Patents

Literature

269results about How to "Easy cutting work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

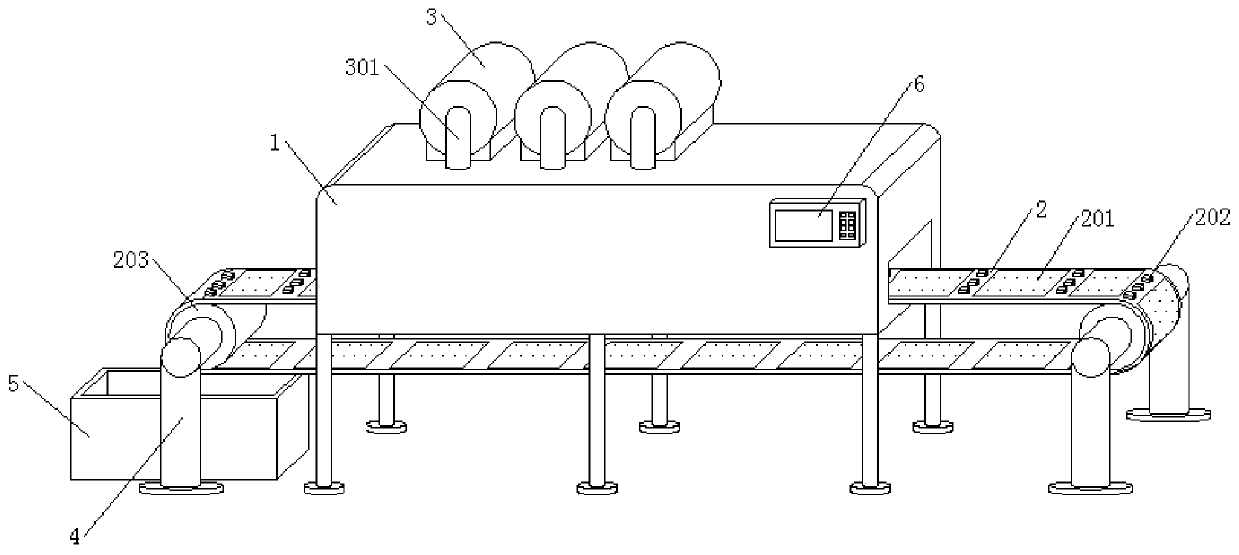

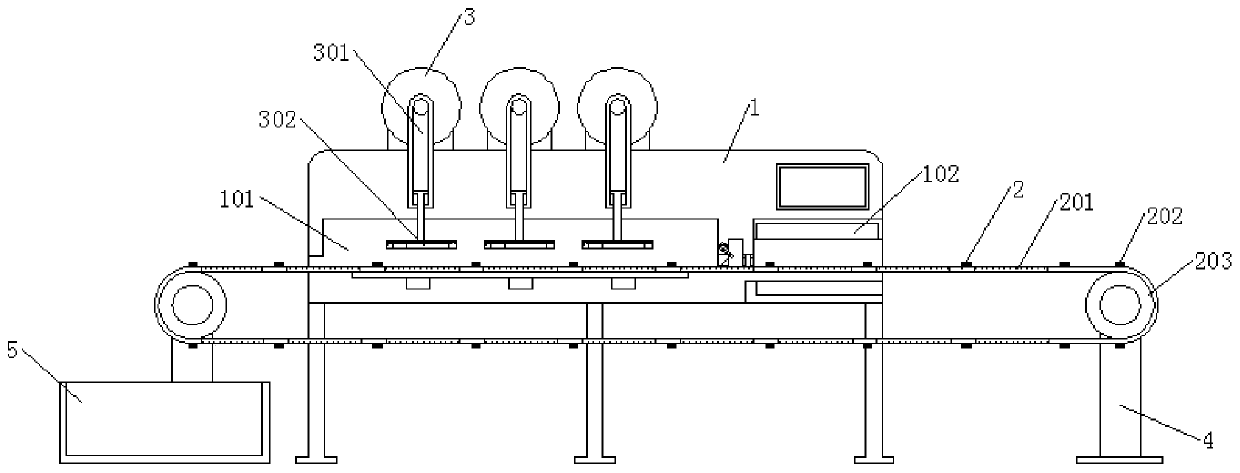

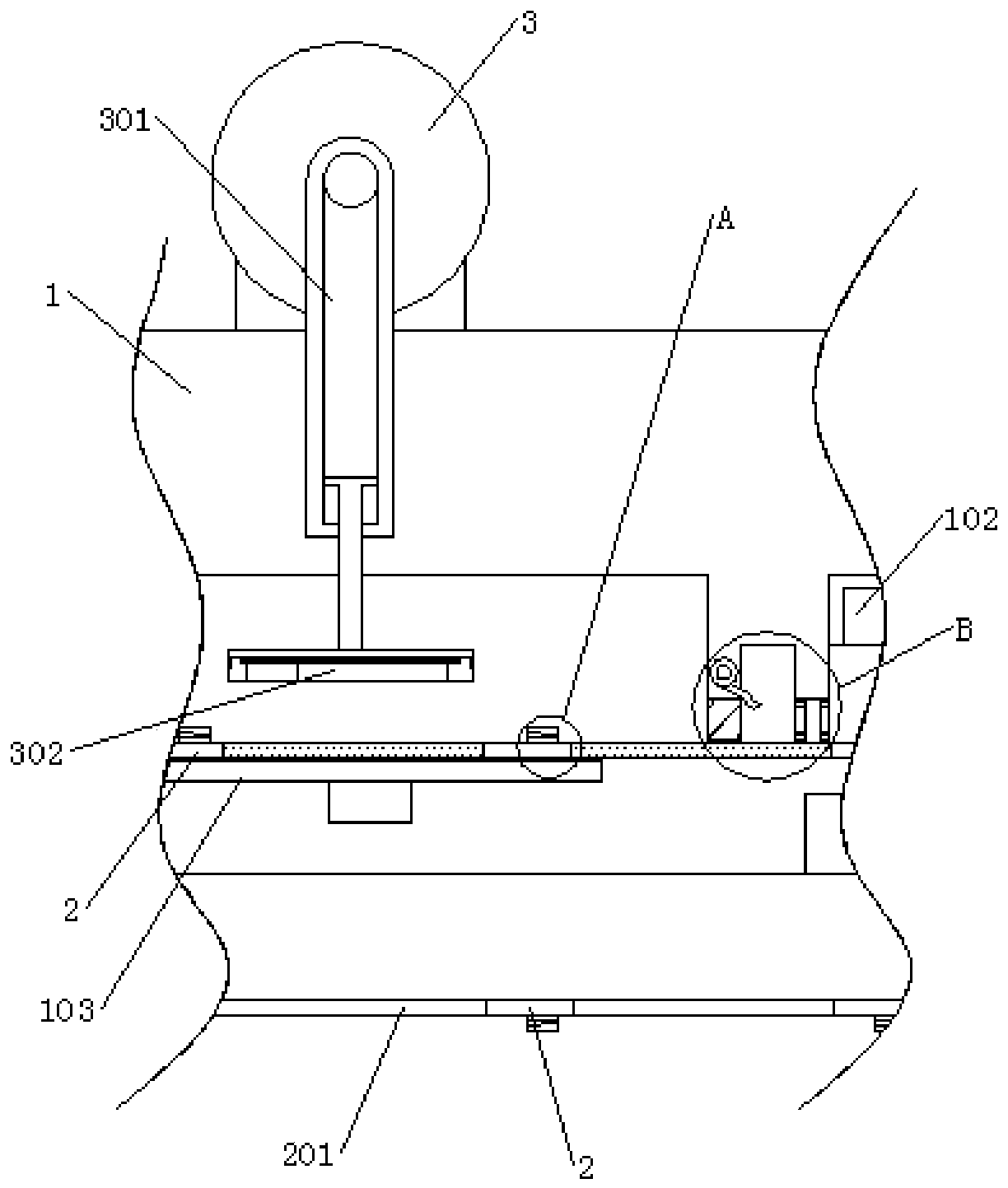

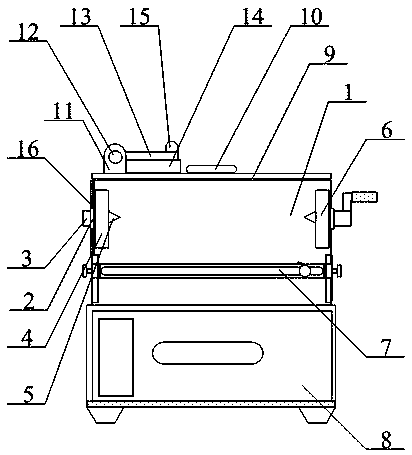

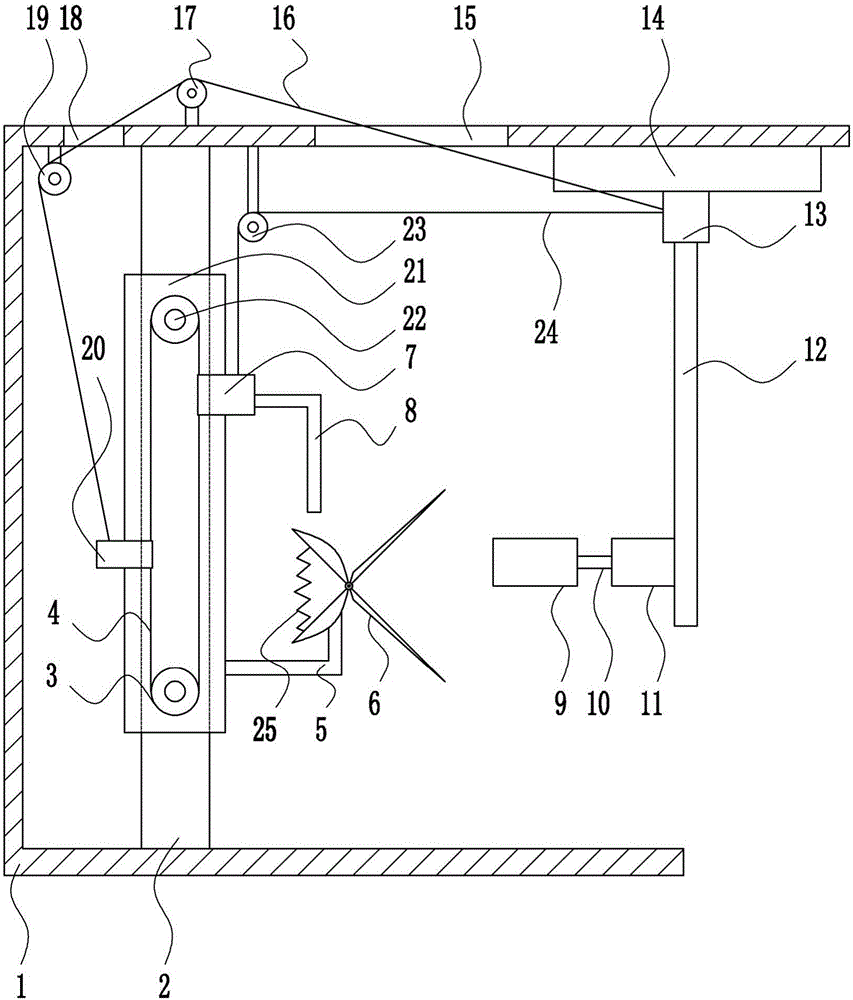

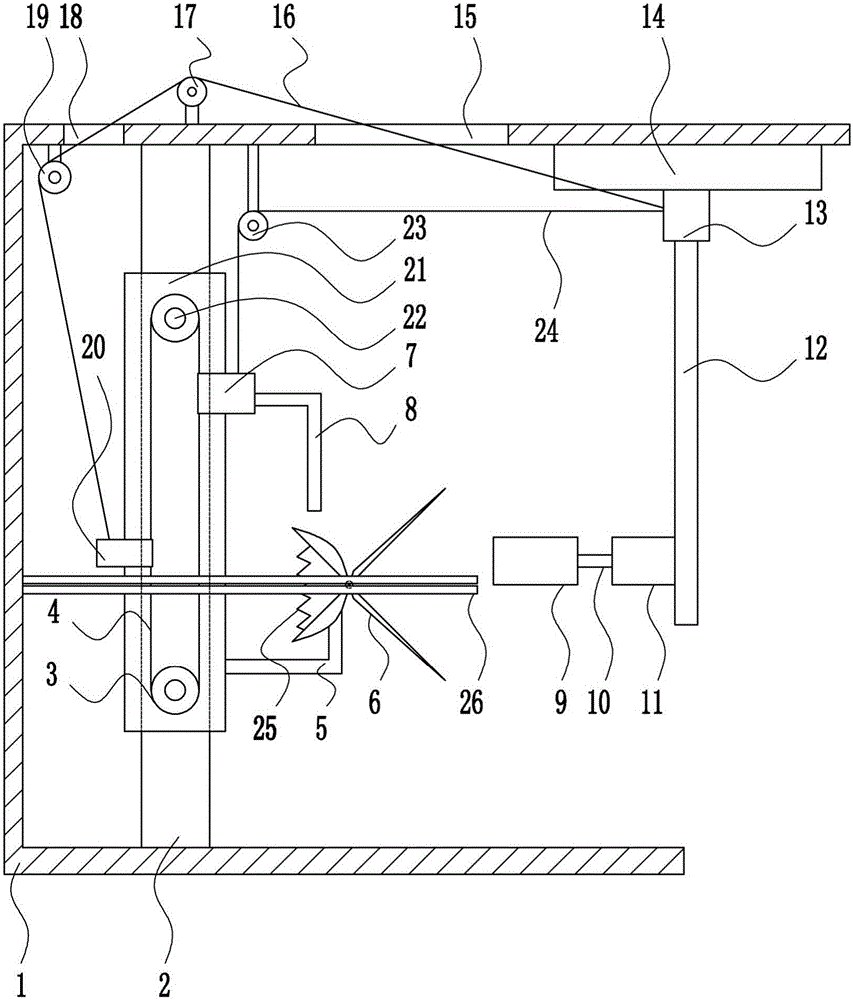

Feather correcting and shearing integrated device for badminton production

ActiveCN111467770AImprove barrier propertiesAvoid blowing awaySport apparatusHydraulic pumpStructural engineering

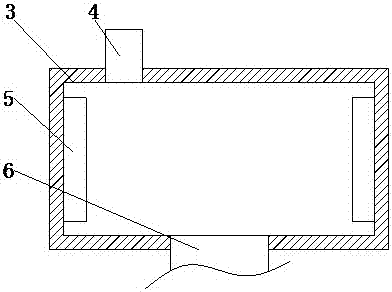

The invention provides a feather correcting and shearing integrated device for badminton production. The device comprises a box, a conveying belt, a hydraulic pump, supporting columns, a collecting box and control equipment, wherein the conveying belt is arranged on the inner side of the bottom end of the box, the hydraulic pump is arranged at the top of the box, the supporting columns are arranged on the left and right sides of the bottom of the conveying belt, the collecting box is arranged at the bottom of the left side of the conveying belt, and the control equipment is embedded in the front end of the box. The whole device is stable in structure, high in feather carding capacity, simple and convenient in shearing operation step, high in feather shearing efficiency, convenient in feather fixing operation and high in stability.

Owner:江山市三鑫体育用品有限公司

Food cutting equipment

The invention discloses a food cutting device, which comprises a working box and a belt. A hot water tank is fixedly connected to the left side of the top of the working box. Both sides of the hot water tank are fixedly connected with heating blocks, the bottom of the hot water tank is connected with a nozzle, the bottom of the nozzle penetrates the top of the working box and extends to the inner cavity of the working box, and the left side of the working box is provided with a feeding port The bottom on the right side of the feed inlet is fixedly connected with a slanting block, the left side of the feed inlet is fixedly connected with a feed hopper, and the inner cavity of the working box is respectively movably connected with a first roller shaft and a second roller shaft through bearings. The present invention can efficiently and evenly cut meat through the cooperation of working box, belt, hot water tank, feed port, conveyor belt, blade, first motor, turntable, connecting rod structure, discharge port and discharge box. Into small pieces, which reduces the labor cost of the production enterprise and can meet the production and processing needs of the enterprise.

Owner:翟端

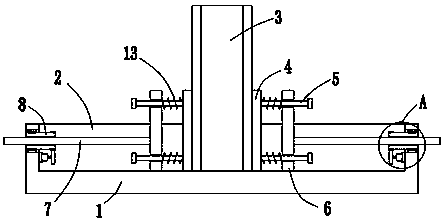

Building pipe cutting clamp

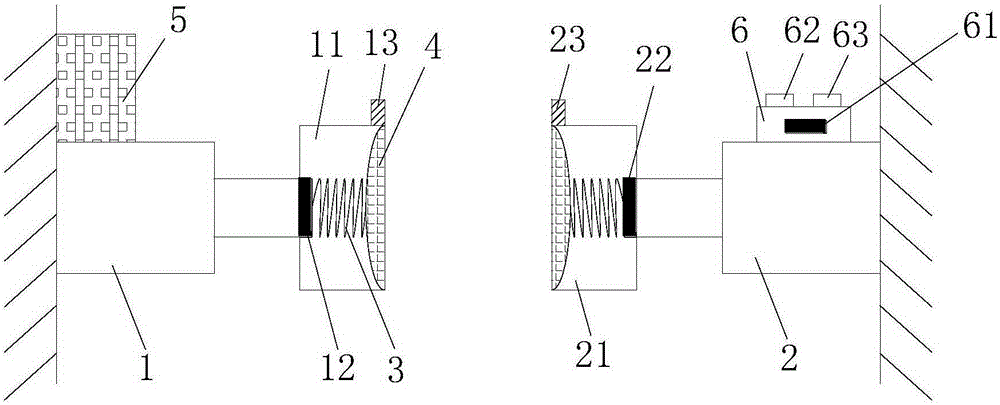

InactiveCN106825810AEasy cutting workAvoid pinchingElectrical-based auxillary apparatusArchitectural engineeringPressure sensor

The invention discloses a building pipe cutting clamp. The building pipe cutting clamp comprises a first extending-and-contracting rod and a second extending-and-contracting rod. A first clamping block is arranged at the end of the inner side of the first extending-and-contracting rod, and a second clamping block is arranged at the end of the inner side of the second extending-and-contracting rod. A first pressure sensor is arranged at the connection position of the first clamping block and the first extending-and-contracting rod, and a second pressure sensor is arranged at the connection position of the second clamping block and the second extending-and-contracting rod. A first infrared sensor is mounted at the inner side of the top of the first clamping block, and a second infrared sensor is mounted at the inner side of the top of the second clamping block. A control box is arranged on the upper surface of the second extending-and-contracting rod. By means of the building pipe cutting clamp, work of the first extending-and-contracting rod and the second extending-and-contracting rod can be adjusted automatically; a to-be-cut pipe can be fixed and prevented from being damaged by clamping; the position and the borne pressure of the to-be-cut pipe can be displayed; and convenience is brought to building pipe cutting work.

Owner:CHONGQING HAOLONG MACHINERY CO LTD

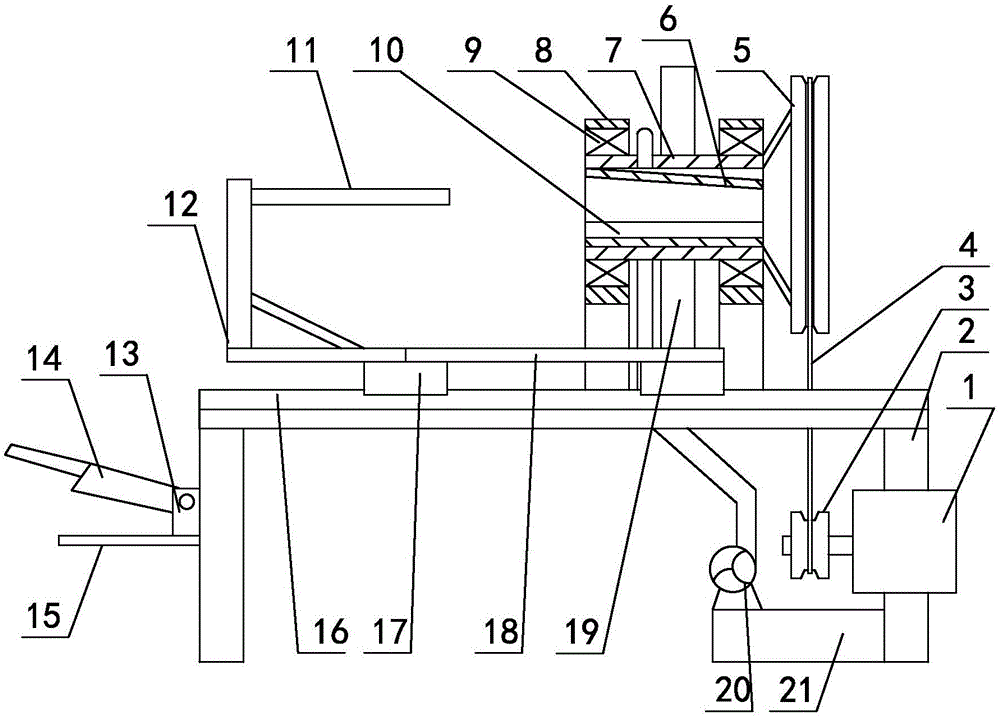

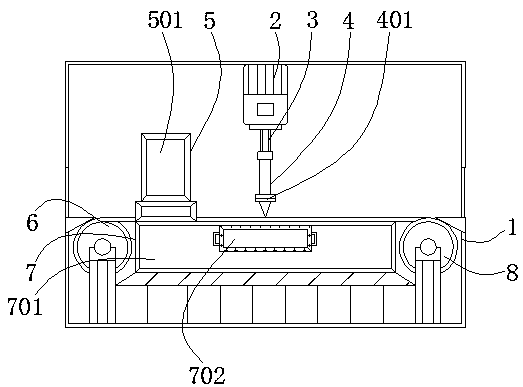

High pressure steam pipe cutting device for treating carbon tetrachloride

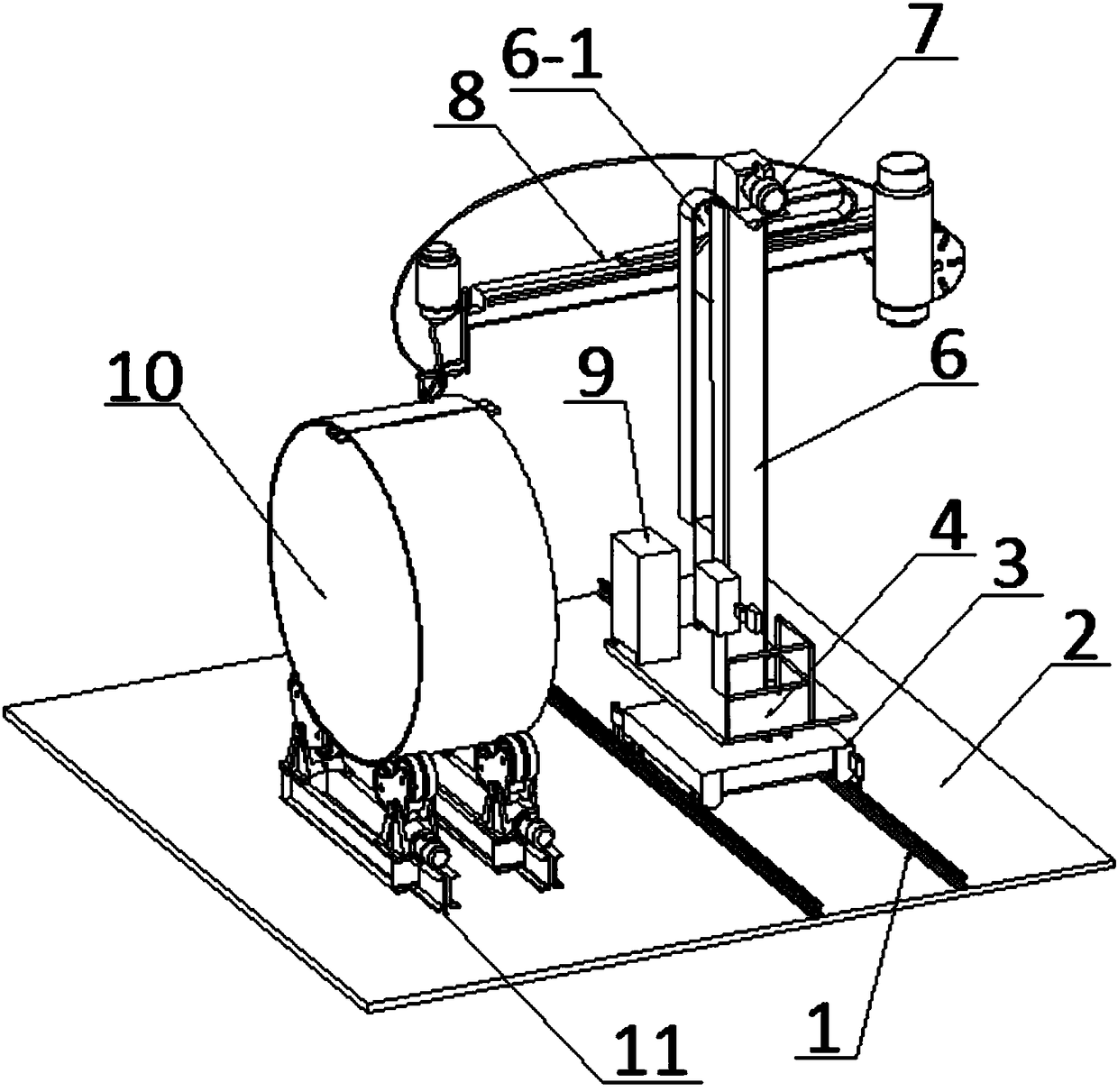

InactiveCN108176909AGuaranteed cutting qualityImprove cutting efficiencyGas flame welding apparatusControl engineeringHigh pressure

The invention relates to a high pressure steam pipe cutting device for treating carbon tetrachloride. A workpiece fixture is fixedly connected to the left side of the upper part of a fixing plate; a rotary platform is rotatably connected to the upper part of a moving trolley through a rotary shaft fixedly connected to the lower part of the rotary platform; a support pillar is fixedly arranged on the front side of the upper part of the rotary platform; a vertical slideway is arranged on the front side of the support pillar; a winch is fixedly arranged on the top part of the support pillar; a mechanical arm is formed by a fixing arm and a sliding arm; a cutting gun nozzle is fixedly connected to the lower part of the left end of the sliding arm; a reel is fixedly connected to the right end of the fixing arm; two sliding chutes II extending vertically and having T-shaped cross sections are arranged on one side, close to the slideway, of a sliding block; two slide rails with T-shaped crosssections are slidably assembled into the two sliding chutes II; the upper ends and the lower ends of the two slide rails are fixedly connected with the upper end and the lower end of the slideway; and two lubricating oil filling devices corresponding to the two sliding chutes II are fixedly arranged on the front side of the sliding block. The device is convenient in operation process, high in operation efficiency, and suitable for cutting circular workpieces.

Owner:XUZHOU UNIV OF TECH

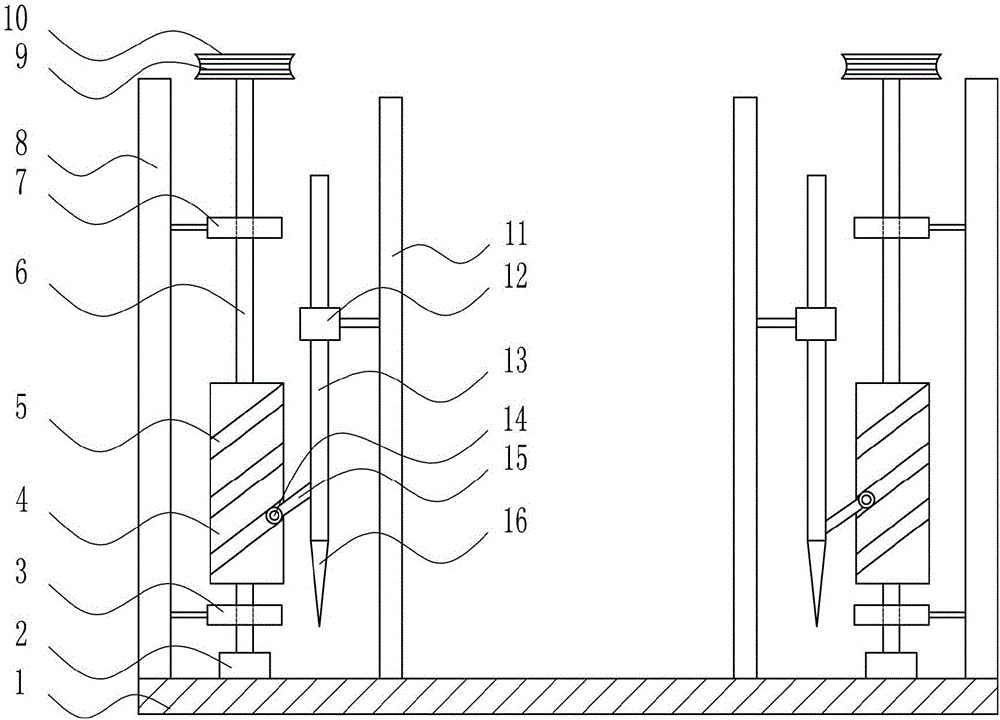

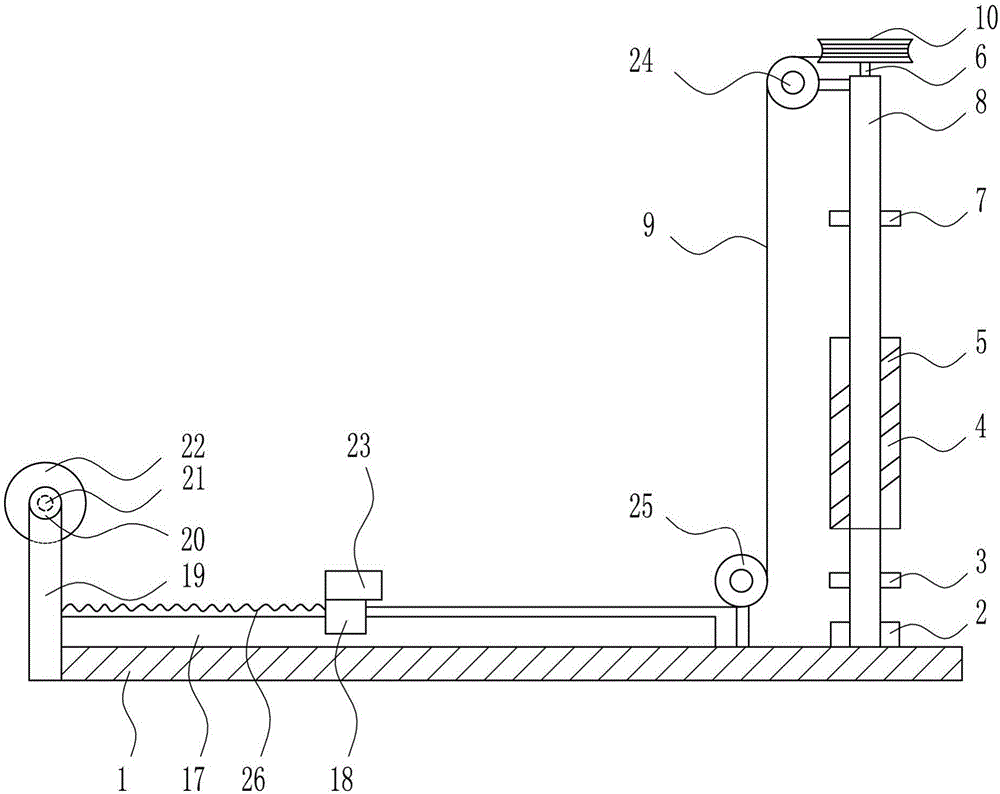

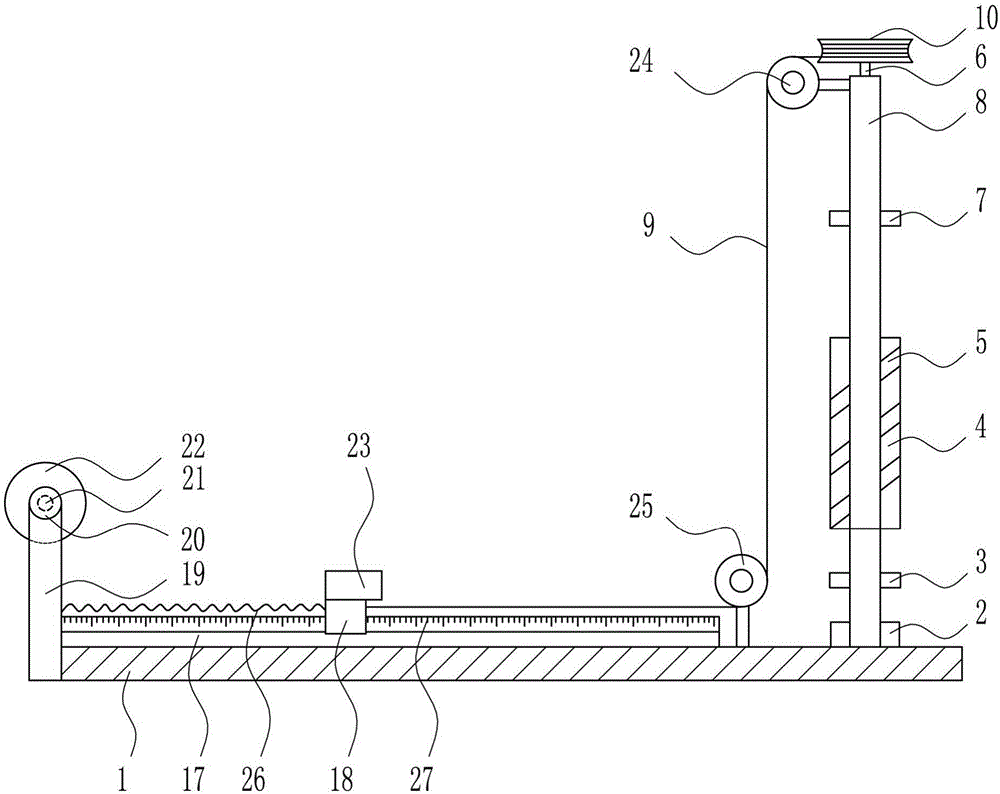

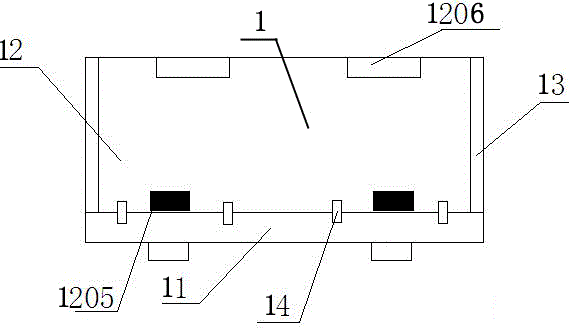

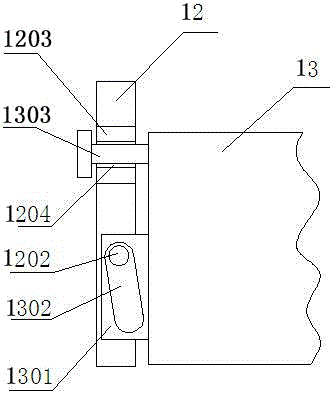

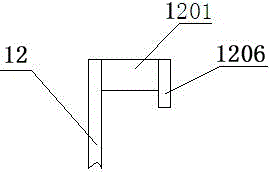

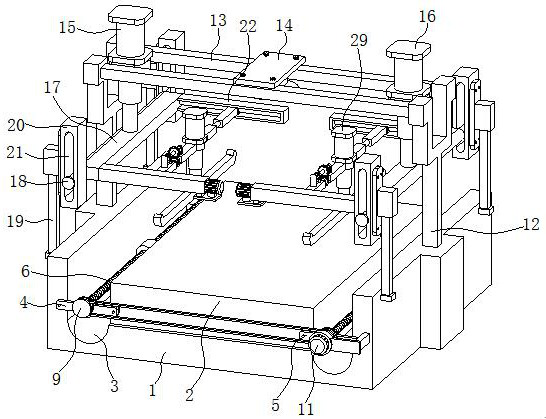

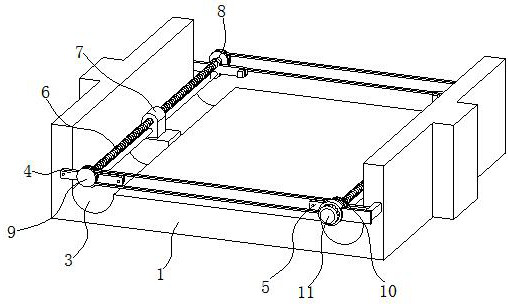

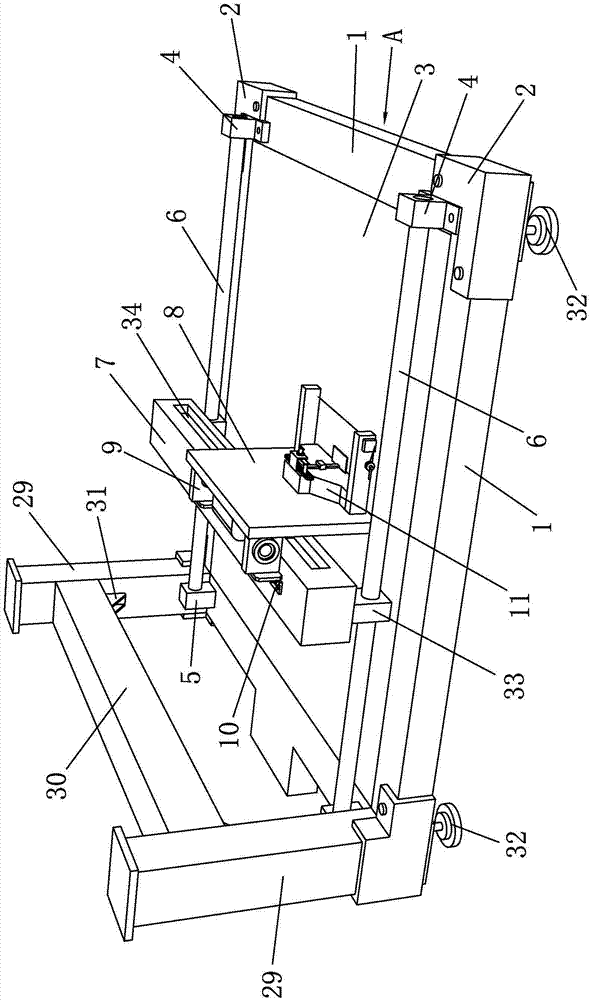

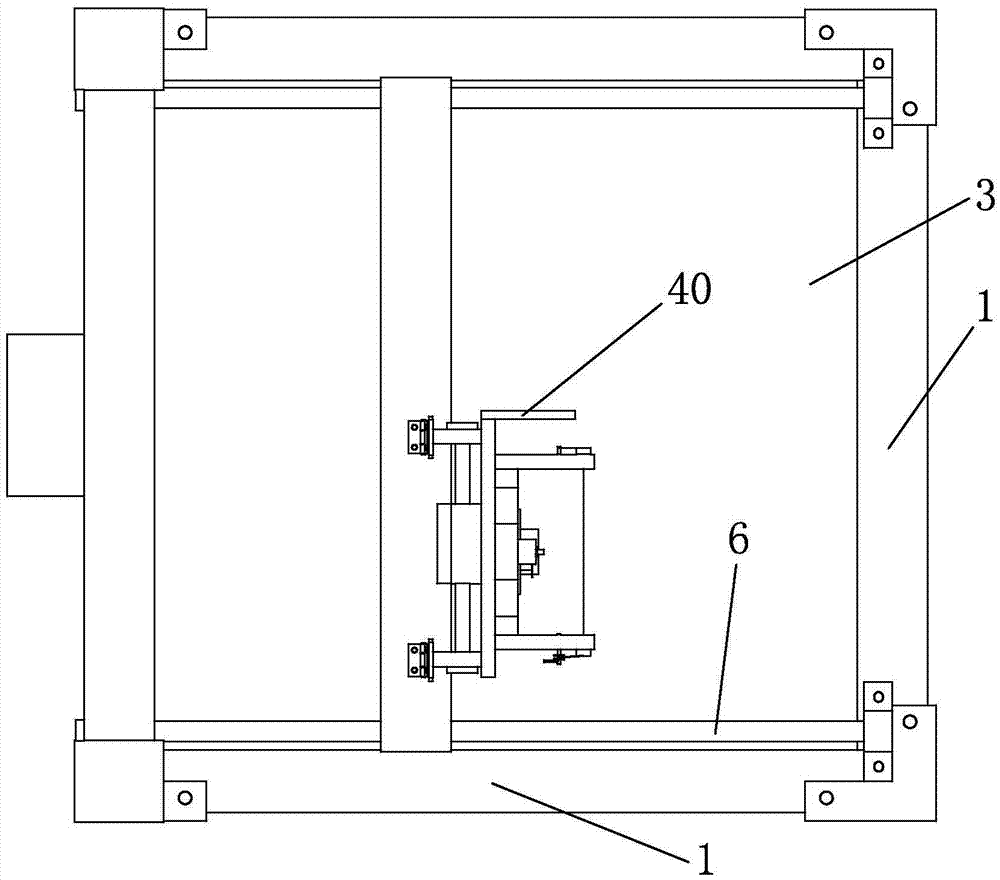

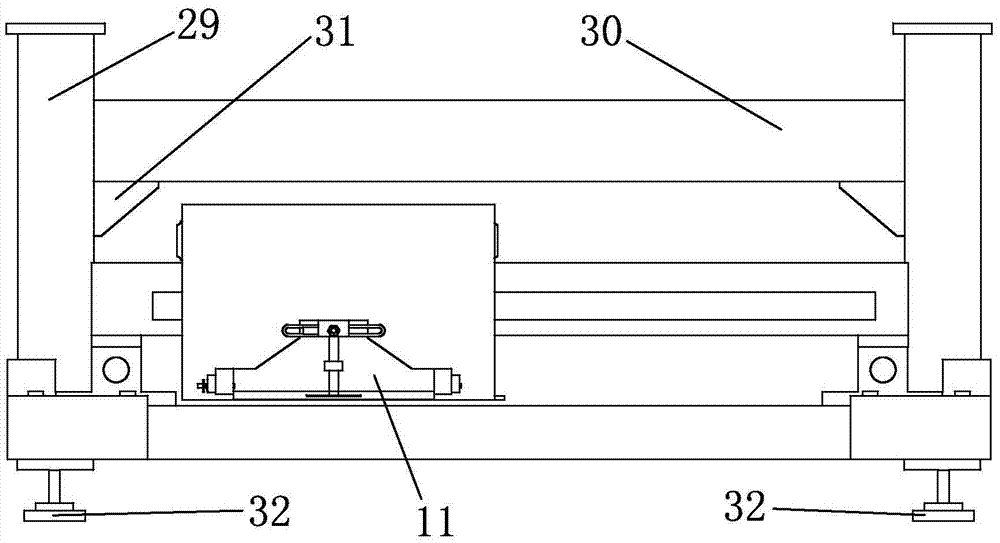

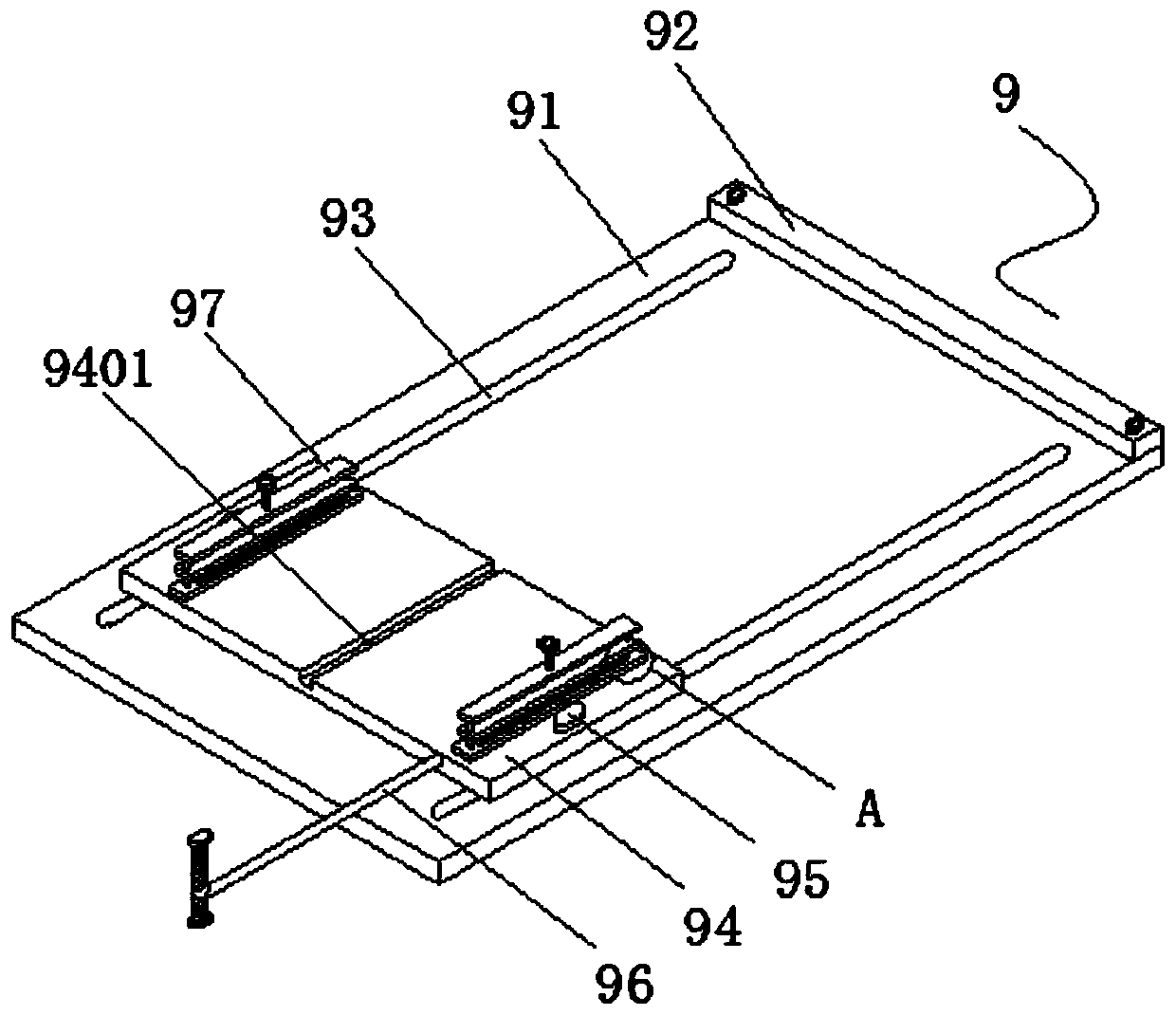

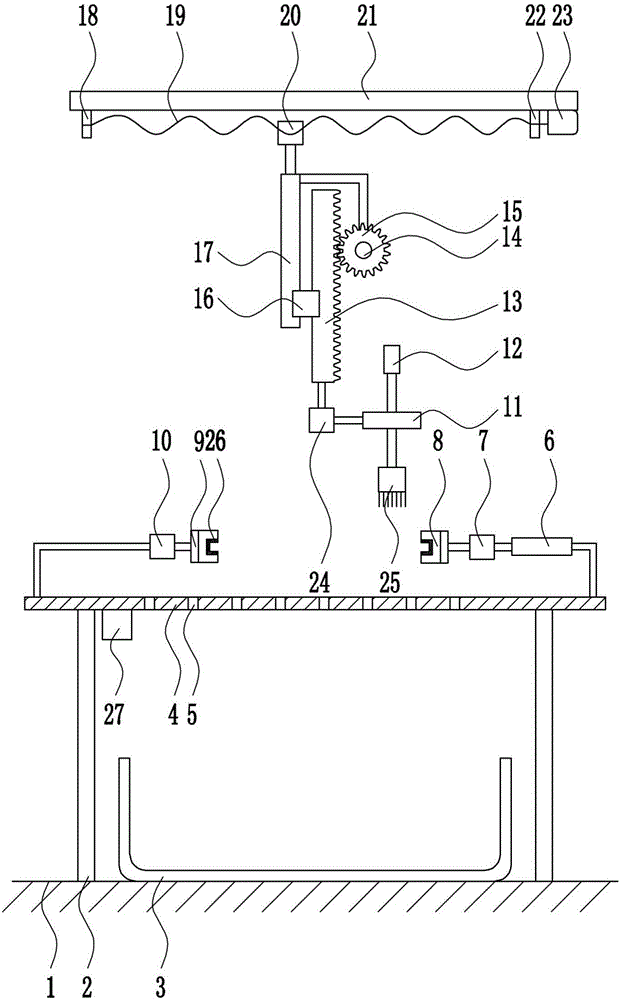

Quick positioning device for cloth cutting

The invention relates to a positioning device, in particular to a quick positioning device for cloth cutting. The aim that the quick positioning device for cloth cutting is high in positioning speed is achieved. The quick positioning device for cloth cutting comprises a positioning plate, rotating motors, first bearing bases, first rolling cylinders, first rotating shafts, second bearing bases, fixing plates, pulling wires, winding wheels, first supporting rods, sliding sleeves, lifting rods, contact rolling wheels, connecting rods, positioning drills, sliding rails, sliding blocks, second supporting rods, a third bearing base, a second rotating shaft, a second rolling cylinder, a thumb air cylinder, a first fixed pulley, a second fixed pulley and a spring, and the fixing plates are symmetrically arranged at the left end and the right end of the front side on the positioning plate. By means of the quick positioning device for cloth cutting, the effects of being high in positioning speed, accurate in positioning and easy to operate is achieved.

Owner:湖南省国锦湘安实业有限公司

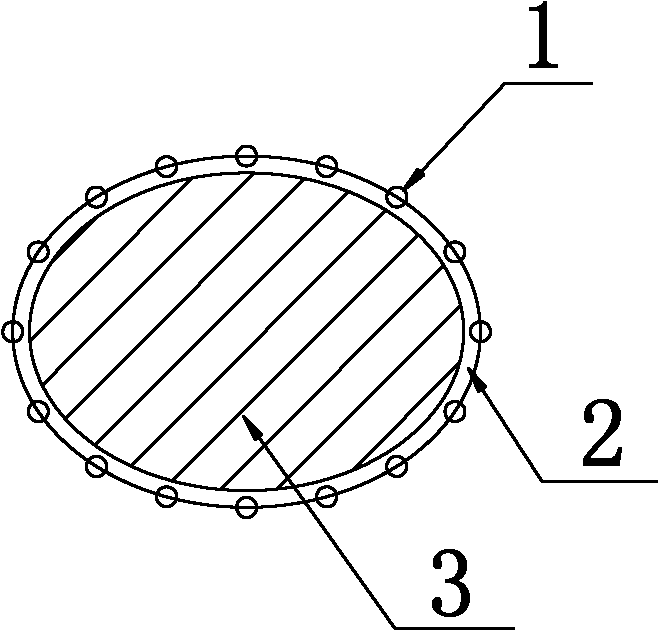

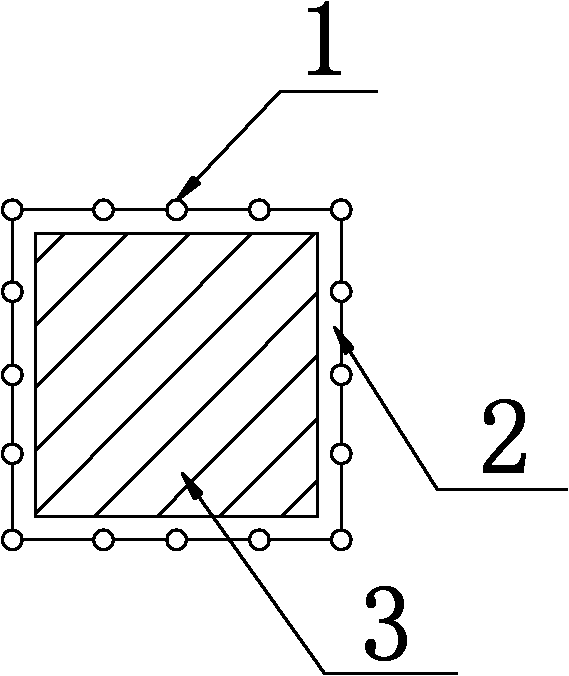

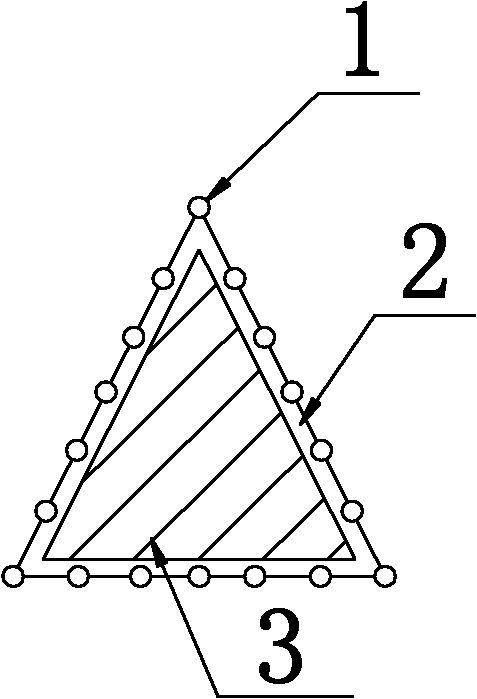

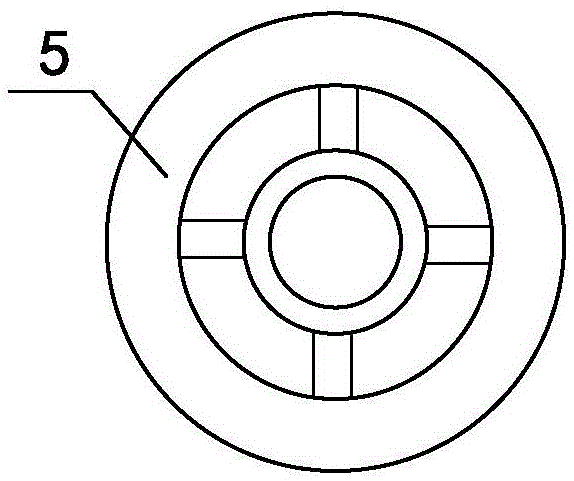

Technology of preparing special-shaped cutting steel wire

InactiveCN102166584AFast cutting speedSimple preparation processExtrusion cleaning devicesMetal rolling arrangementsEllipseElliptic cylinder

The invention relates to a technology of preparing special-shaped cutting steel wire, comprising the following steps: (1) coarse wire drawing, during which step the steel wire rod of Phi5.5-6.5mm is drawn into the steel wire of Phi2.80-3.25mm, (2) middle filament heat treatment, (3) intermediate drawing, during which step the steel wire of Phi2.80-3.25mm is drawn into the steel wire of Phi 0.76-1.15mm, (4) wet drawing, during which step the steel wire of Phi0.76-1.15mm is drawn into the steel wire of Phi0.08-0.3mm, (5) press rolling, during which step the steel wire is rolled into the steel wire having a cross section of polygon or ellipse, (6) electroplate / bonding, during which step SiC or diamond particle abrasive is fixed upon the external surface of the steel wire in an electroplating or glue-bonding manner, and (7) taking up, during which step the finished product is obtained. The preparing technology of the invention is simple, environment-friendly, efficient, and of low cost. The cutting steel wire prepared via this technology takes the shape of elliptic cylinder or polygon body, with hardness and tensile strength substantially improved, effectively decreasing the wire-broken rate, accelerating cutting speed of steel wire, and improving the cutting efficiency.

Owner:合肥得一新材料科技有限公司

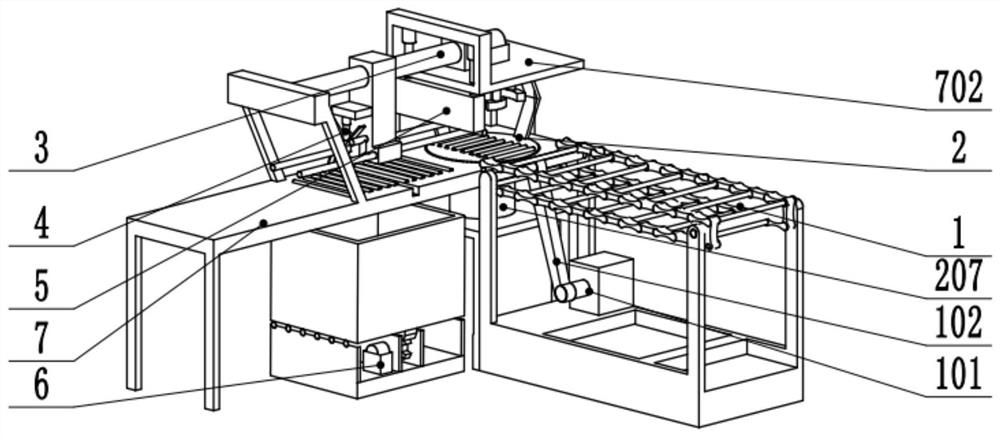

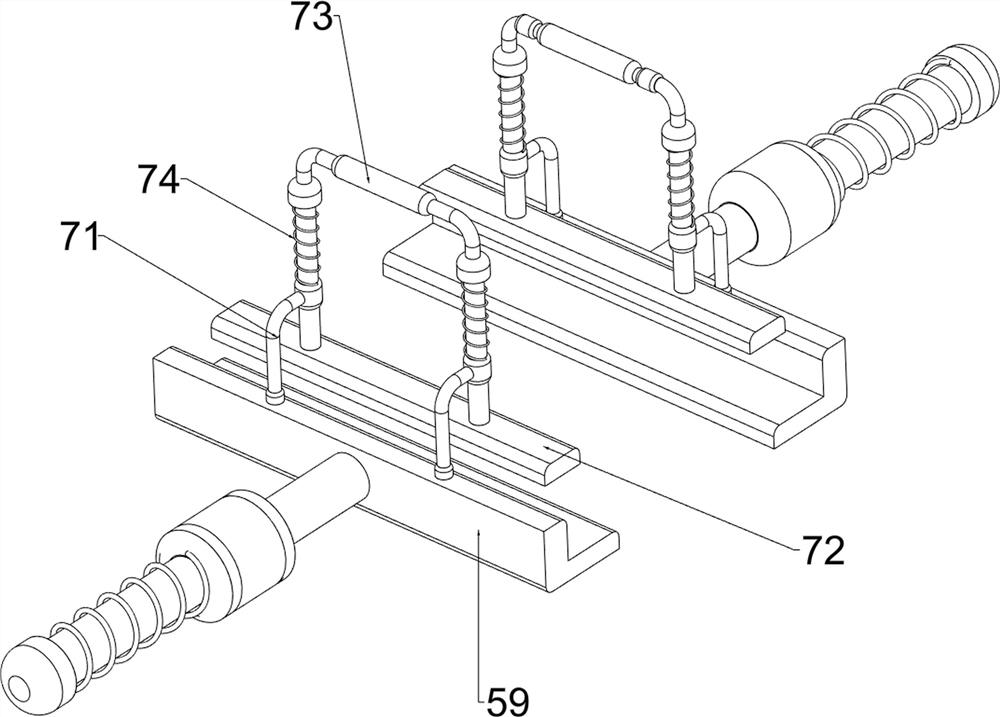

Production assembly line of self-thermal insulation concrete blocks

ActiveCN105799037AIntegrity guaranteedReduce breakageDischarging arrangementCeramic shaping plantsBrickThermal insulation

A production assembly line of self-thermal insulation concrete blocks is composed of a material stirring device, a blank making device, a cutting device, a backward-skating-prevention drying device and a brick holding machine which are sequentially arranged on a rail and further comprises a conveying device which reciprocates along the rail and is used for conveying materials. Raw materials used for making the self-thermal insulation concrete blocks are stirred in the material stirring device and then are injected into the blank making device to be subject to foam forming so as to make green bricks, the green bricks are conveyed to the cutting device through the conveying device to be cut, and the cut green bricks pass through the backward-skating-prevention drying device and then are moved out of the assembly line through the brick holding machine. According to the production assembly line of the self-thermal insulation concrete blocks, in the process of making the self-thermal insulation concrete blocks, effects of being rapid to demould, stable in cutting, free of backward skating of the conveying device during drying, safe in brick holding transferring and the like are achieved, and the production efficiency is greatly improved while the product quality is ensured.

Owner:许昌五星实业有限责任公司

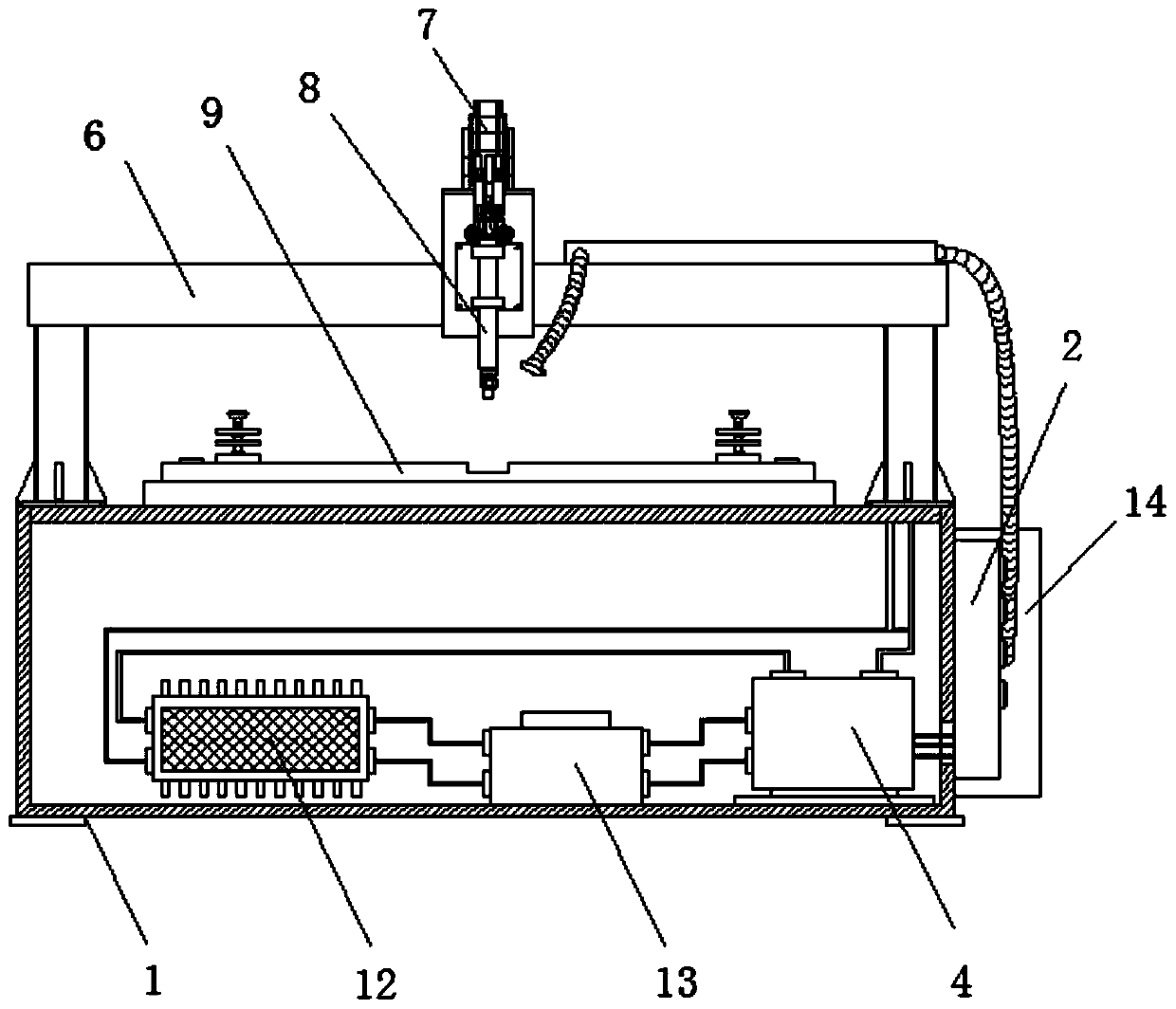

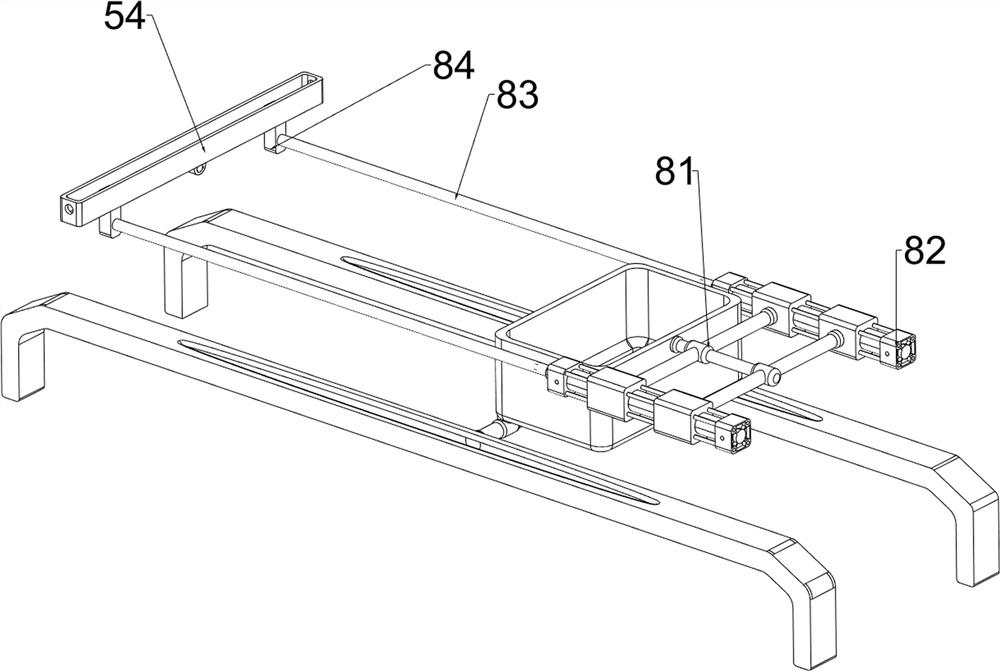

Rapid steel residue cleaning device for sheet metal laser cutting machine

ActiveCN112372135AQuick clean upEasy to handleWelding/soldering/cutting articlesLaser beam welding apparatusElectric machineryLaser cutting

The invention discloses a rapid steel residue cleaning device for a sheet metal laser cutting machine. The rapid steel residue cleaning device comprises a base, a cutting table and cross beams, wherein a cleaning plate sleeves a conveying screw; a first lifting air cylinder is fixedly installed at one ends of the tops of the cross beams, and a second lifting air cylinder is fixedly installed at one ends, away from the first lifting air cylinder, of the tops of the cross beams; two frames are fixedly installed at one side of each receiving plate; sliding plates sleeve adjusting screws and second limiting rods respectively; a transmission rod sleeves the opposite sides of two sliding plates; a telescopic air cylinder is fixedly installed at the top of each support plate; and a scraping plateis fixedly installed at the bottom of each telescopic air cylinder. Through the arrangement of the first lifting air cylinder, the second lifting air cylinder and the telescopic air cylinders, the scraping plates can be moved to the top of the cutting table and move left and right under the action of the second limiting rods, the adjusting screws and adjusting motors, and the two scraping platesoperate at the same time, so that steel residues generated by the sheet metal laser cutting machine at the top of the cutting table can be cleaned and the rapid cleaning effect is achieved.

Owner:德清泰鑫金属制品有限公司

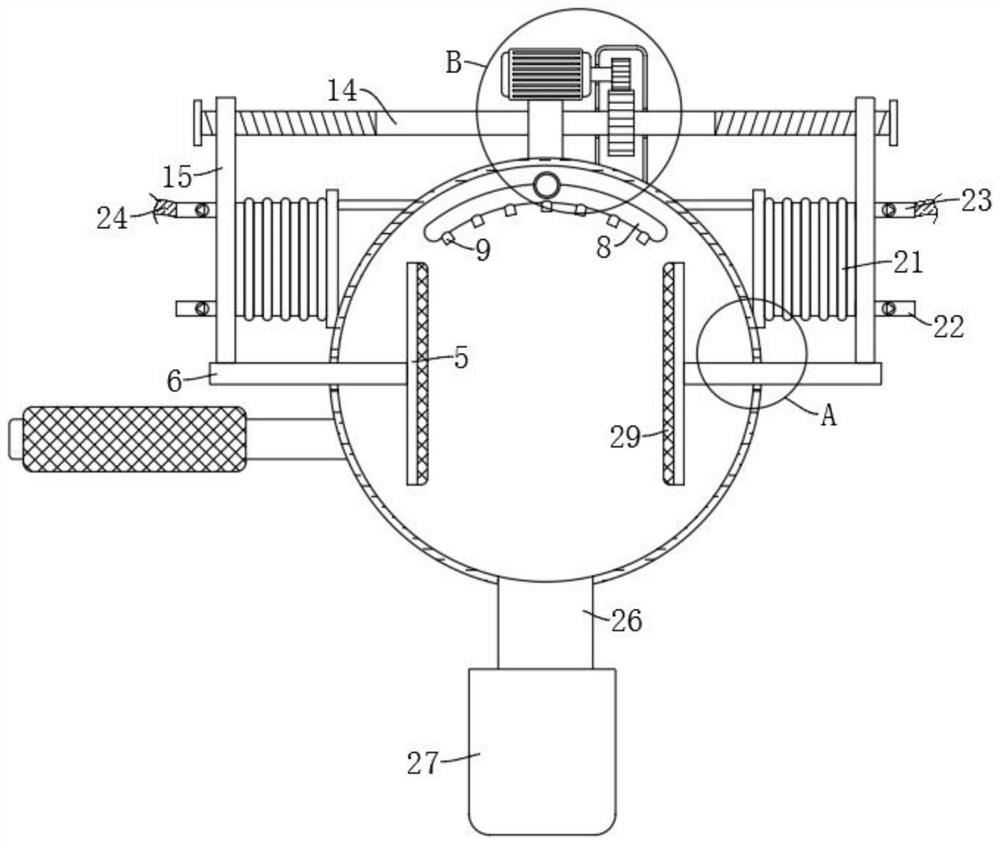

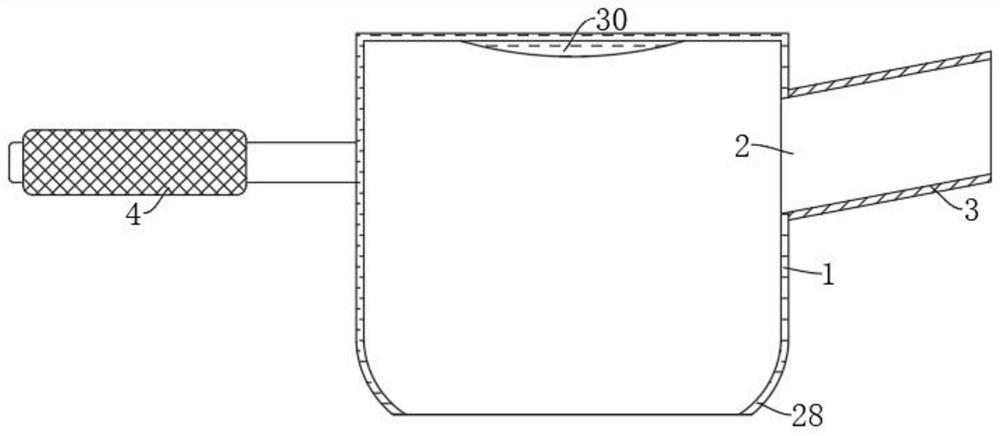

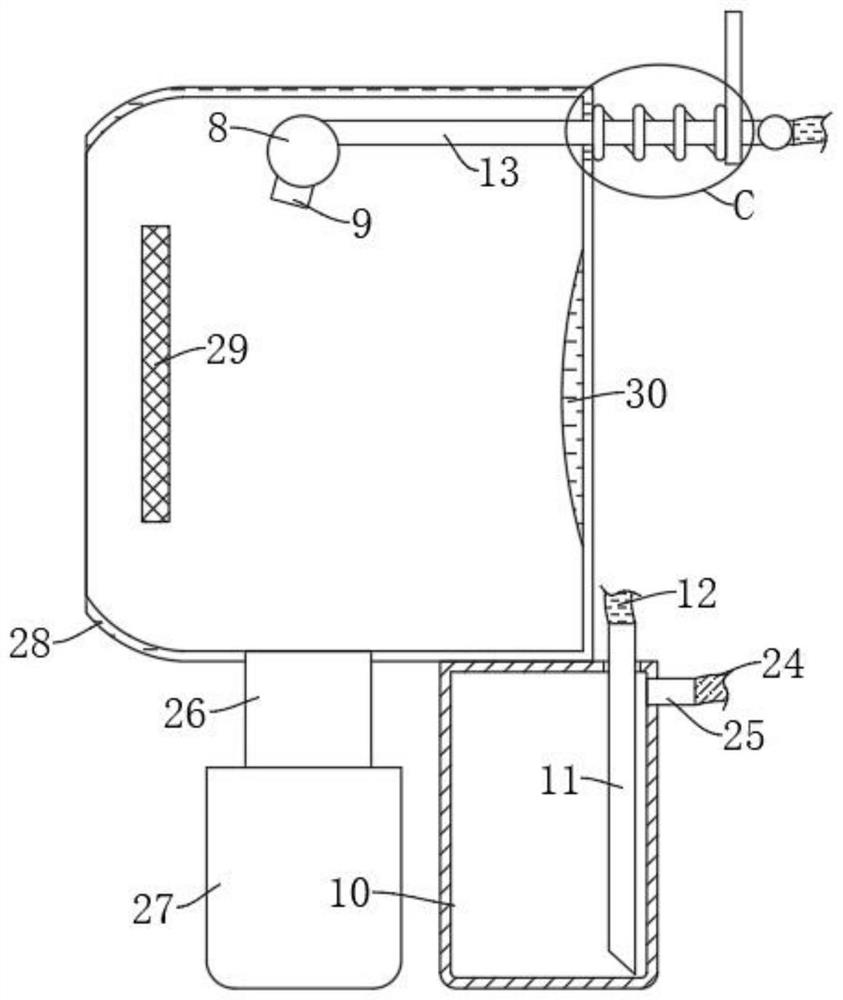

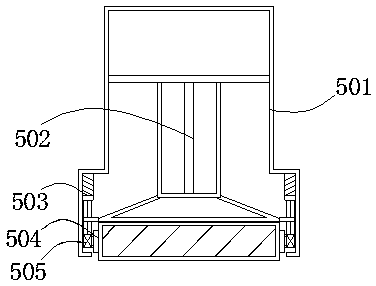

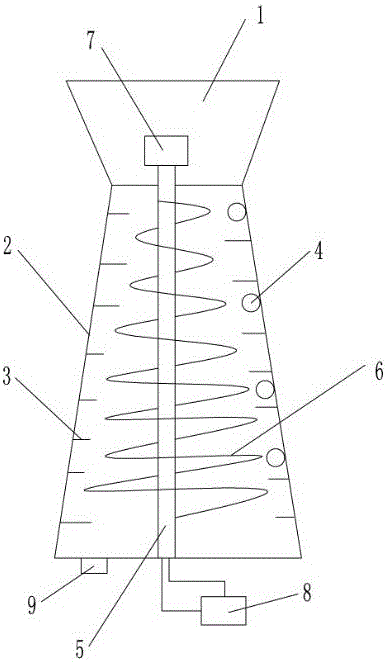

Mechanical sugarcane peeling and washing device with cutting assembly

InactiveCN106360755ASimple structureEasy cutting workVegetable peelingFood treatmentLine tubingElectric machinery

The invention relates to a mechanical sugarcane peeling and washing device with a cutting assembly, and belongs to the technical field of peeling of sugarcanes. The mechanical sugarcane peeling and washing device comprises a work table and a regulating plate, wherein two bearing seats are arranged on the work table, a peel scraping sleeve is arranged corresponding to the two bearing seats, a blade is arranged on the peel scraping sleeve, two ends of the peel scraping sleeve are mounted on the bearing seats through bearings, and the regulating plate is mounted at the bottom in the peel scraping sleeve in a penetrating manner; a motor is horizontally mounted at the lower right half part of the work table, a small belt pulley is mounted at the output end of a motor shaft of the motor, and the small belt pulley is in power connection with a large belt pulley through a belt; and a cutting plate is horizontally fixed to the left side of the work table, a cutting knife which is in cutting fit with the cutting plate is horizontally arranged on the cutting plate, a water pipe for providing cleaning water for the cutting edge of the blade is arranged corresponding to the cutting direction of the blade, a cleaning pump is connected to a water inlet end of the water pipe, and a cleaning water tank is connected to the cleaning pump through a pipeline. The mechanical sugarcane peeling and washing device disclosed by the invention is time-saving and labor-saving when being used for peeling, and is high in peeling efficiency.

Owner:CHONGQING ANSHANGYUAN AGRI TECH DEV CO LTD

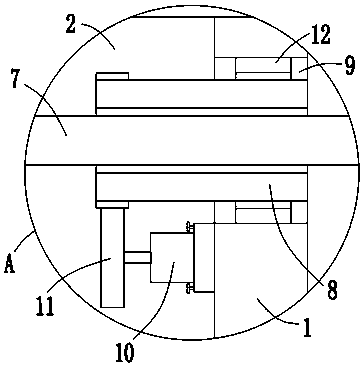

Cutting equipment for machining and forming plastic product

PendingCN107891464ASmooth rotationEasy cutting workMetal working apparatusStructural engineeringMechanical engineering

The invention discloses cutting equipment for machining and forming a plastic product. The cutting equipment comprises a cutting table, wherein a clamping groove is formed in the top of the cutting table; a tubular plastic product is placed in the clamping groove, arc-shaped plates are in contact with the two sides of the tubular plastic product respectively, and the arc-shaped plates are slidingly arranged in the clamping groove; the sides, far away from each other, of the two arc-shaped plates are each provided with two buffer rods; the outer sides of every two buffer rods located on the same side of the tubular plastic product are slidingly provided with one pushing plate; screw rods are welded to the sides, far away from the tubular plastic product, of the pushing plates, and sleeves are screwed to the outer sides of the screw rods; and rotating holes are formed in the inner walls of the two sides of the clamping groove. According to the cutting equipment, the structure is simple,and the tubular plastic product can be conveniently clamped; and the strength of the clamping force between the arc-shaped plates and the tubular plastic product can be determined by observing the deformation of buffer springs, so that damage to the tubular plastic products is prevented, and the use by people is facilitated.

Owner:湖州硕能纺织科技有限公司

Reference line setting device used for wooden plate cutting

ActiveCN105437200AImprove stabilitySimple sliding structureOther workshop equipmentEngineeringReference line

The invention discloses a reference line setting device used for wooden plate cutting. The reference line setting device comprises connecting rods. First bases and second bases are arranged on the connecting rods. Sliding rods are arranged between the first bases and the second bases. A sliding base is slidably connected to the sliding rods. An installation panel is slidably connected to the sliding base. A supporting table is arranged on the front side of the installation panel. A first mechanical arm and a second mechanical arm are arranged on the supporting table. The first mechanical arm and the second mechanical arm are each provided with an ink box. A take-up device is arranged on the outer side of the first mechanical arm. A pay-off rod is arranged on the outer side of the second mechanical arm. An elastic rope is arranged on the pay-off rod. By means of the reference line setting device, clear and straight reference lines can be set in different positions of a wooden plate, the flatness of cutting faces of the wooden plate is improved, and the working efficiency of wooden plate cutting is improved.

Owner:邳州市景鹏创业投资有限公司

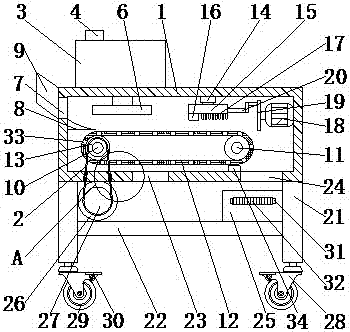

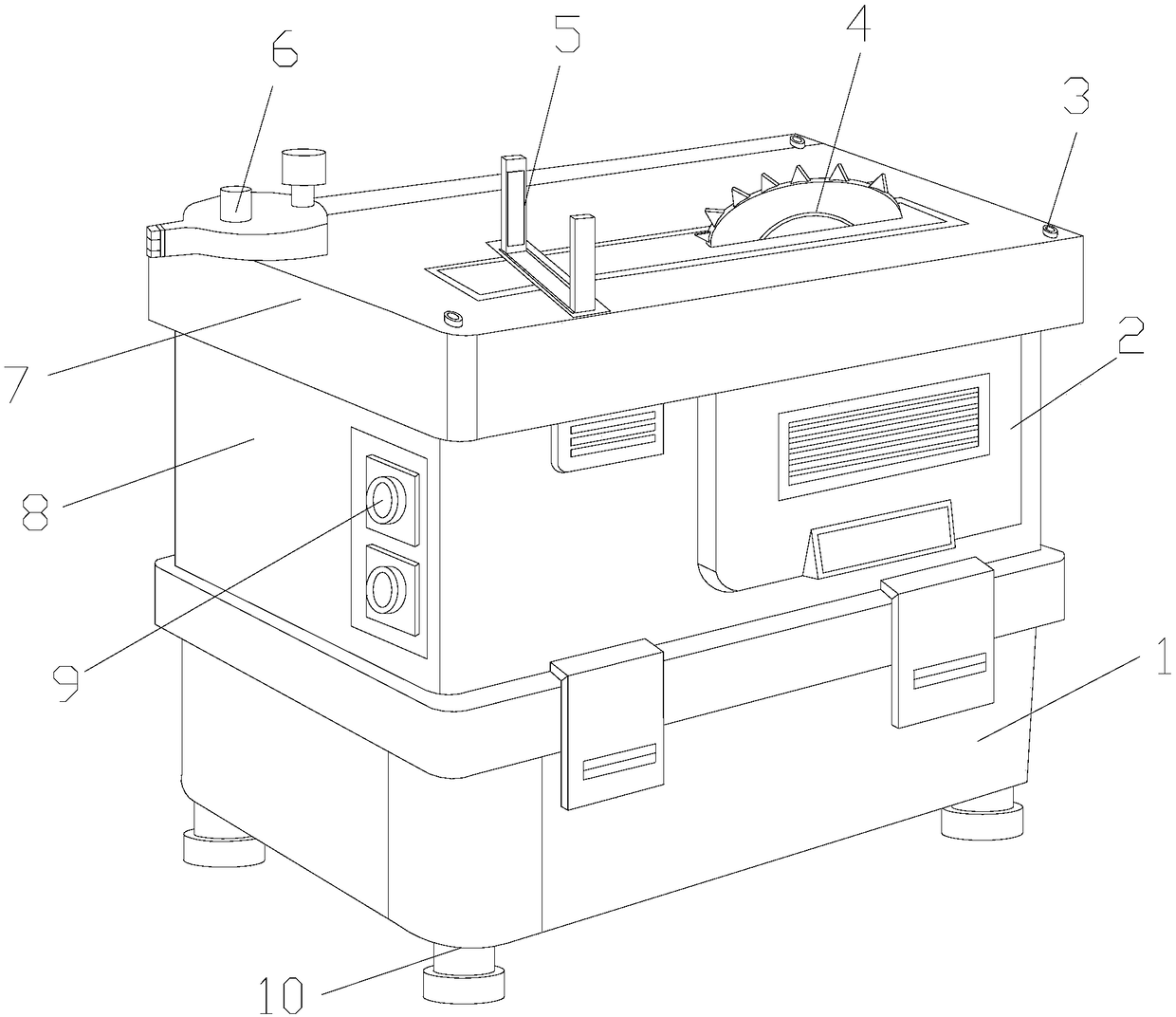

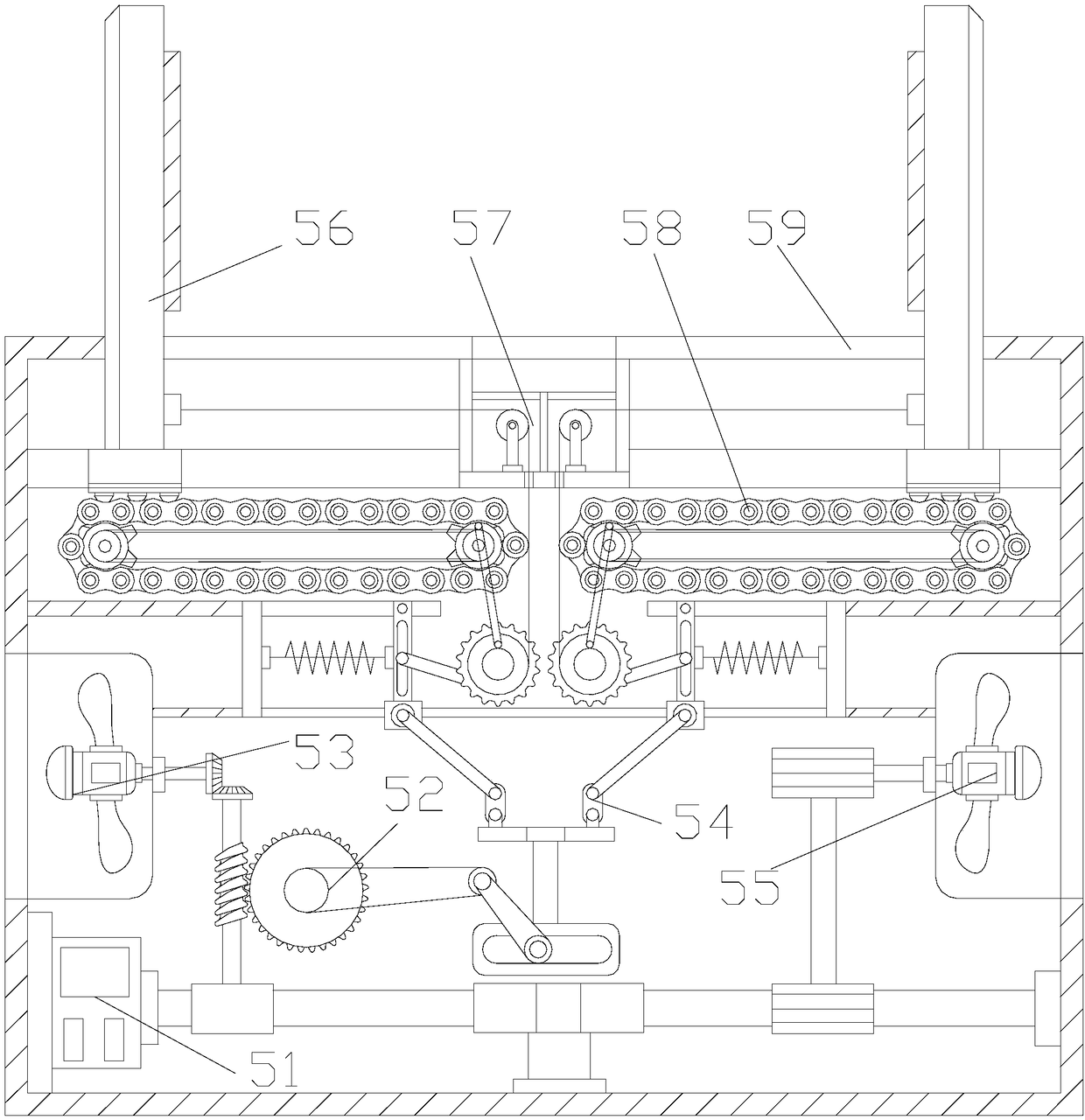

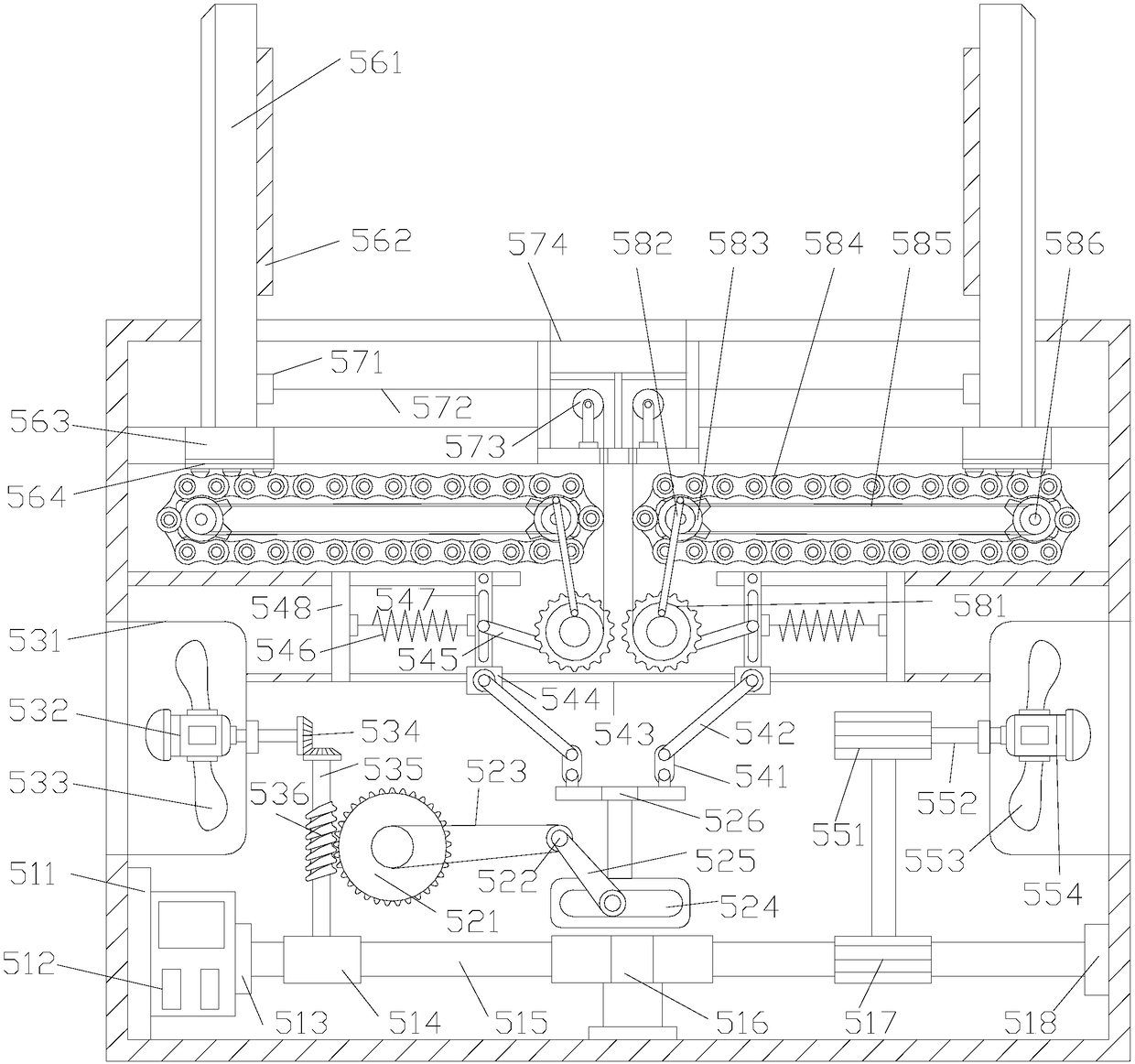

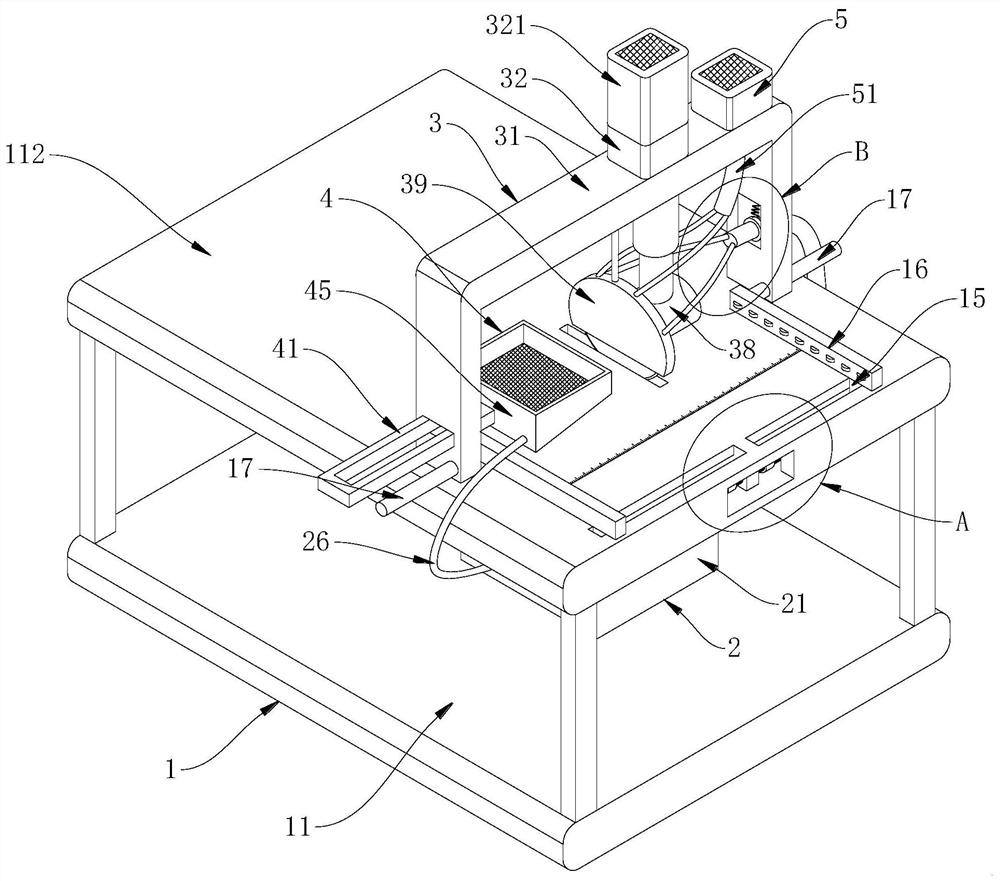

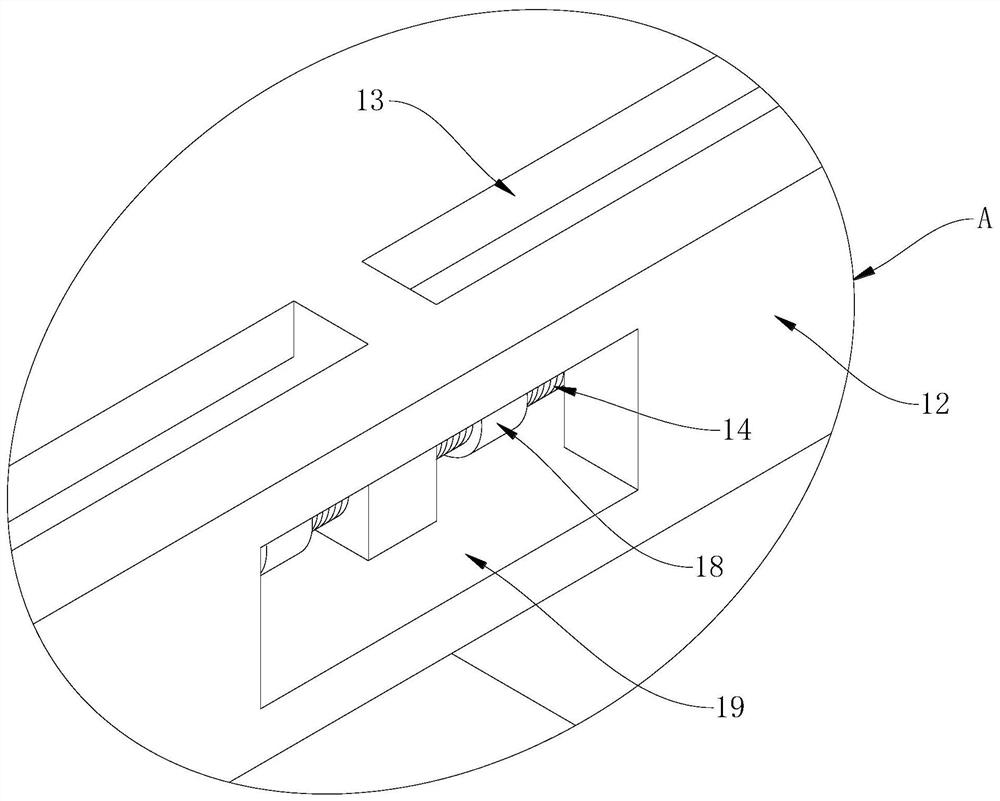

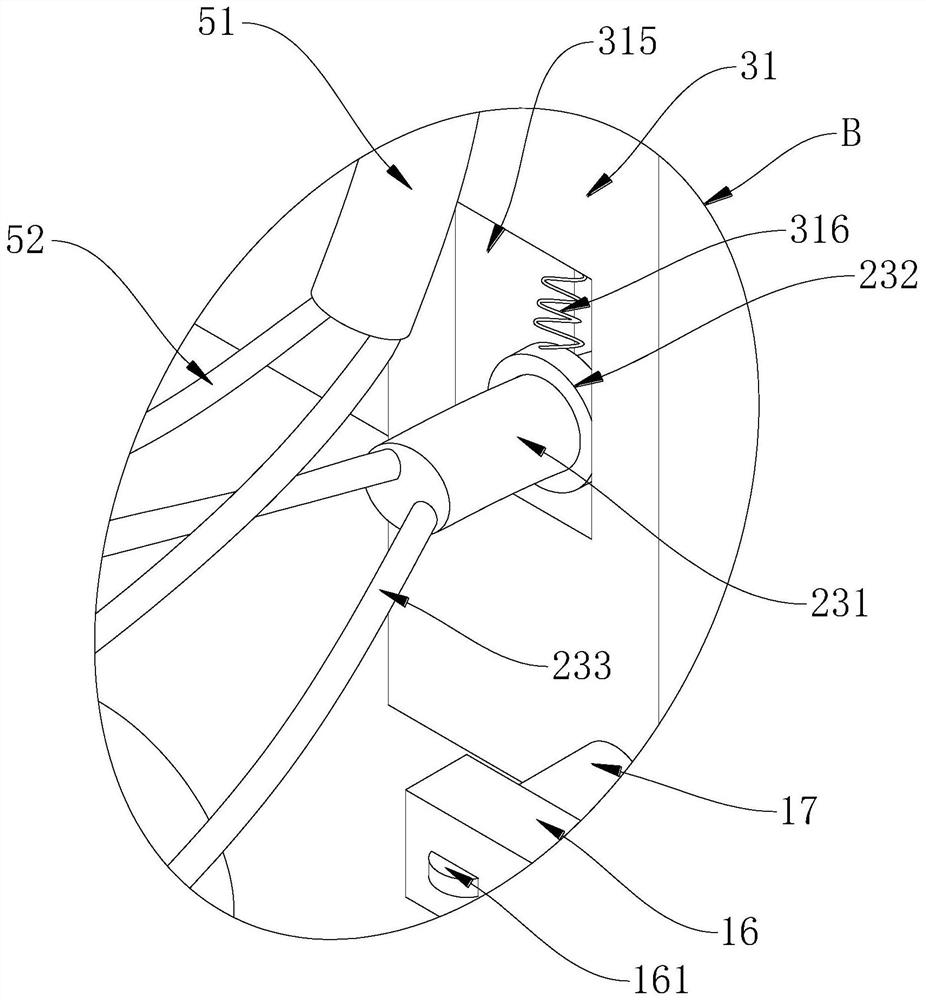

Wood cutting machine with fixing device and dust removal function

InactiveCN108297184APrevent slippingIncrease frictionSawing componentsCircular sawsPulp and paper industryWood cutting

The invention discloses a wood cutting machine with a fixing device and a dust removal function. The wood cutting machine structurally comprises a machine body, a saw web bin, a bolt, a saw web, a fixed clamping dust removal device, an angle push ruler, a working table, a chipping collecting bin, a control panel, bottom feet, a servo motor device, a gear transmission mechanism, a first dust removal mechanism, a lever transmission mechanism, a second dust removal mechanism, a clamping fixing mechanism, an auxiliary clamping mechanism, a chain conveying mechanism and a protection cover. By meansof the wood cutting machine with the fixing device and the dust removal function, wood can be powerfully fixed through mechanical motion, the condition that the wood is prone to shaking, is not stable and moves left and right due to too large vibration during work of equipment is avoided, and the cutting work of a worker on the wood is facilitated; and meanwhile, dust and wood chippings in the equipment can be effectively removed, influences of blockage caused by long-term residual of the dust and the wood chipping on equipment performance are avoided, and the equipment practicability is improved.

Owner:莆田市荔城区自然家居电子商务有限公司

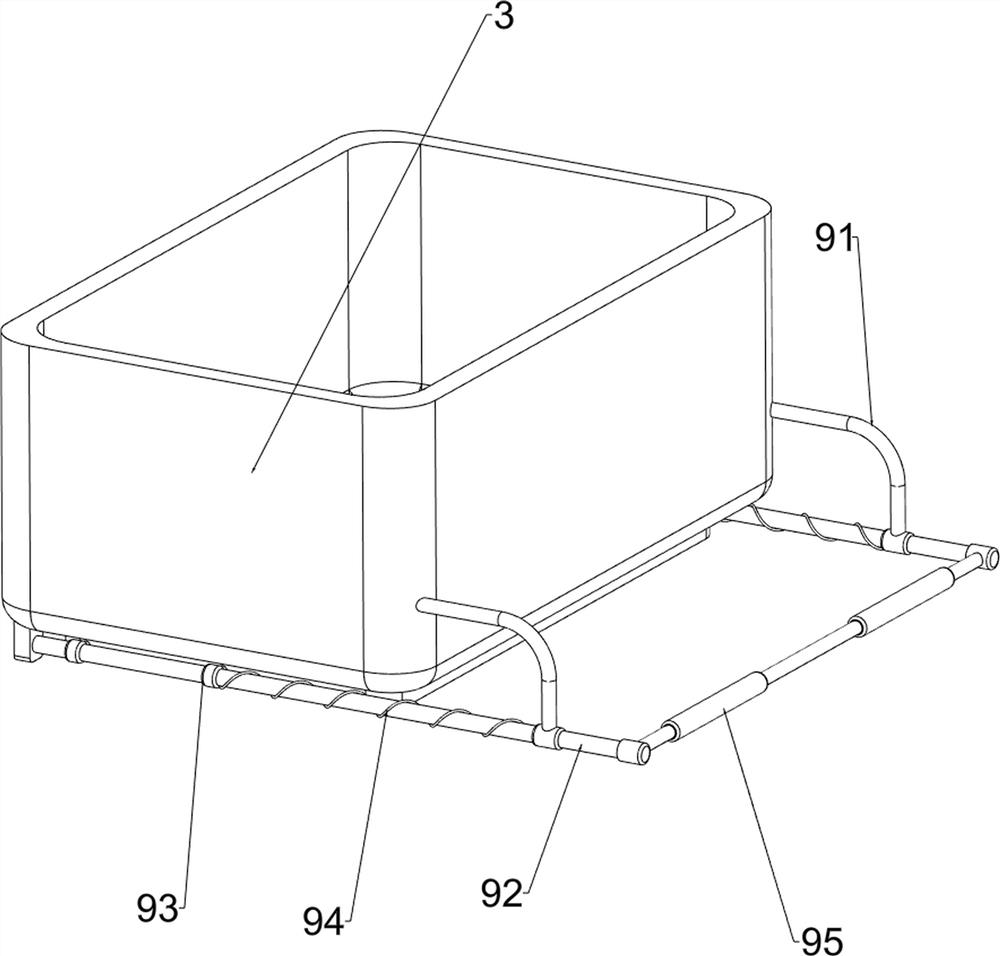

Cooked Chinese yam peeling apparatus

The invention provides cooked Chinese yam peeling apparatus. The cooked Chinese yam peeling apparatus comprises a peeling box, a fixed bearing, a connecting rod, a clamping plate, a fixed needle, a Chinese yam fixing and rotating plate structure, a sliding peeling knife structure, a Chinese yam peel observing and collecting seat structure, a box cover, a cover handle, a U-shaped base, a connectingshaft, a cutting knife, a placing seat, a knife holder and a clamping gate; the clamping gate is in hinged connection with the upper part of the left side of the peeling box; and the fixed bearing isembedded at the middle position inside the clamping gate. By arranging gripping plates, a rotating needle, the clamping plate and the fixed needle, the cooked Chinese yam peeling apparatus is capableof facilitating fixing of Chinese yams when the Chinese yams are being peeled, thereby facilitating peeling operation on the Chinese yams; by arranging a connecting box and a collecting box, the cooked Chinese yam peeling apparatus is capable of facilitating collecting of cut Chinese yam peel, thereby preventing pollution to working environment by the Chinese yam peel; and by arranging a rotatingbearing, the gripping plates, the rotating needle, a rotating rod, the fixed bearing, the connecting rod, the clamping plate and the fixed needle, the cooked Chinese yam peeling apparatus is capableof facilitating rotating of Chinese yams when the Chinese yams are being peeled, thereby facilitating peeling operation on the Chinese yams.

Owner:GUANLING AUTONOMOUS COUNTY DUANQIAO LVHUA AGRI PROD FARMER PROFESSIONAL COOP

Textile fabric tailoring device with convenience in receiving rolling wheels

The invention discloses a textile fabric tailoring device with convenience in receiving rolling wheels. The textile fabric tailoring device comprises a base; a fixed block is arranged on the side wallof one side of the base and is provided with a rotary rod in an inserting manner; a rotation motor is arranged on the upper side wall of the base; a belt is sleeved between a drive shaft of the rotation motor and the rotary rod; a tailoring box is arranged on the upper side wall of the base; a regulation box is arranged on the upper side wall of the tailoring box in the inserting manner; a servomotor is arranged on the upper side wall of the regulation box in the inserting manner; and a first screw rod is connected to the drive end of the servo motor and is sleeved with a first ball nut. Thetextile fabric tailoring device provided by the invention realizes functions of stretching and retraction of the rolling wheels, is convenient to receive the rolling wheels and move, is difficult inshaking, is convenient to tailor a fabric through up-and-down as well as left-and-right movement of the tailoring rod, to spread the fabric by fixing a fabric winding roll with a rotation plate and toperform tailoring work, is simple in structure and is convenient and practical.

Owner:XUZHOU ZHENFANG TEXTILE CO LTD

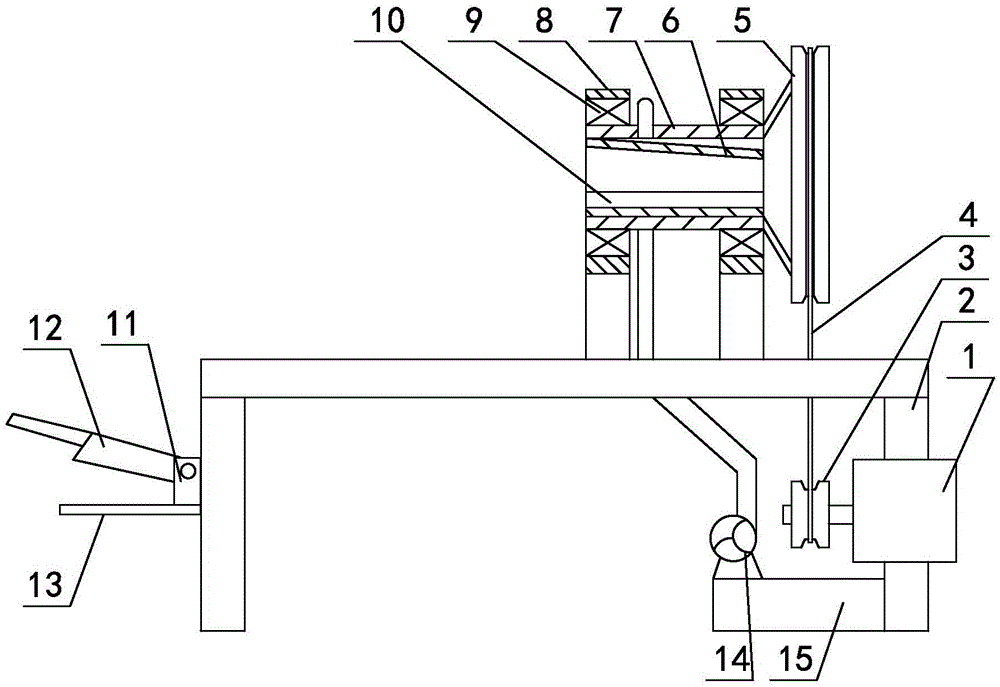

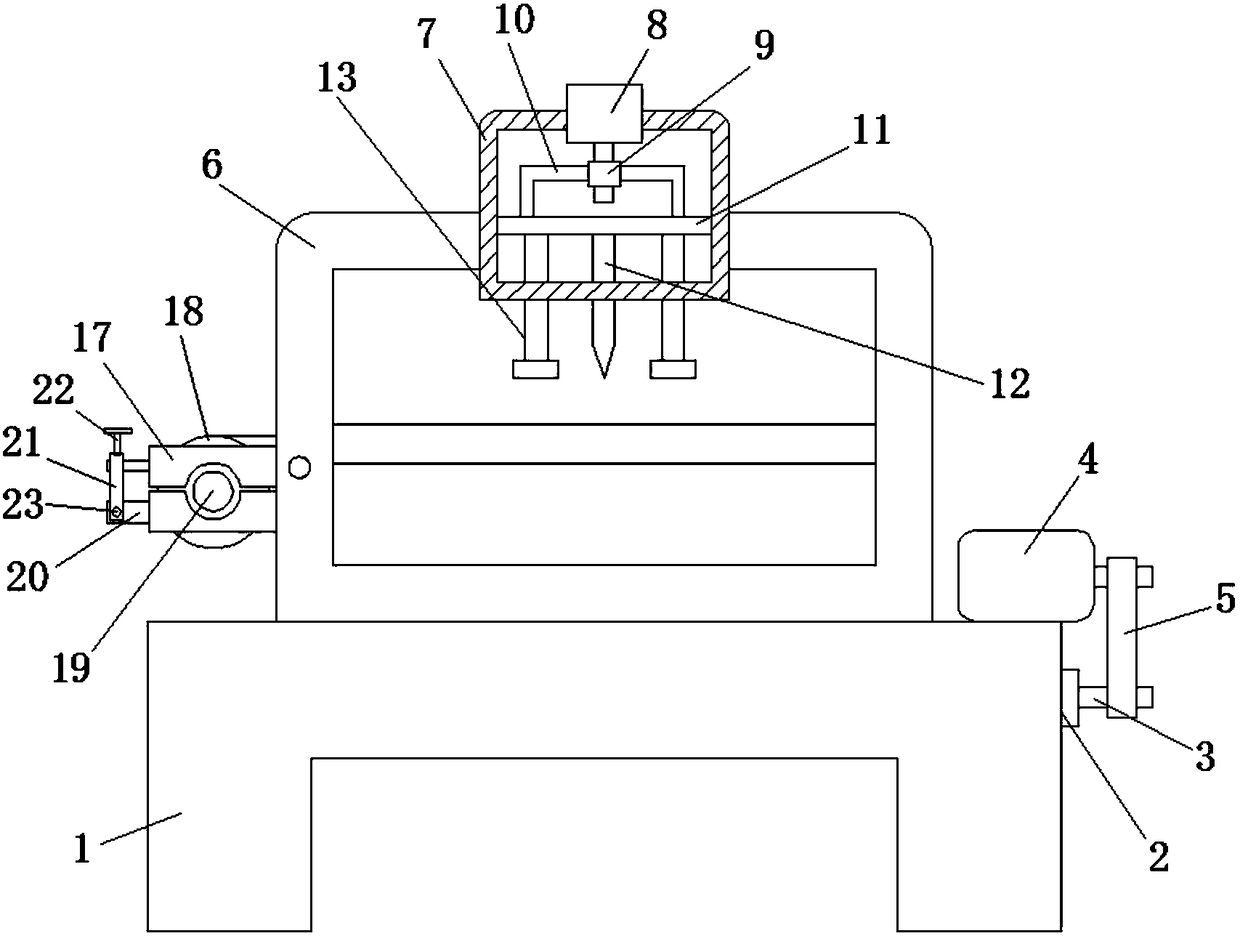

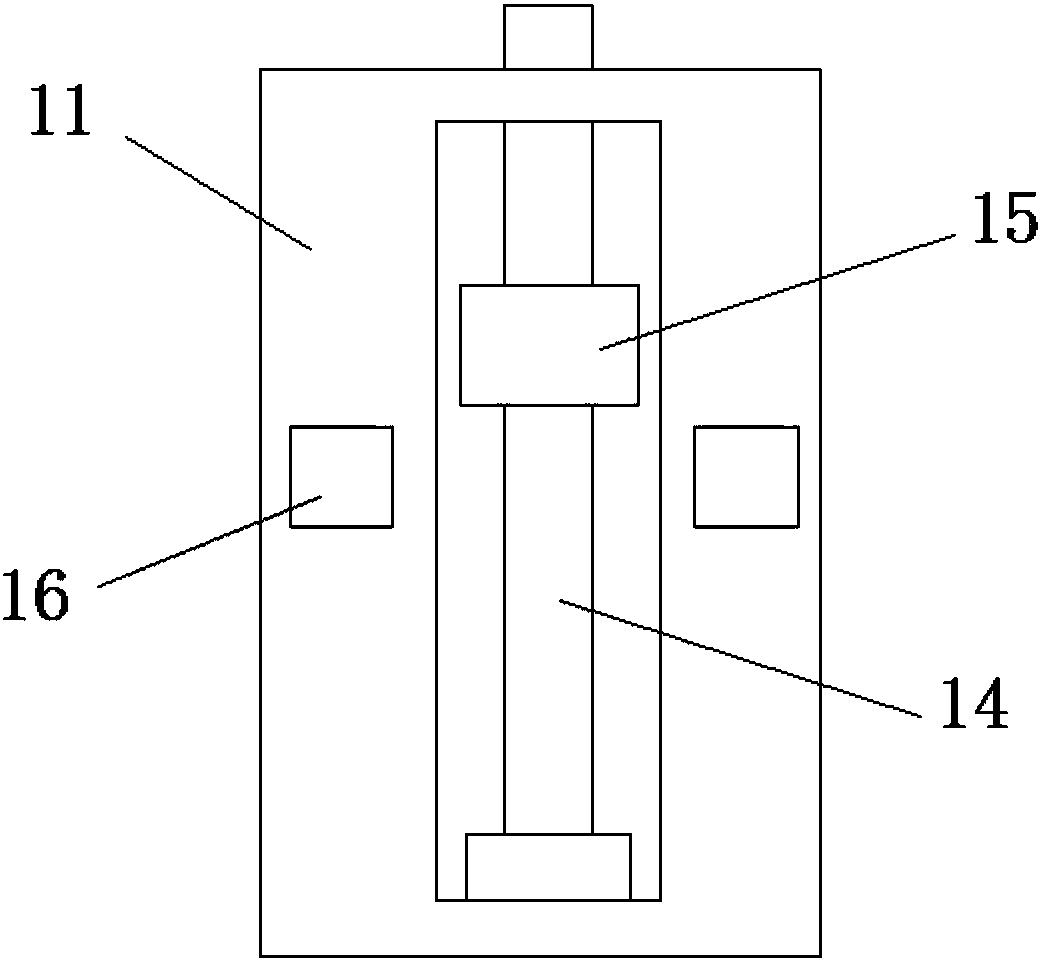

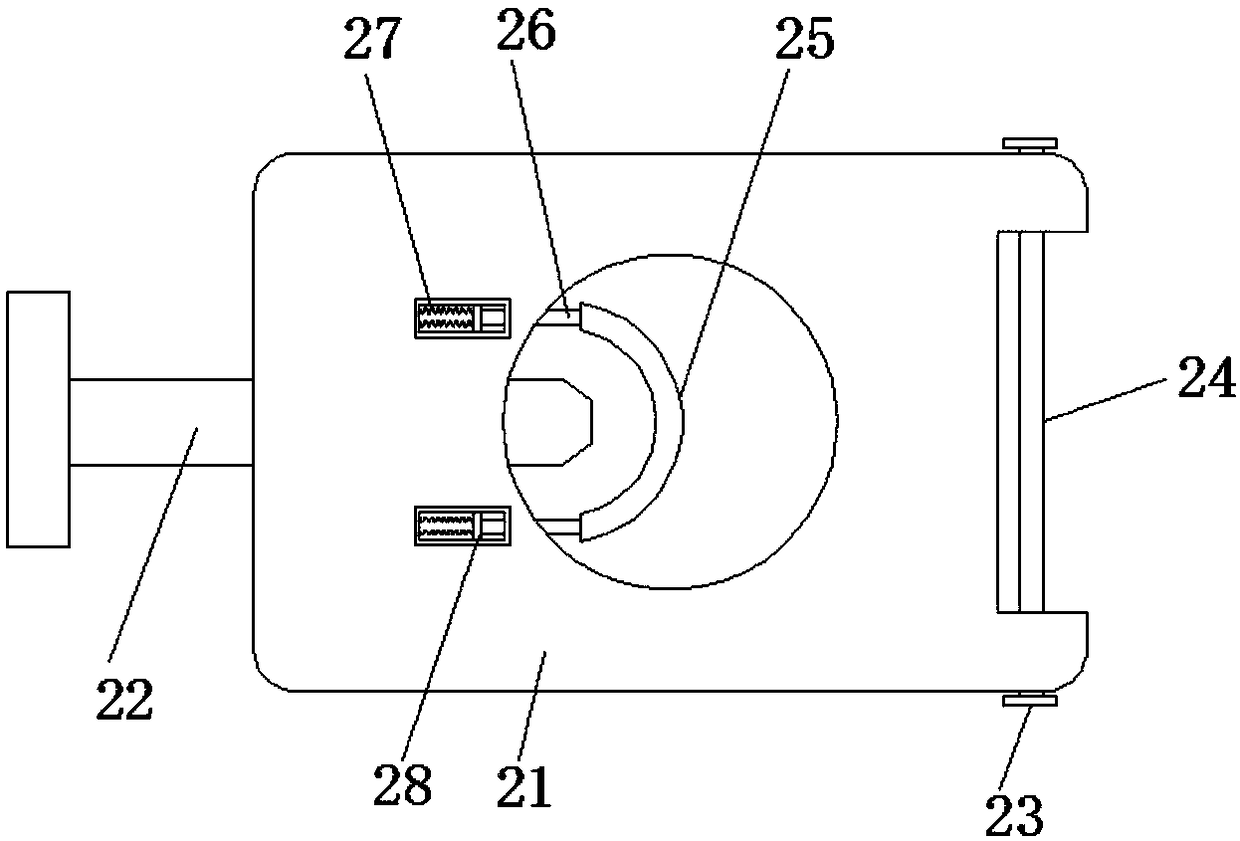

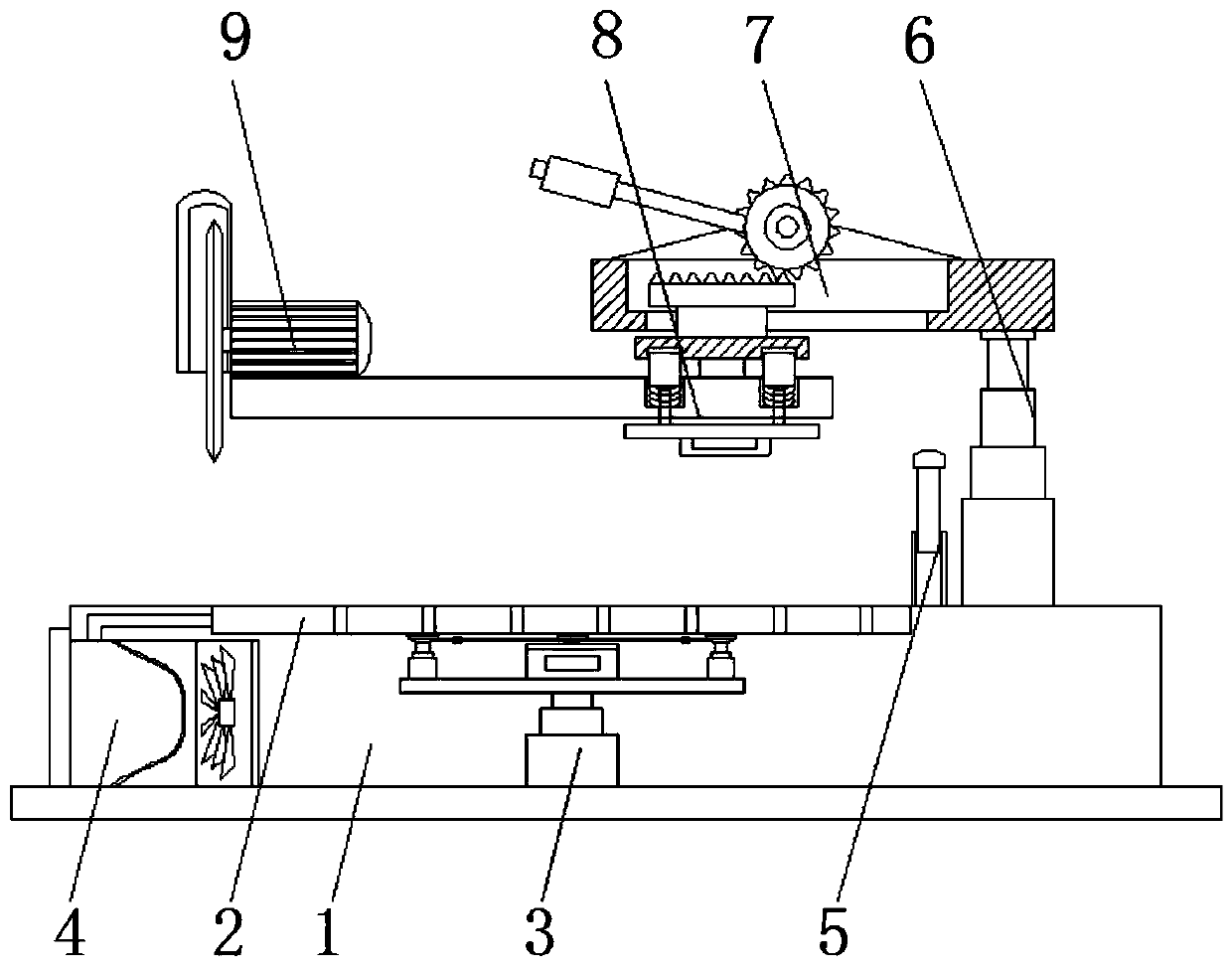

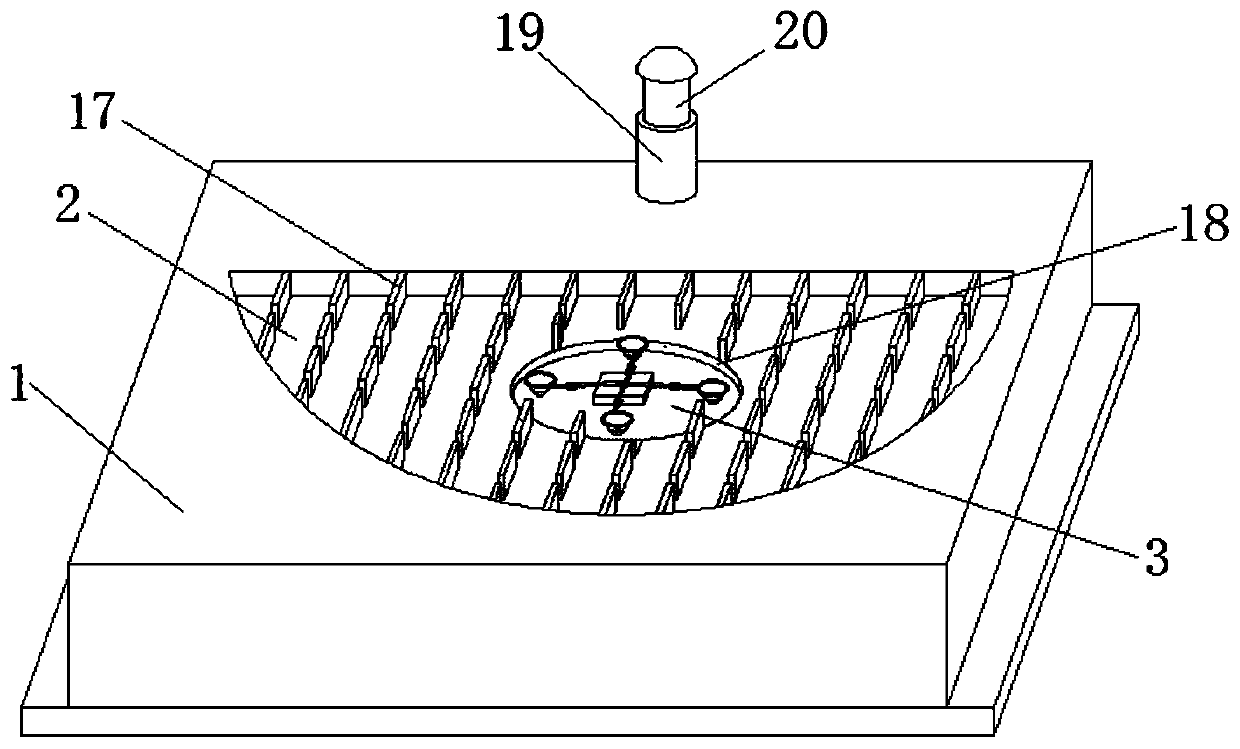

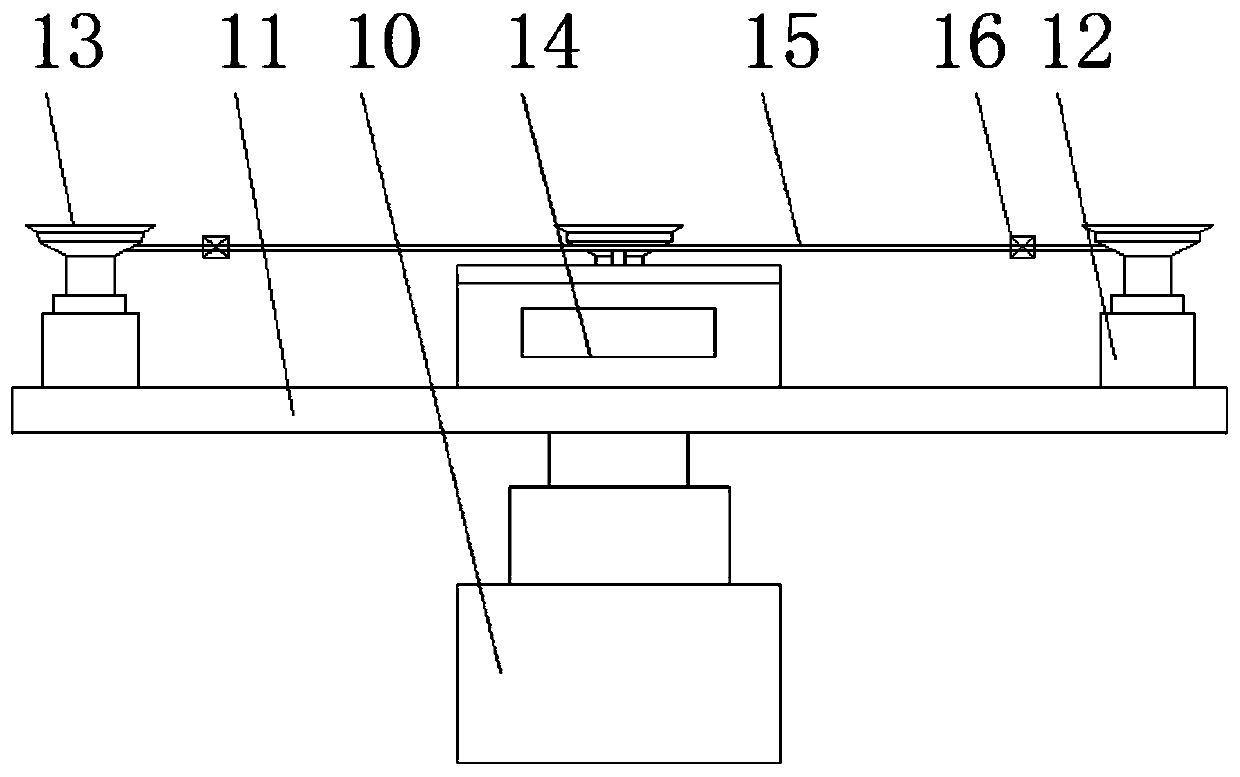

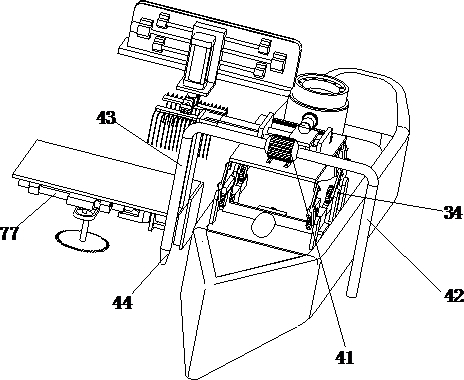

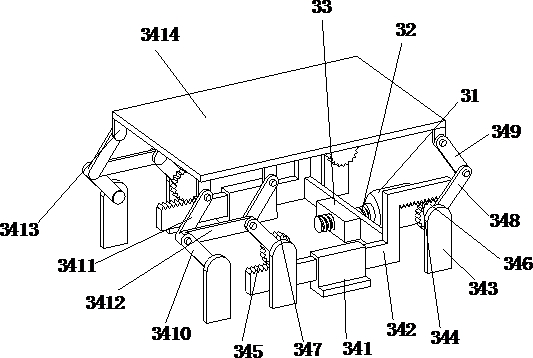

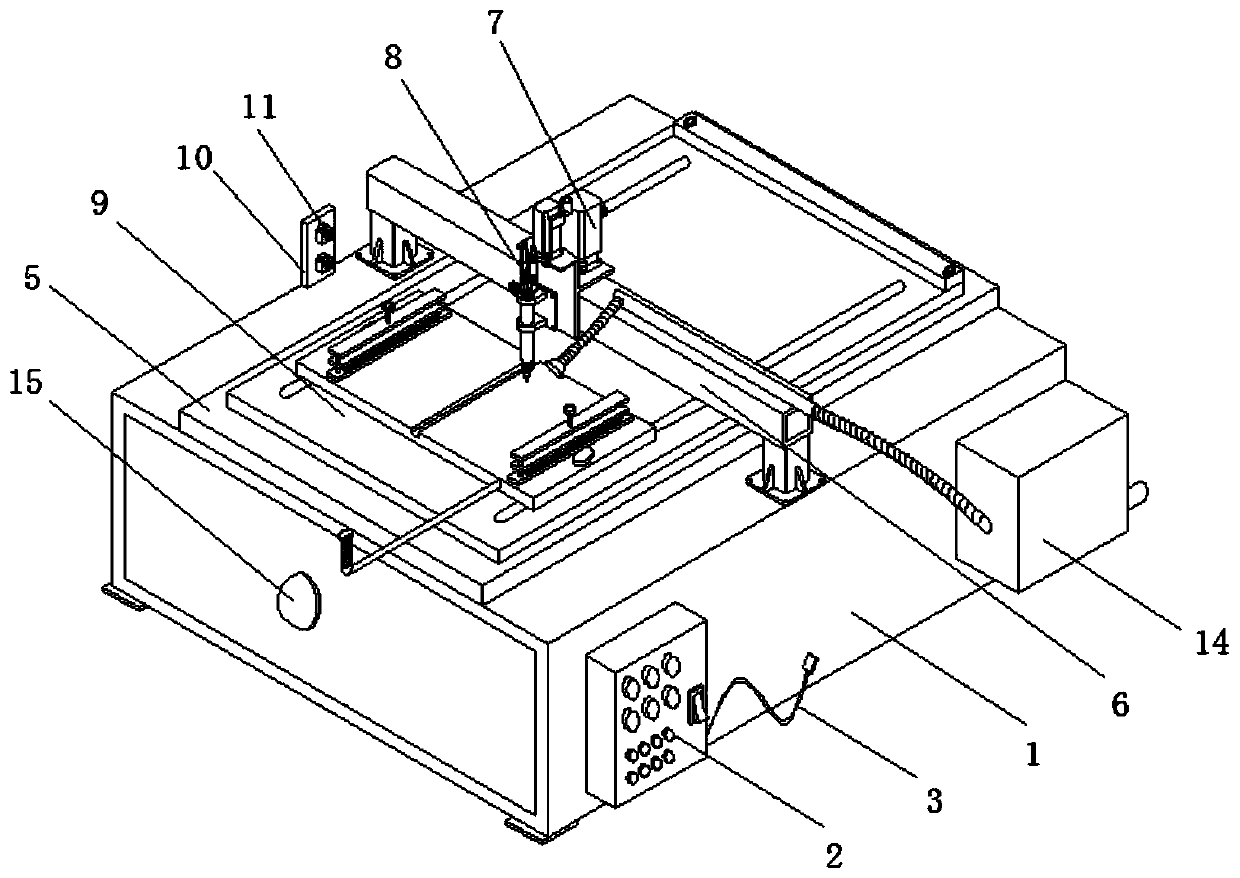

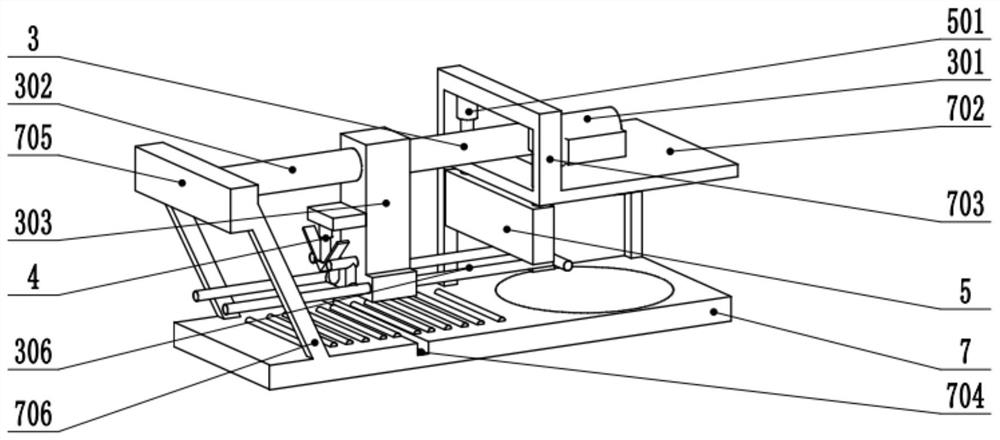

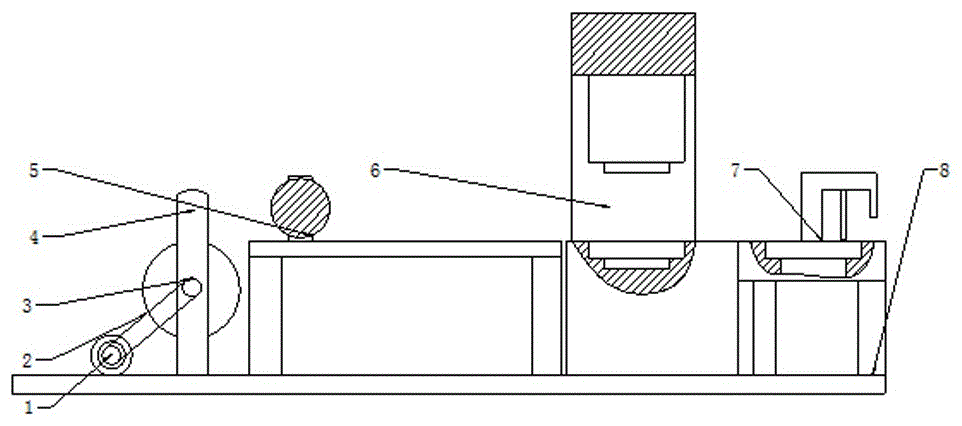

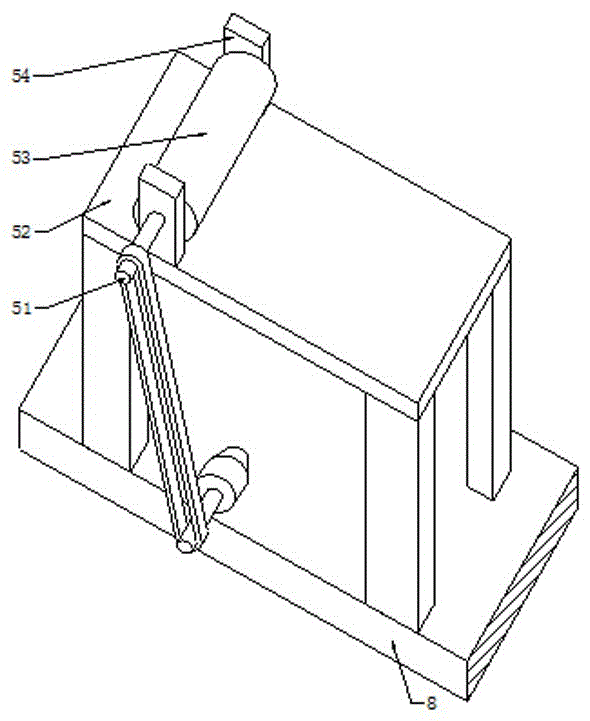

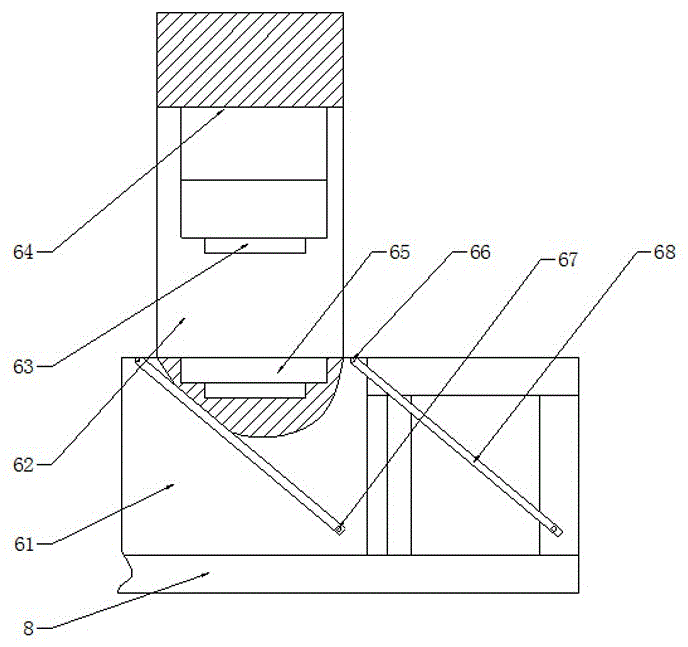

Multi-angle micro-shape cutting machining device and machining method

ActiveCN110666253AControl cutting workEasy cutting workLarge fixed membersMetal working apparatusManufacturing engineeringStable fixation

The invention discloses a multi-angle micro-shape cutting machining device and machining method, and belongs to the technical field of cutting devices. The multi-angle micro-shape cutting machining device comprises a base, wherein a cutting groove is formed in the top of the base, and a workpiece angle adjustment and fixation mechanism is installed in the base; the top of the workpiece angle adjustment and fixation mechanism extends into the cutting groove; and a collection bin is formed in one side in the base, and a limit mechanism is fixed to one side away from the collection bin, of the base. According to the multi-angle micro-shape cutting machining device and machining method, the workpiece angle adjustment and fixation mechanism is installed in the base, stable fixation can be carried out on a cutting workpiece by virtue of the adsorption effect of a plurality of groups of adsorption discs; and meanwhile, the heights of the adsorption discs can be changed by virtue of third lifting cylinders at the bottoms of the adsorption discs, then the inclination angle of the workpiece on the workpiece angle adjustment and fixation mechanism is controlled, then inclination cutting can be carried out on the surface of the workpiece through cooperation with a cutting mechanism, and frequent change on the position of the workpiece is not needed in the cutting process, so that the multi-angle micro-shape cutting machining device is more convenient to use.

Owner:CHANGSHA AERONAUTICAL VACATIONAL AND TECHNICAL COLLEGE +1

Automatic plastic film cutting device

ActiveCN106695923AAvoid enteringRealize automatic cutting workMetal working apparatusPlastic filmLost-foam casting

The invention belongs to the field of evaporative pattern casting machines, and concretely discloses an automatic plastic film cutting device, which comprises a cutting knife and a plurality of baffle plates. A covering plate is sealed on the baffle plates; a knife slot is formed in the covering plate; a first flexible plate and a second flexible plate which are opposite are horizontally arranged on the knife slot; an air suction pipe is arranged at one end of the covering plate; a sucking pump is arranged on the air suction pipe; an electromagnet is fixedly arranged at the other end of the covering plate; a magnet is arranged on a knife handle; supports are arranged at two sides of the covering plate; air cylinders are arranged under the supports, and are provided with piston rods; and the piston rods are connected with the supports. The invention provides the automatic plastic film cutting device capable of continuously automatic cutting plastic films.

Owner:CHONGQING RUITING PLASTIC

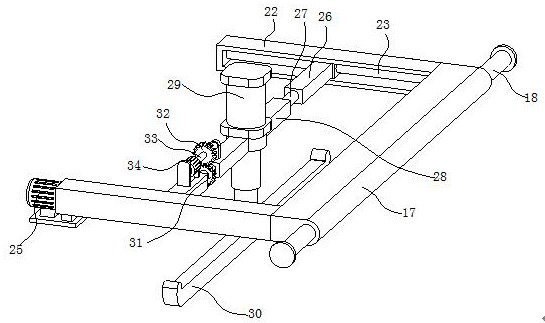

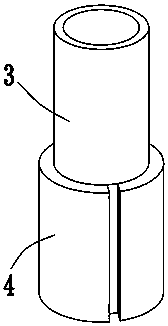

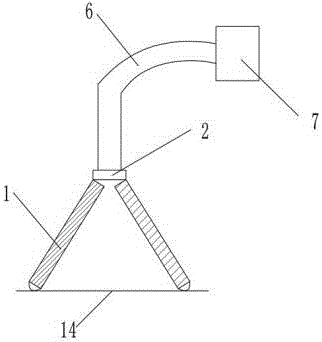

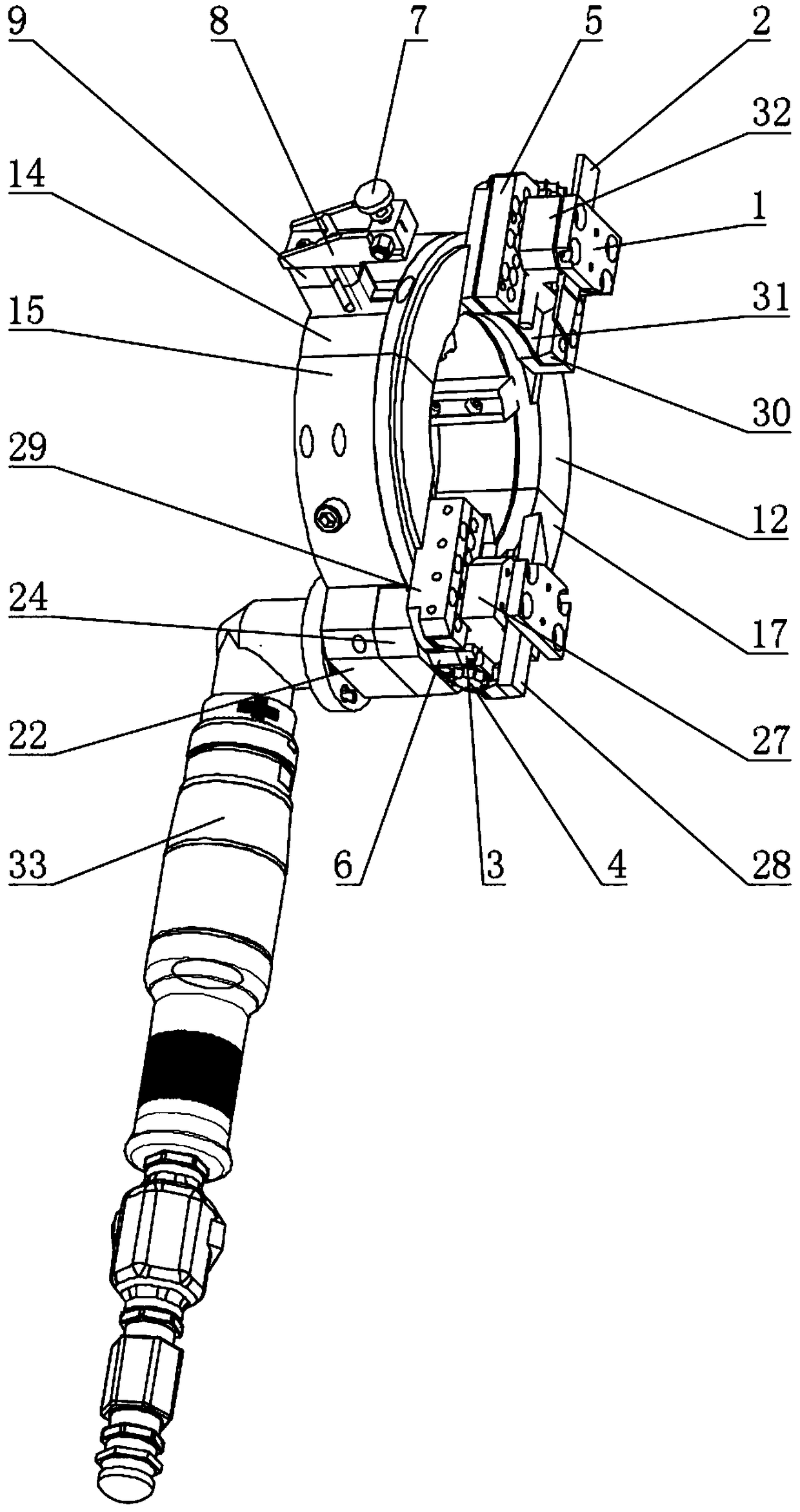

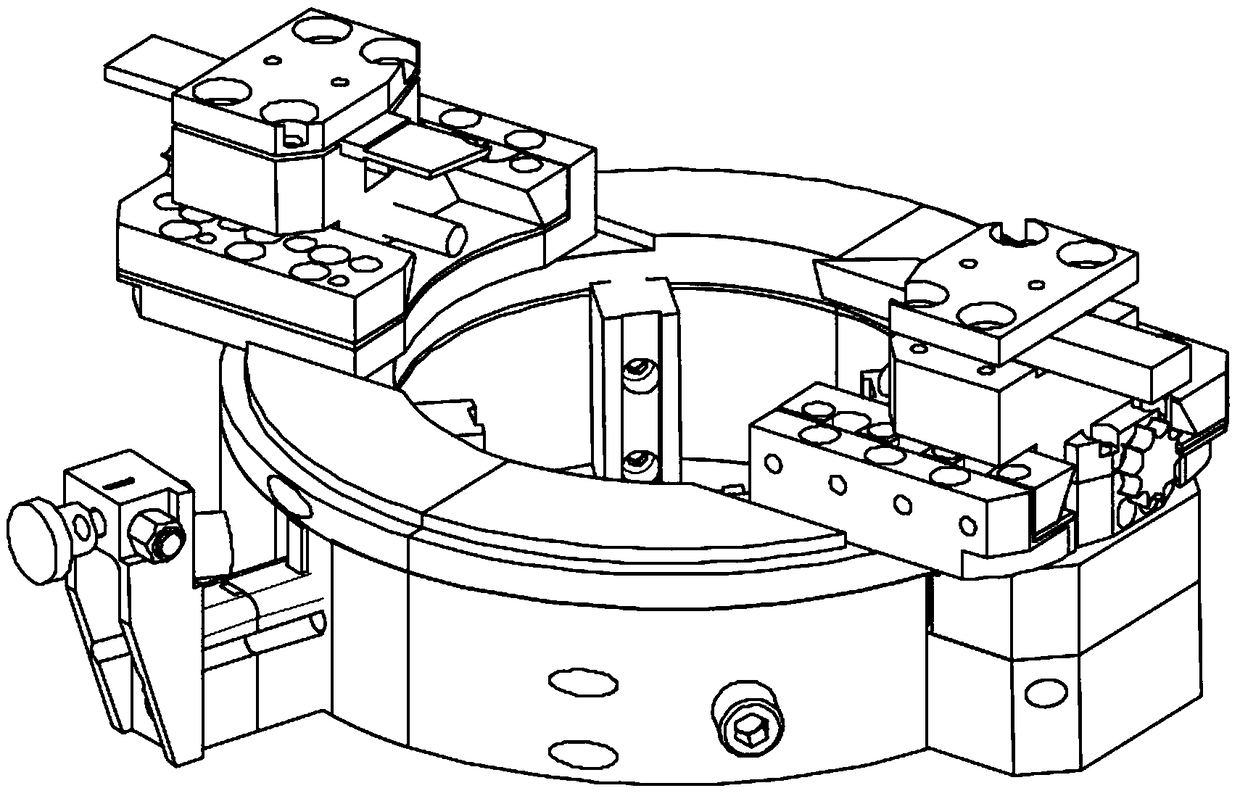

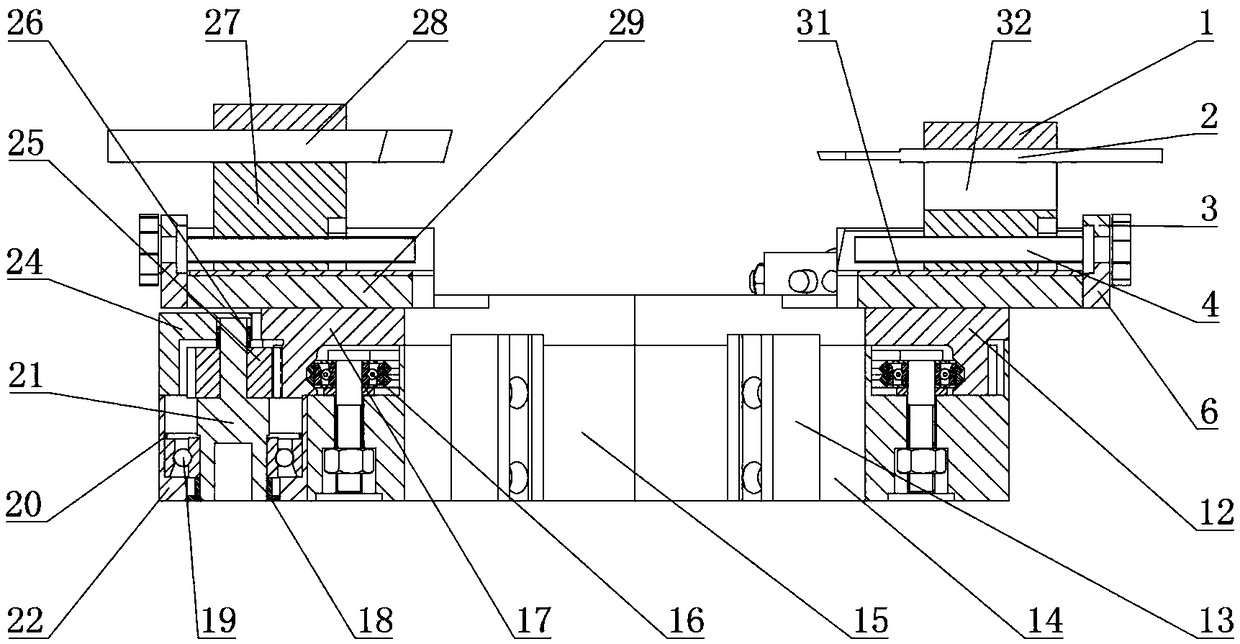

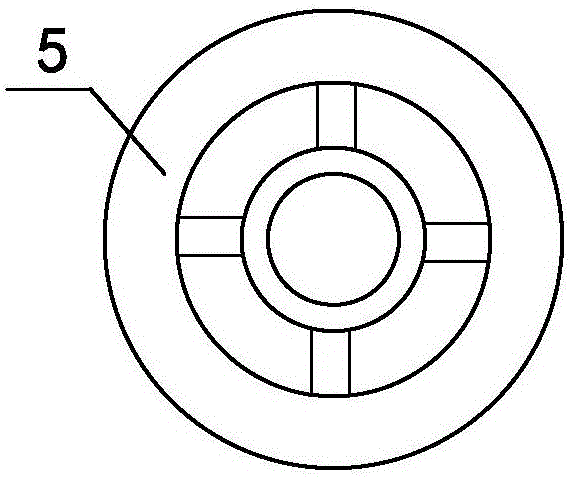

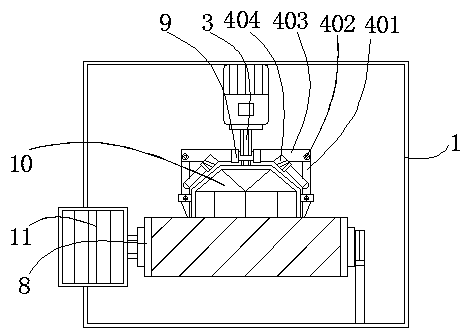

Small-pipe-diameter pipeline cutting and bevelling machine

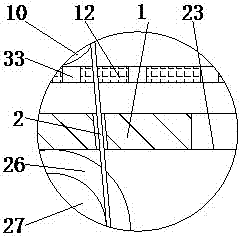

The invention discloses a small-pipe-diameter pipeline cutting and bevelling machine, and belongs to the technical field of pipeline mounting engineering. A power handle 33 is in butt joint with a small gear shaft 21 through a connecting block 3301, and power is transmitted to a moving ring of a main cutting motion mechanism; a clamping mechanism is mounted on a static ring I 15 and a static ringII 14 in the main cutting motion mechanism to clamp workpieces; and a radial feed mechanism is fixed to the moving ring in the main cutting motion mechanism and does radial feed motion of a tool through a stirring rod 7. According to the small-pipe-diameter pipeline cutting and bevelling machine, motion and force are transmitted to a mechanism body through a pair of bevel gears, the energy transmission direction and the operation direction are changed, and operation of operators is facilitated; a throttle valve, a filter, a gate valve, a pneumatic motor, the bevel gears and the other mechanisms are integrated in a power handle, and good integration and portability are achieved; and through replacement of clamping blocks of different lengths, the aims of clamping pipelines of different pipediameters and achieving cutting and bevelling are achieved.

Owner:HARBIN ENG UNIV

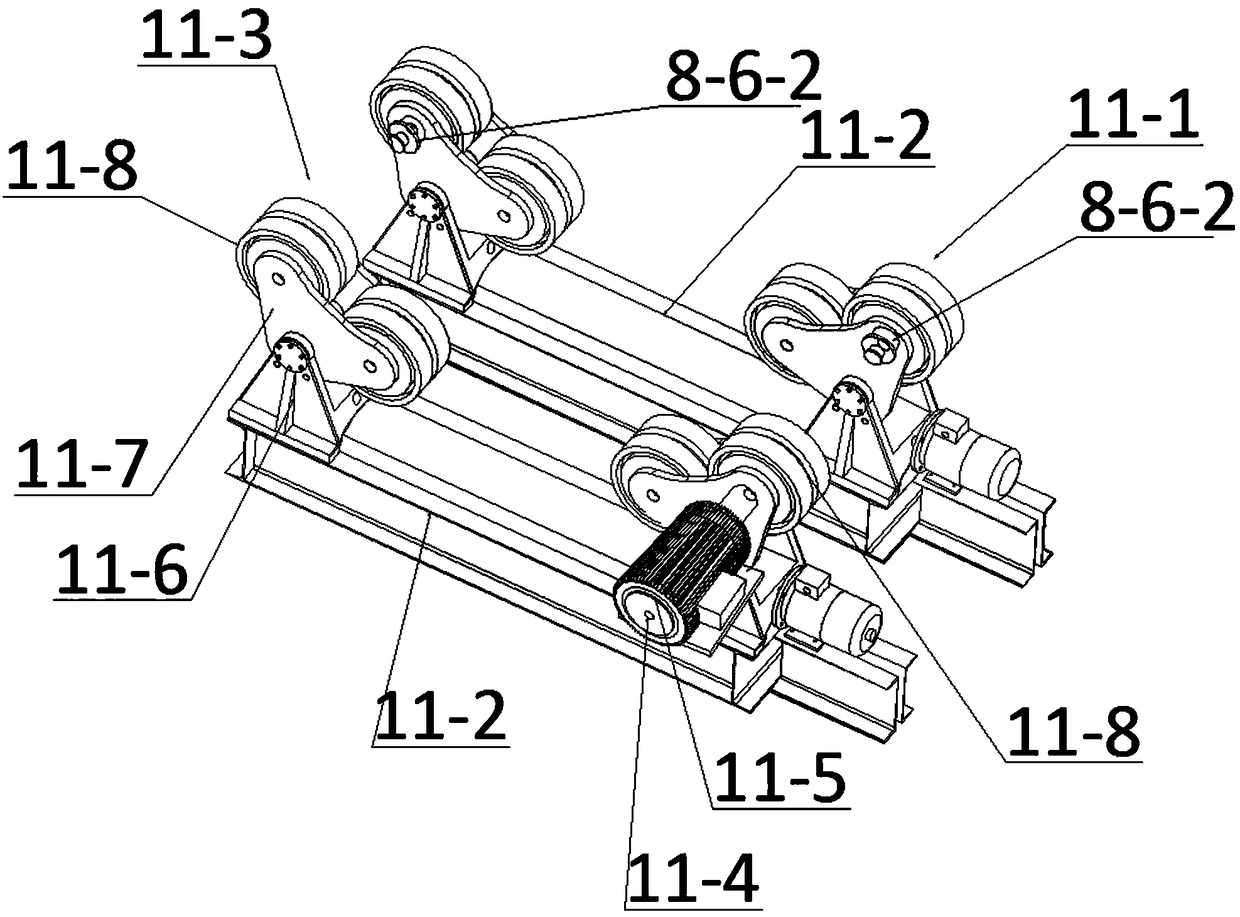

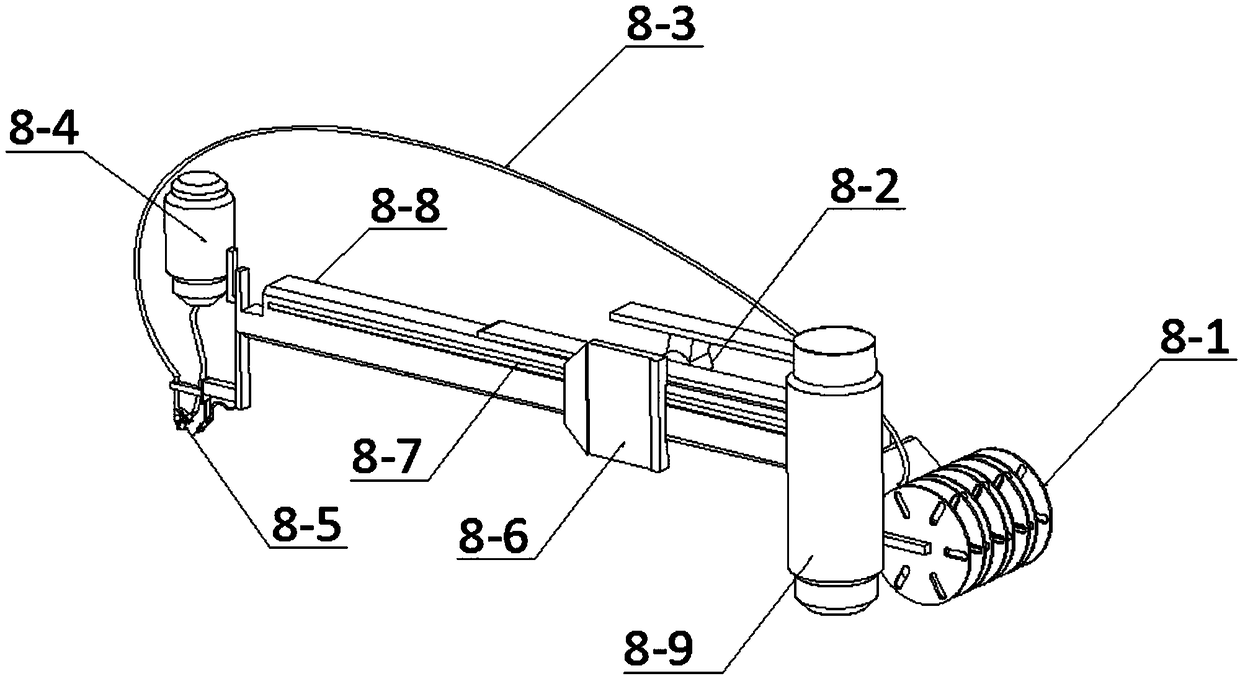

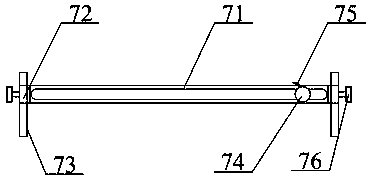

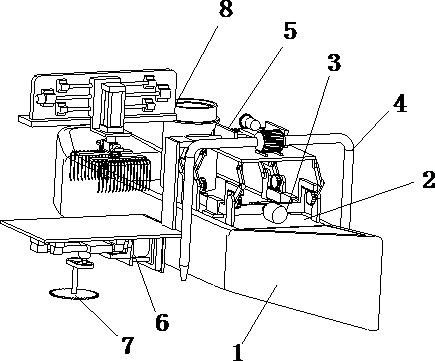

Aquatic plant cleaning device

InactiveCN112211174AEasy cutting workConvenience to workWater cleaningWaterborne vesselsEnvironmental engineeringBiology

The invention discloses an aquatic plant cleaning device, and belongs to the technical field of aquatic plant cleaning. The aquatic plant cleaning device comprises a cleaning ship, a deck, a lifting assembly, a water spraying assembly, a telescopic assembly, a clamping assembly, a cutting assembly and a fishing assembly, wherein the deck is fixedly arranged on the cleaning ship, the lifting assembly is fixedly arranged on one side of the deck, the water spraying assembly is fixedly arranged on the lifting assembly, the telescopic assembly is fixedly arranged on one side of the water spraying assembly, the clamping assembly is fixedly arranged at the working end of the telescopic assembly, the cutting assembly is fixedly arranged beside the clamping assembly, and the fishing assembly is fixedly arranged on the other side of the deck. The aquatic plant cleaning device is high in practicability and high in working efficiency, manual operation is not needed, and time and labor are saved.

Owner:王齐繁

Environment-friendly wood machining cutting device facilitating wood chip collection

ActiveCN112976165AAvoid getting wetWill not polluteGripping devicesClamping devicesWood machiningElectric machinery

The invention discloses an environment-friendly wood machining cutting device facilitating wood chip collection, and relates to the technical field of wood machining. The environment-friendly wood machining cutting device facilitating wood chip collection comprises a supporting assembly, a collecting assembly, a cutting assembly, a water receiving assembly and a pump box. The supporting assembly comprises a mounting base plate, an operation table is fixedly arranged at the top of the mounting base plate, and a clamping plate is movably arranged at the top of the operation table. The collecting assembly comprises a water tank and a collecting barrel, the water tank is fixedly arranged at the top of the mounting base plate, and the collecting barrel is fixedly arranged at the bottom of the operation table. By arranging the supporting assembly, the collecting assembly, the cutting assembly and the water receiving assembly, a driving motor is started to drive a saw blade to ascend, meanwhile, a water receiving disc moves to the position below the saw blade, water in the water tank is pumped through a water pump to cool the saw blade, the water receiving disc is used for receiving water sprayed out during cooling, wood is prevented from being wetted, the surface of the operation table cannot be polluted, the device can be quickly put into use after cooling, and the machining efficiency is ensured.

Owner:JIANGSU REMIT THE WOOD IND

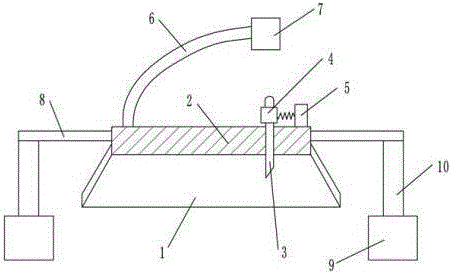

Cotton cloth cutting equipment for textile production

InactiveCN109850658AEasy cutting workThere will be no offsetRegistering devicesArticle deliveryLaser transmitterPulp and paper industry

The invention discloses cotton cloth cutting equipment for textile production. The cotton cloth cutting equipment comprises a machine box, a control box, a power line, a storage battery, a working table, a cross beam, a laser emitter, a laser tube, a pushing device, a support, an infrared sensor, a single chip microcomputer, a circuit breaker, an exhaust device and an alarm, wherein the control box is welded to the front side of the right end of the machine box, the power line is inserted in the rear end of the control box, the storage battery is arranged at the right end of the interior of the machine box, the working table is welded to the middle of the top end of the machine box, and the bottom of the left end and the bottom of the right end of the cross beam are fixed on the left sideand the right side of the middle part of the top end of the machine box through screws on the periphery of the support frame. According to the cotton cloth cutting equipment, a pushing device is arranged on the working table, after cotton cloth is fixed, a push rod is pushed to enable a sliding plate to slide on a bottom plate, a sliding rod slides in a sliding groove so that the sliding plate canbe kept sliding along a straight line, then the cotton cloth can be linearly cut when passing through laser, the cutting work of workers is facilitated, meanwhile, the deviation is avoided, and the quality of the cotton cloth after being cut is improved.

Owner:泉州朔康工业设计服务有限公司

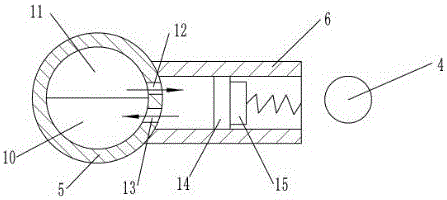

Mechanical sugarcane peeling and cleaning device with feeding assembly and cutting assembly

InactiveCN106690343ASimple structureEasy cutting workVegetable peelingFood treatmentElectric machineryKnife blades

The invention relates to a mechanical sugarcane peeling and cleaning device with a feeding assembly and a cutting assembly, and belongs to the technical field of peeling of sugarcanes. The mechanical sugarcane peeling and cleaning device comprises a work table and an adjusting plate, wherein two bearing seats are arranged on the work table; a peeling sleeve is arranged corresponding to the two bearing seats; a blade is arranged in the peeling sleeve; two ends of the peeling sleeve are separately mounted on the bearing seats through bearings; a handle disk is fixed to the right end of the peeling sleeve; the adjusting plate is mounted at the bottom in the peeling sleeve in a penetrating manner; a push rod is arranged on the left side of the peeling sleeve; a sliding mechanism is arranged corresponding to the push rod; a motor is mounted at the right lower half part of the work table; a cutting plate is fixed to the left side of the work table; a cutting knife is horizontally arranged on the cutting plate; a water pipe for providing cleaning water for the cutting edge of the blade is arranged corresponding to the cutting direction of the blade; and a cleaning pump is connected to the water inlet end of the water pipe. According to the mechanical sugarcane peeling and cleaning device disclosed by the invention, peeling is time-saving and labor-saving, and the peeling efficiency is high.

Owner:CHONGQING ANSHANGYUAN AGRI TECH DEV CO LTD

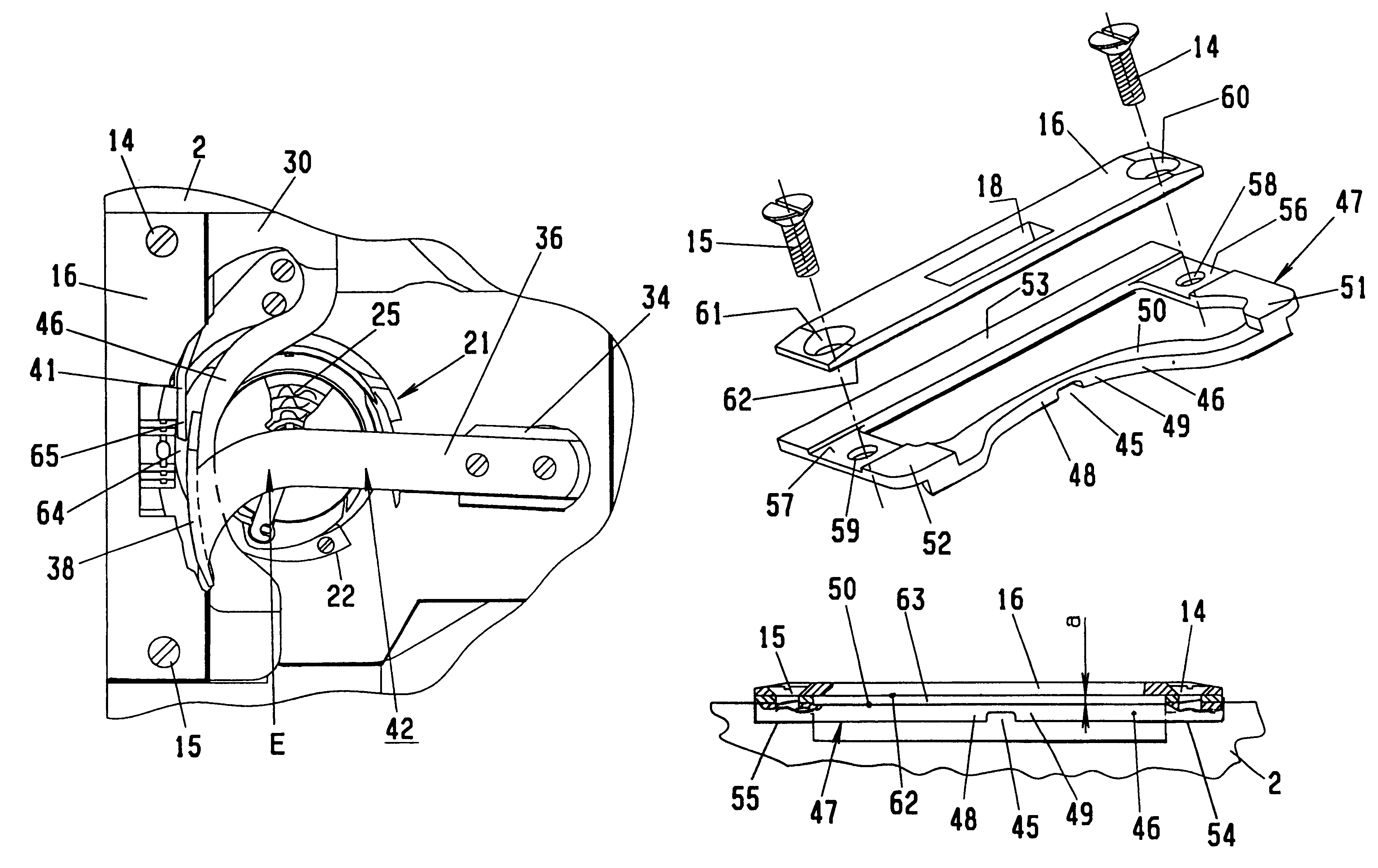

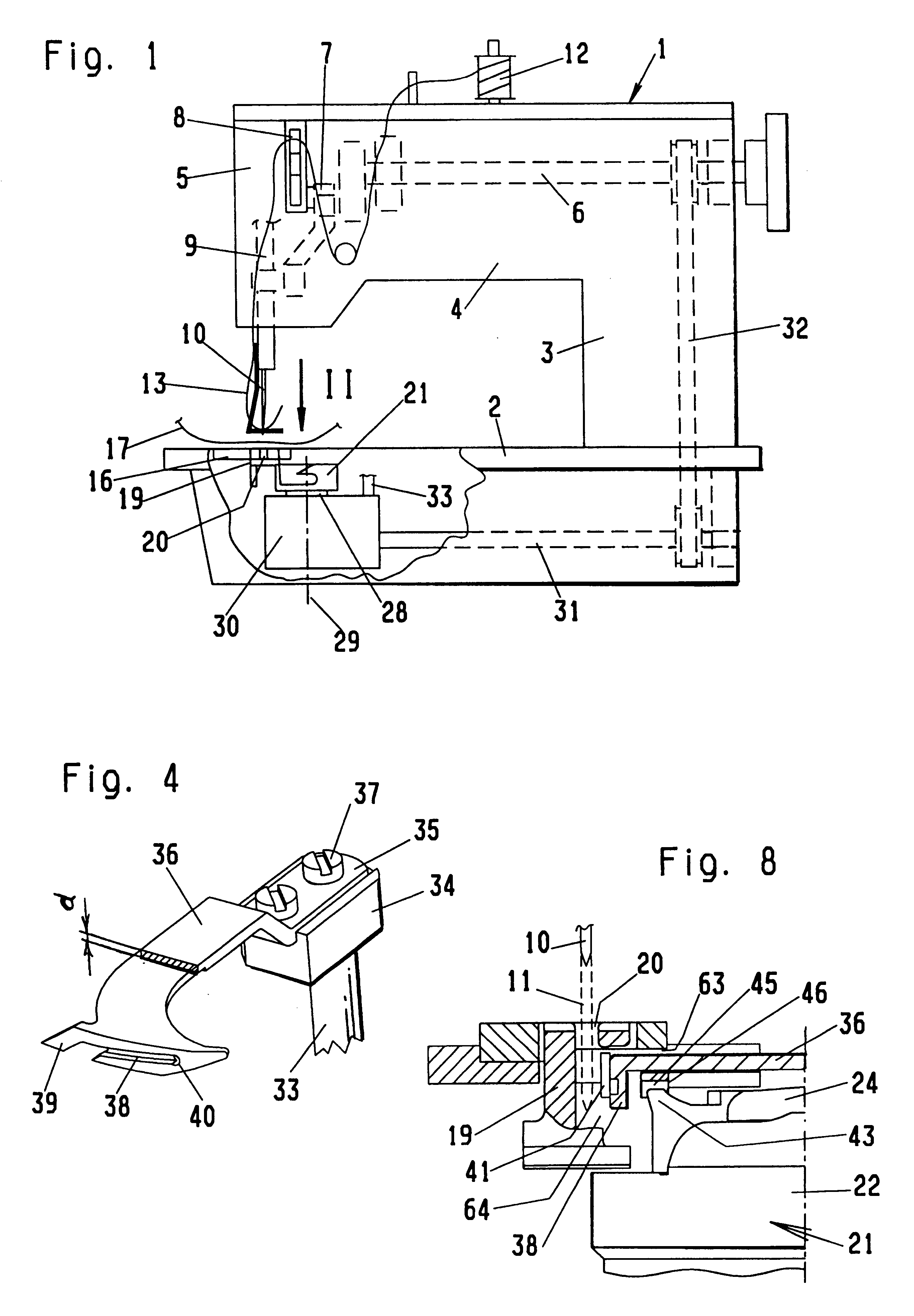

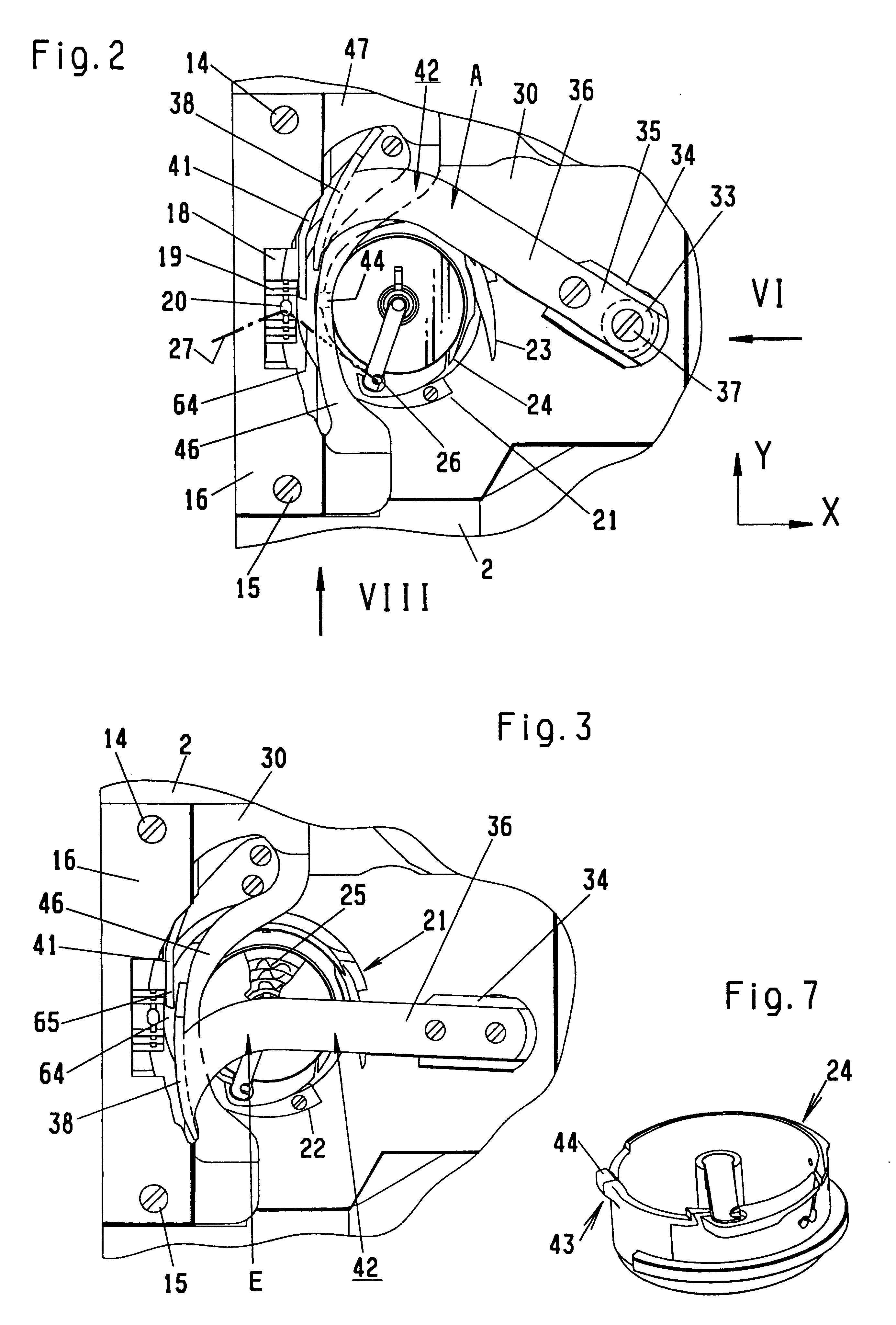

Two-thread lock-stitch sewing machine with thread cutter

InactiveUS6672232B2Reduce manufacturing costReliable mode of operationSewing-machine casingsNeedle severing devicesBobbinEngineering

A two-thread lock-stitch sewing machine with a thread cutter comprises a shaft which is parallel to the vertical axis of a shuttle and has a lever arm with a thread pulling knife disposed on it. The bobbin case in the shuttle has a holding finger which is directed toward a stitch hole and is held between two cams that are arranged on a rib. Formed between the cams and the workpiece bearing plate is an interspace which the lever arm passes through, together with the thread pulling knife projecting into a space between the motion travel of the sewing needle and the cams so that a thread cutting operation is enabled to be performed with very short thread tail pieces remaining on the lower side of the workpiece. The thread cutting operation excels by simple design and reliable operation.

Owner:DURKOPP ADLER AG

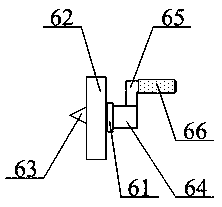

Auxiliary device for wart cutting in dermatology department

InactiveCN113331914AEasy cutting workRealize the cutting operationEnemata/irrigatorsDiagnosticsDermatology departmentSpray nozzle

The invention discloses an auxiliary device for wart cutting in the dermatology department, and belongs to the field of the dermatology department. The auxiliary device for wart cutting in the dermatology department comprises a cylindrical transparent cover, and further comprises a handle fixedly installed on the outer wall of the cylindrical transparent cover, an operation groove, two symmetrically arranged clamping plates and a spray pipe. The operation groove is formed in the outer wall of the cylindrical transparent cover, and an obliquely-arranged operation pipe is fixedly installed in the operation groove. The two symmetrically arranged clamping plates are arranged in the cylindrical transparent cover, are connected with the cylindrical transparent cover through a clamping mechanism and are used for clamping a part to be cut. Spray nozzles are arranged on the side wall of the spray pipe, and the spray pipe is arranged in the cylindrical transparent cover, connected with the cylindrical transparent cover through an adjusting mechanism and used for adjusting the position of the spray pipe. According to the auxiliary device for wart cutting, a cutter can cut warts more safely and conveniently, and cut wounds can be disinfected and flushed conveniently.

Owner:申明

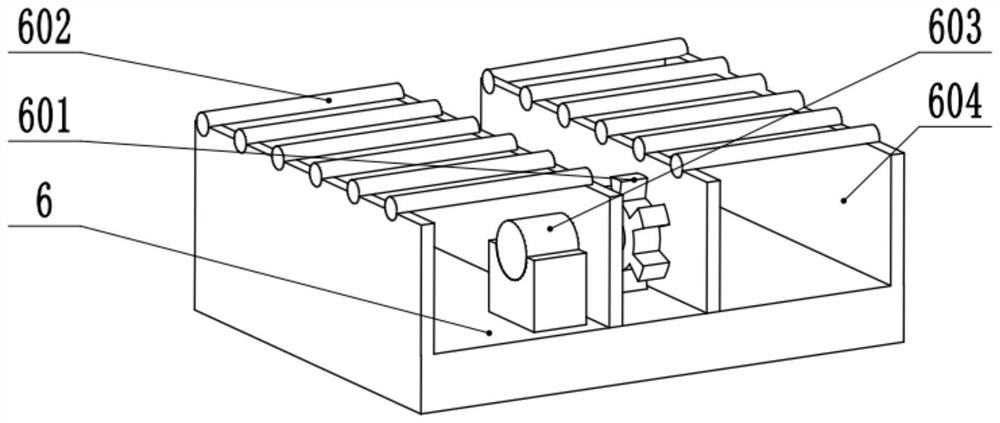

Ginger stem cutting machine

ActiveCN111791275AFast shippingEasy cutting workMetal working apparatusAgricultural engineeringSmall footprint

The invention discloses a ginger stem cutting machine, and belongs to the field of agricultural machinery. The ginger stem cutting machine is composed of a conveying device, a rotary table, a straightmoving mechanism, a steering device, a cutting device, a collecting device and a supporting table; the whole device can automatically achieve the work of ginger conveying, ginger steering, ginger stem cutting, ginger stem collecting and ginger collecting, and the labor intensity of workers is obviously relieved; the overall structure is in an L shape, the occupied area is small, and the device issuitable for ginger harvesting sites; the conveying device of the ginger stem cutting machine can convey ginger subjected to soil removal work to the rotary table, manpower is replaced with the mode,and if the ginger is manually placed on the rotary table, the hand of the worker can touch a cutter and get injured; and the conveying device composed of chains can further achieve falling of soil, and therefore subsequent work is facilitated.

Owner:福建龙植生物科技有限公司

Mask paper anti-folding cutting device for mask processing

The invention discloses a mask paper anti-folding cutting device for mask processing and relates to the technical field of mask processing. The mask paper anti-folding cutting device comprises a mainbody and an anti-folding mechanism; a carrying mechanism is disposed at the bottom end of the inner side of the main body; the anti-folding mechanism is arranged on one side of the top of the carryingmechanism; the inner side of the anti-folding mechanism comprises a shell; a scraper blade is movably disposed at the top end of the interior of the shell; and second electric push rods are fixedly installed on the two sides of the inner wall of the shell. The mask paper anti-folding cutting device for mask processing has the beneficial effects that by arranging a pressing barrel, the second electric push rods, the shell, a first roller and a second roller, the pressing barrel and the shell form a lifting structure through the second electric push rods, when mask paper slides along a carryingtable, the mask paper passes through the anti-folding mechanism, the mask paper which is winded and tightened through the first roller and the second roller can be spread under the pressing action ofthe pressing barrel, and thus the phenomenon of folding of the mask paper is effectively prevented.

Owner:DONGGUAN XIANGFEI INTELLIGENT EQUIP TECH CO LTD

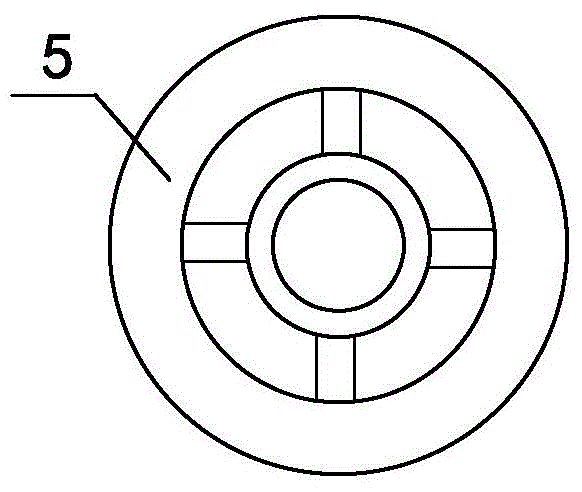

Processing equipment integrally formed with steel coil protective ring

ActiveCN106695341AWon't hurtSolve the problem of complex structure and inconvenient operationOther manufacturing equipments/toolsArchitectural engineeringEngineering

The invention provides processing equipment integrally formed with a steel coil protective ring. The processing equipment comprises a support I, a rotary shaft I, a roller, a supporting base, a stamping device, a convex mould, a concave mould, a supporting plate, a lifting shaft, a beam, a rotary shaft, a connecting plate and a cutter, wherein the roller is fixedly arranged on the rotary shaft I; and the rotary shaft I is mounted at the upper end of the support I. According to the processing equipment provided by the invention, convenience is provided for uncoiling discharging, the convex mould is mounted at the lower end of the stamping device, and the concave mould is embedded into the center position at the upper end of the supporting base, so that the problems such as a complex structure, difficult operation and high cost of a forming device in the prior art are solved; the lifting shaft is mounted at the upper end of the supporting plate, the right end of the beam is fixedly arranged at the upper end of the lifting shaft, the left end of the beam is connected with the rotary shaft, the connecting plate is welded at the lower end of the rotary shaft, and the cutter is mounted at the lower end of the connecting plate, so that the problem that cutting control is difficult in the prior art is solved. The processing equipment is convenient to use, is convenient to operate, is simple in structure, can realize disposable stamping forming and is low in cost.

Owner:苏州科弗曼机械有限公司

Cutting method preventing plastic bottle adhering

ActiveCN106738482AEasy to fallReduce the temperaturePlastic recyclingGrain treatmentsInlet valveWater flow

The invention belongs to the field of plastic chopping methods and particularly discloses a cutting method preventing plastic bottle adhering. The cutting method preventing plastic bottle adhering includes the steps that a motor is started; a spiral cutting knife starts to rotate; the spiral cutting knife and blades jointly cut plastic bottles, and when the spiral cutting knife rotates to meet first magnets, hot water in blind holes is pushed by pistons to open a water outlet valve, and the hot water flows into a hot water chamber from the interiors of the blind holes; and when the spiral cutting knife rotates to be away from the first magnets, second magnets in the spiral cutting knife are also away from the first magnets, the repulsive force disappears, a water inlet valve is opened, cold water enters the blind holes, the temperature of the spiral cutting knife is lowered, and the spiral cutting knife is cooled. By means of the cutting method preventing plastic bottle adhering, plastic bottles cannot become soft or adhere to the spiral cutting knife when the temperature is too high, and the plastic bottles can be cut in a better fragmentation manner.

Owner:浙江利盛包装科技有限公司

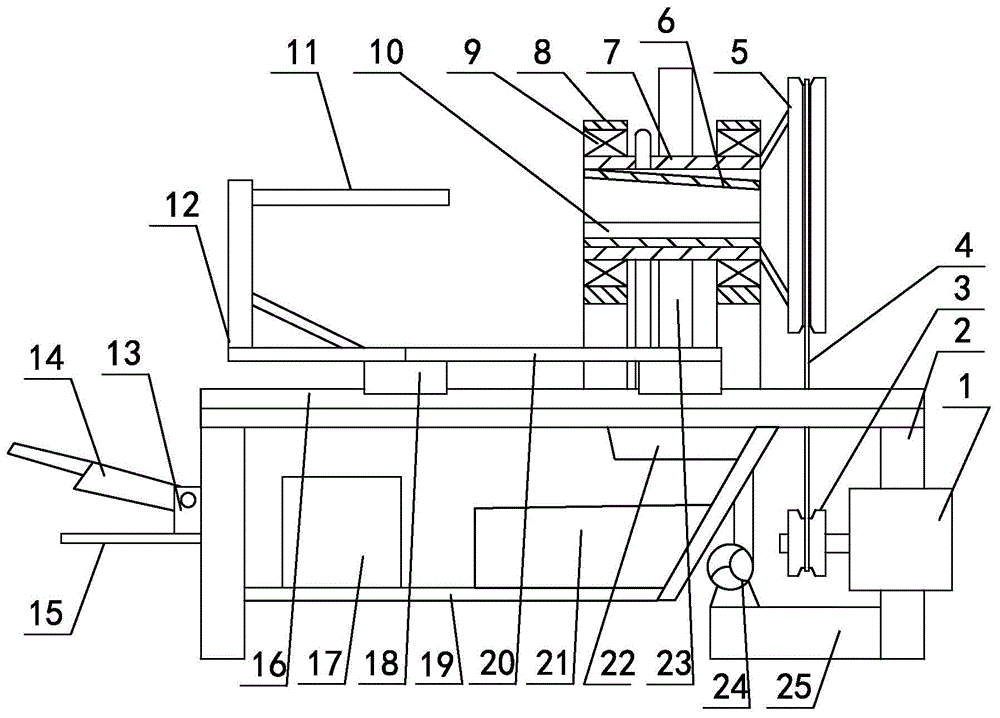

All-In-One machine for peeling and cleaning sugarcane

InactiveCN106690345AEasy to collectConvenient for temporary storageVegetable peelingFood treatmentEngineeringWorkbench

The invention relates an all-In-One machine for peeling and cleaning sugarcane, which belongs to the sugarcane-peeling technology field. The machine comprises a workbench and a adjusting plate. Two bearing brackets are disposed in the workbench, opposite to a scraping sheath. Blades are disposed in the inner top wall. Two ends of the scraping sheath are installed in the bearing brackets by bearings. A handle plate is fixed in the right end of the scraping sheath. The adjusting plate is installed in the bottom of the inside scraping sheath. An ejector pin is disposed in the left of the scraping sheath, opposite to a sliding mechanism. An electric motor is installed in the lower right half part of a workbench. A discharge opening of scrap is disposed in the place opposite to the scraping sheath. A table is arranged at the lower part of the discharge opening of scrap. A sugarcane collecting tank and a scrap collecting tank are disposed in the table. A cutting board is fixed in the left of the workbench. A cutting knife is horizontally placed in the cutting board. A water tube that supplies water for the edge of the blade is disposed in the opposite cutting direction of the blade. The intake end of the water tube is connected with a washing pump. The all-In-One machine for peeling and cleaning sugarcane has the advantages of saving both time and labor, and peeling effectively.

Owner:CHONGQING ANSHANGYUAN AGRI TECH DEV CO LTD

Steel block dividing and polishing equipment for high-end equipment manufacturing

ActiveCN112338669AEasy cutting workAchieve the effect of automatic cuttingGrinding feedersGrinding work supportsGear wheelPolishing

The invention relates to dividing and polishing equipment, in particular to steel block dividing and polishing equipment for high-end equipment manufacturing. The steel block dividing and polishing equipment for high-end equipment manufacturing is safe, easy to operate and capable of saving manpower. The steel block dividing and polishing equipment for high-end equipment manufacturing comprises abottom plate, a special-shaped rail, a collecting frame, a laser cutting gun, a discharging mechanism and a grinding mechanism. The special-shaped rail is arranged on the bottom plate; the collectingframe is arranged on the bottom plate; the laser cutting gun is arranged on the special-shaped rail; the discharging mechanism is arranged on the special-shaped rail, and the discharging mechanism isconnected with the bottom plate and the collecting frame; and the grinding mechanism is arranged in the middle of the special-shaped rail. A first gear is engaged with a second gear, the first gear rotates to drive the second gear to rotate, so that a grinding rod rotates, when divided steel blocks make contact with the grinding rod, the grinding rod grinds and polishes the steel blocks, the automatic grinding and polishing effect is achieved, and operation is easy and convenient.

Owner:SHAOYANG UNIV

Efficient tailoring device for clothing factory

ActiveCN106087378AHigh precisionImprove collection efficiencySevering textilesIndustrial engineeringPulley

The invention relates to a tailoring device, in particular to an efficient tailoring device for a clothing factory. The technical problem to be solved is how to provide an efficient tailoring device high in tailoring efficiency for a clothing factory. In order to solve the technical problem, the efficient tailoring device for the clothing factory comprises a box, a base plate, a second electric wheel, a first pull rope, a first supporting rod, a pair of scissors, a third sliding block, a push rod, a roller, a rotating shaft, a servo motor, a second supporting rod, a first sliding block, a second sliding rail, a second pull rope, a first fixed pulley, a second fixed pulley, a second sliding block, a first sliding rail and a first electric wheel and the like. The base plate is arranged between the front wall and the rear wall in the box. The efficient tailoring device for the clothing factory has the advantages of high tailoring efficiency, tailoring length accuracy, simplicity in operation, convenience in the operation process and long service life. Besides, since a limiting plate and a limiting block are arranged, the tailoring accuracy can be further improved.

Owner:平湖凯隆新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com