Quick cutting device for cemented carbide round rod

A fast cutting, cemented carbide technology, used in auxiliary devices, welding/cutting auxiliary equipment, metal processing equipment, etc. Accurate effect of speed and cutting length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

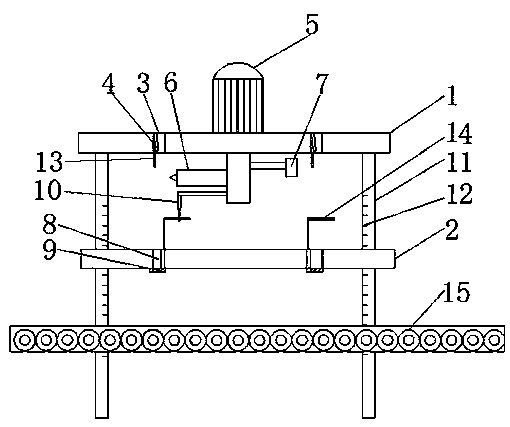

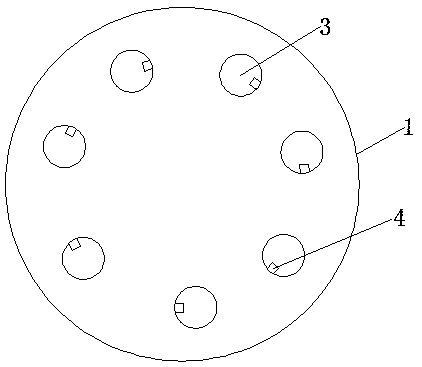

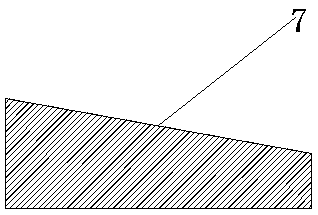

[0018] see Figure 1~Figure 3 , figure 1 It is a structural schematic diagram of a cemented carbide round rod rapid cutting device provided by an embodiment of the present invention; figure 2 It is a schematic structural diagram of the directional movement device provided by the embodiment of the present invention; image 3 It is a structural schematic diagram of the insulating frame provided by the embodiment of the present invention.

[0019] The invention provides a fast cutting device for hard alloy round rods. The fast cutting device for hard alloy round rods includes: a tooling platform 1, a receiving platform 2 and a transmission device; wherein, the tooling platform 1 is provided with multiple A working hole 3, the plurality of working holes 3 are equidistantly spaced to form a circle, and each working hole 3 is provided with a telescopic die block 4 for engaging an alloy round bar; the upper end of the tooling platform 1 is provided with an inverted A rotary motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com