Cutting method preventing plastic bottle adhering

A cutting method and technology for plastic bottles, applied in plastic recycling, mechanical material recycling, recycling technology and other directions, can solve problems such as plastic bottles not falling easily, plastic bottles becoming soft, affecting cutting quality and cutting speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

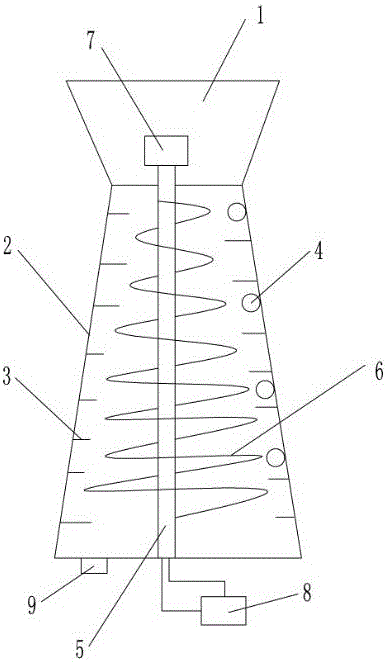

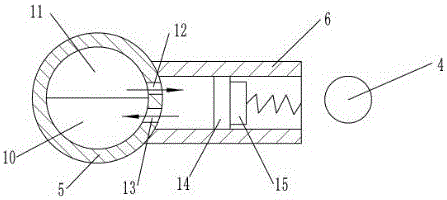

[0017] The reference signs in the drawings of the description include: material inlet 1, machine body 2, blade 3, first magnet 4, rotating shaft 5, spiral cutting knife 6, motor 7, cooling device 8, material outlet 9, cold water chamber 10 , hot water chamber 11, water outlet valve 12, water inlet valve 13, piston 14, second magnet 15.

[0018] The cutting method for preventing the sticking of plastic bottles in this program includes the following steps:

[0019] (1) The motor 7 is started, which drives the rotating shaft 5 to start rotating, and the rotating shaft 5 drives the spiral cutting knife 6 to also start rotating. The plastic bottle enters the body 2 from the feeding port 1, and the plastic bottle falls along the direction of the spiral cutting knife 6, and the spiral cutting knife 6 starts to rotate. The knife 6 and the blade 3 cut the plastic bottle together,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com