High-thermal-stability SPC floor and manufacturing method thereof

A technology with high thermal stability and production method, applied in the direction of flat products, other household appliances, floors, etc., can solve the problems of high dimensional shrinkage of substrates, large changes in floor size, deformation and warpage, etc., to achieve thermal stability. Good, improve durability, not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

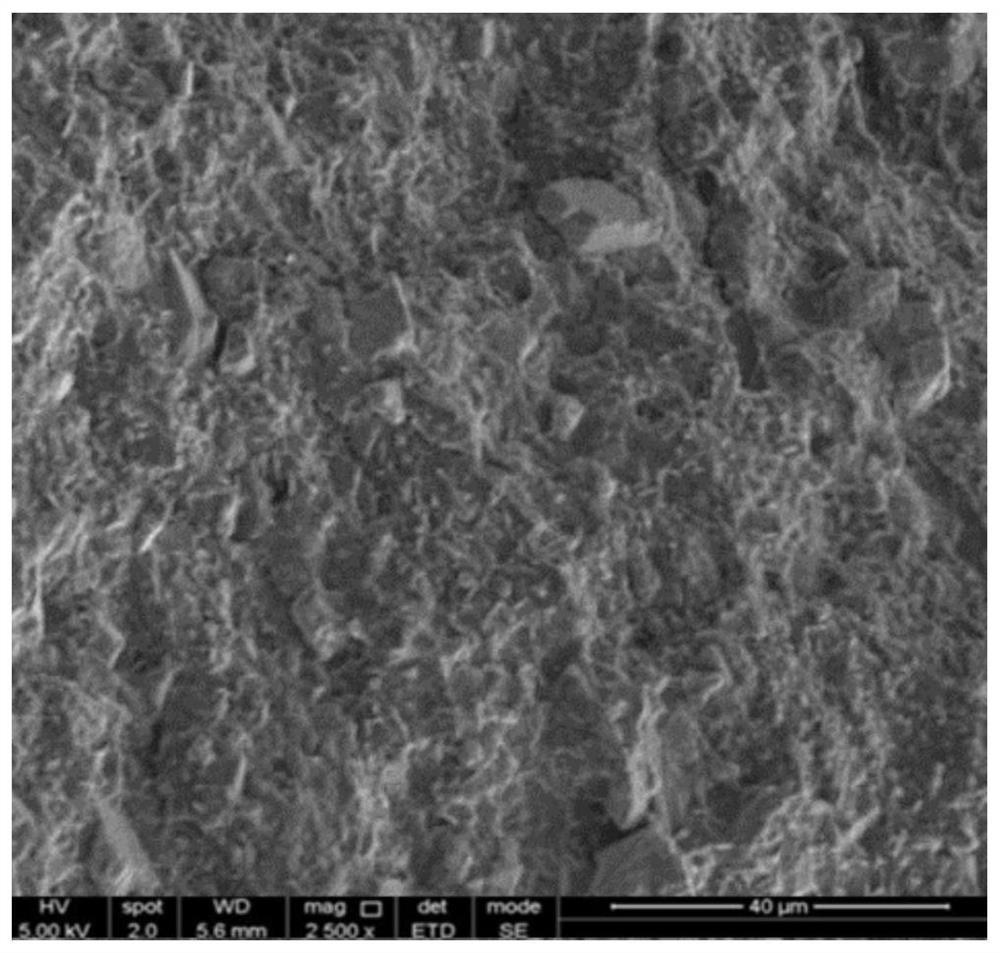

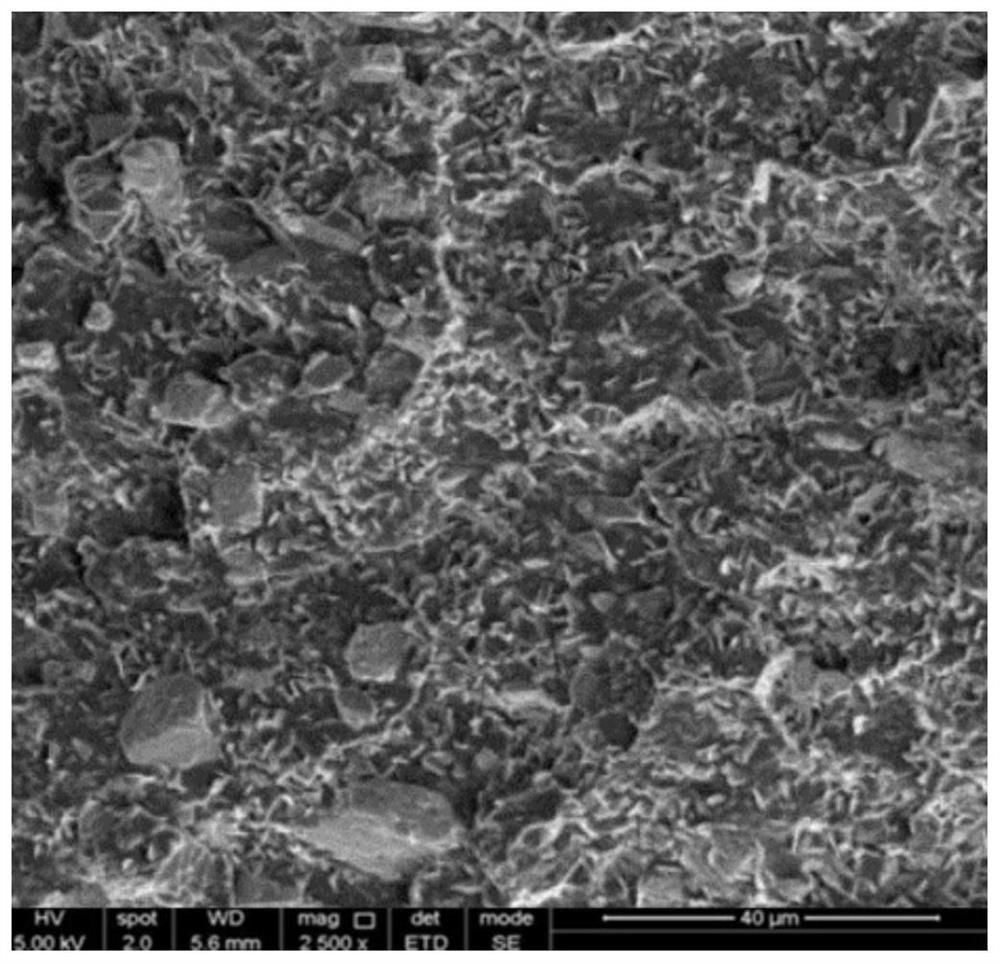

Image

Examples

Embodiment 1

[0034] A high thermal stability SPC floor, comprising a wear-resistant layer, a color film decoration layer and an SPC substrate layer arranged sequentially from top to bottom; wherein, the SPC substrate layer is calculated in parts by weight and includes the following components:

[0035] 65 parts of polyvinyl chloride resin powder, 212 parts of modified heavy calcium carbonate, 15 parts of regenerated rubber, 18 parts of tributyl citrate, 2.2 parts of calcium zinc stabilizer and 2 parts of polyethylene wax;

[0036] Wherein, the preparation method of modified heavy calcium carbonate is:

[0037] M1. Weigh heavy calcium carbonate and mix it with absolute ethanol. After ultrasonication is uniform, add bis(2-hydroxyethyl)-3-aminopropyltriethoxysilane, and stir at 25-30°C for 3-5 hours. , to obtain hydroxylated heavy calcium carbonate; wherein, the mass ratio of heavy calcium carbonate, two (2-hydroxyethyl)-3-aminopropyltriethoxysilane and dehydrated alcohol is 1:0.4:12;

[003...

Embodiment 2

[0045] A high thermal stability SPC floor, comprising a wear-resistant layer, a color film decoration layer and an SPC substrate layer arranged sequentially from top to bottom; wherein, the SPC substrate layer is calculated in parts by weight and includes the following components:

[0046] 50 parts of polyvinyl chloride resin powder, 184 parts of modified heavy calcium carbonate, 10 parts of regenerated rubber, 15 parts of trioctyl citrate, 1.2 parts of calcium zinc stabilizer and 1 part of polyethylene wax;

[0047] Wherein, the preparation method of modified heavy calcium carbonate is:

[0048] M1. Weigh heavy calcium carbonate and mix it with absolute ethanol. After ultrasonication is uniform, add bis(2-hydroxyethyl)-3-aminopropyltriethoxysilane, and stir at 25-30°C for 3-5 hours. , to obtain hydroxylated heavy calcium carbonate; wherein, the mass ratio of heavy calcium carbonate, two (2-hydroxyethyl)-3-aminopropyltriethoxysilane and dehydrated alcohol is 1:0.2:10;

[0049...

Embodiment 3

[0056] A high thermal stability SPC floor, comprising a wear-resistant layer, a color film decoration layer and an SPC substrate layer arranged sequentially from top to bottom; wherein, the SPC substrate layer is calculated in parts by weight and includes the following components:

[0057] 72 parts of polyvinyl chloride resin powder, 225 parts of modified heavy calcium carbonate, 18 parts of regenerated rubber, 20 parts of acetyl tributyl citrate, 3 parts of calcium zinc stabilizer and 3 parts of polyethylene wax;

[0058] Wherein, the preparation method of modified heavy calcium carbonate is:

[0059] M1. Weigh heavy calcium carbonate and mix it with absolute ethanol. After ultrasonication is uniform, add bis(2-hydroxyethyl)-3-aminopropyltriethoxysilane, and stir at 25-30°C for 3-5 hours. , to obtain hydroxylated heavy calcium carbonate; wherein, the mass ratio of heavy calcium carbonate, two (2-hydroxyethyl)-3-aminopropyltriethoxysilane and dehydrated alcohol is 1:0.5:15;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com