Method for fixing ceramic product by using ceramic fastener

A technology for fixing ceramics and fasteners, applied in threaded fasteners, connecting components, screws, etc., can solve the problems of troublesome construction, high labor cost, slow work efficiency, etc., and achieve the effect of simple engineering construction and good integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

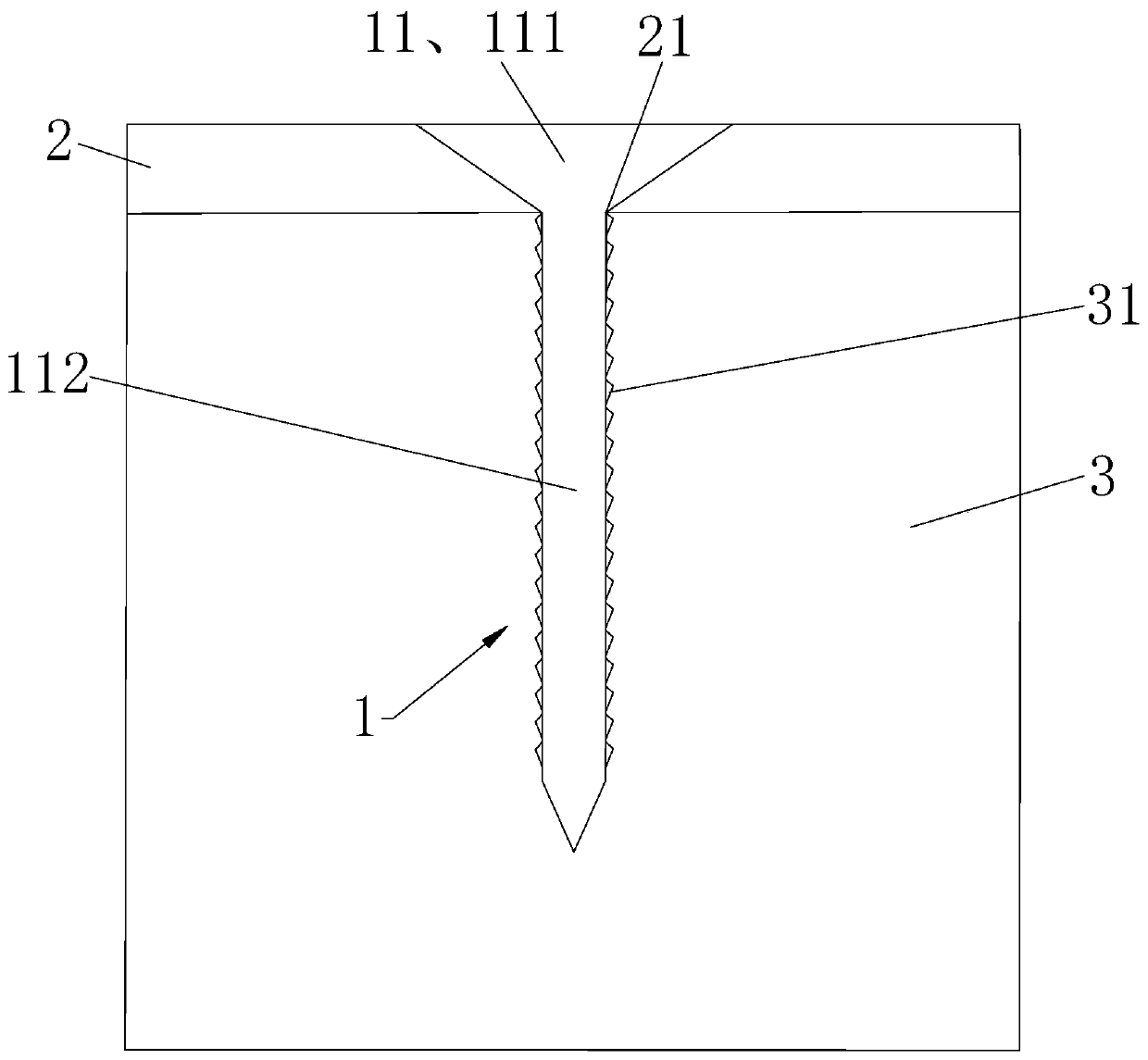

[0041] see image 3 , Figure 4 As shown, the method for adopting ceramic fasteners to fix ceramic products may further comprise the steps:

[0042] (1) directly get through the body hole 21 on the fired ceramic tile or ceramic plate 2, and punch the holes of arrangement, distribution and size according to the requirements before leaving the factory or on the installation site according to the requirements;

[0043] (2) Decorate the surface of the ceramic screw or ceramic screw 11 with the fixed ceramic tiles and ceramic plates 2 to keep the color, texture and pattern consistent;

[0044] (3) The ceramic screw or the ceramic screw 1 is penetrated into the perforation 21 of the ceramic tile and the ceramic plate of the top floor and the perforation 31 of the base body 3 of the bottom layer, and the ceramic brick or the ceramic plate 2 is fixed on the base body 3 .

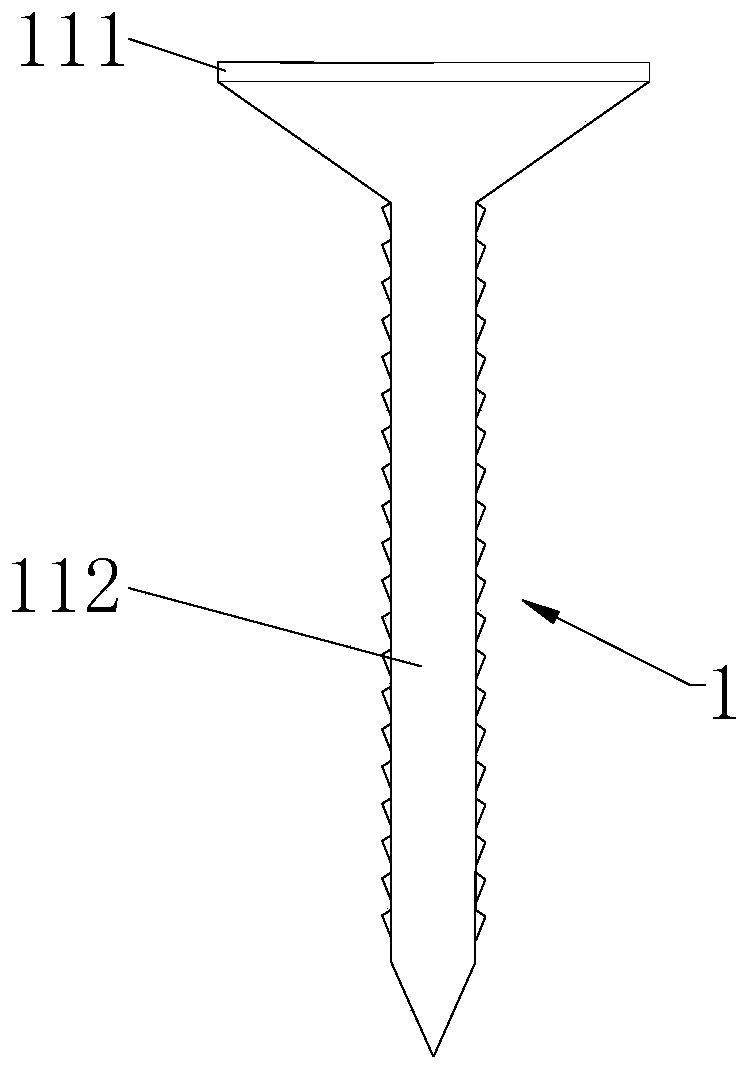

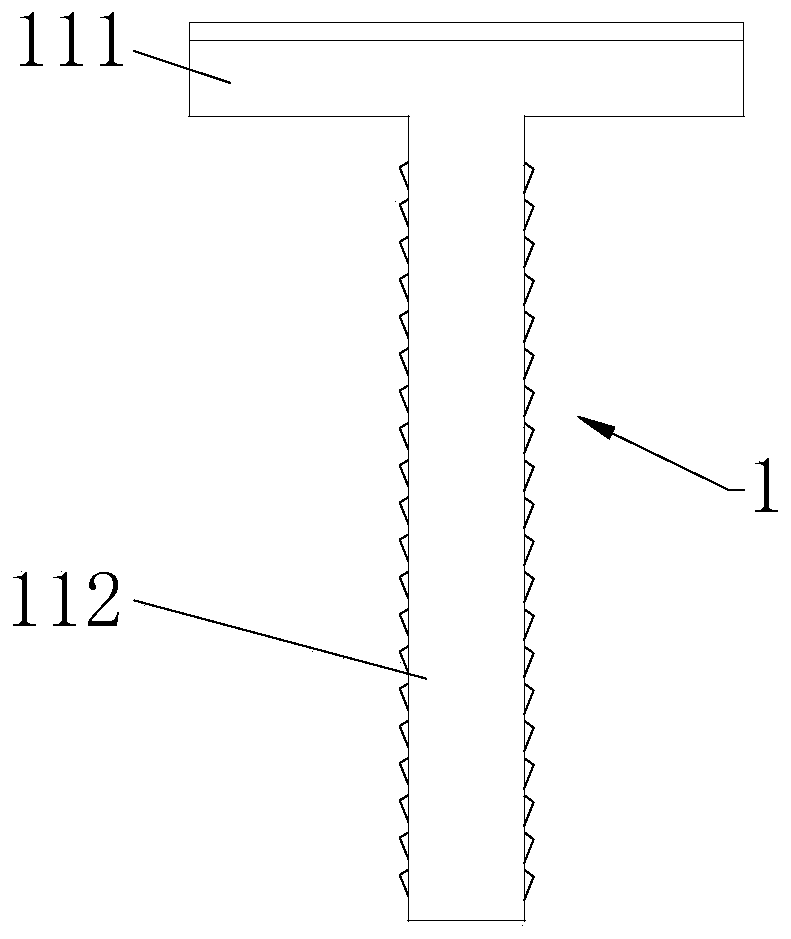

[0045] see figure 1 , figure 2 As shown, the ceramic screw 11 and the screw 11 are composed of a ceramic cap...

Embodiment 2

[0048] see Figure 5 As shown, the method for adopting ceramic fasteners to fix ceramic products may further comprise the steps:

[0049] (1) In the process of producing ceramic tiles or ceramic plates 2, punch holes 21 on the green body to sinter into products with holes;

[0050] (2) Decorate the surfaces of ceramic bolts 12 and ceramic nuts 13 with the fixed ceramic tiles or ceramic plates 2, so that the colors, textures and patterns are consistent;

[0051] (3) Ceramic bolts 12 and ceramic nuts 13 are penetrated into the perforations 21 of the ceramic tiles or ceramic plates 2 of the top floor and the perforations 31 of the bottom substrate 3, and the ceramic tiles or ceramic plates 2 are fixed on the substrate 3.

[0052] In this embodiment, the ceramic bolt 12 and the nut 13 are composed of a ceramic bolt cap 121 , a ceramic bolt bolt 122 , and a ceramic nut 13 , and the surface of the ceramic bolt cap 121 is glazed and fired.

[0053] In this embodiment, the structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com