Glass cutting method

A glass cutting and glass technology, used in stone processing equipment, grinding machines, grinding/polishing equipment, etc., can solve the problems of poor automation and inaccurate glass cutting length, to facilitate cutting work, improve efficiency and accuracy, Enhance the effect of precise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

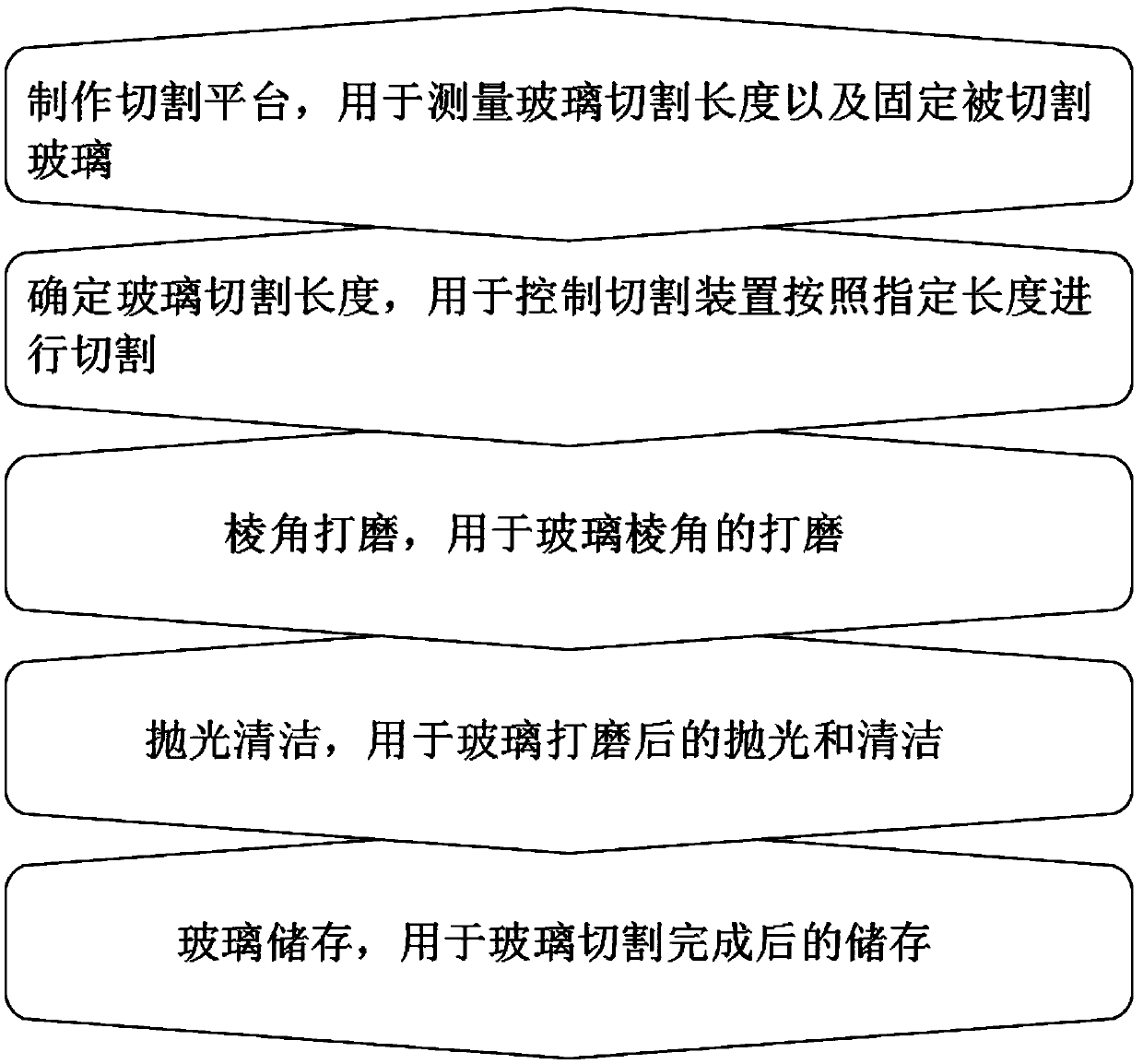

[0024] The invention discloses a glass cutting method, comprising the following steps:

[0025] 1) Make a cutting platform for measuring the cutting length of glass and fixing the glass to be cut; the cutting table is surrounded by a measuring ruler, and a distance sensor is set on the zero scale at one end of the measuring ruler, and the four corners of the cutting table are fixed with glass suction cups. The diameter of the glass suction cup is 10cm ;

[0026] 2) Determine the glass cutting length, which is used to control the cutting device to cut according to the specified length; the cutting device includes a computer numerical control automatic cutting machine, an automatic knife setting instrument and a distance sensor, and the distance sensor and the automatic knife setting instrument are connected to the cutting knife for control. The distance sensor on the cutting knife corresponds to the distance sensor at one end of the measuring ruler. The computer controls the di...

Embodiment 2

[0031] The invention discloses a glass cutting method, comprising the following steps:

[0032] 1) Make a cutting platform for measuring the cutting length of glass and fixing the glass to be cut; the cutting table is surrounded by a measuring ruler, and a distance sensor is set on the zero scale at one end of the measuring ruler, and the four corners of the cutting table are fixed with glass suction cups. The diameter of the glass suction cup is 13cm ;

[0033] 2) Determine the glass cutting length, which is used to control the cutting device to cut according to the specified length; the cutting device includes a computer numerical control automatic cutting machine, an automatic knife setting instrument and a distance sensor, and the distance sensor and the automatic knife setting instrument are connected to the cutting knife for control. The distance sensor on the cutting knife corresponds to the distance sensor at one end of the measuring ruler. The computer controls the di...

Embodiment 3

[0038] The invention discloses a glass cutting method, comprising the following steps:

[0039] 1) Make a cutting platform for measuring the cutting length of glass and fixing the glass to be cut; the cutting table is surrounded by a measuring ruler, and the zero scale at one end of the measuring ruler is equipped with a distance sensor. The four corners of the cutting table are fixed with glass suction cups, and the diameter of the glass suction cup is 15cm. ;

[0040] 2) Determine the glass cutting length, which is used to control the cutting device to cut according to the specified length; the cutting device includes a computer numerical control automatic cutting machine, an automatic knife setting instrument and a distance sensor, and the distance sensor and the automatic knife setting instrument are connected to the cutting knife for control. The distance sensor on the cutting knife corresponds to the distance sensor at one end of the measuring ruler. The computer control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com