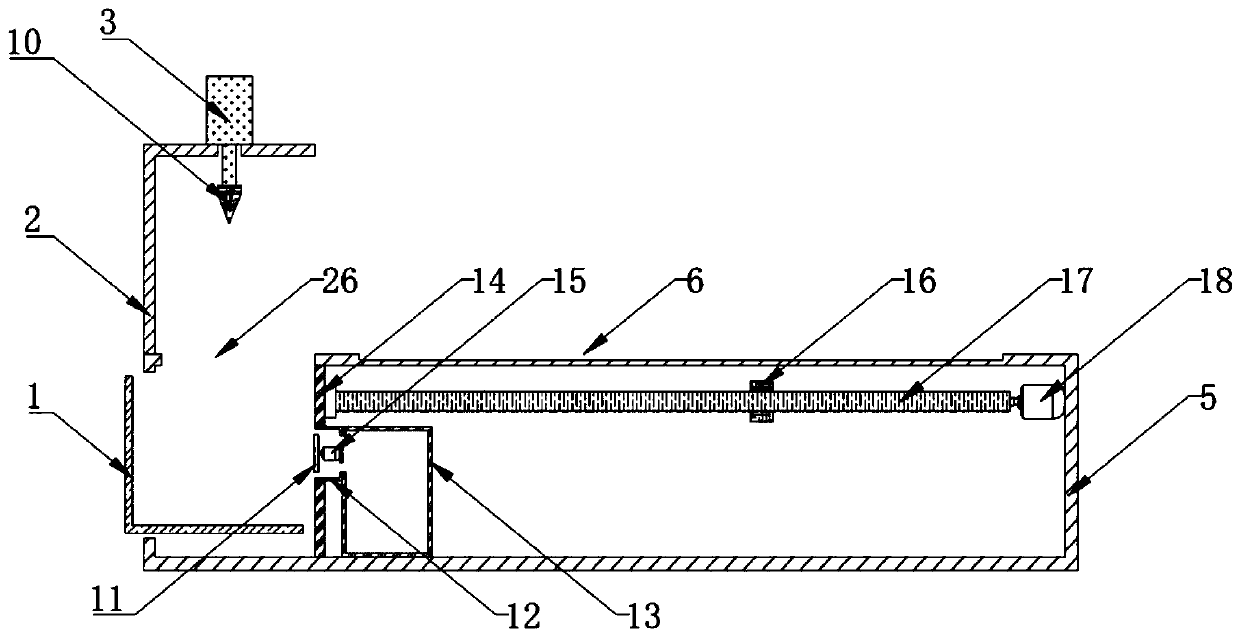

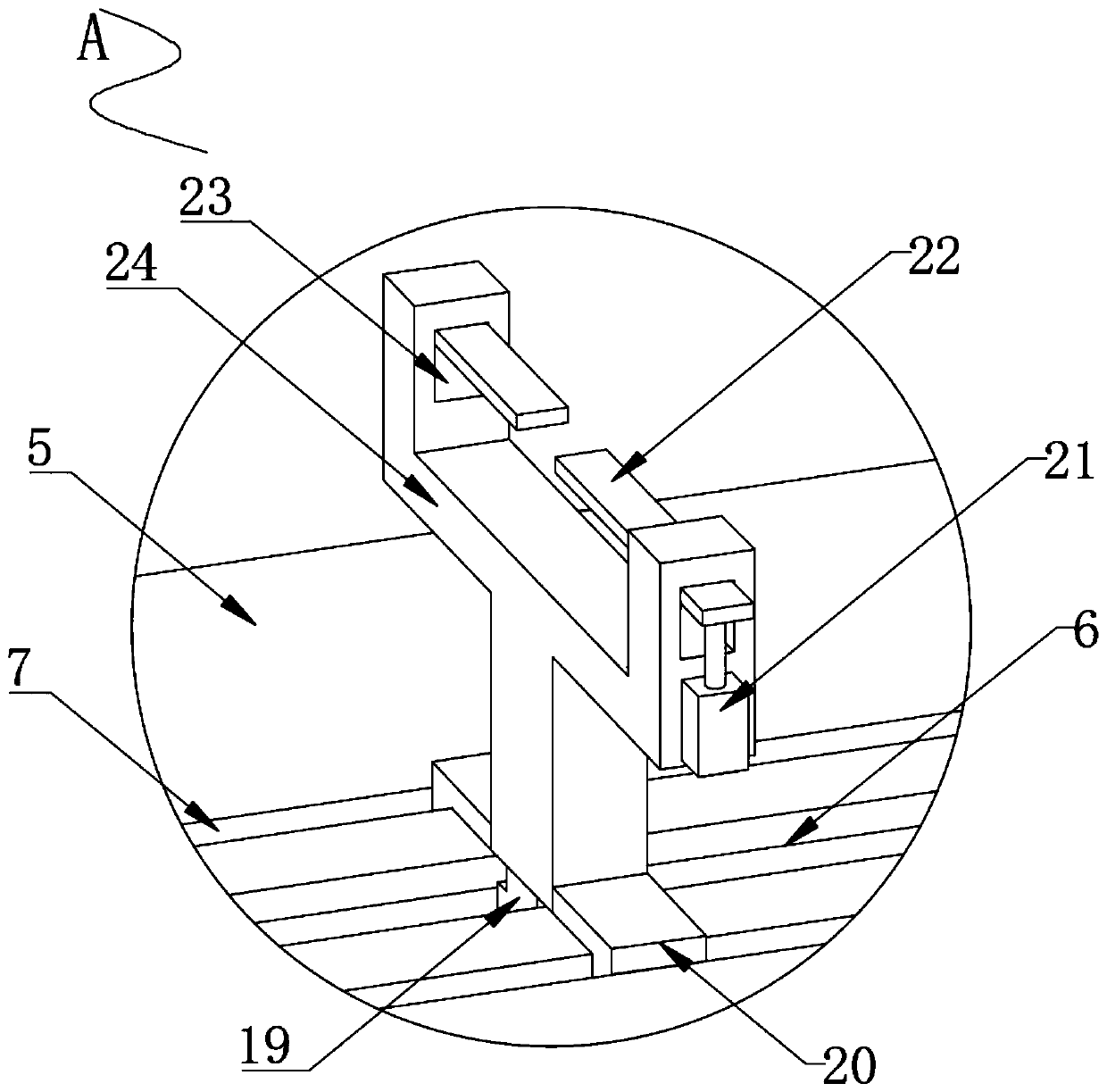

[0022] see Figure 1~4 , in an embodiment of the present invention, a high-precision raw material cutting device for chopsticks production includes a workbench 5, a controller 8 is installed on the front side of the workbench 5, and a cover plate 2 is provided on one side of the top of the workbench 5 , the top of the workbench 5 is connected with a fixed frame 4 near the position of the cover plate 2, the top of the workbench 5 is connected with a movable frame 24, and the top of the workbench 5 is provided with two first square holes 7, and the top of the workbench 5 is provided with two first square holes 7. A chute 6 is provided in the middle of the top, a second motor 18 is installed on one side of the inner side of the workbench 5, a ball screw 17 is installed on the other side of the inner side of the workbench 5, and a ball nut is sleeved on the outside of the ball screw 17. 16. The outer side of the ball nut 16 is connected with two connecting rods 25, the bottom end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com