Electric control integrated motor

An integrated, electronically controlled technology, applied in electromechanical devices, electrical components, electrical components, etc., can solve the problems of large overall volume and poor integration, and achieve the effects of good integration, cost reduction, and good heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

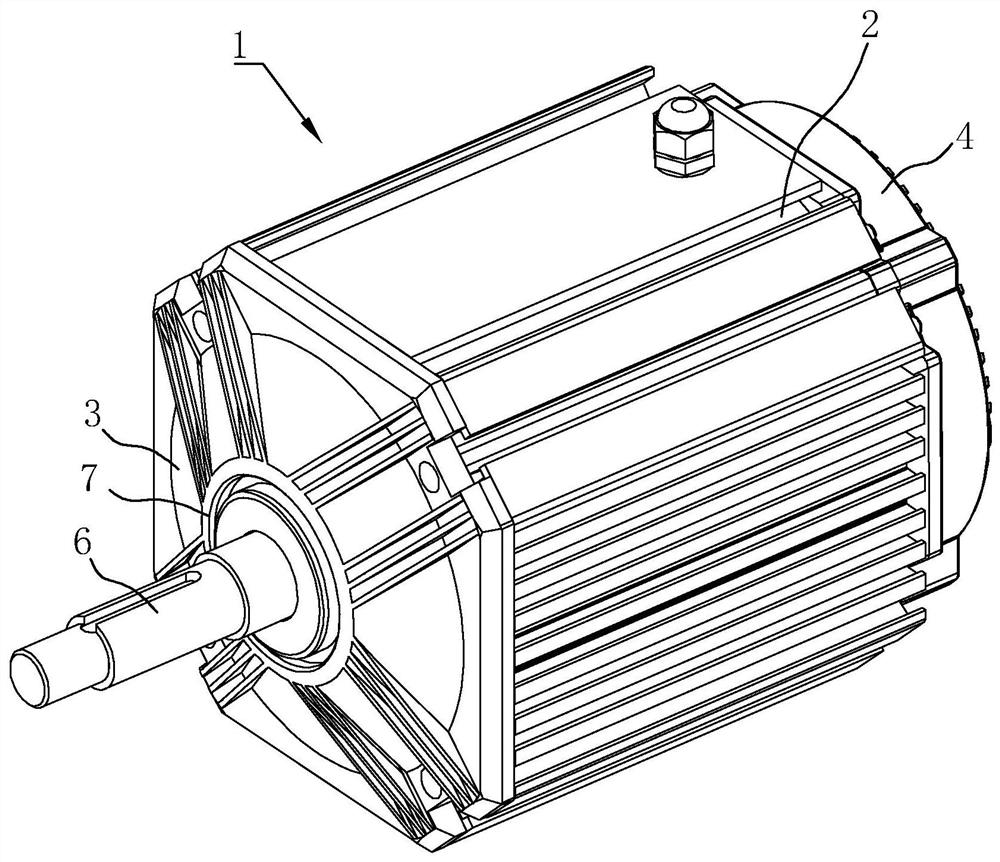

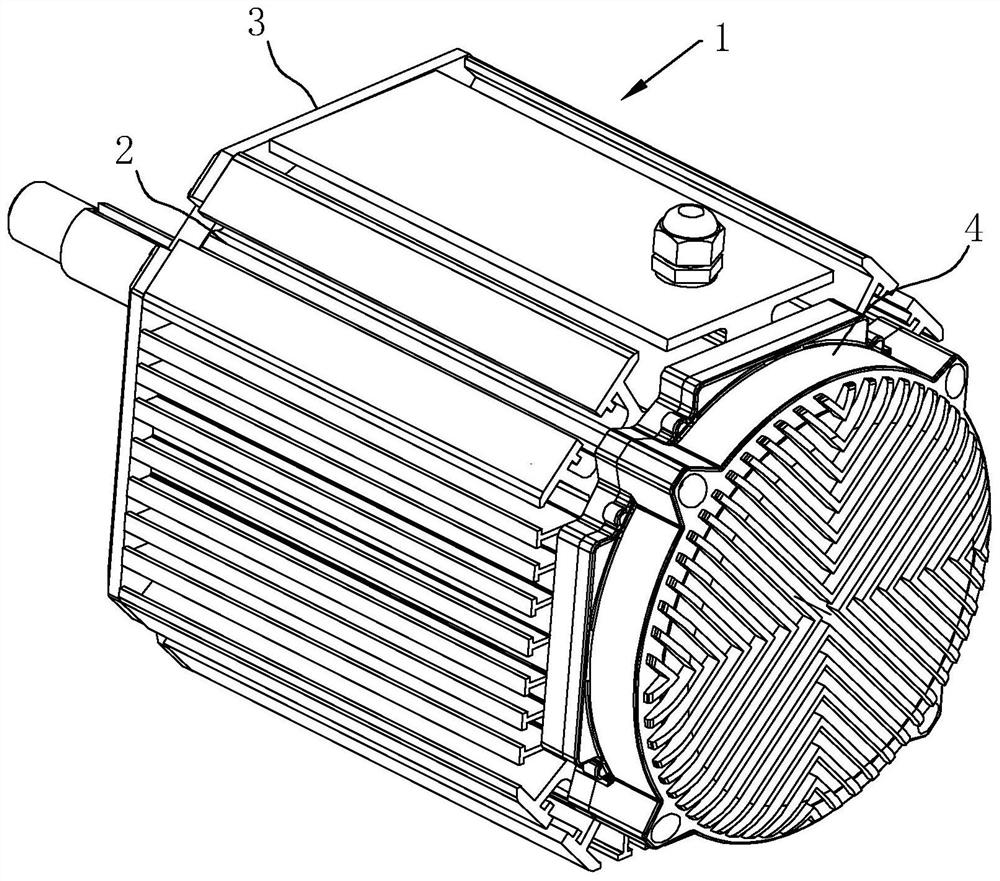

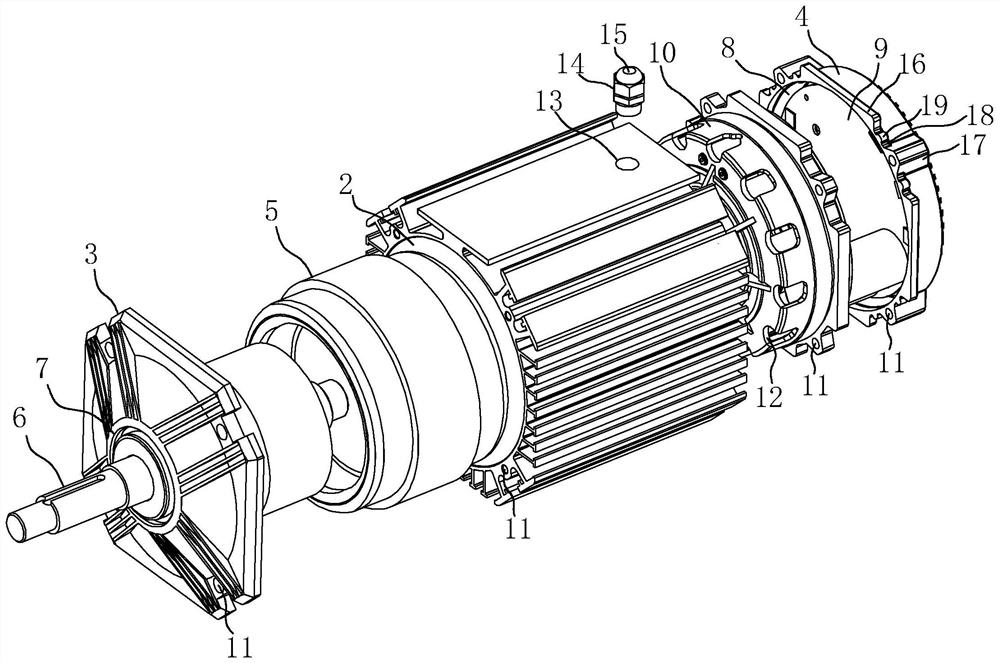

[0042] Electric control integrated motor, refer to figure 1 with figure 2 As shown, a body 1 is included, and the body 1 includes a casing 2, a front cover 3 and a rear cover 4. The surface of the cover 4 away from the front cover 3 is fixedly provided with cooling fins, and at the same time, the cooling performance of the motor as a whole is improved through the cooling of the cooling fins.

[0043] Such as figure 1 with image 3 As shown, a stator 5 and a rotor 6 are arranged inside the casing 2, and the center of the front cover 3 is provided with a perforation 7 for the rotor 6 to pass through, and one end of the rotor 6 passes through the perforation 7 to form the driving end of the motor; the rear cover 4 is formed with an installation cavity 8, the circuit board 9 of the controller is installed and fixed in the installation cavity 8, and the space inside the back cover 4 is rationally used to integrate the circuit board 9 of the controller into the whole motor, so t...

Embodiment 2

[0052] Electric control integrated motor, refer to Image 6 with Figure 7 The difference between this embodiment and Embodiment 1 is that the structure of the bearing mounting seat 10 is different. In this embodiment, the bearing mounting seat 10 is provided with a positioning hole 24 corresponding to the line head 14, and the positioning hole 24 runs through the bearing. The side wall of the mounting seat 10; the bottom end of the threading head 14 can be inserted into the positioning hole 24 in the process of rotating and tightening the threading head 14 to realize the positioning and locking of the bearing mounting seat 10. When the circuit board 9 is overhauled, after the nuts of the bolts in the mounting holes 11 are removed, the rear cover 4 can be moved away from the casing 2, during which the bearing mounting seat 10 will not be loosened from the casing 2, and the bearing The stability of the mounting seat 10 is convenient for the subsequent assembly of the back cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com