Processing equipment integrally formed with steel coil protective ring

A technology for processing equipment and steel coils, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of high production cost, low labor efficiency, slow production speed, etc., and achieve cutting control difficulties, simple structure, and cutting operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

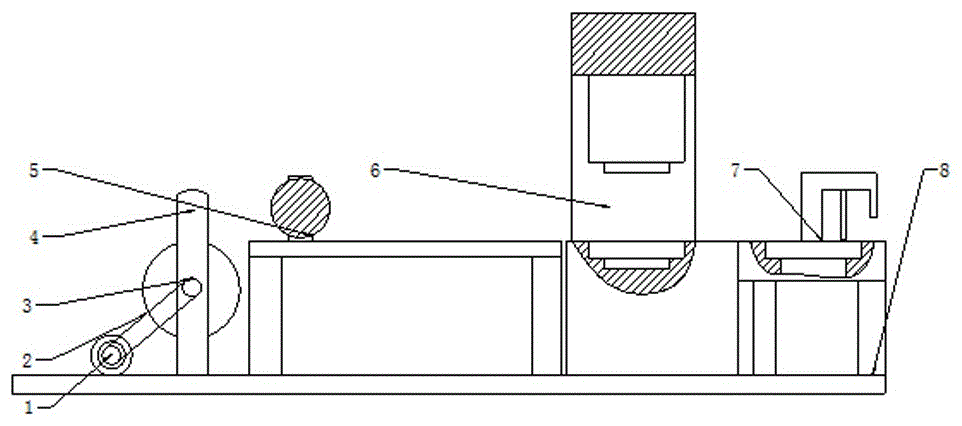

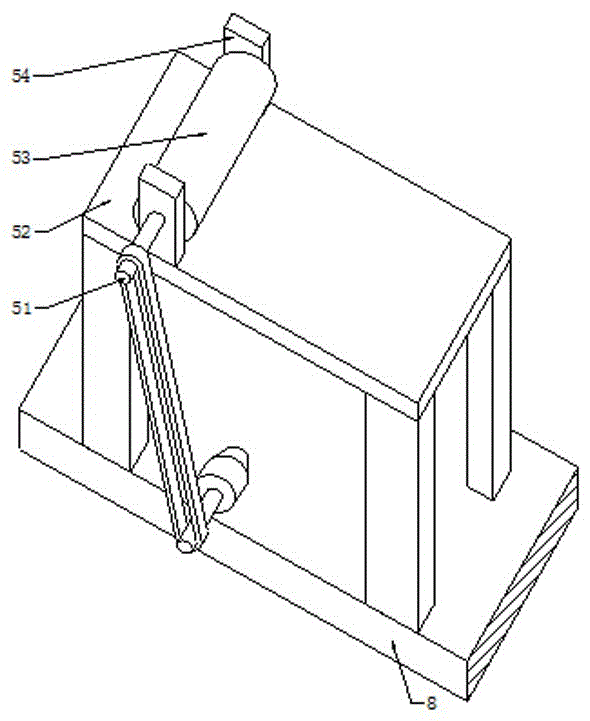

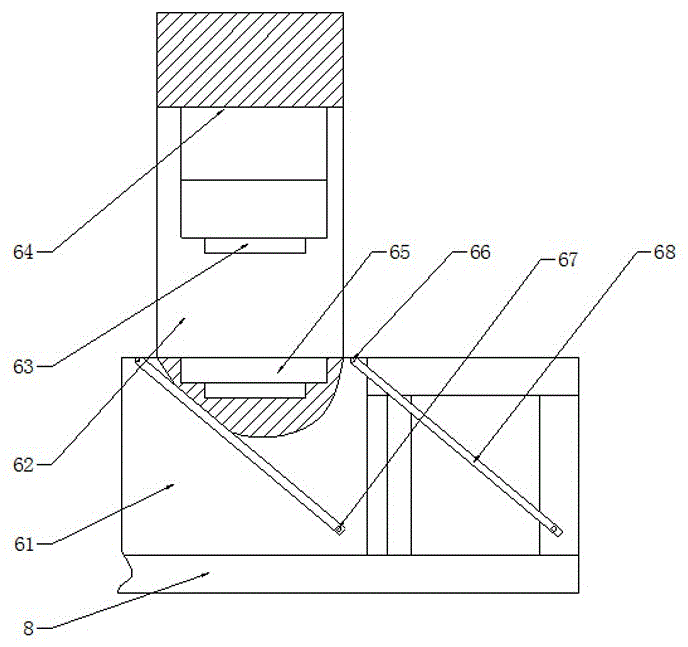

[0028] The specific embodiment: when the operator uses it, according to the size of the retainer to be processed, the corresponding size of the die 65 and the punch 63 are installed, and then the steel coil is installed on the steel coil rotating shaft 3, and the connection with the steel coil rotating shaft 3 is connected. The power supply of motor 1, the operation of motor 1 drives the steel coil rotating shaft 3 to rotate, thereby drives the steel coil to rotate, and then makes the steel strip contact with the flat plate 52 and moves forward, the operator connects the power supply of the motor 1 connected with the rotating shaft 51, The operation of the motor 1 drives the rotating shaft one 51 to rotate, and then drives the roller 53 to rotate. After the steel strip moves between the roller 53 and the flat plate 52, it moves forward under the friction between the roller 53. This design is uncoiling and discharging Provides convenience, simple structure, will not damage the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com