Water-gas separator

A water-gas separator and water pipe technology, which is applied in the field of tail gas treatment, can solve the problems that small-sized water-gas separators cannot realize liquid level detection, etc., and achieve the effect of reducing economic losses and improving analysis accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

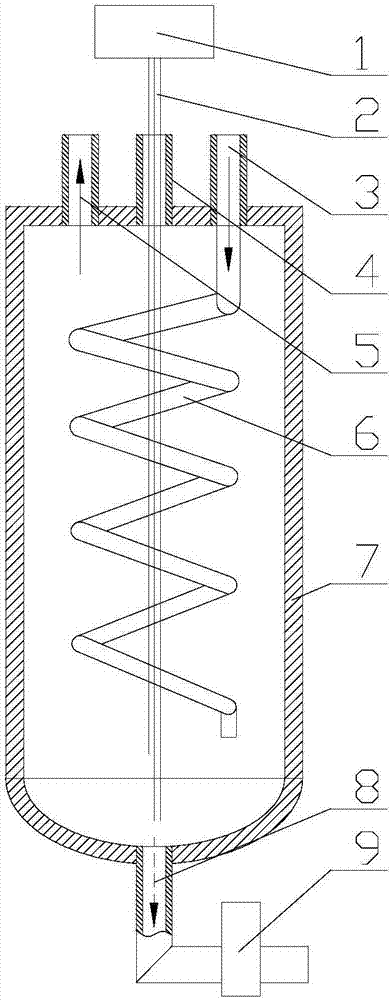

[0052]A water-gas separator, comprising a housing 7, the upper part of the housing 7 is provided with an exhaust gas inlet 3, an exhaust gas outlet 5 and a cable penetration inlet 4, the exhaust gas inlet 3 is mainly used for inletting exhaust gas, the The exhaust gas outlet 5 is mainly for exhausting exhaust gas, and the cable penetration port 4 is used to penetrate the liquid level detection cable 2 into the housing 7; the lower part of the housing 7 is provided with a water outlet 8, and the separated water passes through the water outlet 8 discharge. A drainage pipeline is connected to the water outlet 8 of the water-gas separator, and a drainage valve 9 is arranged on the drainage pipeline. In addition, a liquid level detection cable 2 is also provided, and the liquid level detection cable 2 is mainly used for detecting the liquid level in the water-gas separator. One end of the liquid level detection cable 2 extends into the casing 7 of the water-gas separator, and the ...

Embodiment 2

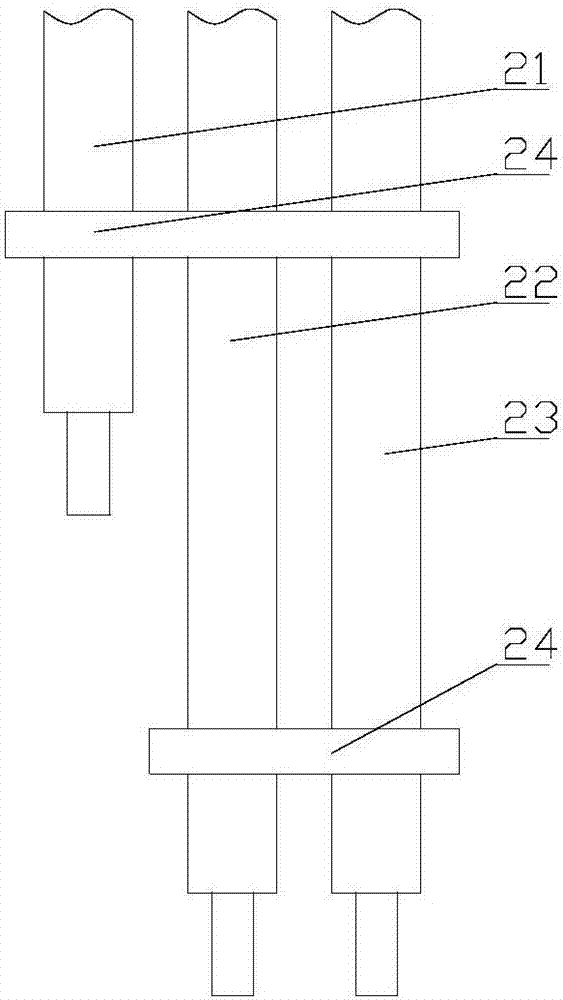

[0054] On the basis of Embodiment 1, the liquid level detection cable 2 is set as three sets of lines, namely, the high water level detection cable 21, the low water level detection cable 22 and the common detection cable 23, and one end of the high water level detection cable 21 1. One end of the low water level detection cable 22 and one end of the common detection cable 23 all extend into the water-air separator, the other end of the high water level detection cable 21, the other end of the low water level detection cable 22 and the common detection cable The other end of 23 is electrically connected with the controller 1 after passing through the water-gas separator. The lower end of the high water level detection cable 21 is higher than the lower end of the low water level detection cable 22, and the lower end of the common detection cable 23 is lower than the lower end of the low water level detection cable 22 or flush with the lower end of the low water level detection c...

Embodiment 3

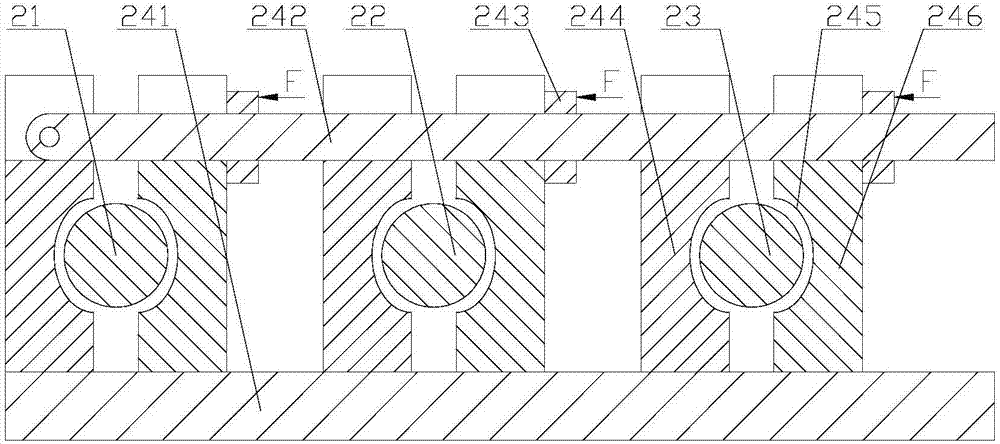

[0056] On the basis of the second embodiment, the liquid level detection cable 2 is also sleeved with a cable clamping assembly, and the high water level detection cable 21, the low water level detection cable 22 and the common detection cable can be connected through the cable clamping assembly. Any two or all of the cables 23 are clamped together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com