Patents

Literature

43results about How to "Avoid scattered distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

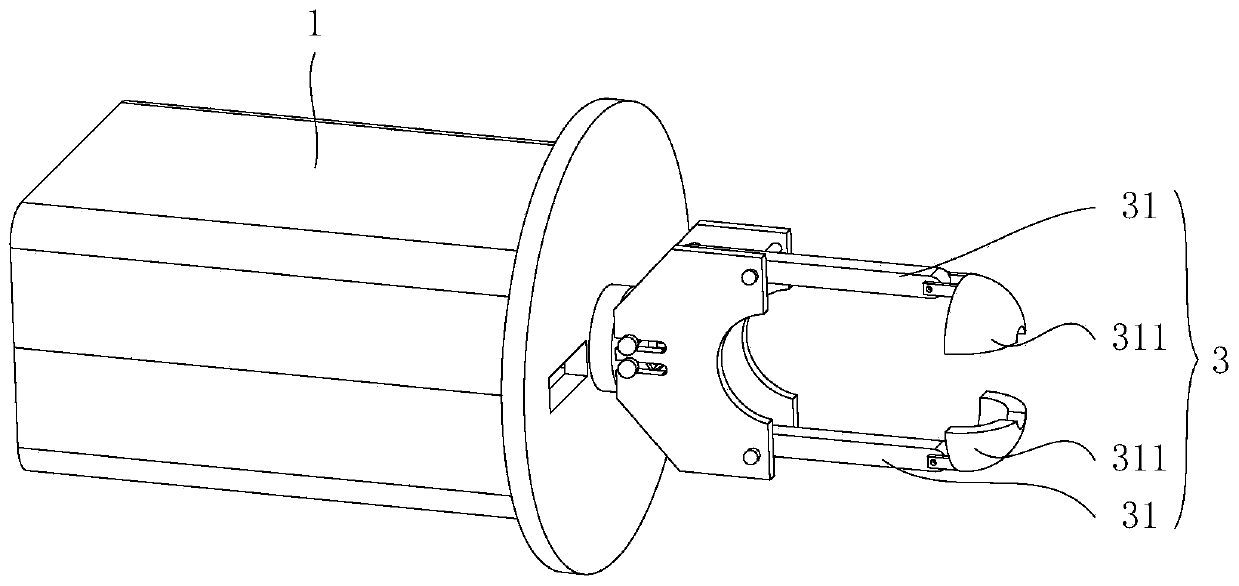

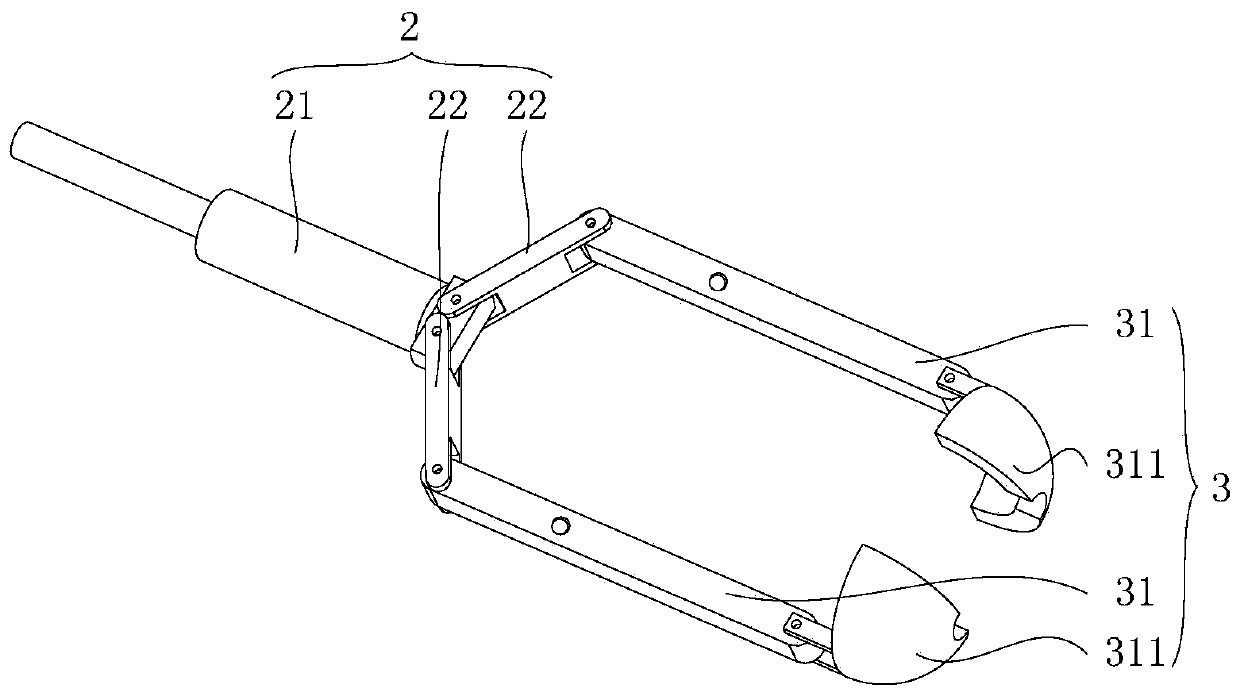

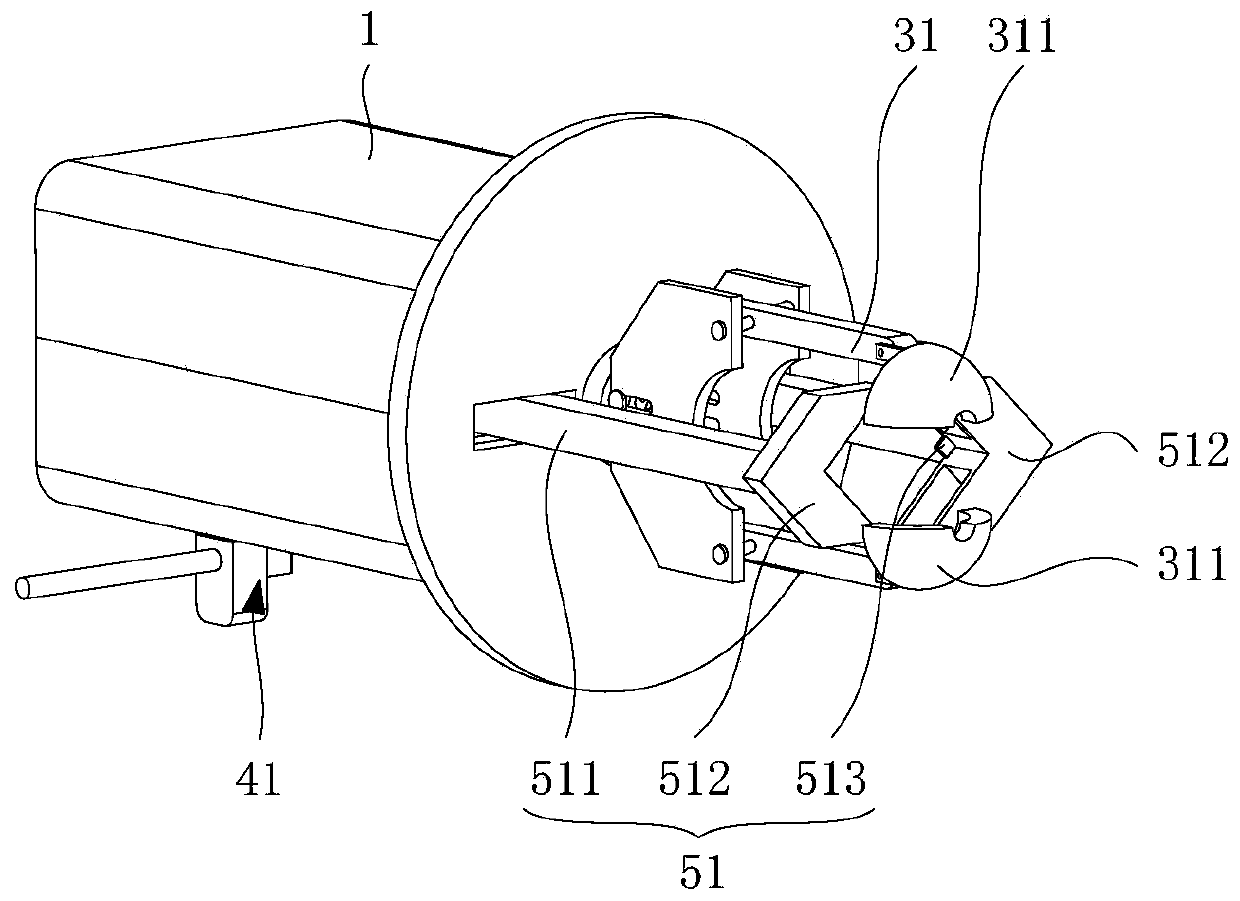

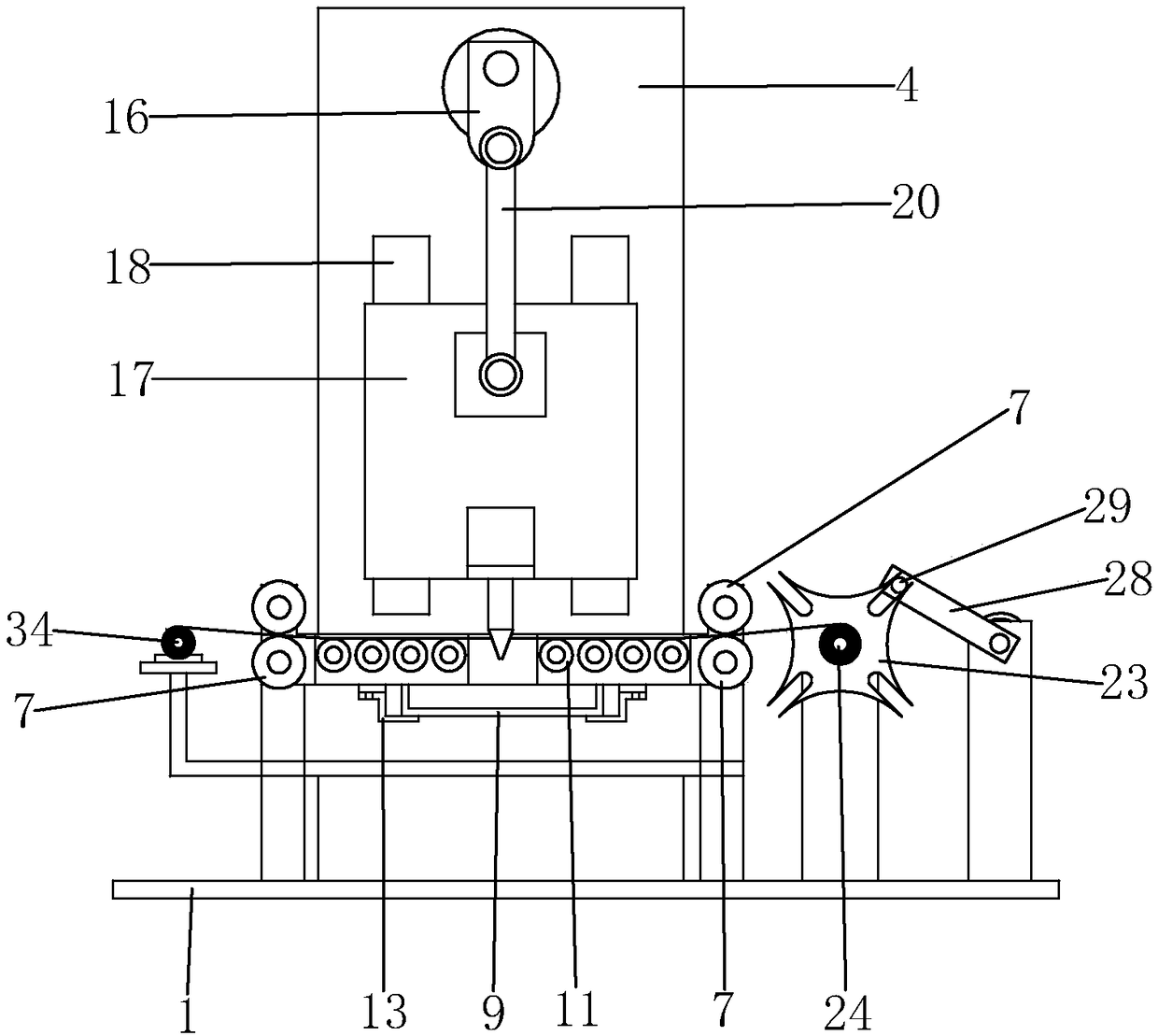

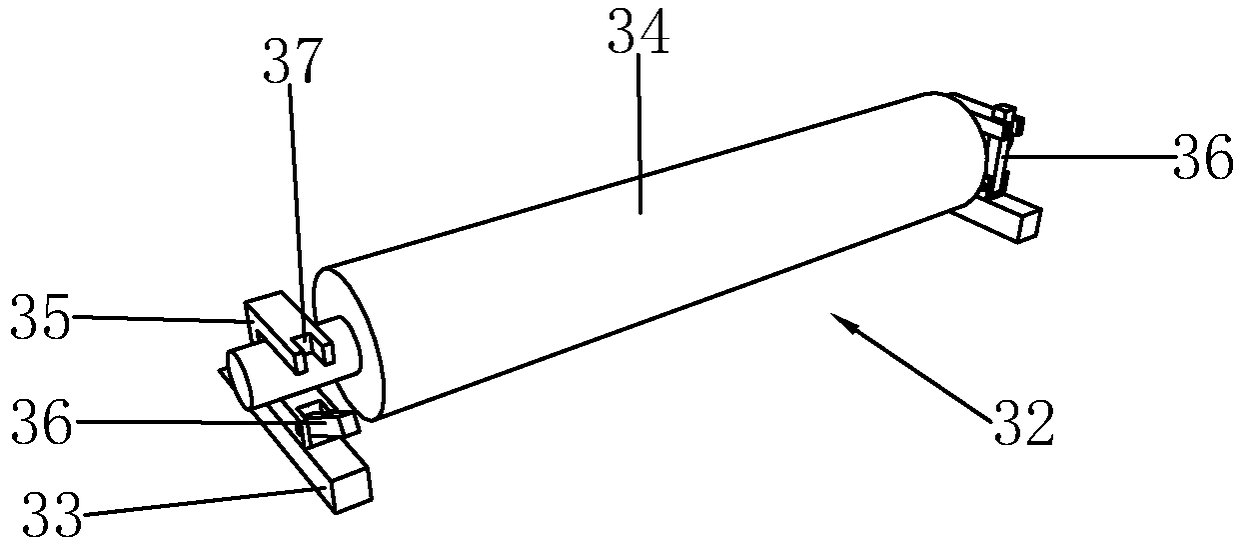

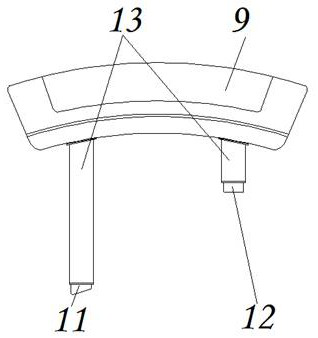

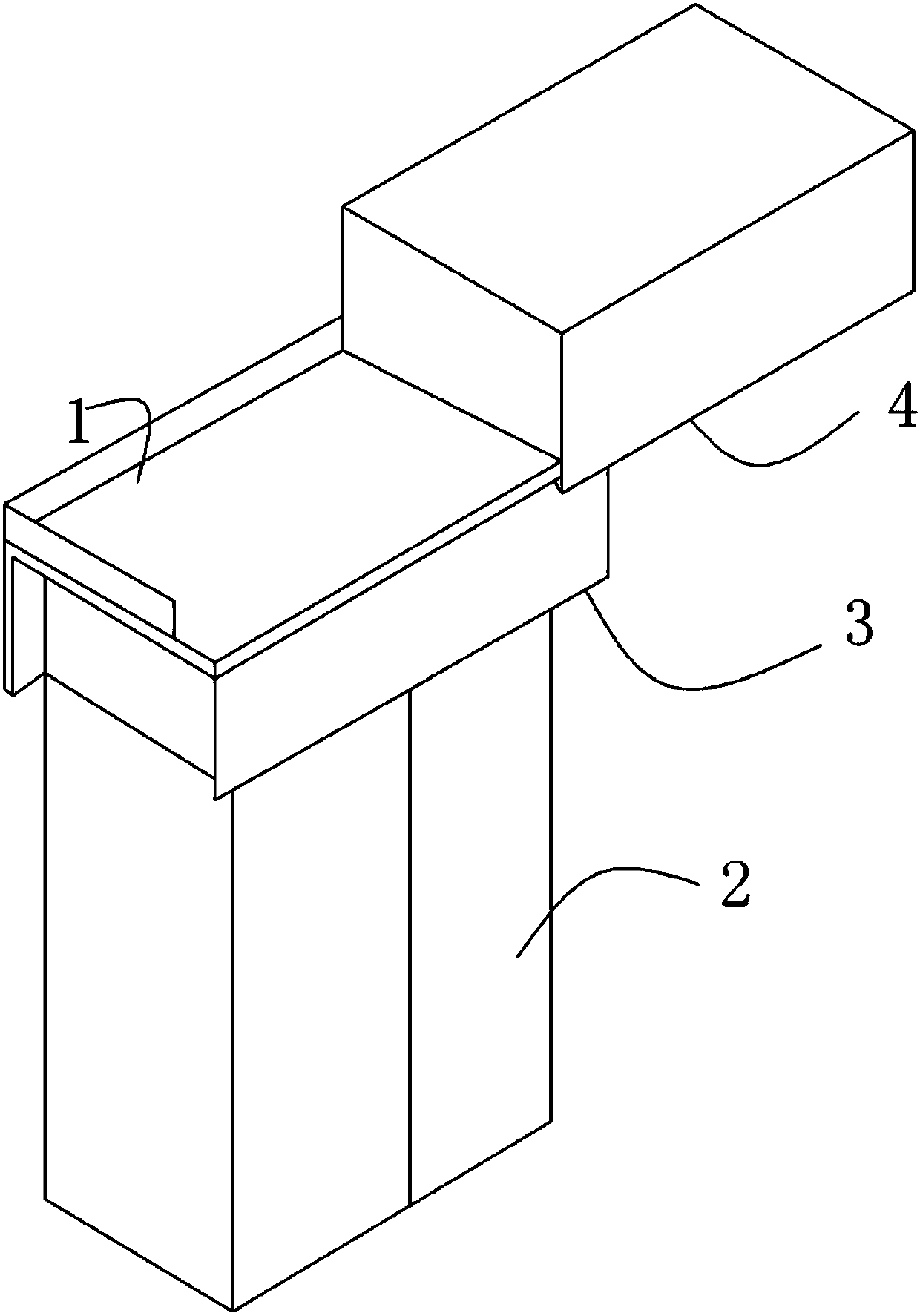

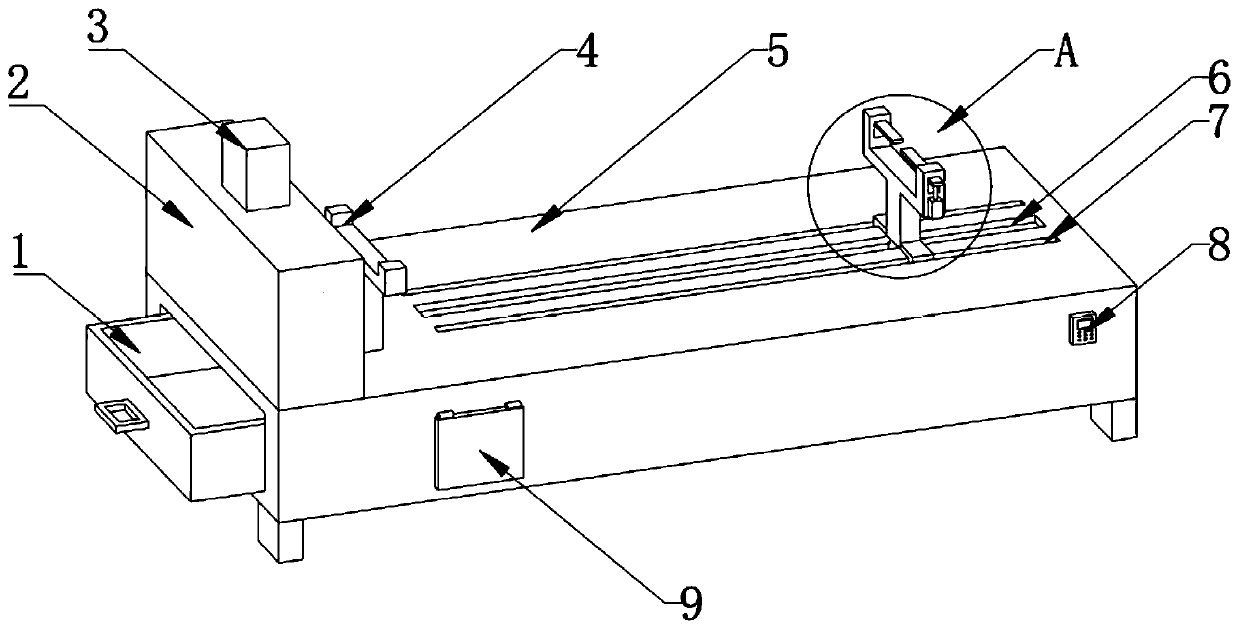

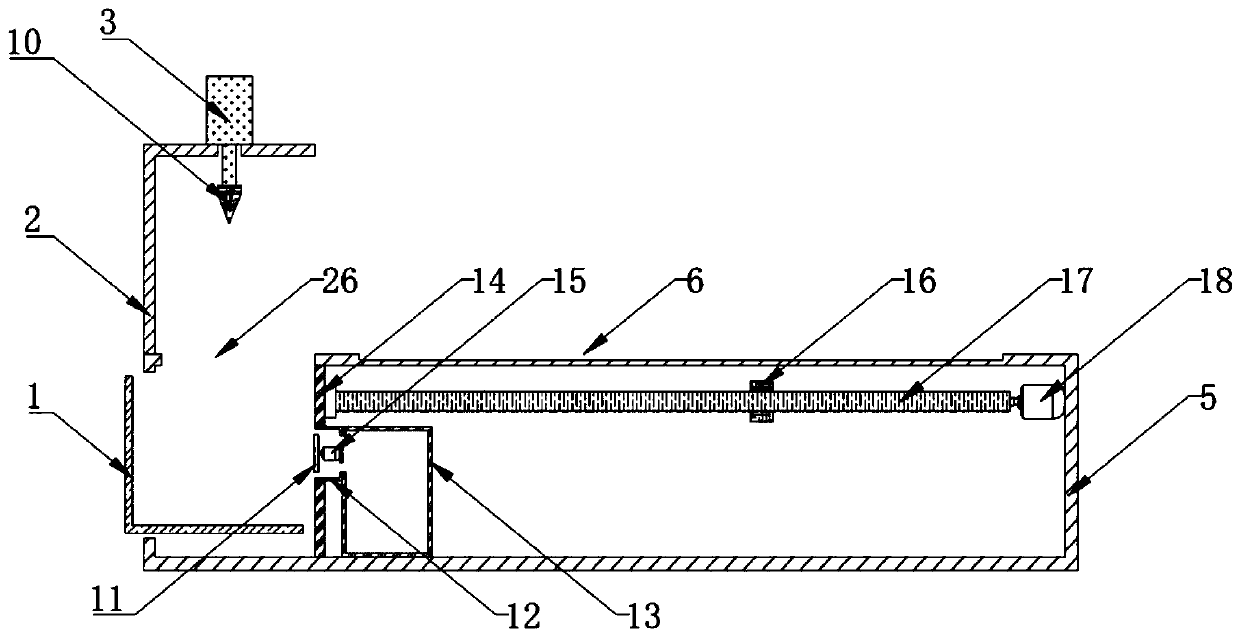

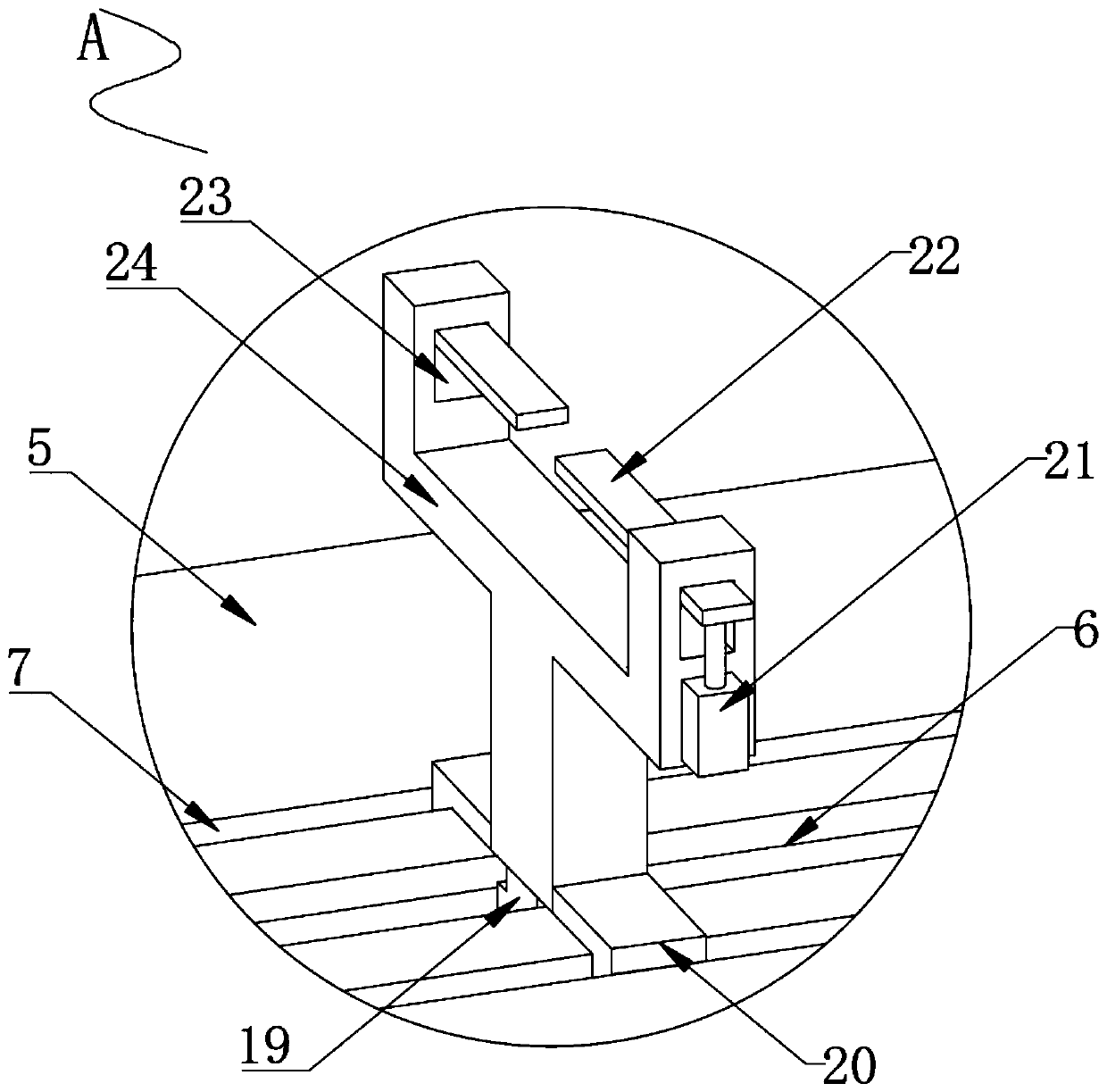

Lifting apparatus and safflower picking manipulator

PendingCN111083990AAvoid scattered distributionReduce incomplete pickingGripping headsPicking devicesAgricultural engineeringStructural engineering

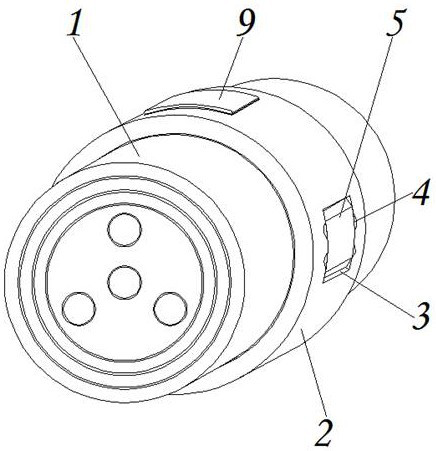

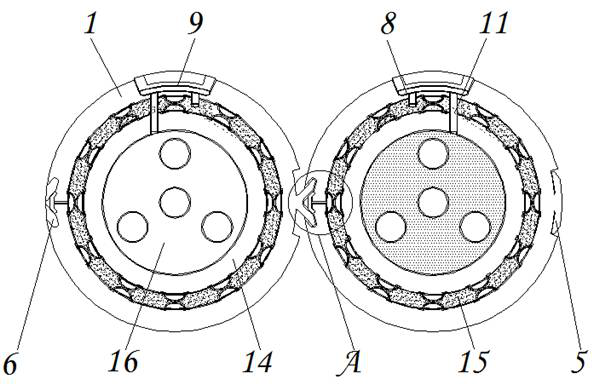

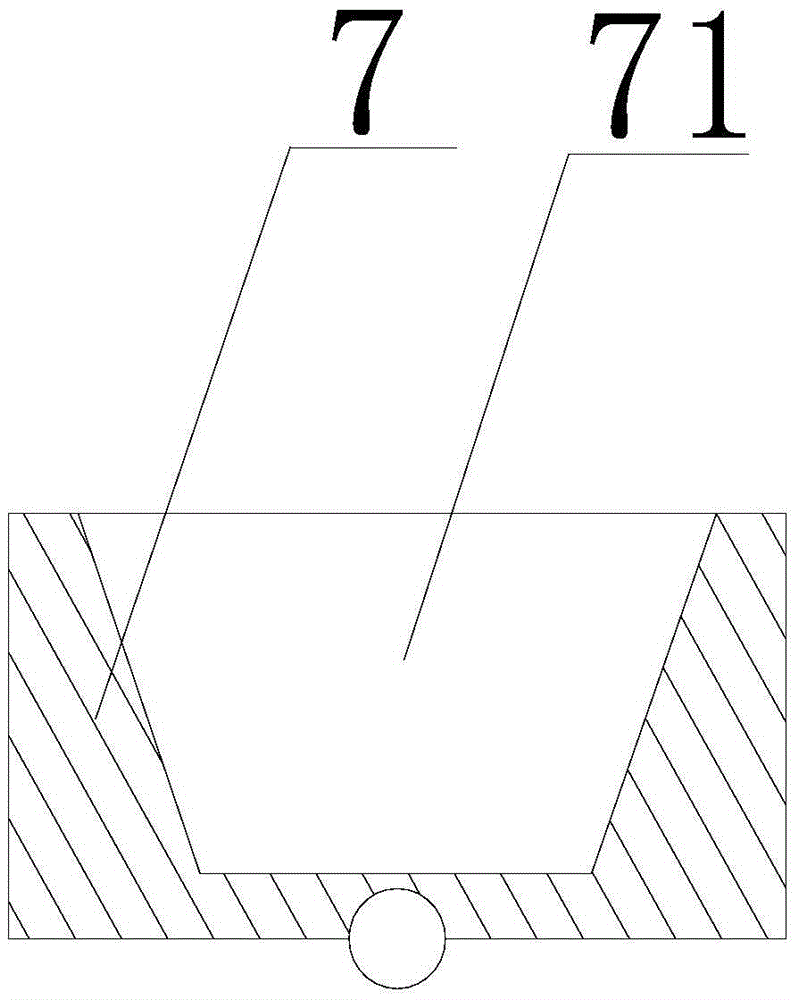

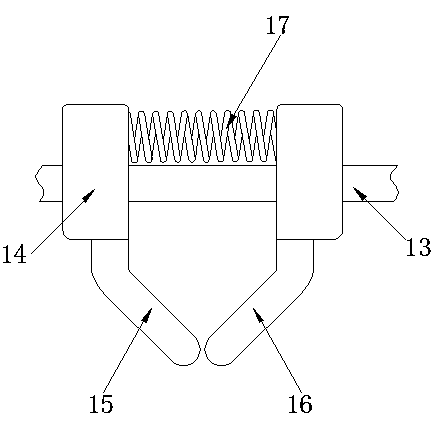

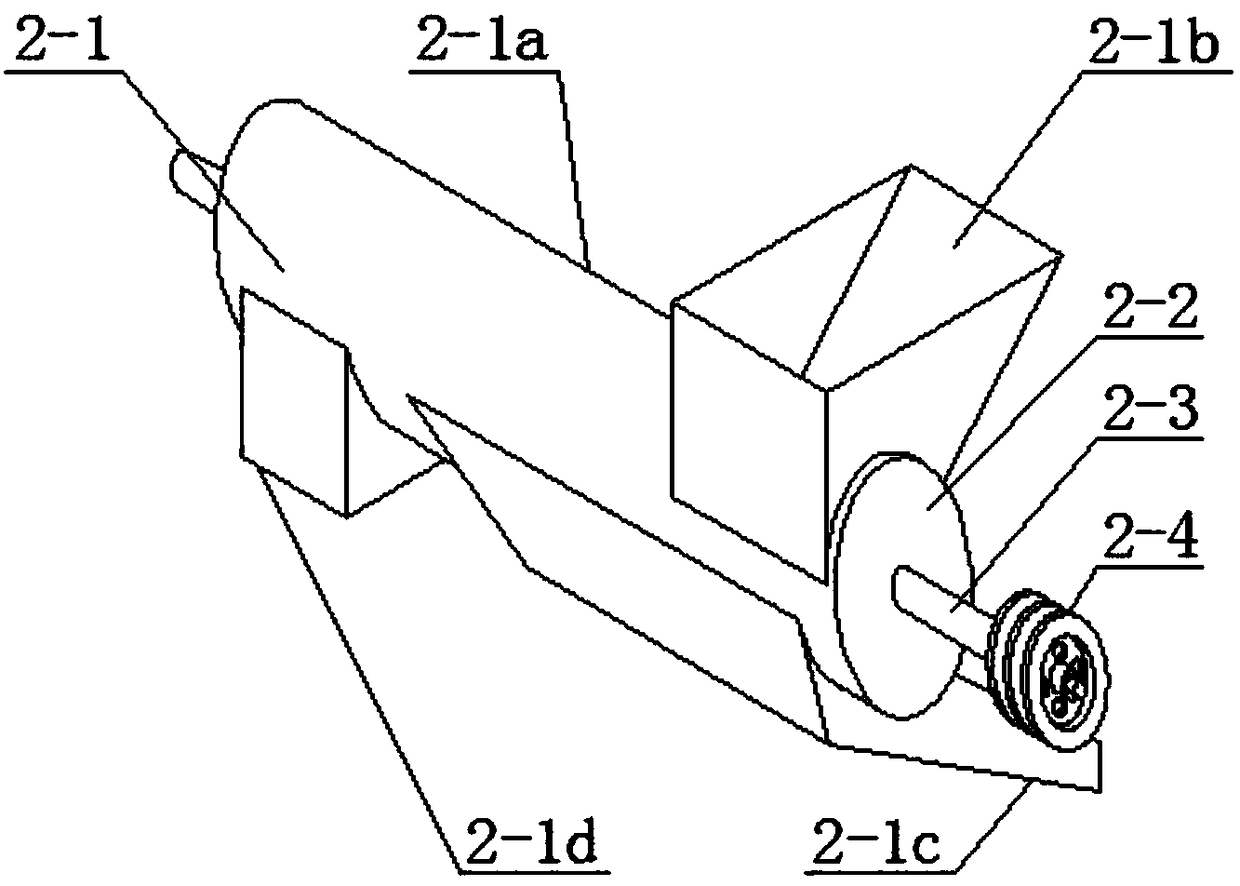

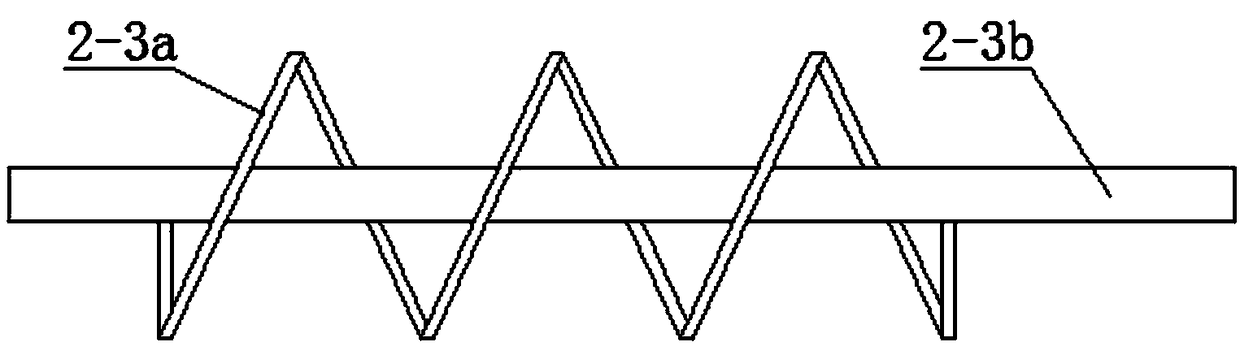

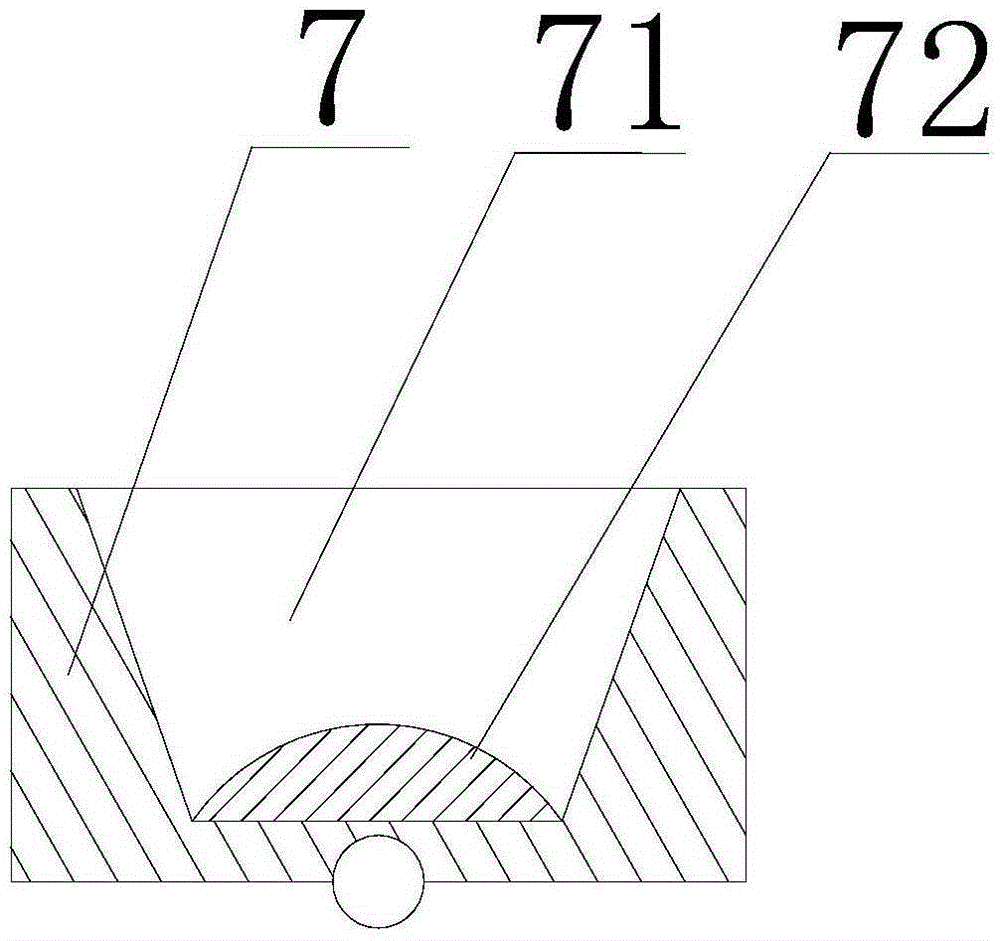

The invention provides a lifting apparatus and a safflower picking manipulator, and relates to the technical field of safflower picking. The lifting apparatus provided by the invention comprises a support shell, a first driving mechanism, and a position-limiting claw movably connected with the support shell, wherein the support shell and the position-limiting claw are connected with the first driving mechanism, and the first driving mechanism is used to drive the position-limiting claw to move relative to the support shell, so that the position-limiting claw forms a channel for grabbing a flower stem, and a lifting cavity for lifting filaments. The lifting apparatus provided by the invention can directly grasp the flower stem and lift the filaments through the lifting cavity, and effectively limits a position of a fruit ball. Even in relatively severe weather, such as windy weather, the position-limiting claw can ensure that the flower stem is stable, the lifting cavity formed by the position-limiting claw can play a certain position-limiting role in the filaments to avoid scattered distribution of the filaments, and thereby the occurrence of incomplete filament picking is effectively reduced.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

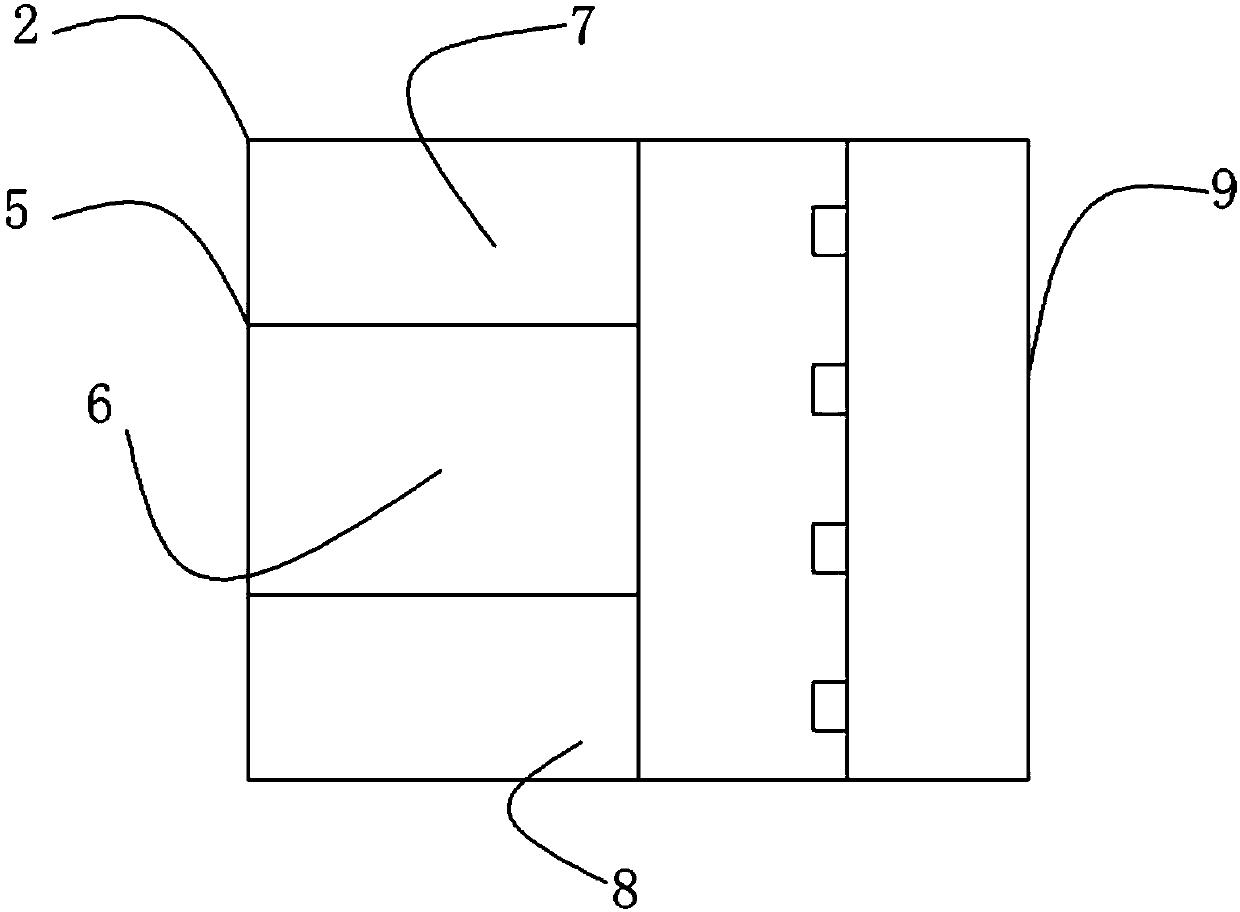

Punching device for packaging cardboards

InactiveCN109177303AComply with punching requirementsPlay a leveling rolePaper-makingBox making operationsCardboardPunching

The invention discloses a punching device for packaging cardboards. The punching device includes a bottom plate, wherein an H-shaped bracket, a support plate, a vertical plate and a support frame arearranged on the bottom plate; U-shaped plates are symmetrically distributed on the support frame; a pressure roller is arranged between the U-shaped plates and movably connected with each U-shaped plates; a conveying roller assembly and a material receiving groove are arranged between the U-shaped plates; a drive motor is arranged on the vertical plate; the drive motor is connected with a turntable; a drive plate is eccentrically connected with the turntable; a mounting plate is slidably connected with the vertical plate; a swinging rod is arranged between the mounting plate and the drive plate; an L-shaped fixing block is arranged on the drive plate; a punch head is arranged on the L-shaped fixing block; a transmission wheel is movably connected with the H-shaped bracket; a material receiving motor is arranged on the support plate; the receiving motor is connected with a drive board; drive pins are arranged on the drive plate; stop grooves are circumferentially distributed on the outer circumference of the transmission wheel; and the stop grooves correspond to the drive pins. The punching device has the advantages of compact structure, flexible connection, good punching effect, continuous order, automatic and convenient usage, and more in line with the punching requirements of the cardboards.

Owner:嵊州市东浦天地彩印包装有限公司

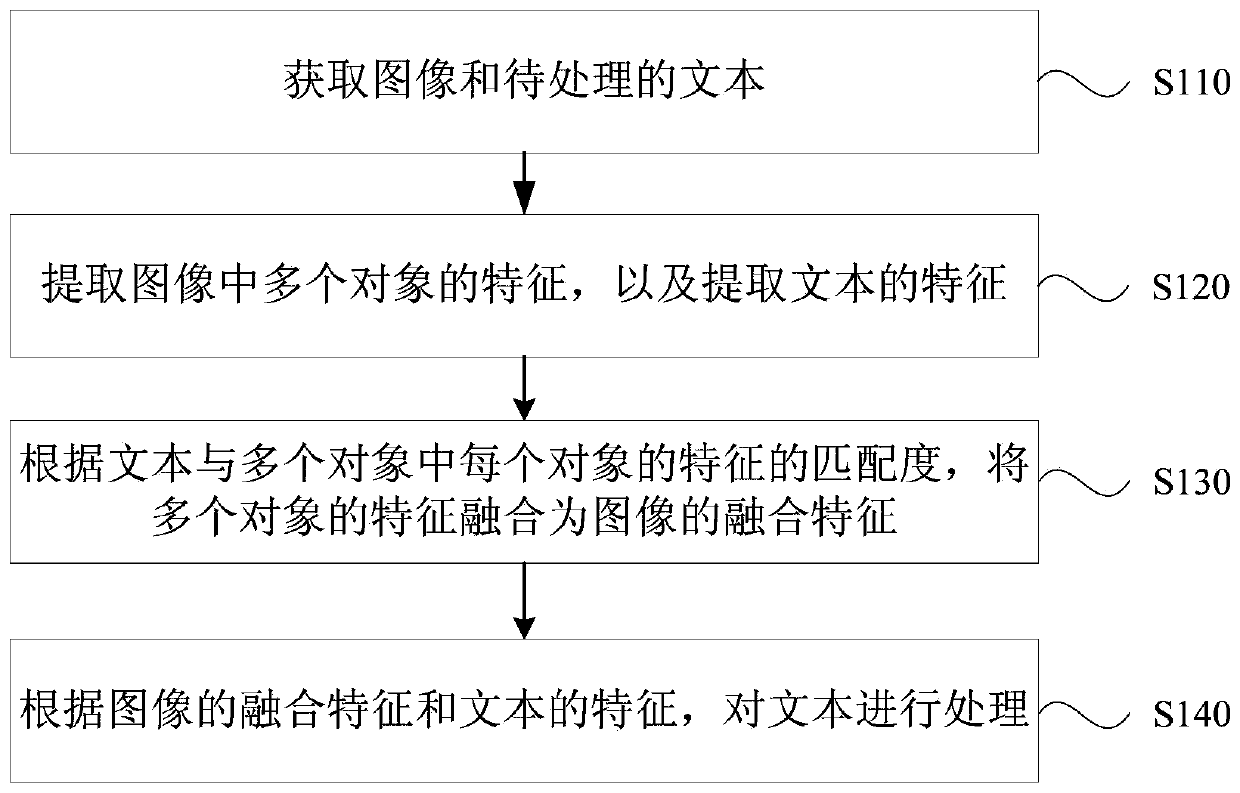

Image-based data processing method, apparatus and device, and readable storage medium

ActiveCN109858555AImprove accuracyAvoid scattered distributionImage enhancementImage analysisProcessing accuracyImage based

The embodiment of the invention discloses an image-based data processing method, apparatus and device and a readable storage medium. The method comprises the steps of obtaining an image and a to-be-processed text; extracting features of a plurality of objects in the image, and extracting features of the text; according to the matching degree of the text and the features of each of the plurality ofobjects, fusing the features of the plurality of objects into fused features of the image; and processing the text according to the fusion features of the image and the features of the text. According to the embodiment of the invention, the association relationship between the text and each object in the image can be accurately learned, and the processing accuracy is improved.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

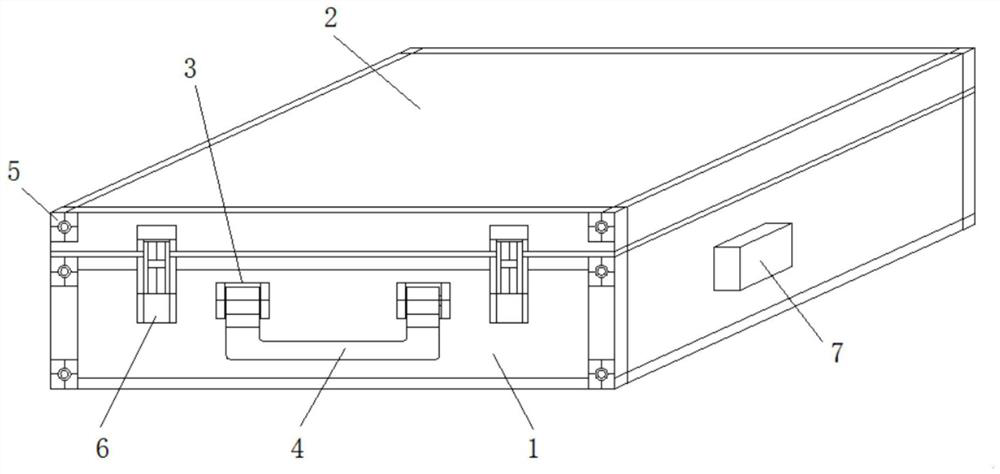

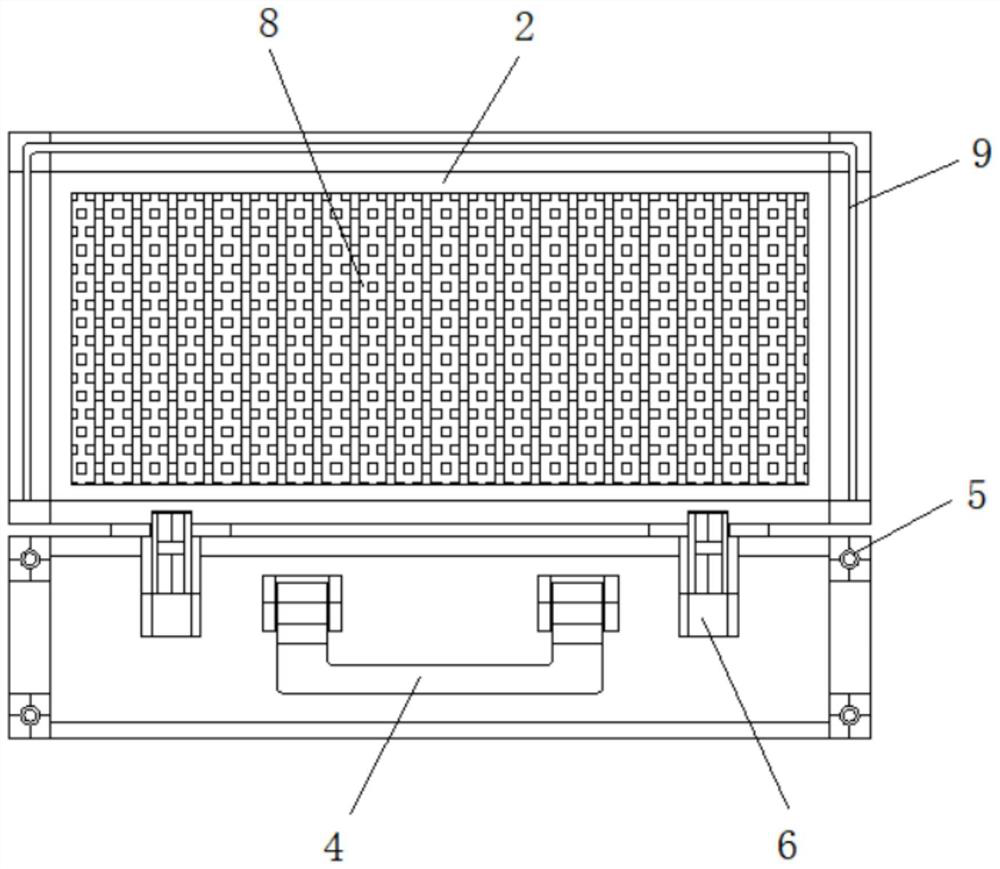

High-end electric wire packaging design and method

InactiveCN111846585AImprove anti-pull performanceImprove crash performanceSynthetic resin layered productsBagsPackage designStructural engineering

The invention discloses a high-end electric wire packaging design and a method. The high-end electric wire packaging design comprises a packaging box, a sealing and connecting structure and a connecting port structure. The upper portion of the rear end of the packaging box is connected with a connecting hinge, and the upper portion of the connecting hinge is connected with a packaging cover platestructure. The sealing and connecting structure is arranged on the outer side of a handle connecting seat, and the connecting port structure is arranged on the right end face of the packaging box. Anelectric wire assembling groove is formed in the packaging box, and a sealing groove is formed in the outer side of the electric wire assembling groove. The high-end electric wire packaging design isprovided with the connecting port structure, electric wires in the packaging box can be conveniently taken for use without opening and closing the packaging box, the two electric wires can be externally connected conveniently through two arranged connecting ports, and thus the use convenience of the electric wires can be improved; and according to the packaging design, the electric wires can be taken for use according to use needs, two set taking manner can both achieve a sealing effect during sealing, and thus it can be guaranteed that packaging of the electric wires cannot be influenced whenthe electric wires are taken for use.

Owner:贵阳中安科技集团有限公司

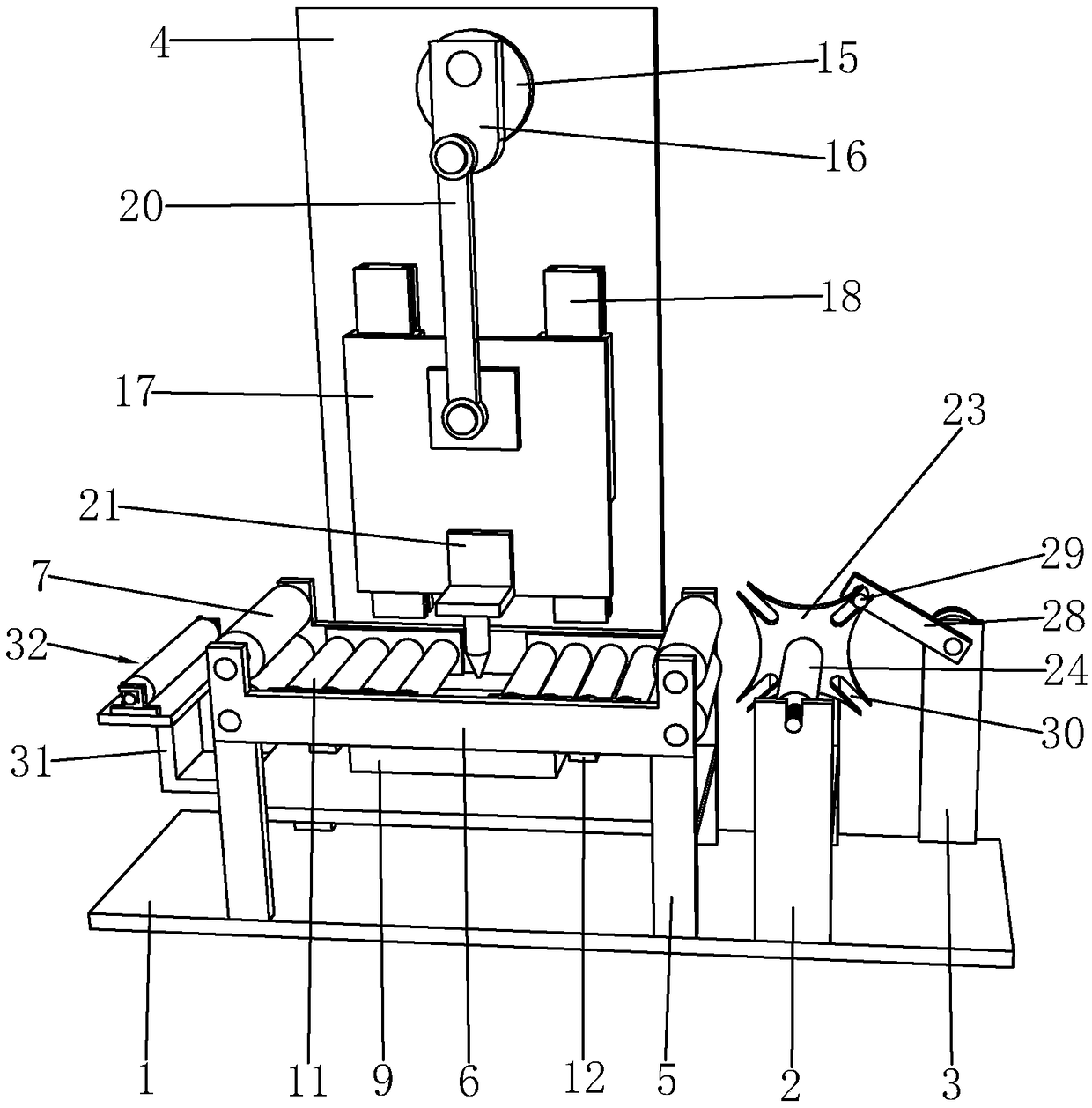

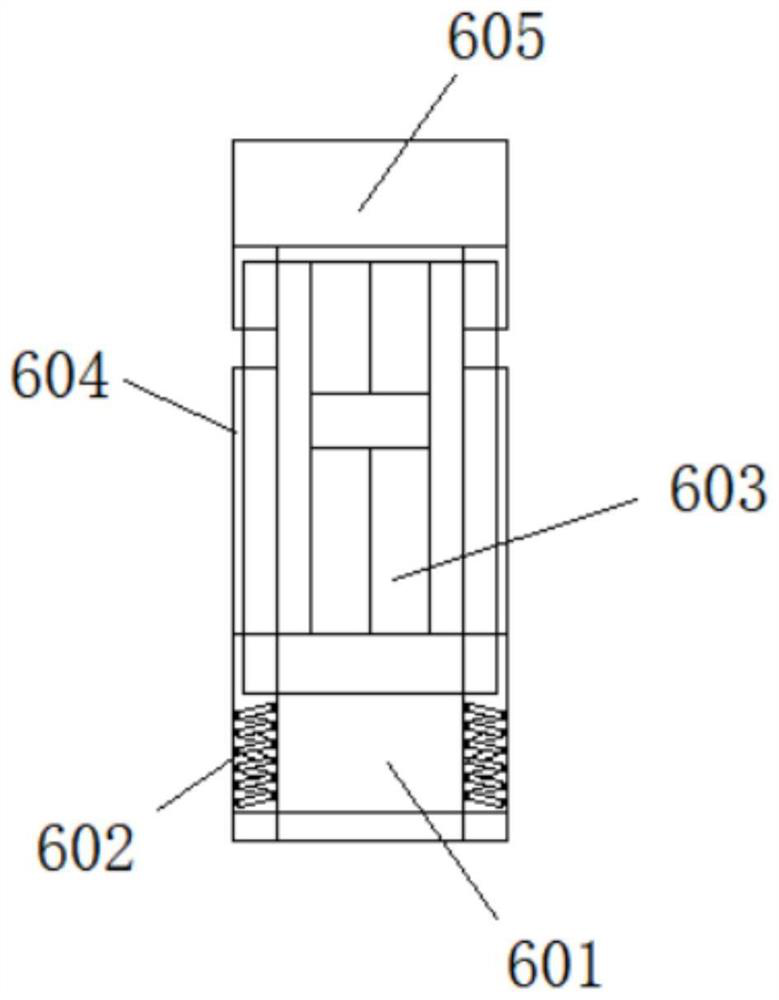

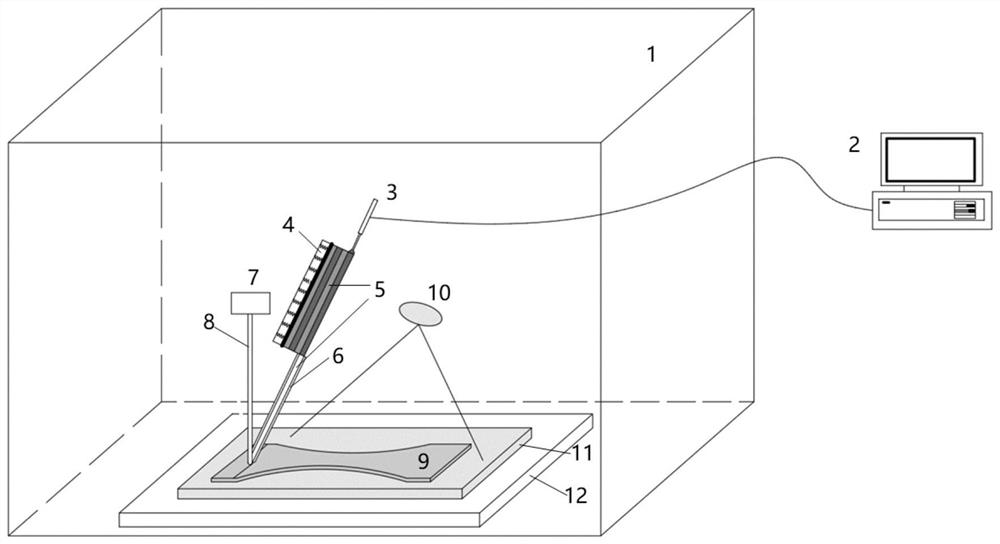

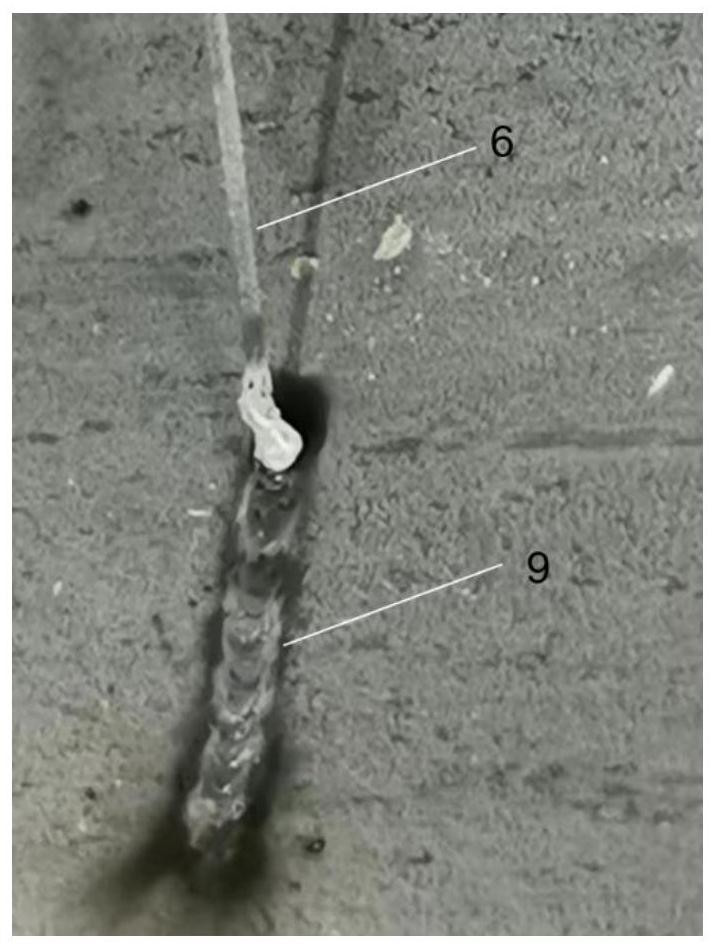

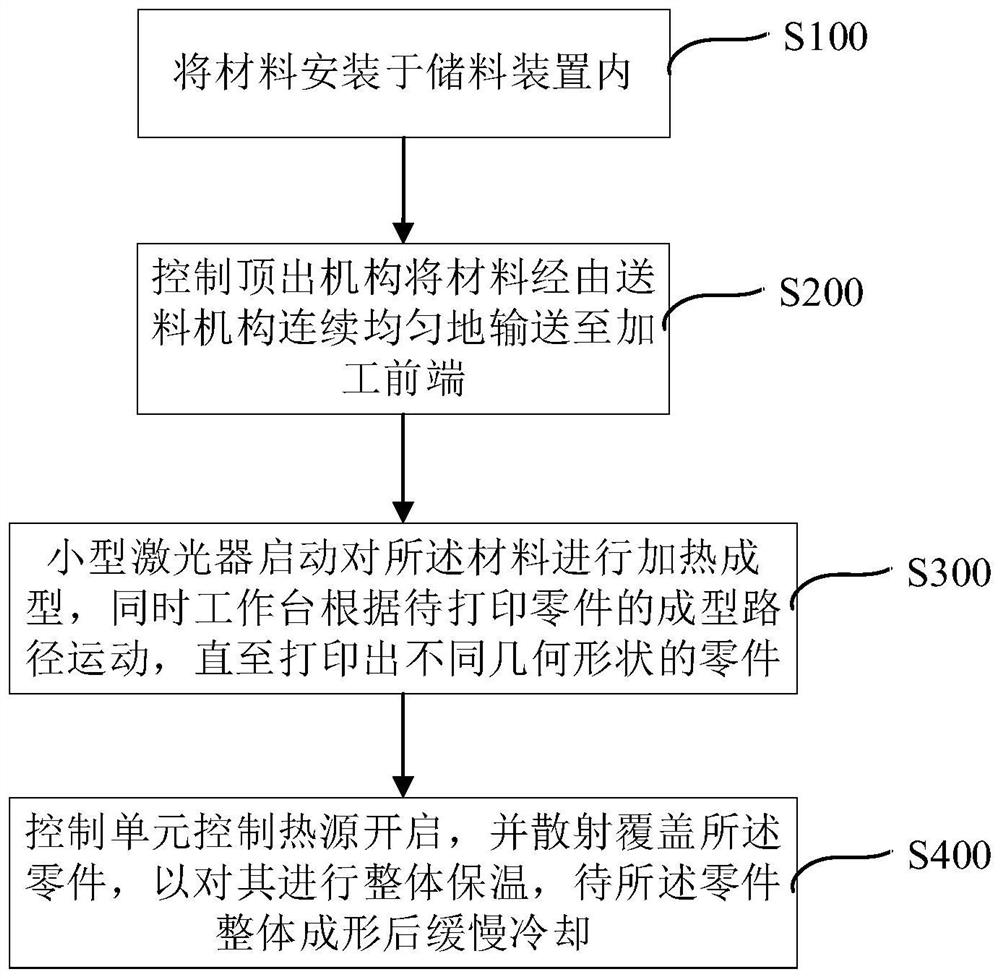

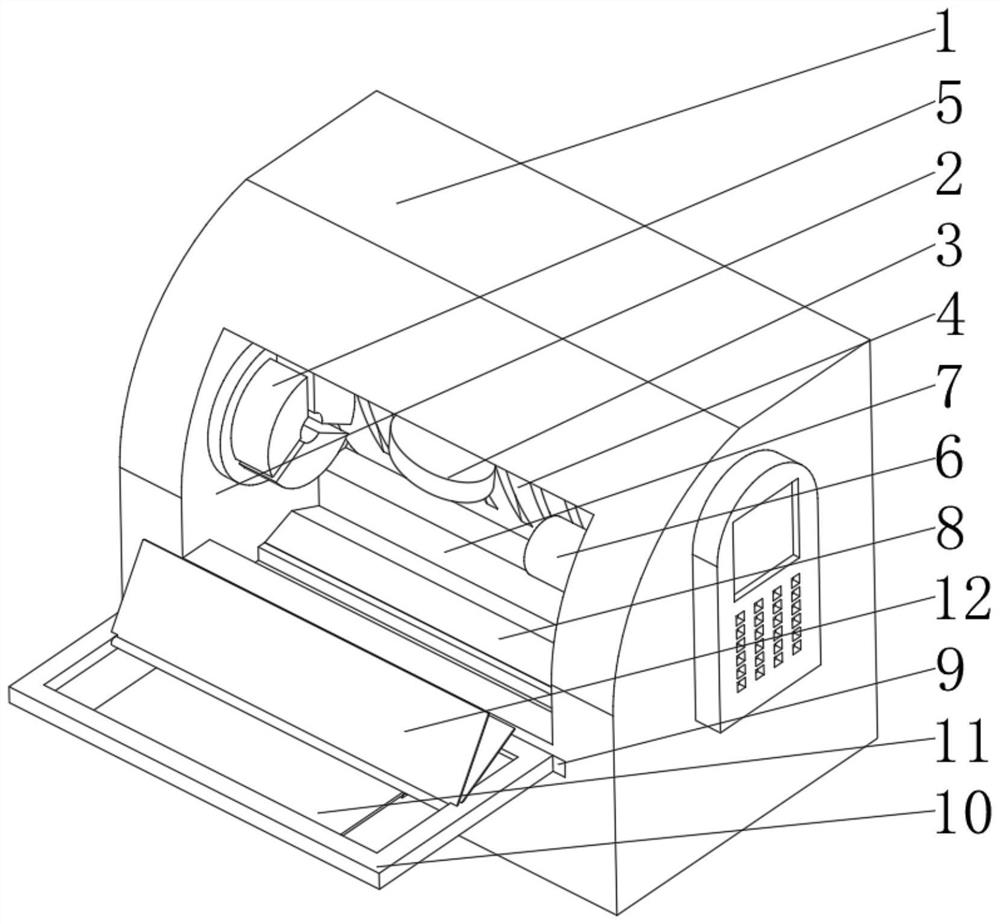

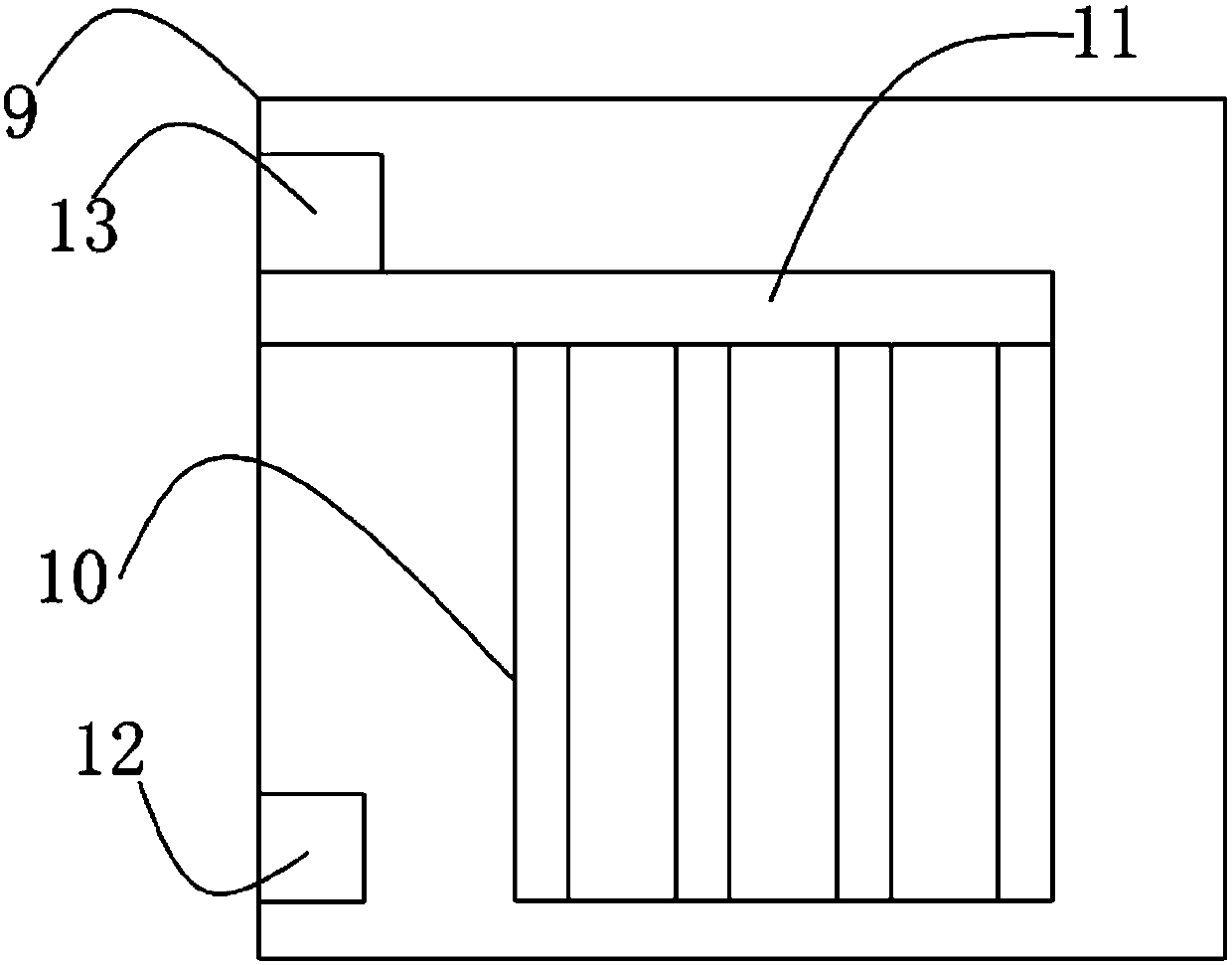

3D printing system and method suitable for micro-gravity space environment

InactiveCN111761063AResistant to atomic oxygen ablationAvoid cold weldingAdditive manufacturing apparatusControl cellEngineering

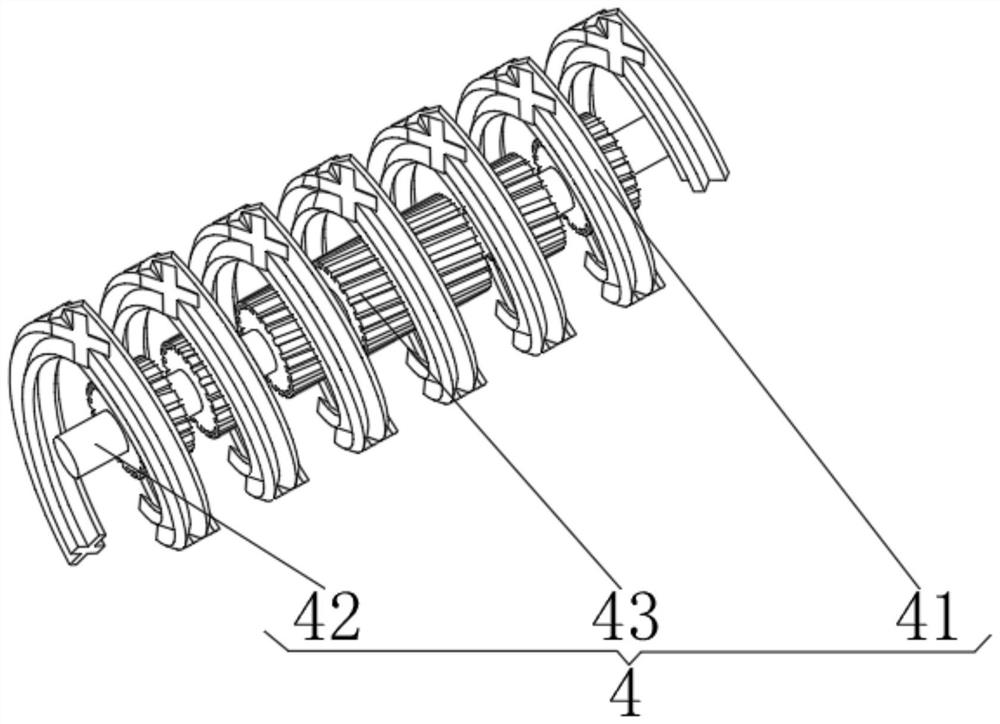

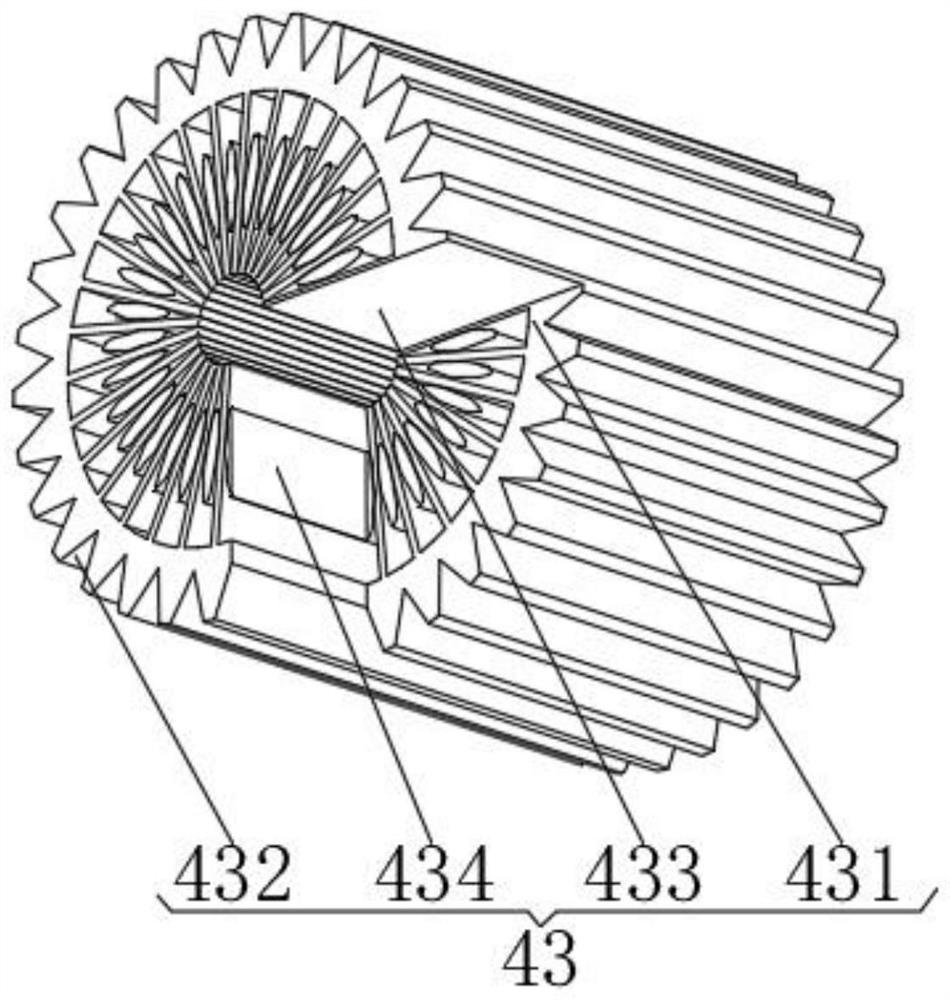

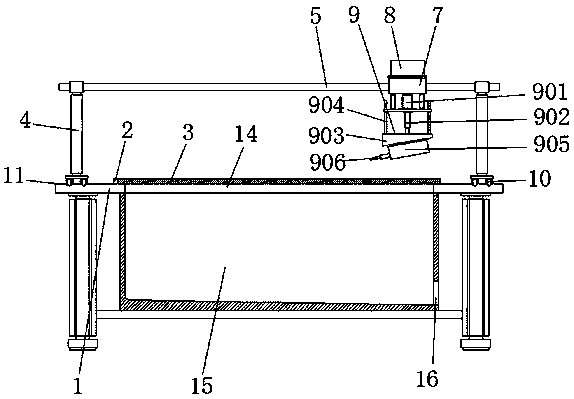

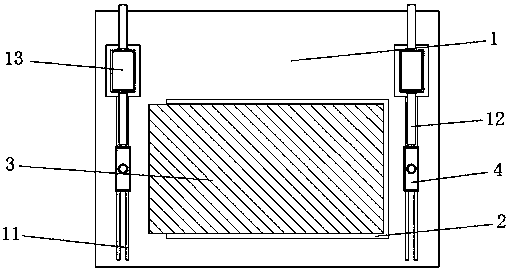

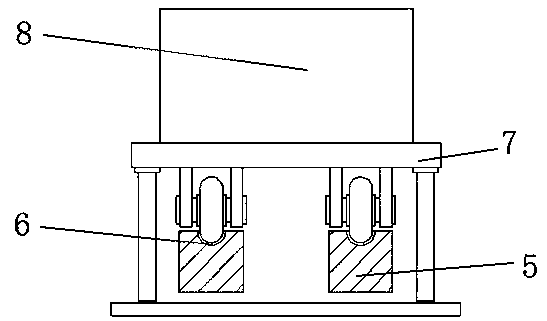

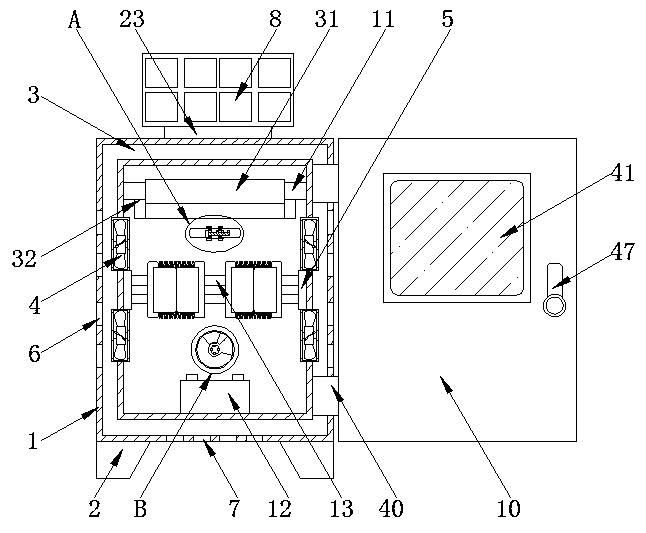

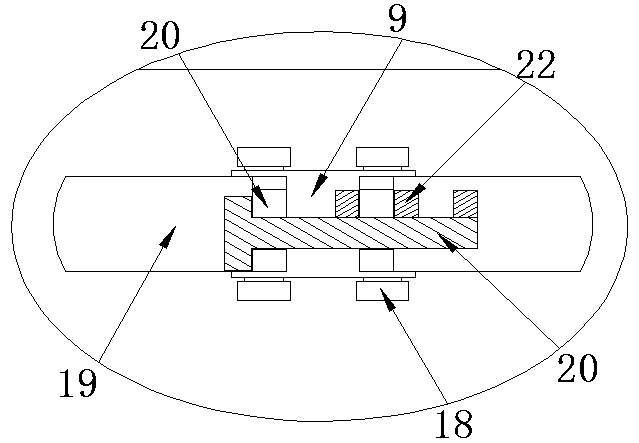

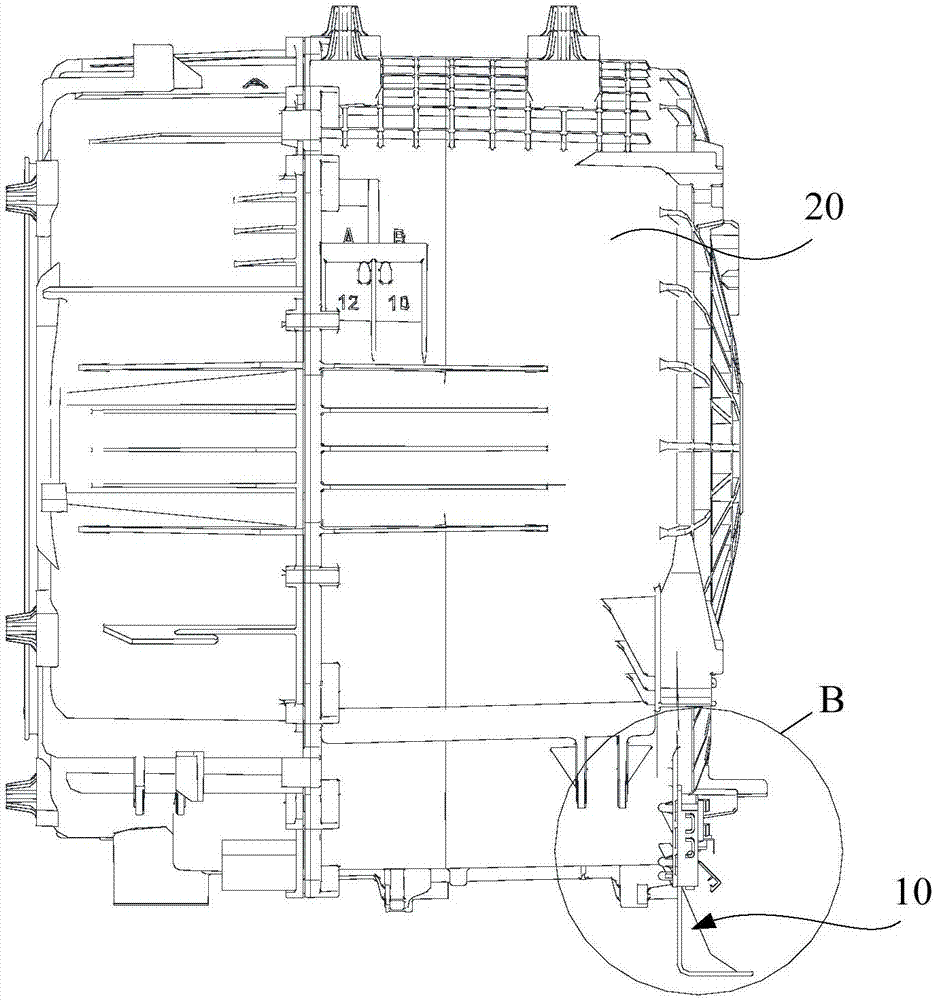

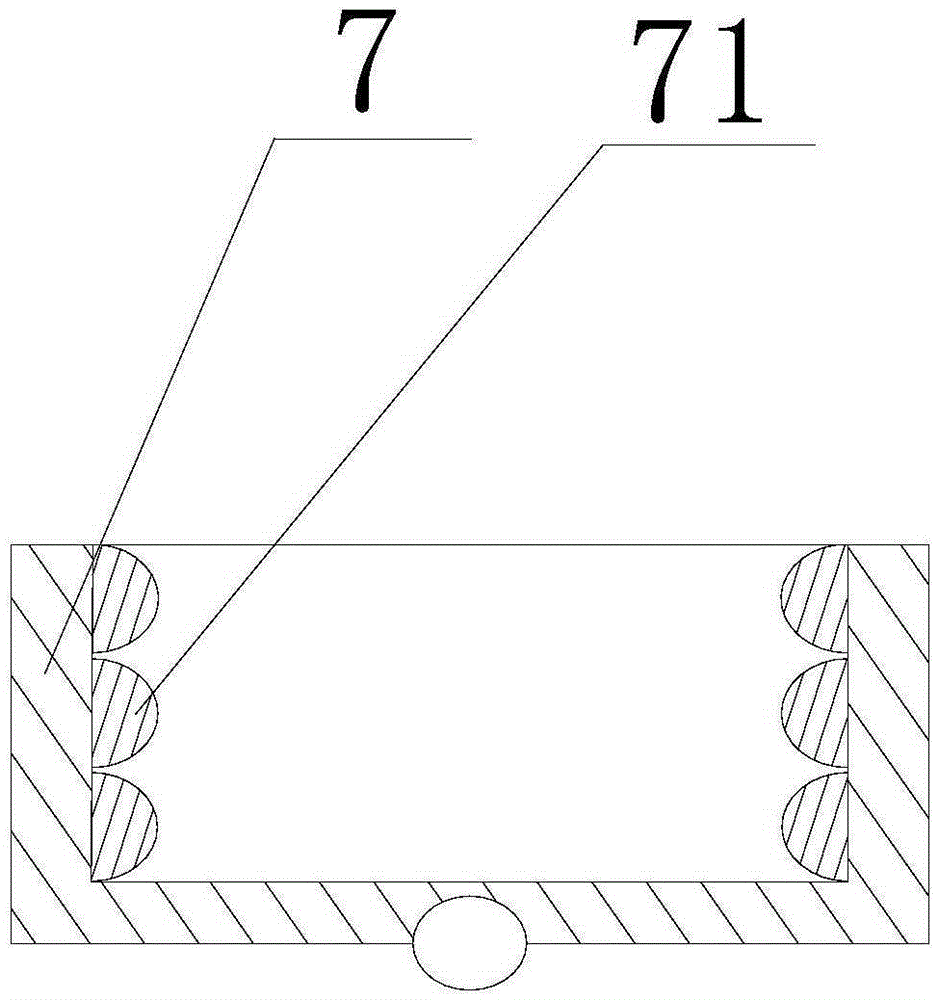

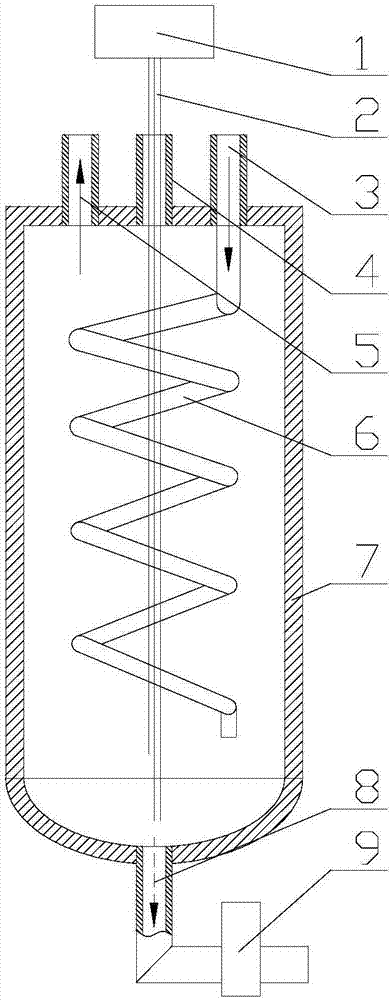

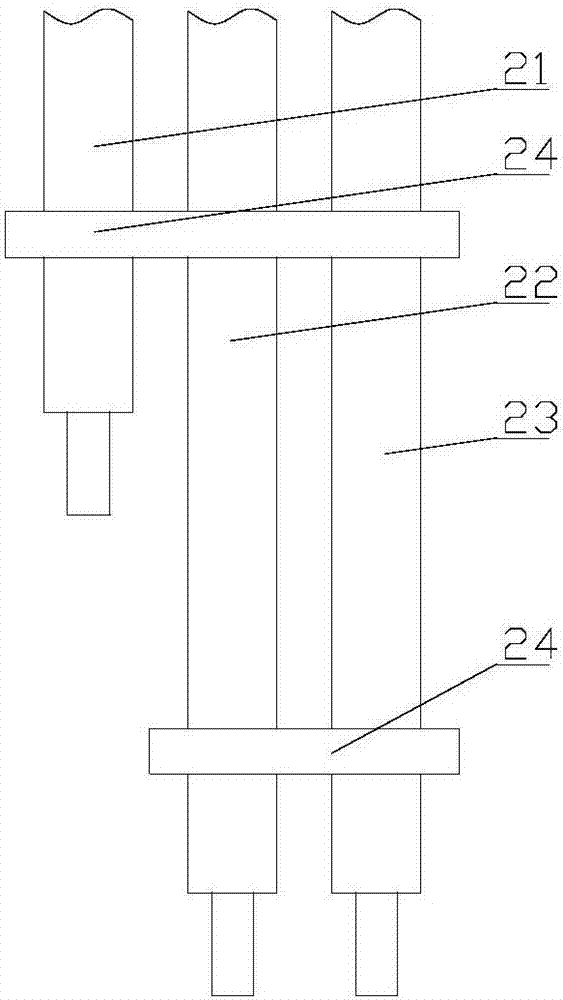

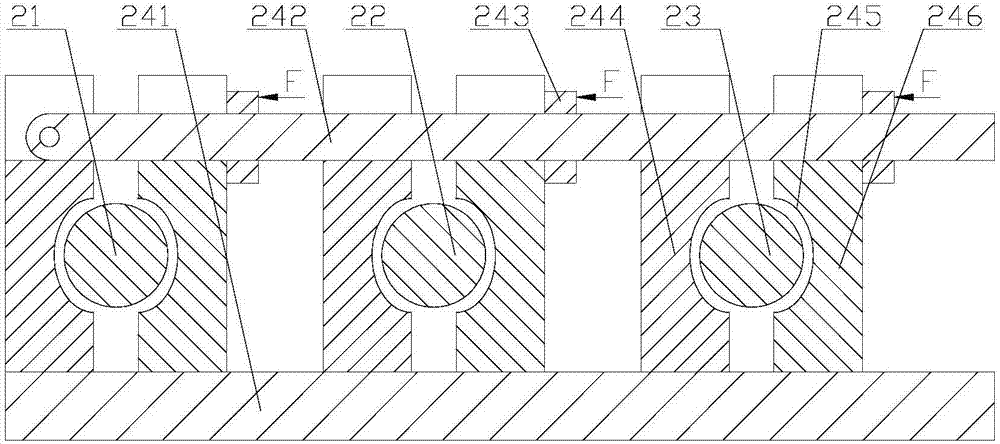

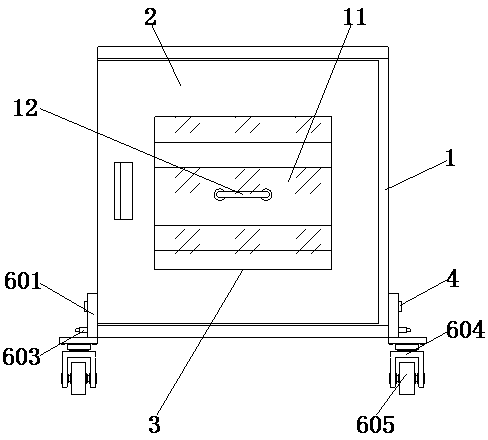

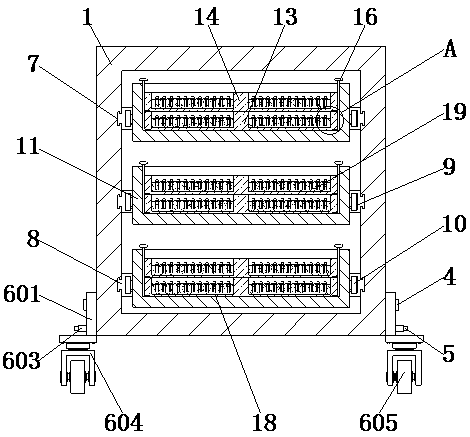

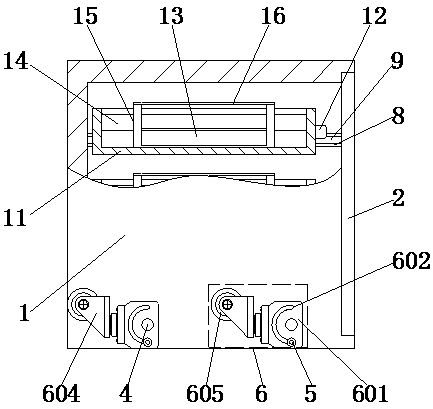

The invention discloses a 3D printing system suitable for a micro-gravity space environment. The 3D printing system comprises a housing (1) and a control unit (2) as well as a workbench (12) arrangedinside the housing (1), a base plate (11) arranged on the workbench (12), a feeding unit, and a processing head part, wherein the feeding unit comprises a storage device (4), a feeding mechanism (6) arranged at one end of the storage device (4) and an ejecting-out mechanism (3) arranged at the other end of the storage device (4); and the processing head part comprises a small laser unit (7). The invention further discloses a 3D printing method suitable for the micro-gravity space environment. The system avoids the crystallization risk that an amorphous alloy is connected and formed in a thermoplastic mode under a long-time high-temperature condition, can achieve coaxial feeding, is high in forming efficiency, guarantees uniform and continuous discharge, can form a part of any shape, can obtain a large-dimension amorphous alloy part with high forming quality, can keep good equipment work stability, and is especially suitable for on-track manufacturing in the space environment.

Owner:HUAZHONG UNIV OF SCI & TECH

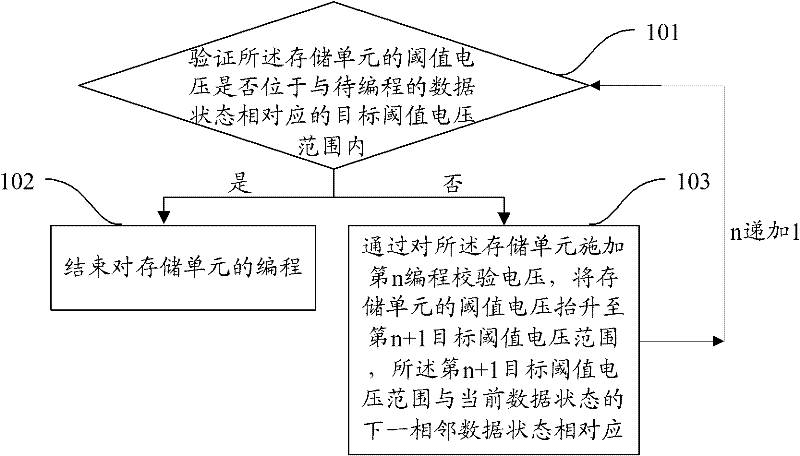

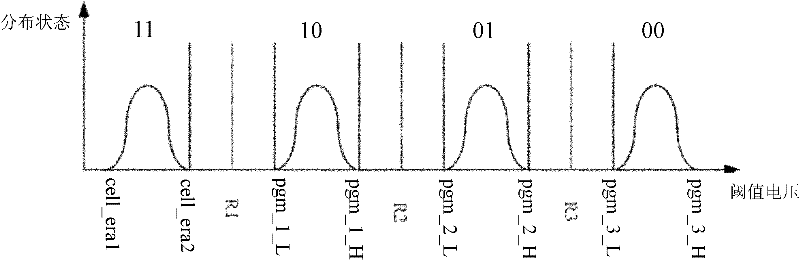

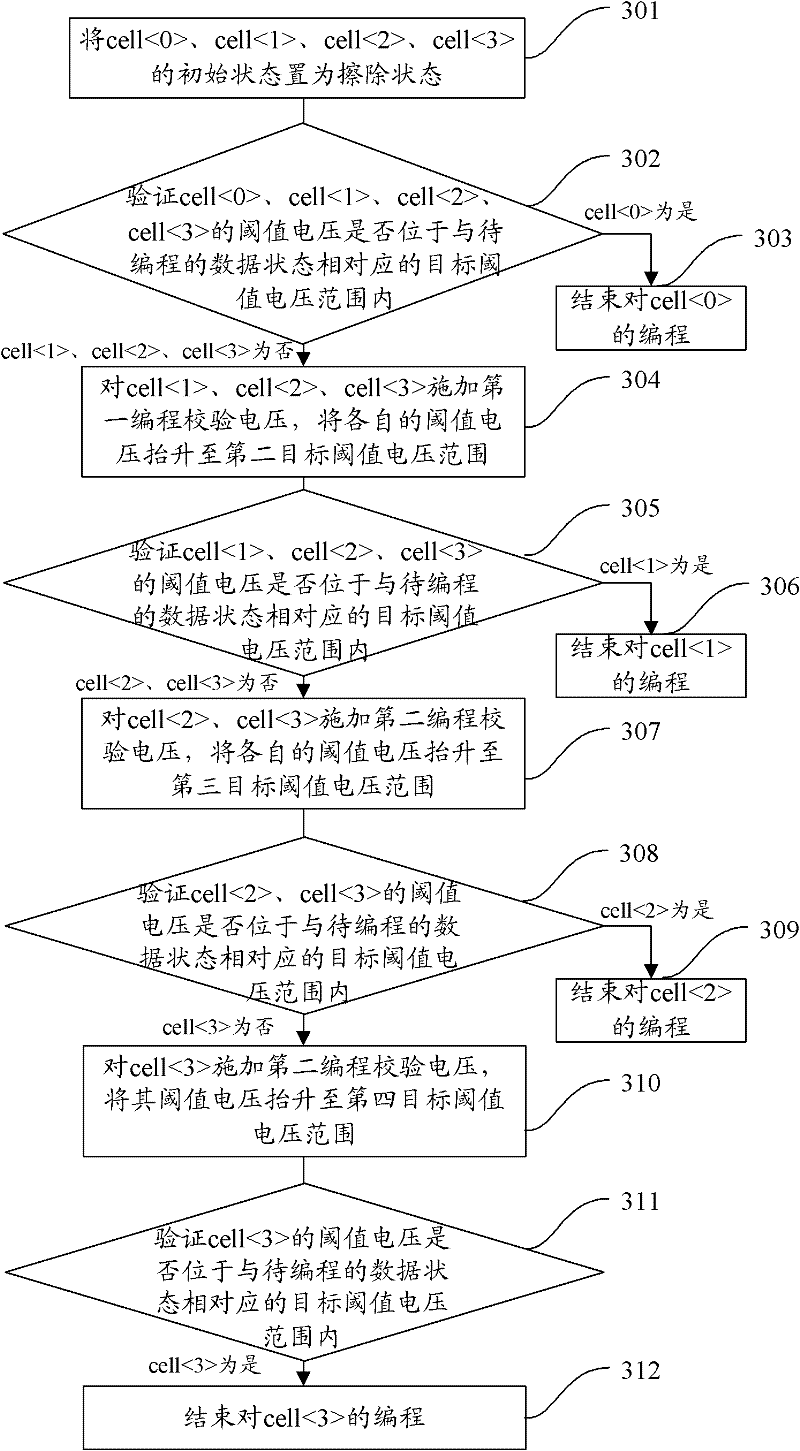

Programming method of MLC (Multi-Level Cell) storage unit and device thereof

ActiveCN102543198AWeaken the changeAvoid scattered distributionRead-only memoriesVoltage rangeStorage cell

The invention provides a programming method of an MLC (Multi-Level Cell) storage unit, and a device thereof. The storage unit stores N bits of data which are in 2N data states. The method comprises the steps of: verifying whether the threshold voltage of the storage unit is within the target threshold voltage range corresponding to the data state to be programmed; ending the programming on the storage unit if yes; executing the threshold voltage raising step if no, and raising the threshold voltage of the storage unit to be in the (n+1)th target threshold voltage range through applying the nth programming verification voltage on the storage unit, wherein the (n+1)th target threshold voltage range is corresponding to the next adjacent data state of the current data state; and then returning to the verification step of threshold voltage, wherein the initial value of n is 1, the value of n is successively increased by 1 whenever returning to the verification step of the threshold voltage, and the maximum value of n is 2N-1. Through the method and the device disclosed by the invention, the accuracy of programming is improved.

Owner:GIGADEVICE SEMICON (BEIJING) INC

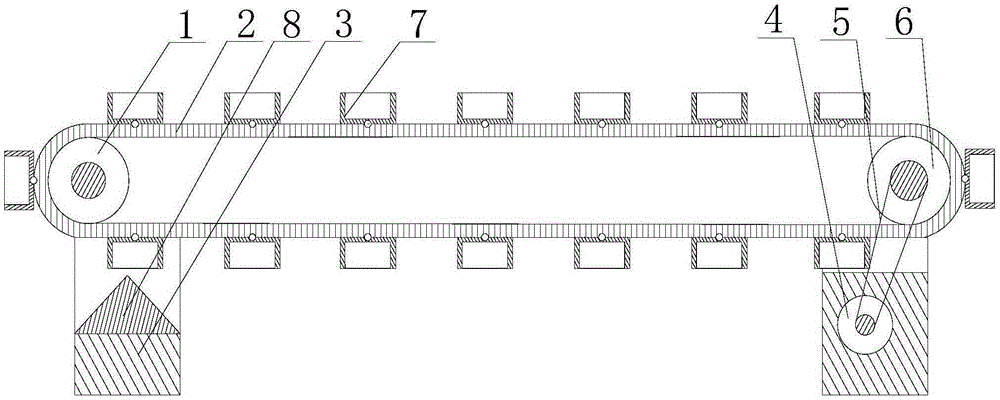

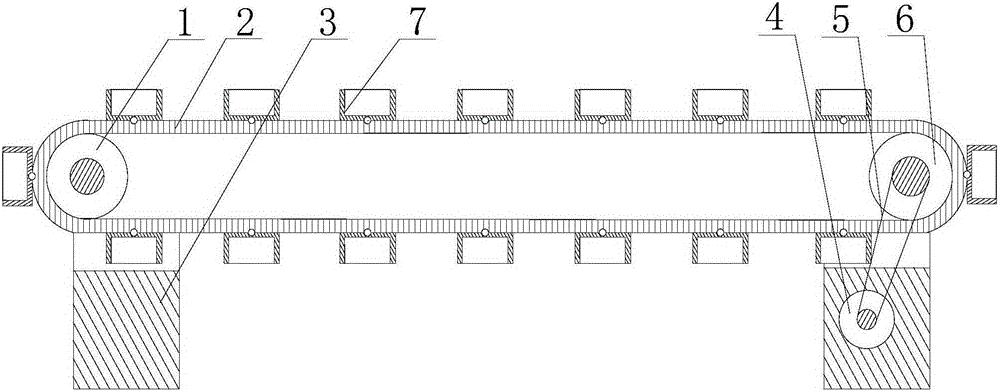

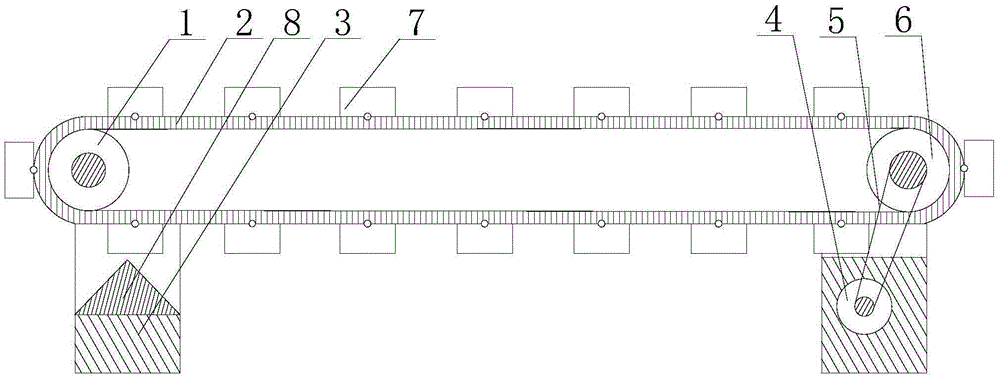

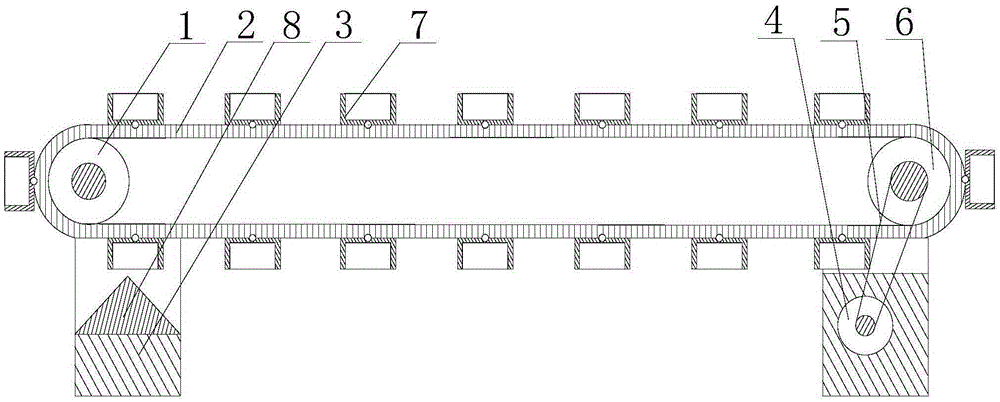

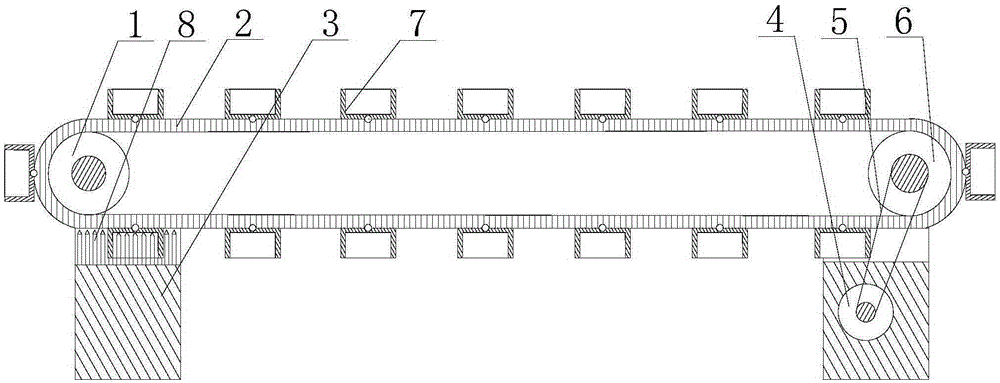

Feeding device for metal machining

InactiveCN106697732AAvoid scattered distributionFeed effectiveConveyorsConveyor partsTransfer procedureMetal machining

The invention discloses a feeding device for metal machining. The feeding device comprises two supporting bases and a conveying chain plate. A main roller and an auxiliary roller are rotationally arranged on the two supporting bases correspondingly. The two ends of the conveying chain plate are arranged in U-shaped areas of the supporting bases and matched with the main roller and the auxiliary roller. Multiple hoppers with the interiors matched with the outlines of aluminum ingots are hinged to the conveying chain plate. A motor is arranged at the bottom of one supporting base, and the output end of the motor is connected and matched with a rotating shaft of the main roller through a belt. A collection block is installed at the bottom of the U-shaped area of the supporting base corresponding to the auxiliary roller. The upper end of the collection block is composed of two connected inclined faces. The connected point of the two inclined faces is right opposite to the conveying chain plate. In the conveying process, the aluminum ingots are in one-to-one correspondence with the hoppers, the traditional problem that aluminum ingots are distributed on a conveying belt in a scattered mode when conveyed is avoided, the step that manual picking is carried out again during feeding is omitted, and feeding of the aluminum ingots is effectively carried out.

Owner:重庆龙之火科技有限公司

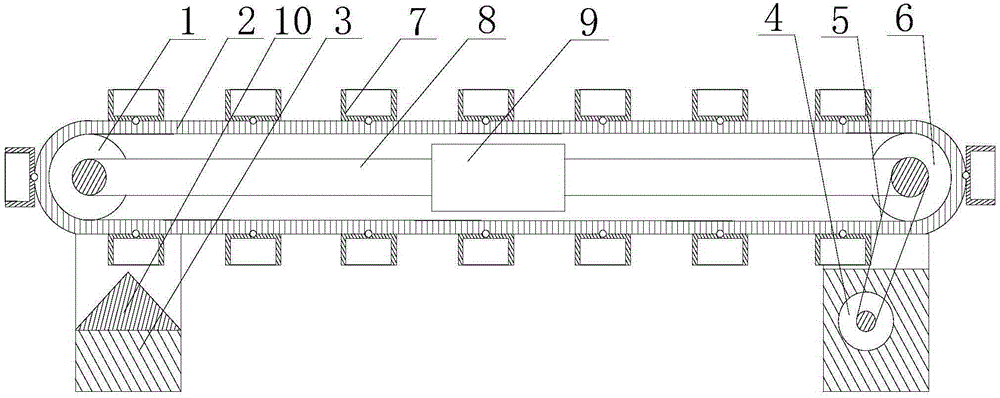

Machining lathe

PendingCN112427663AAvoid scattered distributionEasy to cleanAuxillary equipmentMaintainance and safety accessoriesBalancing machineEngineering

The invention discloses a machining lathe which comprises a lathe body, a machining cavity is formed in the middle of the front face of the lathe body, a flow guide mechanism is fixedly connected to the back face of an inner cavity of the machining cavity, an auxiliary fixing mechanism is movably connected to the middle of the inner wall of the right side of the inner cavity of the machining cavity, an electromagnet is fixedly connected to the bottom of an inner cavity of a bottom groove, a cleaning groove is formed in the position, located above the electromagnet, of the front face of the inner cavity of the bottom groove, a waste disc is slidably connected to the inner surface of the cleaning groove, a balance mechanism is fixedly connected to the middle of the bottom of an inner cavityof the waste disc, and a collecting mechanism is fixedly connected to the top of the balance mechanism. The invention relates to the technical field of lathes. A rotating air screen is formed throughair flow generated by rotation of the equipment, so that splashing of sweeps is blocked, and the periphery is protected; and through wind power generation, electromagnetic force is generated to adsorbthe sweeps, so that he sweeps are cleaned in a centralized mode, the sweeps are prevented from being scattered and distributed in the equipment, and cleaning is convenient.

Owner:焦超锦

Fireproof cable with damage self-alarm function for machine room and alarm method therefor

The invention discloses a fireproof cable with a damage self-alarm function for a machine room and an alarm method therefor. The fireproof cable comprises an elastic protective layer, a rubber block, an alarm, a cable core and an air storage bag. A bundling layer is arranged on the outer side of the elastic protective layer. The outer sides of a positive electrode guide piece and a negative electrode guide piece are sleeved with insulating sleeves. A fireproof layer is arranged on the inner side of the elastic protective layer, and a filling layer is arranged between the elastic protective layer and the fireproof layer. Sliding grooves are formed in the inner wall of the elastic protective layer and the outer wall of the fireproof layer. When the fireproof cable with a damage self-alarm function for a machine room is damaged, fluid gelatin mixed with iron powder on the inner side of the fireproof cable makes contact with the cable core, the alarm is connected to the outer side of the cable core in parallel, and therefore the alarm can give an alarm automatically. The iron powder in the gelatin makes contact with external air at the damaged part and is oxidized to become red, so that a worker can conveniently and quickly check and repair the damaged part. A plurality of cables can be conveniently spliced and bundled, so that the cable is convenient to use.

Owner:王贵友

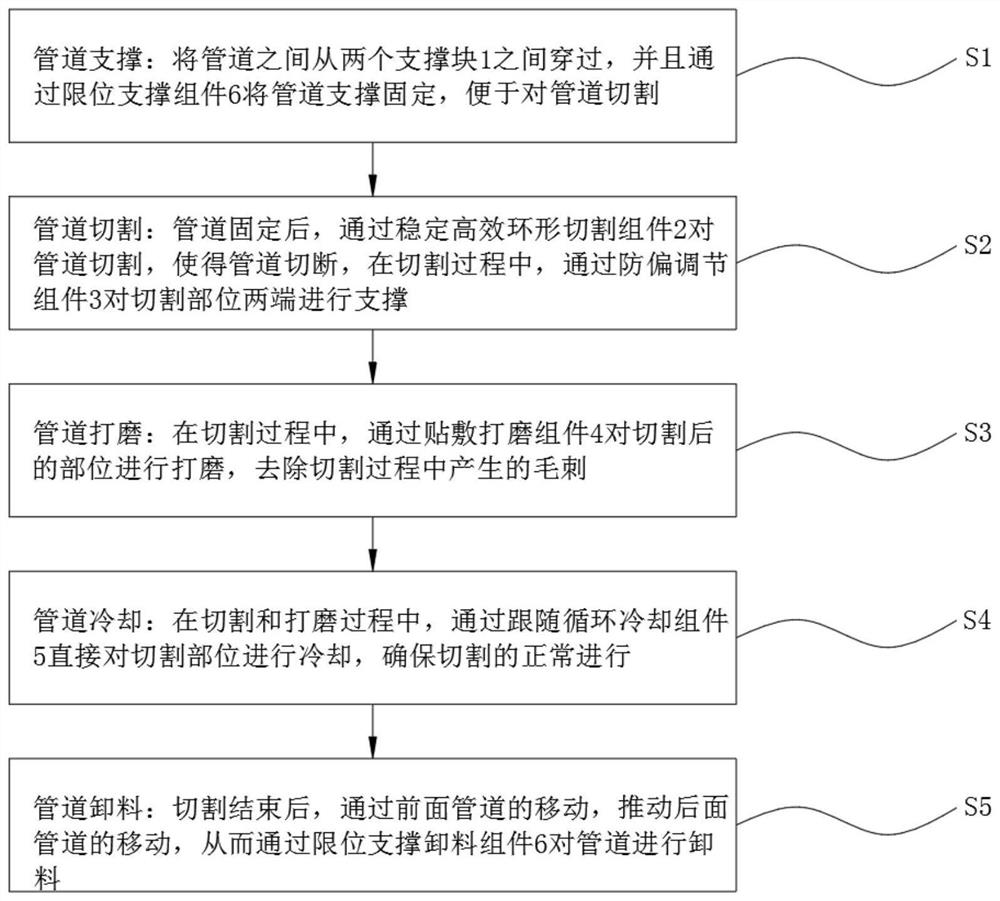

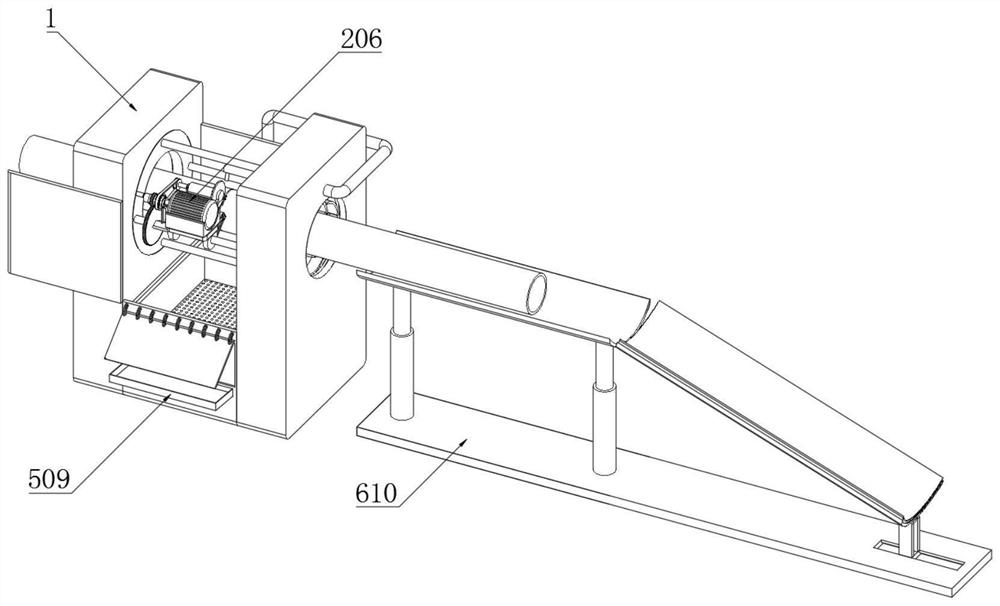

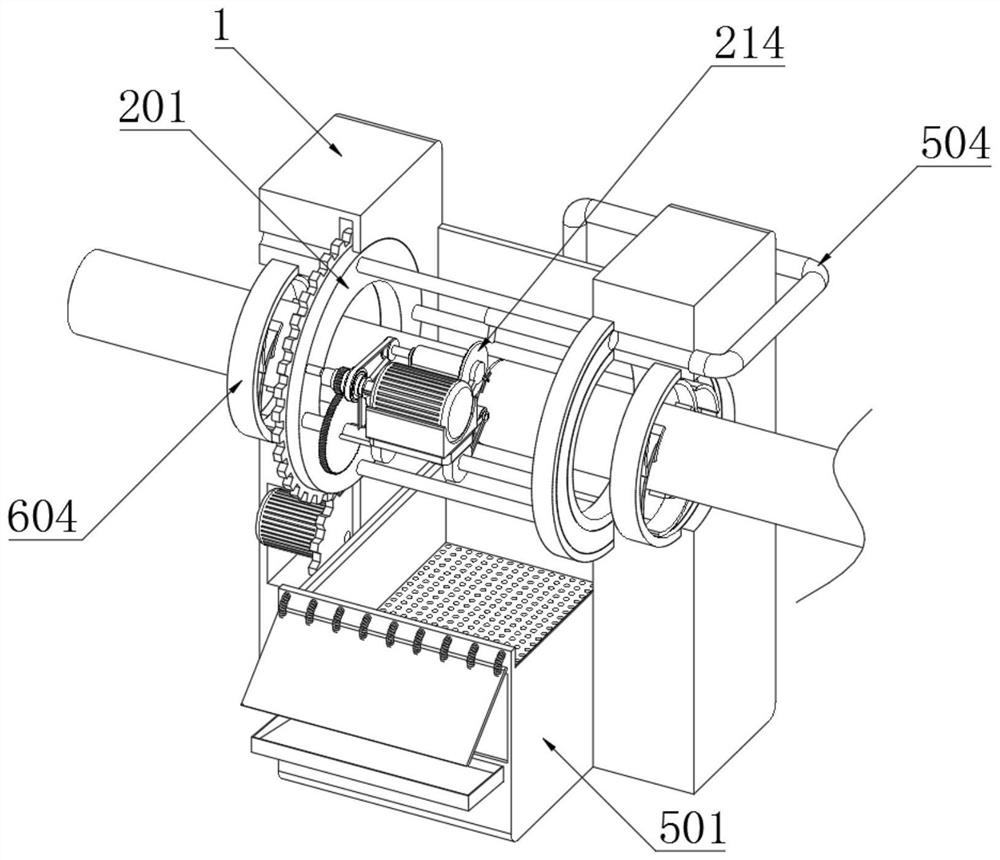

Efficient treatment method based on pipeline machining

ActiveCN112045429AEven by forceAvoid wrinklesOther manufacturing equipments/toolsTube shearing machinesRotational axisElectric machine

The invention discloses an efficient treatment method based on pipeline machining. The method is characterized in that two rotating rings are arranged at the two ends of the bottom of a driving motorcorrespondingly, an output shaft of the driving motor is fixedly connected with a rotating shaft, the outer side of the rotating shaft is movably sleeved with a rotating cylinder, a movable electric push rod is arranged at one end of the rotating cylinder, one end of the movable electric push rod is arranged at one end of the rotating ring, one end of the rotating cylinder is movably connected toone end of a first belt driving mechanism in a sleeve mode, the other end of the first belt driving mechanism is connected to the outer side of the rotating shaft in a sleeving mode, the outer side ofone end of the rotating shaft is provided with a cutting blade through a screw, a fixing frame is movably arranged on the outer side of the rotating shaft, and one end of the fixing frame is arrangedon the one end of the driving motor. According to the method, the cutting blade can gradually go deep in the cutting process, so that cutting is easy, the cutting effect and efficiency are improved,the phenomena that the cutting blade is stuck and broken in the cutting process are effectively prevented, the safety coefficient in the cutting process is improved, the cutting quality and efficiencyare improved, and the service life of the cutting blade is effectively prolonged.

Owner:沧州市鑫宜达管道有限公司

Device for recycling waste template of construction engineering

InactiveCN111456436AReduce construction costsClean up comprehensivelyForm treatmentHydraulic cylinderElectrical battery

The invention discloses a device for recycling a waste template of construction engineering. The device comprises a cleaning platform and a cleaning device; the surface of the cleaning platform is provided with a U-shaped baffle; supporting columns are arranged at the upper parts of the two ends of the cleaning platform; a first sliding chute is arranged inside a sliding rod; a battery box is fixed to the top of a sliding plate box; the cleaning device is fixed to the bottom of the sliding plate box; the bottom of each supporting column is connected with a pulley; the upper surfaces of the twoends of the cleaning platform are each provided with a second sliding chute; the middle part of the cleaning platform is provided with a pouring opening; and the bottom of one side of a container isprovided with a discharging opening. According to the device for recycling the waste template of construction engineering, a second hydraulic cylinder is used for pushing a hydraulic rod to make surethat a crushing shovel is close to the surface of a template body; after the crushing shovel is close to the surface of the template body, a vibrating motor starts to vibrate to oscillate and crush concrete blocks on the surface of the template body; the concrete blocks on the surface of the template body can be reused after being removed; and thus the construction cost of the engineering can be beneficially lowered.

Owner:华夏董氏实业集团有限公司

Use method of feed transmission mechanism for semi-finished aluminum ingots

InactiveCN106697891AAvoid scattered distributionFeed effectiveConveyorsConveyor partsMetallurgyWork in process

The invention discloses a use method of a feed transmission mechanism for semi-finished aluminum ingots. The use method comprises the steps: the produced semi-finished aluminum ingots are put into hoppers, the surroundings of each aluminum ingot directly contacts with the inner wall of a containing chamber, the aluminum ingot extrudes the inner wall of the containing chamber by gravity, and therefore the aluminum ingot is stably placed; a main roller is driven by a starting motor to run, and a slave roller is matched with the main roller; a transmission chain plate starts continuous motion from the main roller to the slave roller, and the hoppers correspond to the aluminum ingots one to one; when the hopper move to the transmission chain plate directly facing to the slave roller, the hoppers tip over, and therefore the feed transmission of the aluminum ingots is realized.

Owner:重庆龙之火科技有限公司

Power distribution cabinet with good heat dissipation effect

InactiveCN110932142AImprove cooling effectSimple structurePhotovoltaic supportsSolar heating energyEngineeringWrench

Owner:南京荧河谷科技有限公司

Multi-purpose multimedia platform

InactiveCN108041812AEasy to detectAvoid scattered distributionPulpitsLecternsAudio power amplifierEngineering

The invention relates to the technical field of teaching equipment, and discloses a multi-purpose multimedia platform. The multi-purpose multimedia platform comprises a main box and a platform body, wherein the platform body is fixedly mounted at the upper side of the main box, a baffle is fixed on the platform body, the platform body is provided with a cover which forms an inner cavity when beingin covering with the baffle, the cover is in sliding connection with the platform body, a dust hole is formed in the platform body, the main box comprises a machine room part and a cord arrangement part, the machine room part is provided with a host groove used for placing a computer host, the host groove is provided with a limiting block capable of sliding on the host groove, an air amplifier isfixed at one side of the host groove, an air pump is fixed at the other side of the host groove, a high pressure air box communicates with the air amplifier through an electromagnetic valve, and thehost groove communicates with the air pump; a plurality of groove racks for wiring which are uniformly distributed on the main box are arranged on the cord arrangement part, the outlet of the air amplifier points to the groove racks, a main groove rack communicating with the groove racks is fixed on the main box, and a multi-purpose power socket is fixed at one side of the main groove rack. For the multi-purpose multimedia platform, a power cord of a multimedia device is reasonably arranged while dust prevention is realized.

Owner:重庆远望广告有限公司

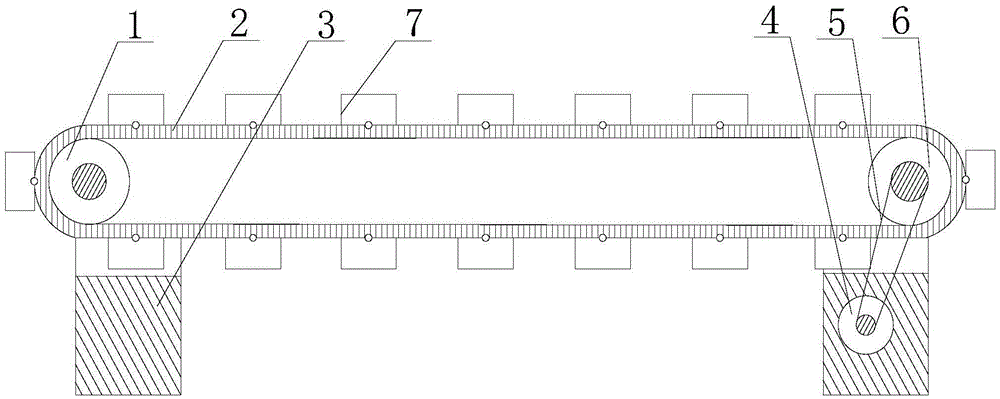

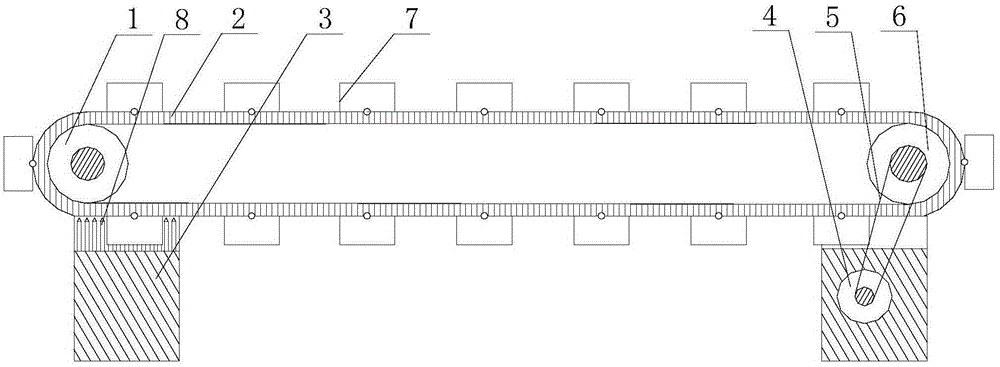

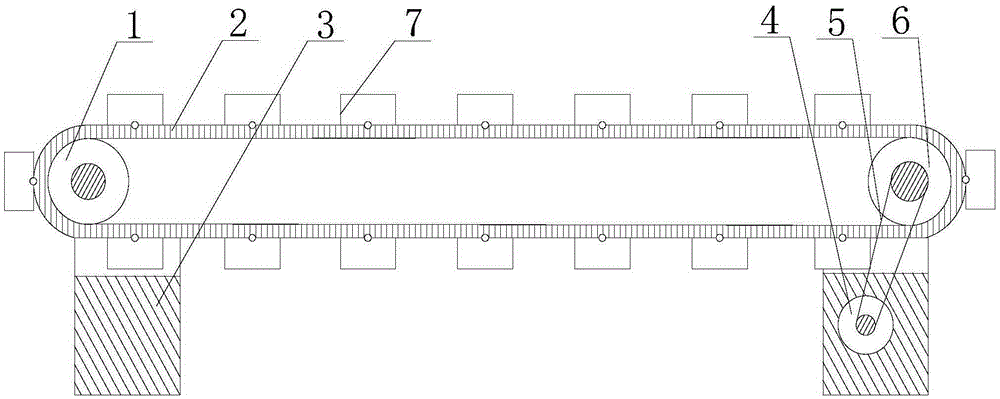

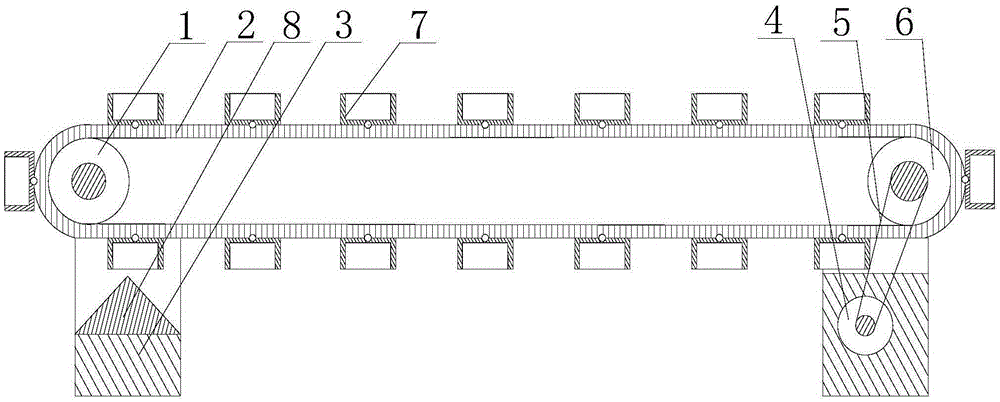

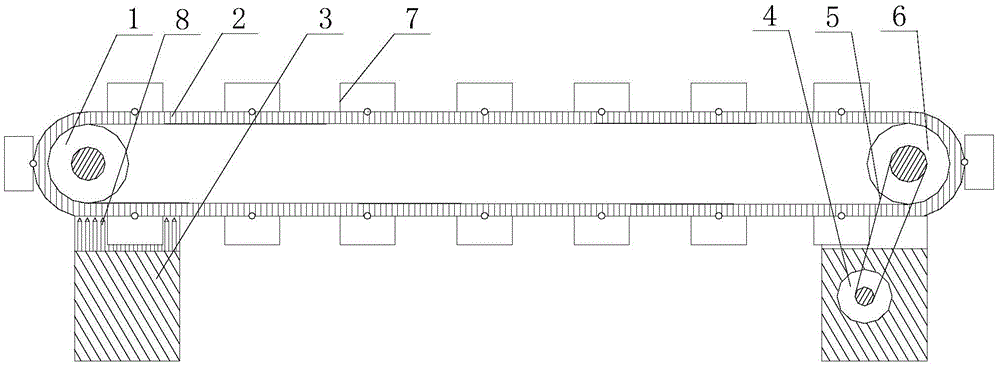

Automatic aluminium ingot conveying structure

InactiveCN106697731AAvoid scattered distributionFeed effectiveConveyorsTransfer procedureEngineering

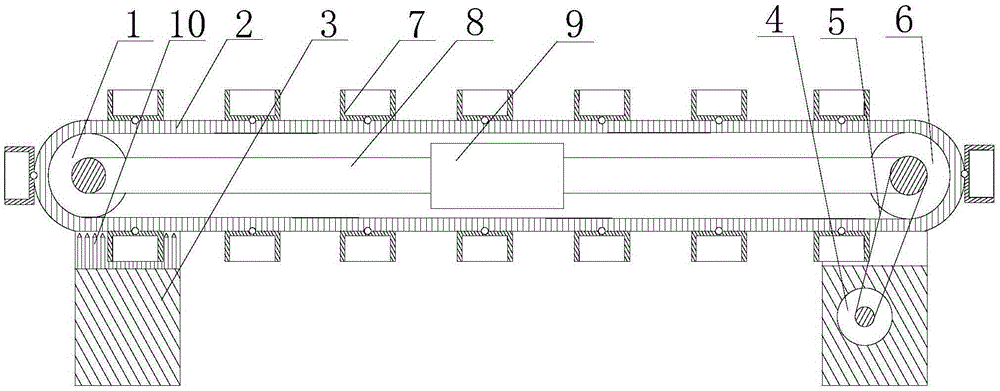

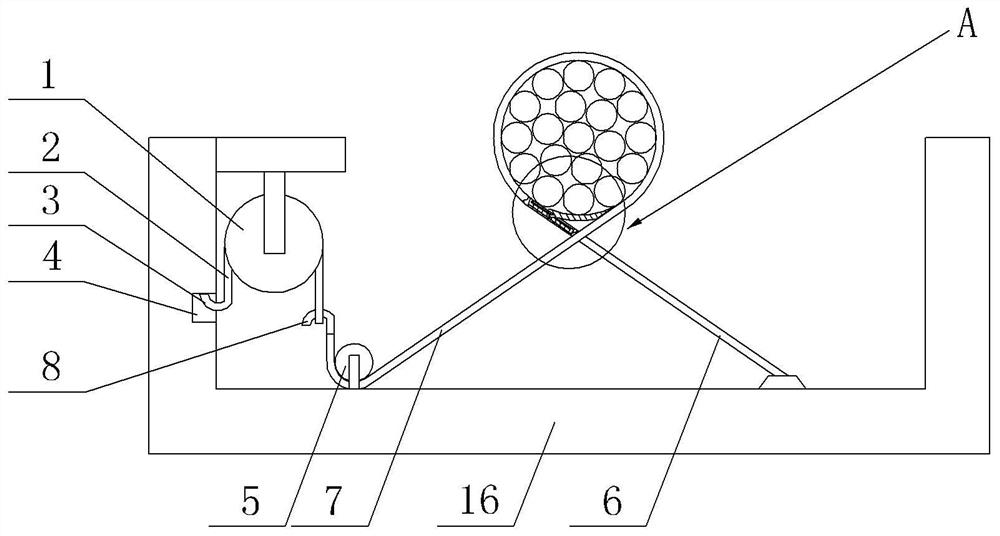

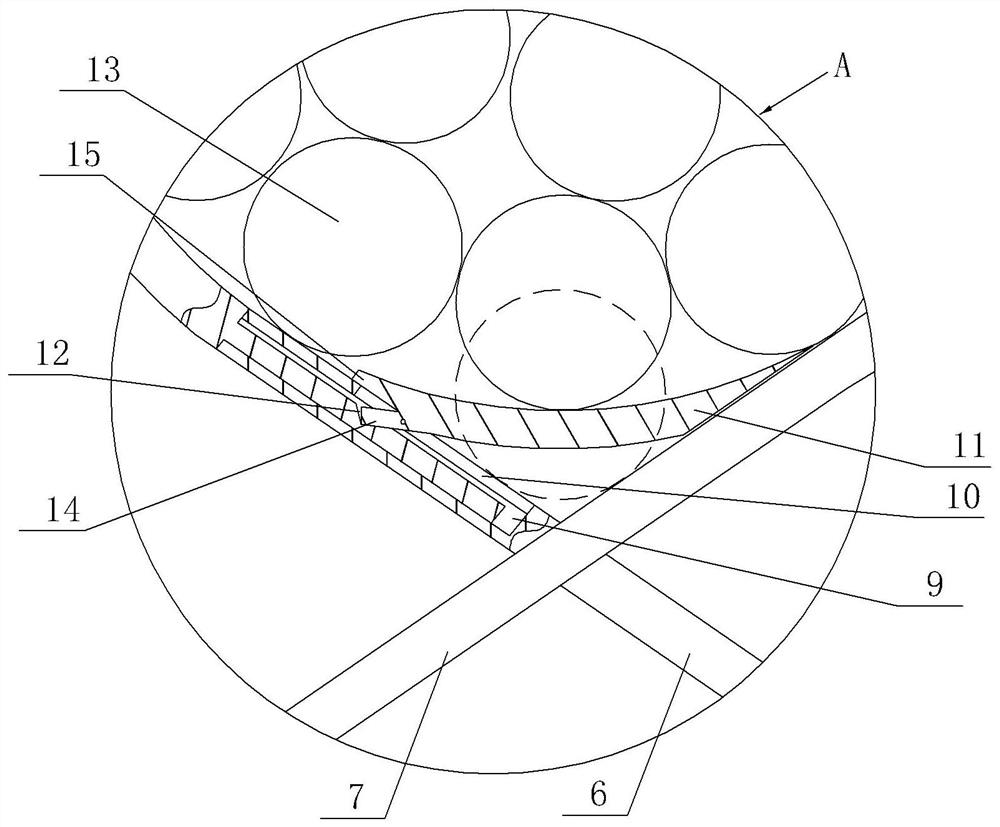

The invention discloses an automatic aluminium ingot conveying structure. The automatic aluminium ingot conveying structure comprises two U-shaped supporting seats which are arranged at an interval and a conveying chain plate; a master roller and a slave roller are respectively and rotatably arranged on the two supporting seats; the two ends of the conveying chain plate are placed in U-shaped areas of the supporting seats and are matched with the master roller and the slave roller; a plurality of material hoppers of which the interiors are matched with the appearance of aluminium ingots are hinged to the conveying chain plate; the automatic aluminium ingot conveying structure also comprises a motor; the motor is placed at the bottom of a supporting seat, and an output end of the motor is connected and matched with a rotating shaft of the master roller through a belt. During a conveying process, the aluminium ingots are in one-to-one correspondence with the material hoppers, so that the aluminium ingots are prevented from being dispersedly distributed on a conveying belt in conventional conveying; the step of manual picking when the aluminium ingots are fed is omitted, and the aluminium ingots are fed effectively.

Owner:重庆龙之火科技有限公司

Feeding structure for finishing aluminum ingot

The invention discloses a feeding structure for finishing aluminum ingots, comprising two supporting bases and conveyor chain plates; a drive roller and a driven roller are rotatably arranged on the two supporting bases respectively, and both ends of the conveyor chain plates are arranged in the U-shaped areas of the supporting bases and fit to the drive roller and the driven roller; a plurality of hoppers are hinged on the conveyor chain plates, motors are arranged at the bottoms of the supporting bases, and the output ends of the motors are connected to the rotating shaft of the drive roller through a belt; a collecting block is arranged at the bottom of the U-shaped area of the supporting base corresponding to the driven roller, the upper end of the collecting block is composed of two inclined planes connected to each other, and the connecting points of the two inclined planes are dead against the conveyor chain plates. In the conveying process, the aluminum ingots are corresponding to the hoppers one by one, thereby avoiding the disadvantage that the aluminum ingots are scattered on the conveyor chain plate in traditional conveying, and omitting the step of manually sorting the aluminum ingots once again in feeding, so that the aluminum ingots are fed effectively.

Owner:重庆龙之火科技有限公司

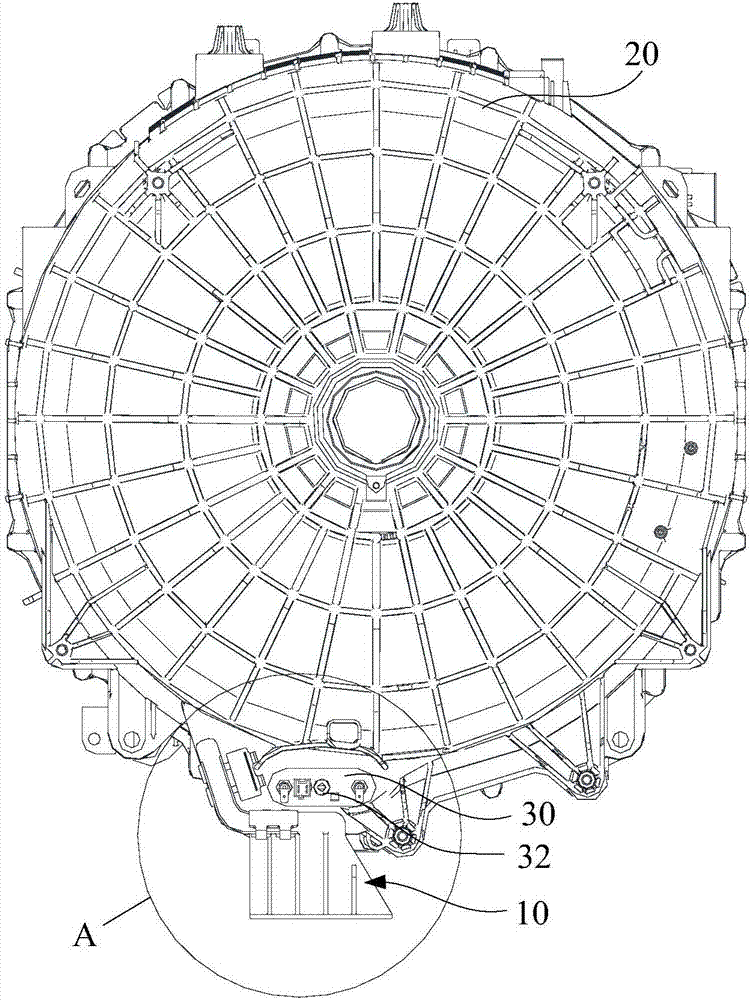

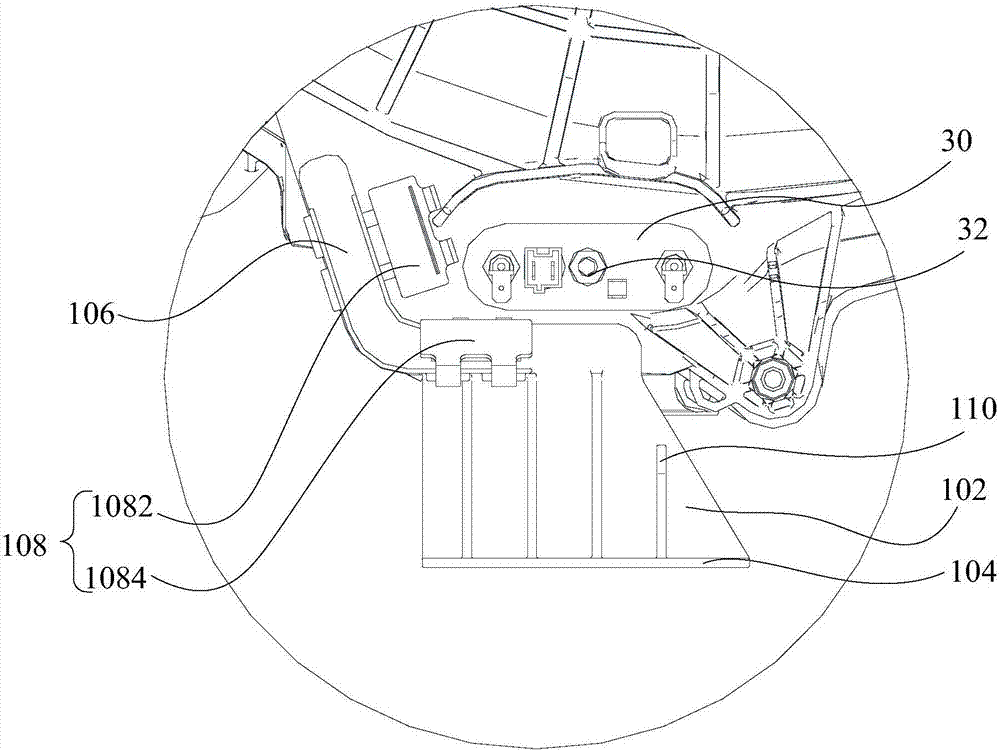

Safety plate assembly and washing machine

ActiveCN107385801AImprove securityImprove reliabilityOther washing machinesTextiles and paperEngineeringMechanical engineering

The invention provides a safety plate assembly and a washing machine. The safety plate assembly comprises a connecting plate and a collecting plate. The connecting plate is connected with the collecting plate and an outer barrel, and the collecting plate is positioned below a heating terminal. The safety plate assembly and the washing machine have the advantages that the projection of the heating terminal in the vertical direction falls on the collecting plate, so that molten materials can be collected by the safety plate assembly once the heating terminal is molten due to excessively high temperatures, fire hazards caused by molten materials which fall on ignitable articles such as carpets can be prevented, and the safety and the reliability can be enhanced when the washing machine is used by users; the safety plate assembly further comprises reinforcing ribs, the reinforcing ribs are connected with the connecting plate and the collecting plate, accordingly, effects of improving the strength of the safety plate assembly can be realized, and the connecting plate and the collecting plate further can be prevented from being damaged in transport procedures.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Radix paeoniae alba sorting machine

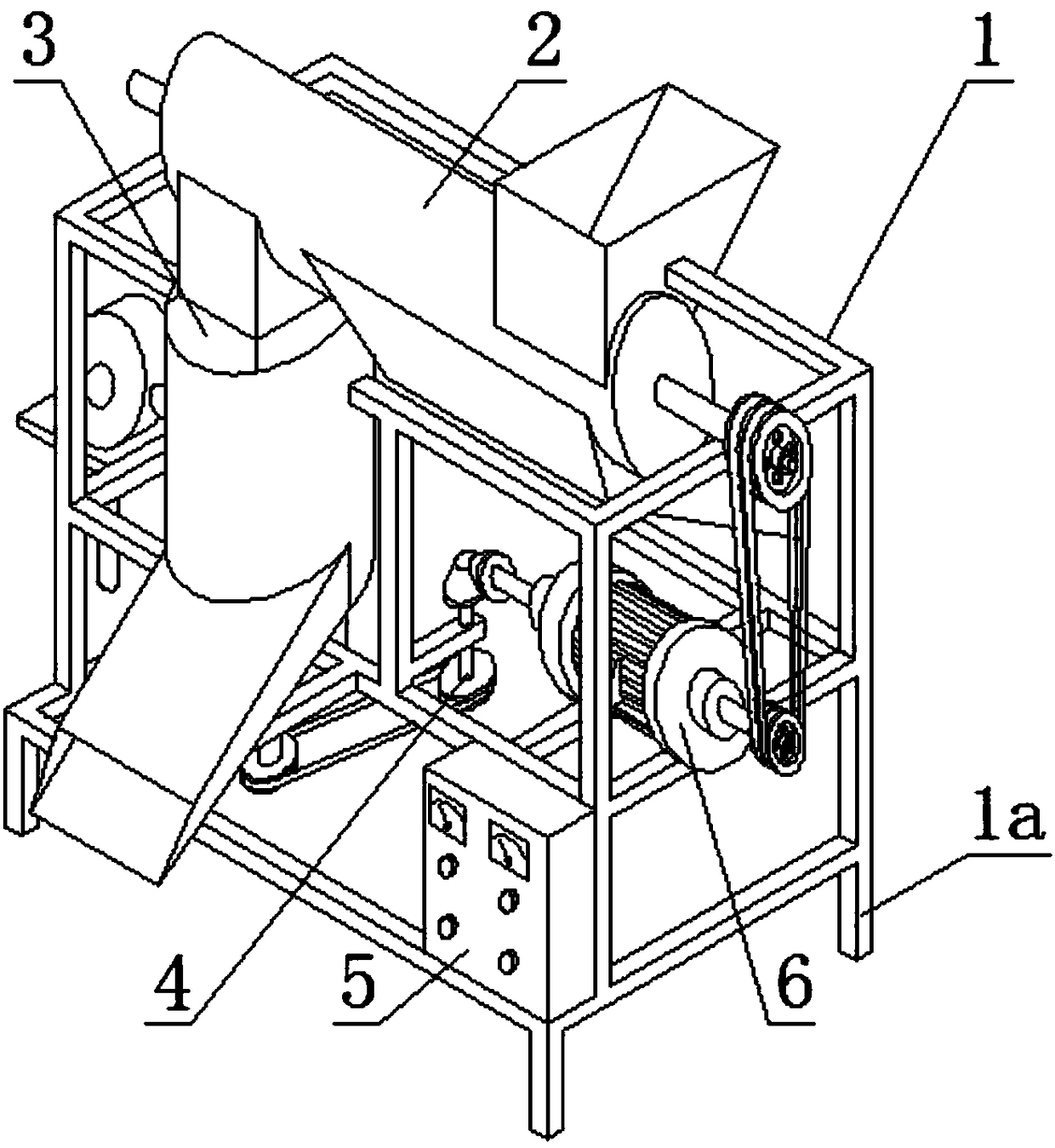

InactiveCN108160489AConvenient for centralized processingEasy to disengageSievingGas current separationTransmission beltPulp and paper industry

The invention relates to the technical field of medicinal materials and discloses a radix paeoniae alba sorting machine. The machine comprises a rack, a screening device, an air suction device, an intermediate shaft assembly, a motor assembly and a control electric cabinet. Supports are arranged at the bottom of the rack. The screening device is mounted at the top of the rack and comprises a barrel, an auger assembly, end covers sand a second transmission belt pulley. The end covers are mounted at the two ends of the barrel correspondingly. Through holes are formed in the end covers. The augerassembly is mounted in the barrel through the end covers. The second transmission belt pulley sleeves one end of an auger. According to the radix paeoniae alba sorting machine, the screening device enables sliced radix paeoniae alba to be transported through the auger, granulate impurities contained in the radix paeoniae alba are discharged through impurity discharging holes in the bottom of thebarrel, the large granular impurities are automatically screened and discharged, the air suction device enables thread residues or tiny dust in the radix paeoniae alba to be extracted out, the cleanliness of the radix paeoniae alba is further improved, and the machine is low in cost, high in efficiency and beneficial for popularization.

Owner:李朋飞

Feeding mechanism for machine tool

InactiveCN106697742AAvoid scattered distributionFeed effectiveConveyorsTransfer procedureEngineering

The invention discloses a feeding mechanism for a machine tool. The feeding mechanism comprises two supporting seats and a transfer chain plate. A driving roller and a driven roller are rotatably arranged on the two supporting seats separately; the two ends of the transfer chain plate are placed in the U-shaped regions of the supporting seats and the transfer chain plate is matched with the driving roller and the driven roller; and a plurality of hoppers matched with aluminum ingots in shape inside are hinged to the transfer chain plate. The motor is placed in the bottom of one of the supporting seats and the output end of the motor is connected to and matched with a rotary shaft of the driving roller; and a collecting block is mounted in the bottom of the U-shaped region of the supporting seat corresponding to the driven roller, the upper end of the collecting block is formed by two inclined surfaces which are connected to each other, and the connecting points of the two inclined surfaces is aligned to the transfer chain plate. In the transfer process, the aluminum ingots are in one-to-one correspondence to the hoppers, the aluminum ingots are prevented from being scattered and distributed to a conveyor belt during conventional conveyance, and the step of manually sorting the aluminum ingots during feeding is cancelled, so that the aluminum ingots are effectively fed.

Owner:重庆龙之火科技有限公司

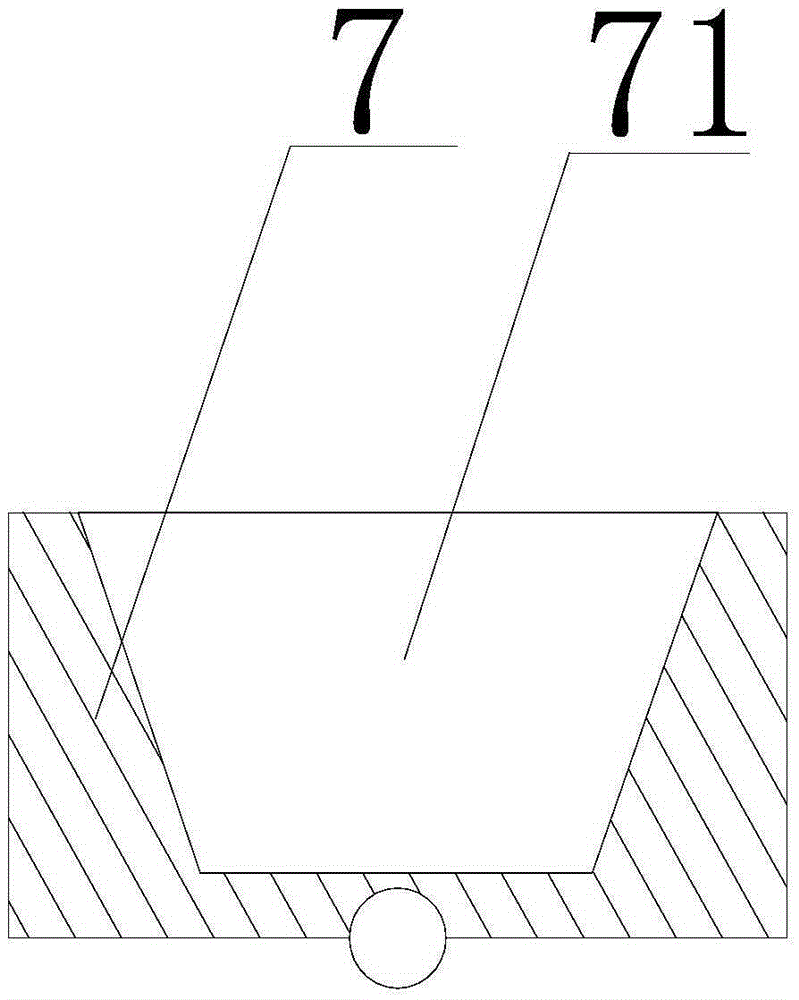

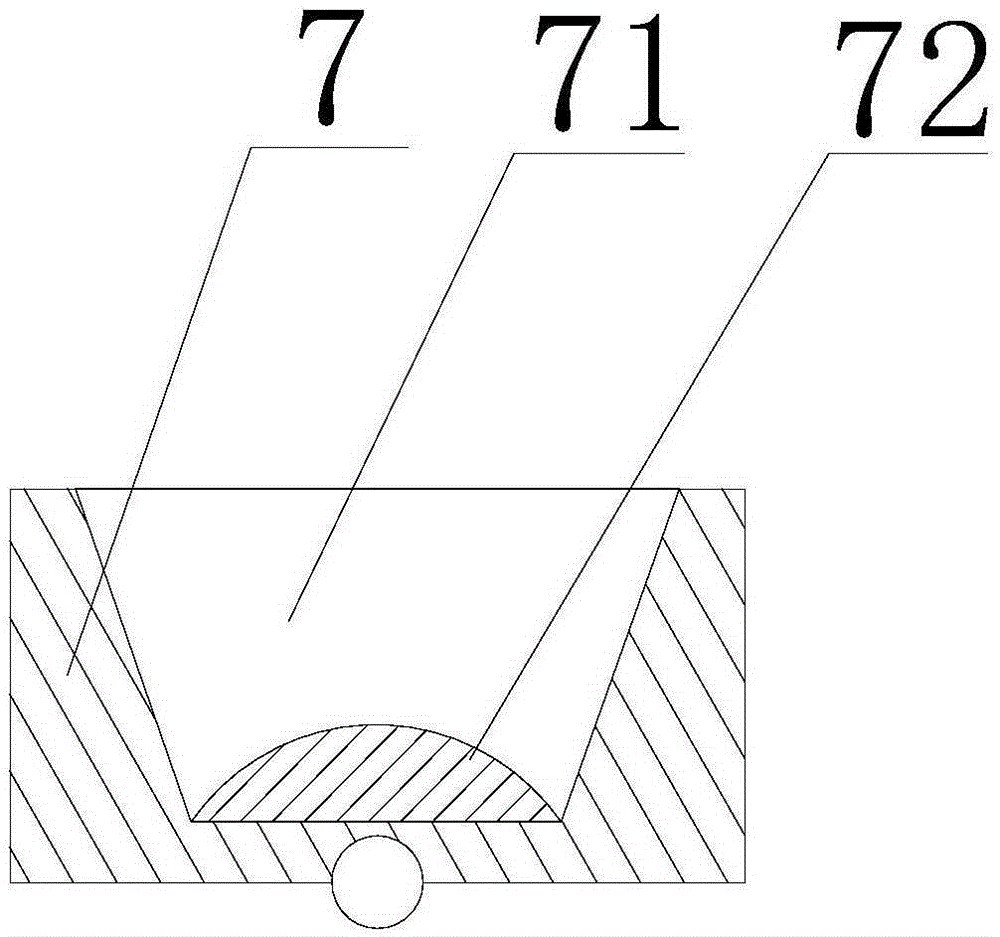

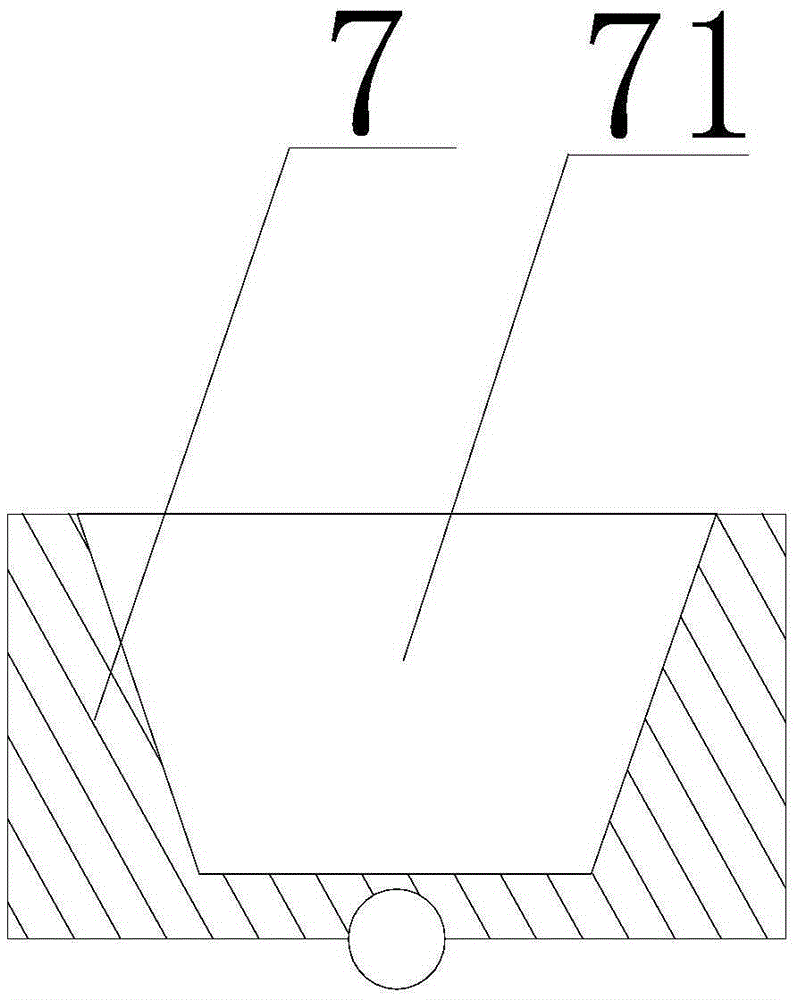

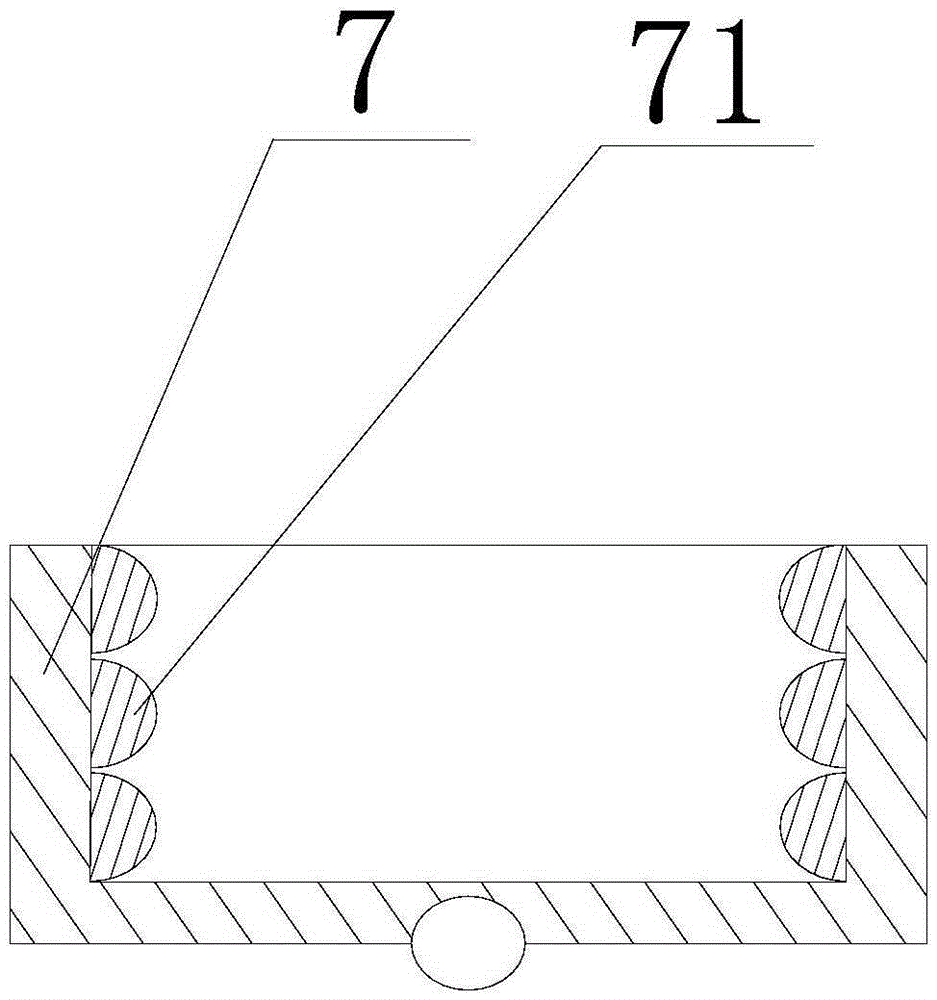

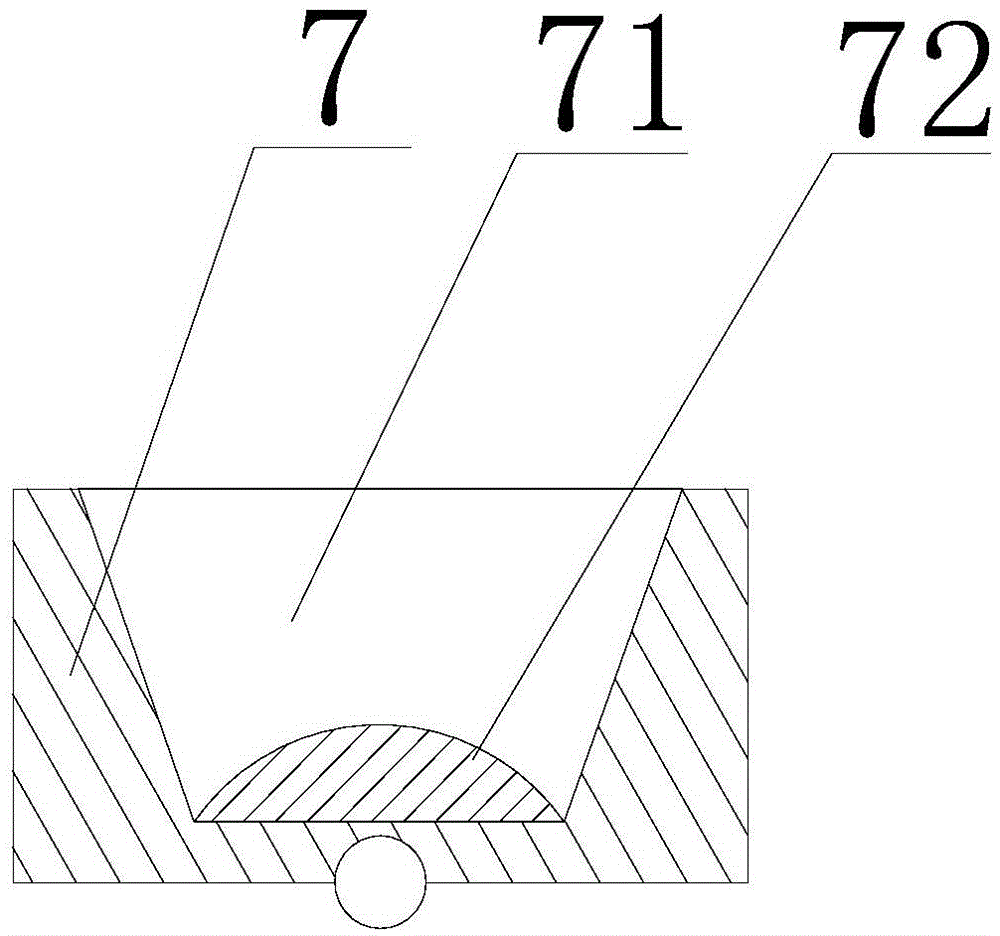

Conveying transfer structure

InactiveCN106697745AAvoid scattered distributionLarge carrying capacityConveyorsCleaningBristleTransfer procedure

The invention discloses a conveying transfer mechanism which comprises two supporting bases and a conveying chain plate. A main roller and an auxiliary roller are rotationally arranged on the two supporting bases correspondingly. The two ends of the conveying chain plate are arranged in U-shaped areas of the supporting bases and matched with the main roller and the auxiliary roller. Multiple hoppers with the interiors matched with the outlines of aluminum ingots are hinged to the conveying chain plate. A bristle brush is installed at the bottom of the U-shaped area of the supporting base corresponding to the auxiliary roller. A containing cavity is formed in the middle of each hopper. The longitudinal section of each containing cavity is in a trapezoid shape, and the width of each containing cavity is gradually decreased in the direction vertically from the upper end to the lower end of the corresponding hopper. In the conveying process, the aluminum ingots are in one-to-one correspondence with the hoppers, the traditional problem that aluminum ingots are distributed on a conveying belt in a scattered mode when conveyed is avoided, the step that manual picking is carried out again during feeding is omitted, and feeding of the aluminum ingots is effectively carried out.

Owner:重庆龙之火科技有限公司

High-precision raw material cutting device for chopstick production

InactiveCN110919779AEasy to fixControl cutting lengthProfiling/shaping machinesBark-zones/chip/dust/waste removalElectric machineryFan blade

The invention relates to the technical field of chopstick production, and discloses a high-precision raw material cutting device for chopstick production. The high-precision raw material cutting device comprises a workbench; a controller is mounted on the front side of the workbench; a cover plate is arranged on one edge of the top end of the workbench; a fixed lapping frame is connected in the position, close to the cover plate, of the top end of the workbench; a moving lapping frame is connected at the top end of the workbench; two first square holes are formed in the top end of the workbench; a sliding groove is formed in the middle of the top end of the workbench; and a second motor is mounted on one edge of the inner side of the workbench. According to the high-precision raw materialcutting device, by the aid of a receiving hole, a receiving plate, a first motor, fan blades, a ventilation hole, an air draft casing, a wood dust collecting box and a sealing door, wood dust producedby cutting of raw materials can be collected conveniently and can be prevented from being distributed in a scattered manner during cutting of the raw materials, and the raw materials cut into sections can be collected conveniently, so that use by workers is facilitated.

Owner:陈雪军

Using method of metal aluminum product transporting mechanism

The invention discloses a using method of a metal aluminum product transporting mechanism. The using method comprises the following steps that produced aluminum ingot semi-finished products are placed in hoppers, the peripheries of the aluminum ingots make direct contact with the inner walls of cavities, the aluminum ingots form extrusion for the inner walls of the cavities through the self gravity, elastic protrusions are arranged at the bottoms of the cavities, accordingly, the bottoms of the aluminum ingots make contact with the tops of the elastic protrusions when the aluminum ingots are placed in the hoppers, and then it is ensured that the aluminum ingots are stably placed; a motor is started to drive a main roller to operate, and an auxiliary roller is used in cooperation with the main roller; a conveying chain plate starts to continuously move in the direction from the main roller to the auxiliary roller, the hoppers are turned over when moving to the conveying chain plate part right opposite to the auxiliary roller, and then conveying feeding of the aluminum ingots is achieved; and when each hopper enters the bottom of the conveying chain plate after finishing dumping, a bristle brush is bent to enter the hopper through the self elasticity, meanwhile, relative movement occurs between the hopper and the bristle brush, and therefore the bristle brush starts to remove scraps in the hopper.

Owner:重庆龙之火科技有限公司

Water-gas separator

PendingCN107063822AEasy to analyzeImprove analysis accuracyPreparing sample for investigationMechanical engineeringWater treatment

The invention discloses a water-gas separator and belongs to the technical field of tail gas treatment. The invention aims at providing the water-gas separator with a liquid level detection function and the water-gas separator can be used for effectively controlling a liquid level in the water-gas separator. The water-gas separator comprises a shell body, wherein a tail-gas inlet, a tail-gas outlet and a cable threading-in opening are formed in the upper part of the shell body; a water outlet is formed in the lower part of the shell body; the water outlet is connected with a water drainage pipeline; the water drainage pipeline is provided with a water drainage valve; the water-gas separator is further provided with a liquid level detection cable for detecting the liquid level; one end of the liquid level detection cable stretches into the shell body through the cable threading-in opening; the other end of the liquid level detection cable is electrically connected with a controller; the controller is electrically connected with the water drainage valve. The water-gas separator is applicable to water removal treatment of tail gas.

Owner:CHENGDU NANFANG ELECTRONICS METER CO LTD

Anti-bending classified storage device for semiconductor light emitting diodes

The invention discloses an anti-bending classified storage device for semiconductor light emitting diodes. The anti-bending classified storage device comprises a cabinet body, a connecting frame and asecond sliding groove. A cabinet door is mounted on one side of the cabinet body; a window is formed in the middle of the cabinet door, a rotating shaft is arranged on the lower portion, perpendicular to the surfaces of the two sides of the cabinet door, of the cabinet body, the outer side of the rotating shaft is connected with a moving mechanism, the connecting frame is connected into a connecting groove in the bottom of the first containing disc through a first sliding groove, and a semiconductor light-emitting diode is placed in a second sliding groove. The anti-bending classified storagedevice for the semiconductor light emitting diodes is provided with a square groove; when the first containing disc and the second containing disc are placed in an overlapped mode, due to the fact that the pins of the semiconductor light-emitting diodes are arranged in the fixing pads and the tops of the semiconductor light-emitting diodes are located in the square grooves and are not extruded bythe bottom of the second containing disc, the situation that the pins of the semiconductor light-emitting diodes are bent and accordingly fracture, inconvenient welding and the like are caused is avoided.

Owner:深圳市宏迪尼斯技术有限公司

Aluminum ingot conveyor

The invention discloses an aluminum ingot conveyor. The aluminum ingot conveyor comprises two supporting bases and a conveying chain plate. A drive roller and a driven roller are rotationally arranged on the two supporting bases correspondingly. A plurality of hoppers are hinged to the conveying chain plate. A motor is arranged at the bottom of one supporting base, and the output end of the motor is connected and matched with a rotating shaft of the drive roller through a belt. Containing cavities are formed in the middle portions of the hoppers, the longitudinal sections of the containing cavities are in a trapezoid shape, and the widths of the containing cavities are gradually reduced in the direction that the upper ends of the hoppers vertically point at the lower ends of the hoppers. Elastic protrusions are arranged at the bottoms of the containing cavities, the longitudinal sections of the elastic protrusions are in an arc shape, the vertical distance between the highest point of the elastic protrusions and the bottoms of the containing cavities is h, and the height of the containing cavities is H, wherein h<=1 / 2H. In the transmission process, aluminum ingots correspond to the hoppers in a one-to-one manner, the traditional manner that during conveying, the aluminum ingots are distributed on a conveying belt in a scattered manner is avoided, the step of conducting manual sorting again during feeding is omitted, and aluminum ingot feeding is effectively conducted.

Owner:重庆龙之火科技有限公司

Using method of conveying mechanism capable of achieving tensioning adjustment

The invention discloses a using method of a conveying mechanism capable of achieving tensioning adjustment. The using method includes the following steps that produced aluminum ingot semi-finished products are placed into hoppers; a motor is started to drive a main roller to run, and an auxiliary roller is used in cooperation with the main roller; a conveying chain plate starts to continuously move in the direction from the main roller to the auxiliary roller, when the hoppers move to the part, right facing the conveying chain plate, of the auxiliary roller, the hoppers overturn, and then conveying feeding of aluminum ingots is achieved; when pouring of the signal hoppers is finished and the hoppers enter the bottom of the conveying chain plate, a bristle brush is bent through self elasticity to enter the interiors of the hoppers, meanwhile, the hoppers and the bristle brush do relative movement, and therefore the bristle brush starts to remove chippings in the hopper; and when the conveying efficiency of the conveying chain plate is reduced or the tensioning force of the conveying chain plate is reduced, the distance between the opposite ends of two connecting rods is increased by rotating threads, and therefore the distance between rotating shafts of the auxiliary roller and the main roller returns to the normal level.

Owner:重庆龙之火科技有限公司

Self-anchored suspension bridge main cable tightening cable pretensioning device and method

ActiveCN112144410BAvoid scattered distributionImprove bundling efficiencySuspension bridgeBridge structural detailsStructural engineeringControl theory

Owner:中国铁建投资集团有限公司

Conveying feeding device

InactiveCN106697739AAvoid scattered distributionFeed effectiveConveyorsTransfer procedureEngineering

Disclosed is a conveying feeding device. The conveying feeding device comprises two supporting bases and a conveying chain plate. A driving roller and a driven roller are arranged on the supporting bases in a rotating mode respectively. The two ends of the conveying chain plate are arranged in U-shaped regions of the supporting bases and matched with the driving roller and the driven roller. A plurality of hoppers are arranged on the conveying chain plate in a hinged mode, and the interior of each hopper is matched with the appearance of the corresponding aluminum ingot. A motor is arranged at the bottom of one supporting base, and the output end of the motor is connected with a rotating shaft of the driving roller through a belt and matched with the rotating shaft. A collecting block is installed at the bottom of the U-shaped region of the supporting base corresponding to the driven roller, the upper end of the collecting block is formed by two inclined planes which are connected with each other, and the point of connection between the inclined planes exactly faces the conveying chain plate. In the conveying process, the aluminum ingots and the hoppers correspond in a one-to-one mode, the phenomenon that according to a conventional conveying feeding device, aluminum ingots are distributed on a conveying belt in a scattered mode when conveying is conducted is avoided, the step that manual sorting is conducted again in the feeding process is omitted, and feeding of the aluminum ingots can be effectively conducted.

Owner:重庆龙之火科技有限公司

Use method of conveying structure

The invention discloses a use method of a conveying structure, comprising the steps of putting aluminum ingot semi-finished products produced properly into hoppers, the inner wall of an accommodating cavity is extruded by the aluminum ingot through its own gravity, at the same time, an elastic protrusion is arranged at the bottom of the accommodating cavity, so that the bottom of the aluminum ingot gets in touch with the top of the elastic protrusion when the aluminum ingot is placed in the hopper so as to ensure that the aluminum ingot is arranged stably; starting a motor to drive a drive roller to run, a driven roller is fit to the drive roller; conveyor chain plates start running continuously from the drive roller to the driven roller, and the hoppers are corresponding to the aluminum ingots one by one, when the hopper is moved to the conveyor chain plate dead against the driven roller, the hopper is turned over, thereby achieving the purpose of conveying and feeding the aluminum ingots; when a single hoper enters into the bottom of the conveyor chain plates after discharging, a bristle brush is bent and enters into the hopper through its own elastic force, and at the same time, relative motion is formed between the hopper and the bristle brush, so that chippings in the hopper are cleaned by the bristle brush.

Owner:重庆龙之火科技有限公司

Use method of conveyor with tension adjusting function

The invention releases a use method of a conveyor with a tension adjusting function, comprising the steps of putting aluminum ingot semi-finished products produced properly into hoppers; starting a motor to drive a drive roller to run, a driven roller is fit to the drive roller; conveyor chain plates start running continuously from the drive roller to the driven roller, and the hoppers are corresponding to the aluminum ingots one by one; when the hopper is moved to the conveyor chain plate dead against the driven roller, the hopper is turned over, thereby achieving the purpose of conveying and feeding the aluminum ingots; after the hopper is turned over, chippings scattering can be caught by two inclined planes connected to each other on a collecting block and slide to the bottom of a supporting base along the inclined planes, convenient for recycling the chippings; when the transport efficiency or the tension of the conveyor chain plates is reduced, the spacing between the opposite ends of two connecting rods is increased through rotating threads, namely that the spacing between the rotating shafts of the driven roller and the drive roller is restored to the normal level.

Owner:重庆龙之火科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com