Small-pipe-diameter pipeline cutting and bevelling machine

A pipe cutting and beveling machine technology, which is applied in the field of pipe installation engineering, can solve problems such as limited conditions and difficulty in cutting pipes, and achieve good integration, improve transmission efficiency, and save costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

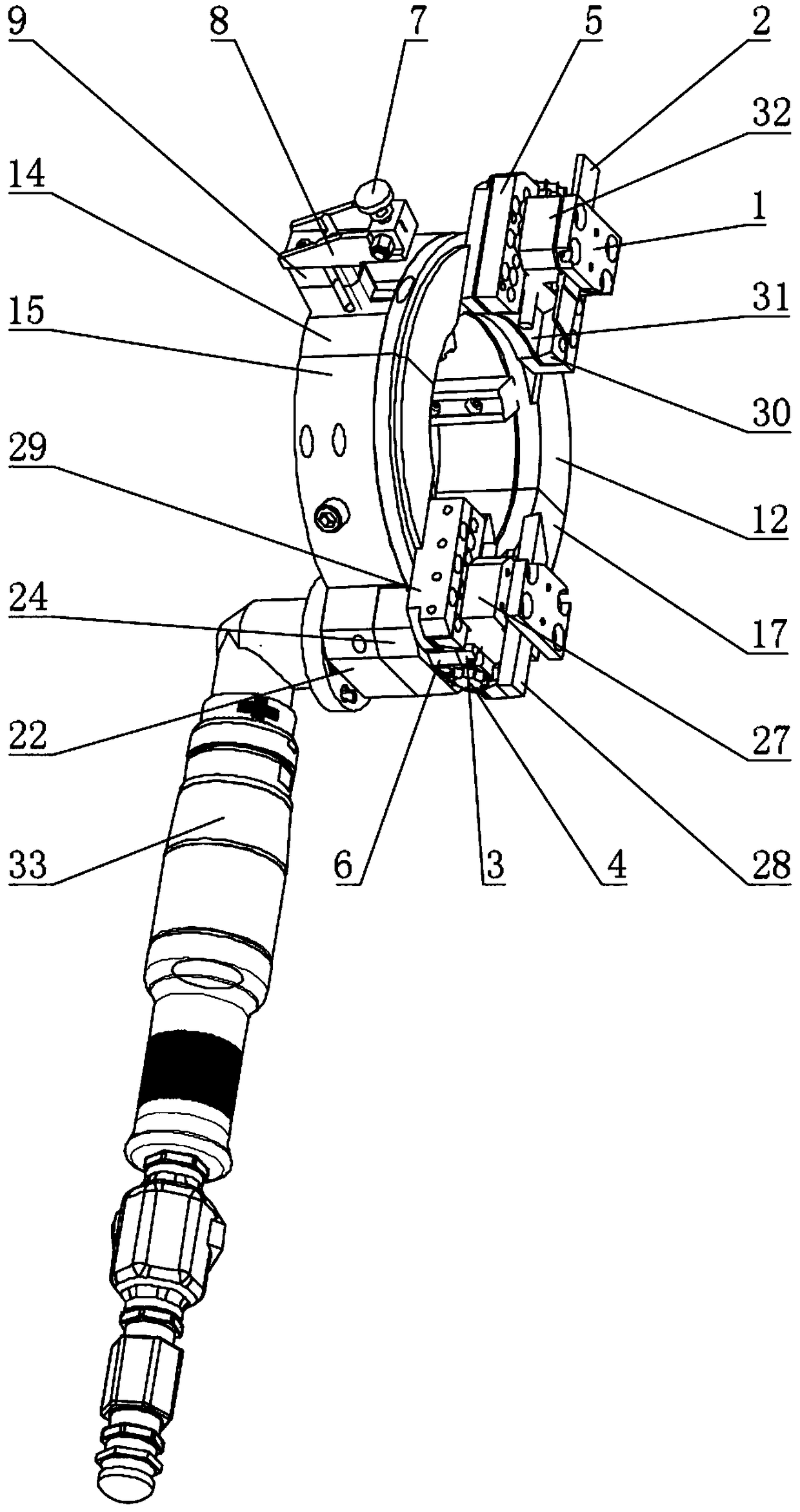

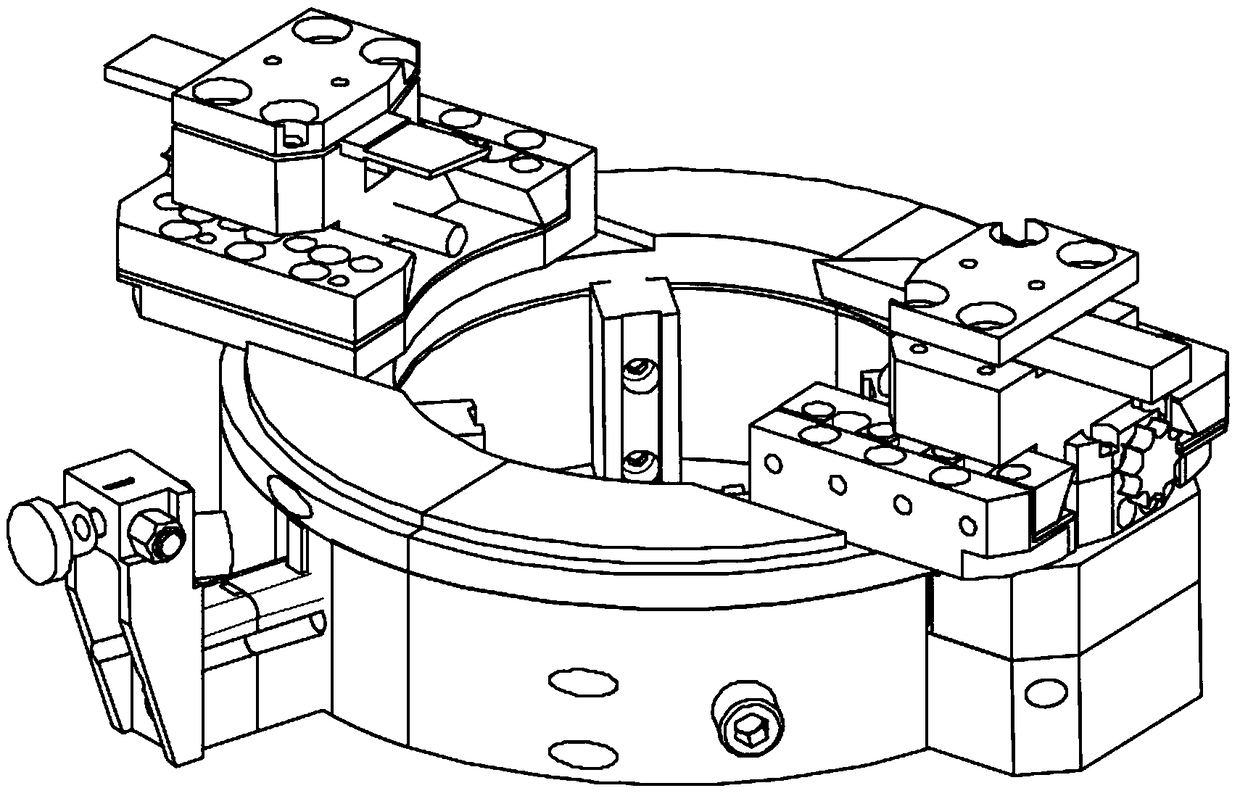

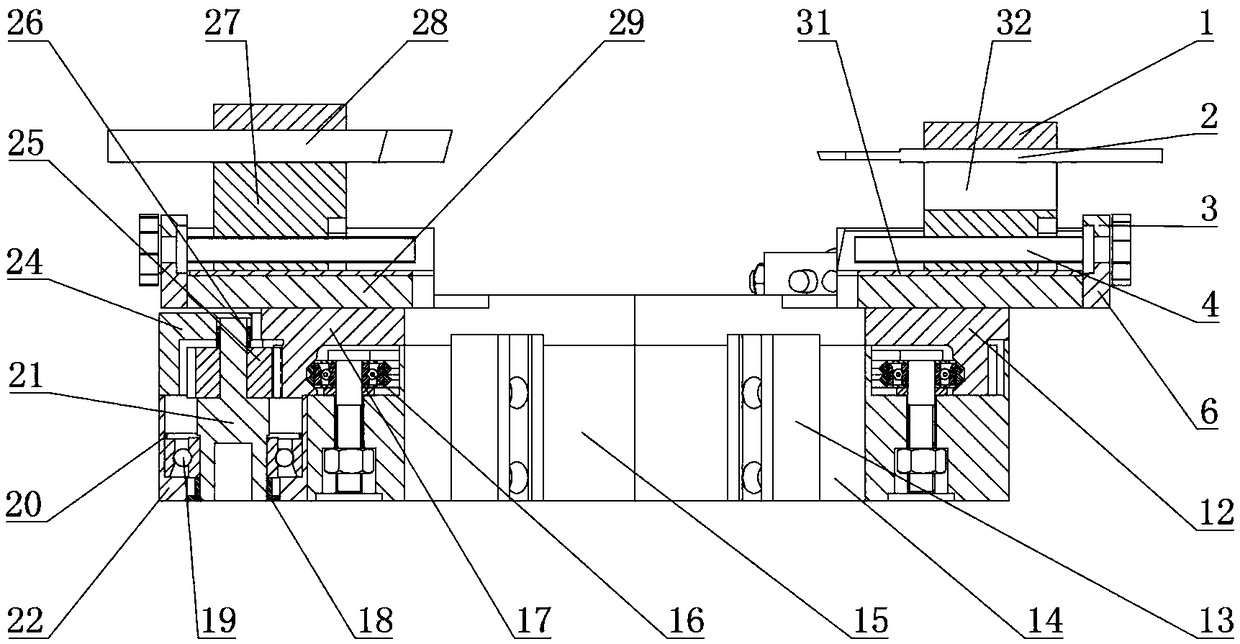

[0032] The invention discloses a small-diameter pipe cutting beveling machine, which comprises a power handle, a clamping mechanism, a main cutting movement mechanism and a radial feeding mechanism. The power handle includes a throttle valve 3307, a filter 3306, a gate valve 3305, an air motor 3304, a bevel gear 3303, a flange 3302 and a connecting block 3301; the clamping mechanism includes a lead screw II10, a guide block 11, Clamping block 13, etc.; the main cutting motion mechanism includes static ring I15, static ring II14, moving ring I12, moving ring II17 (big gear), pinion 25, special bearing 16, pinion shaft 21, bearing 19, Key 23 and supporting block 18 etc.; Described radial feed mechanism comprises driving lever 7, lead screw I4, lead screw end cover 3 and lead screw base 6 etc.

[0033] The present invention pushes the guide block 11 and the clamping block 13 to move radially through the movement of the lead screw II10 on the static ring to realize the clamping of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com