Efficient treatment method based on pipeline machining

A processing method and pipeline technology, applied in metal processing equipment, metal processing mechanical parts, pipe cutting devices, etc., can solve the problems of uneven force on the cutting part of the pipeline, high scrapping rate of the pipeline, and easy damage to the cutting piece, and prevent the Stuck and fracture, scientific and reasonable structure, ensure the effect of roundness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

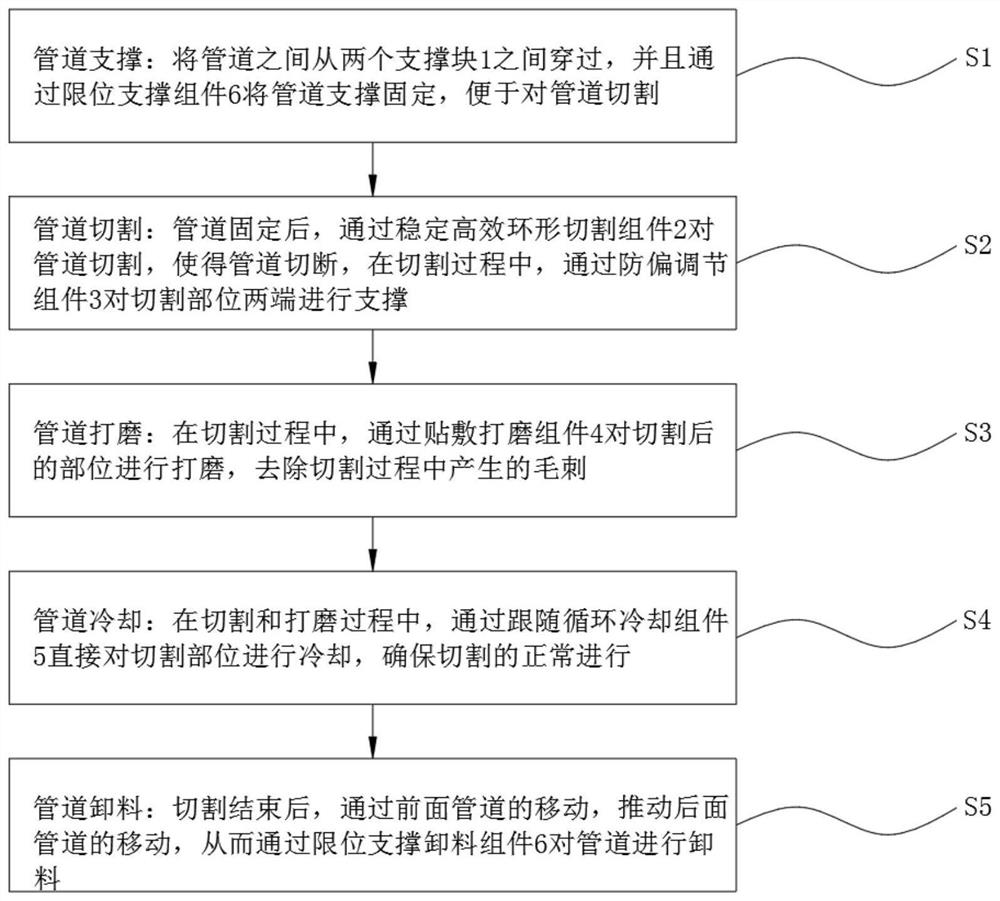

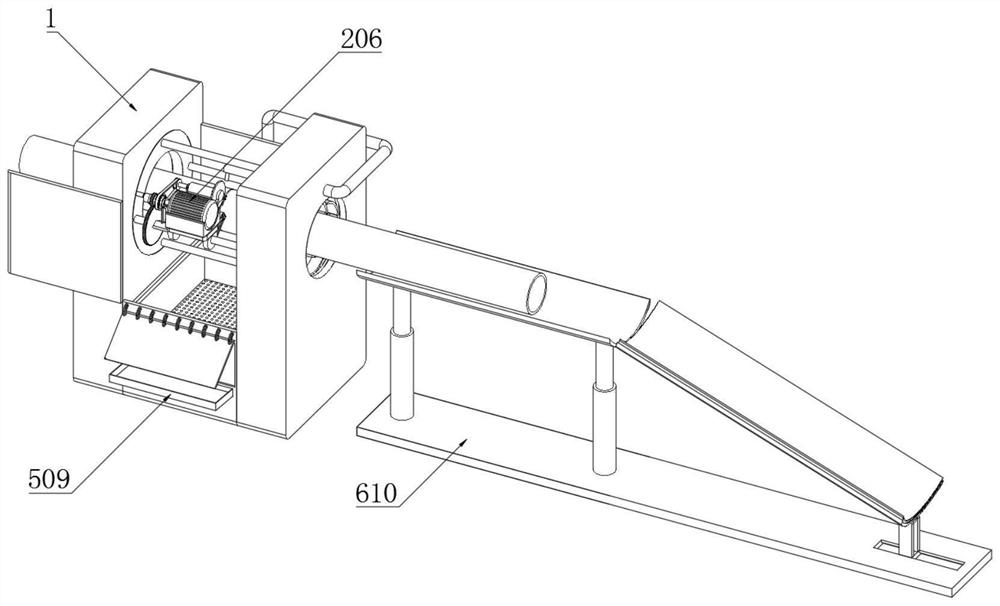

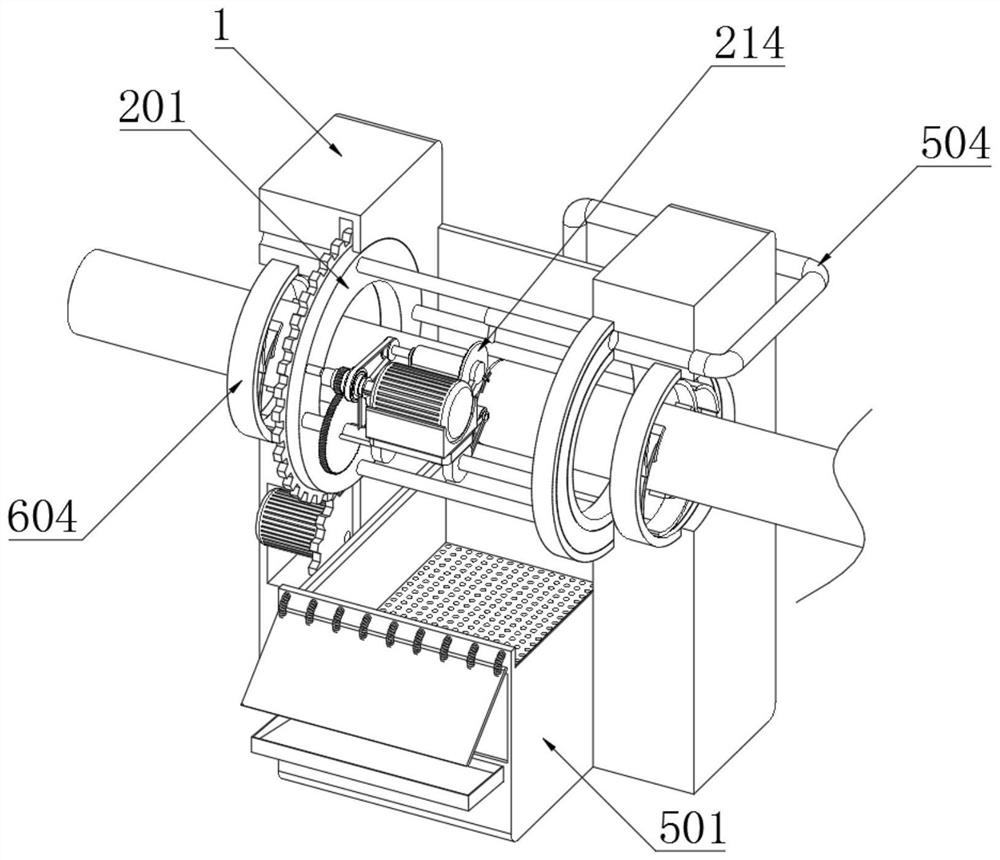

[0056] Example: such as Figure 1-12 As shown, the present invention provides technical scheme, a kind of efficient processing method based on pipeline processing, comprises the following steps:

[0057] S1. Pipe support: pass the pipe between the two support blocks 1, and fix the pipe support through the limit support unloading assembly 6, so as to facilitate cutting of the pipe;

[0058] S2. Pipe cutting: after the pipe is fixed, cut the pipe through the stable and high-efficiency ring cutting assembly 2 to cut the pipe. During the cutting process, use the anti-deflection adjustment assembly 3 to adjust the support at both ends of the cutting part;

[0059] S3. Pipe grinding: during the cutting process, the cut part is polished by applying the grinding component 4 to remove the burrs generated during the cutting process;

[0060] S4. Pipeline cooling: during the cutting and grinding process, the cutting part is directly cooled by following the circulating cooling component ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com