Technology of preparing special-shaped cutting steel wire

A preparation process and a technology for cutting steel wires, which are used in manufacturing tools, metal extrusion cleaning equipment, metal rolling, etc., can solve the problems of low bonding strength of abrasives and steel wires, low removal rate of processing materials, and limited life of steel wires, etc. Achieve the effect of promoting application prospects, improving cutting efficiency and reducing wire breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

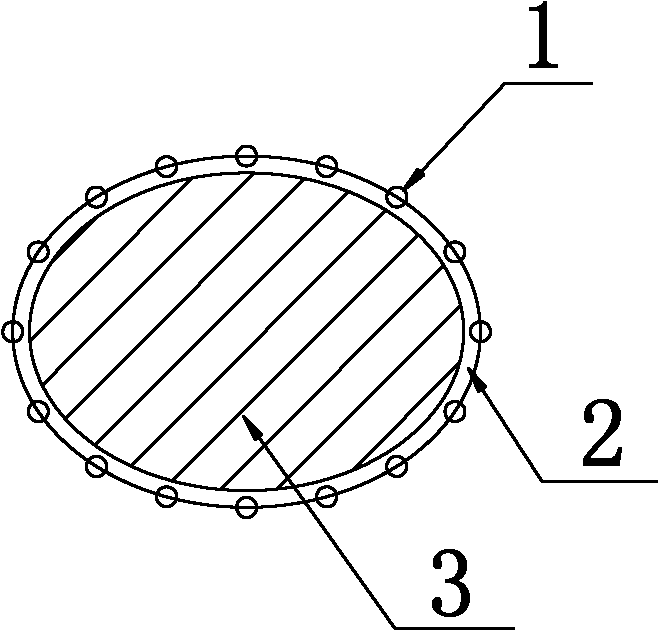

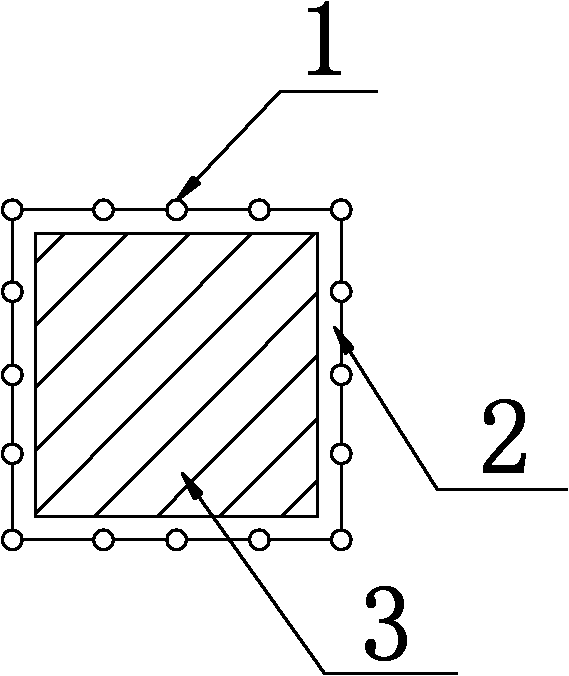

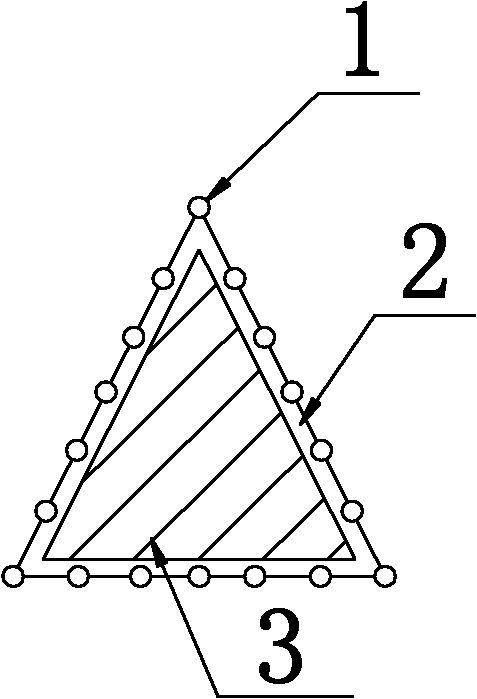

Image

Examples

Embodiment Construction

[0024] The preparation process steps of the present invention include:

[0025] (1), large pull: mechanically descaling, cleaning, boron coating, drying on the surface of ∮5.5, 5.8, 6.0, 6.2, 6.5mm wire rod, and then drawing to ∮2.80, 2.90, 3.00, 3.10, 3.25 mm steel wire with a maximum total compression rate of 74.1%. The cleaning process adopts pickling and water rinsing, and the pickling solution adopts sulfuric acid solution with concentration: 100, 150, 180, 220, 250g / L or concentration: 100, 150, 200, 250, 280g / L Hydrochloric acid solution, deionized water is used for washing at room temperature for the water washing; the borax concentration of the boron coating process is: 200, 250, 300, 350, 380 mol / L; the temperature of the drying process is 50, 100, 120, 150 mol / L , 200 ℃, time: 0.1, 0.5, 1, 1.5, 2 minutes; the drawing process adopts a straight-forward dry drawing machine, the diameter of the reel is: 350, 450, 550, 650, 750mm, and multi-pass drawing is carried out. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com