Patents

Literature

137 results about "Evaporative-pattern casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Evaporative-pattern casting is a type of casting process that uses a pattern made from a material that will evaporate when the molten metal is poured into the molding cavity. The most common evaporative-pattern material used is polystyrene foam.

Evaporative pattern casting coating and preparation method and using method thereof

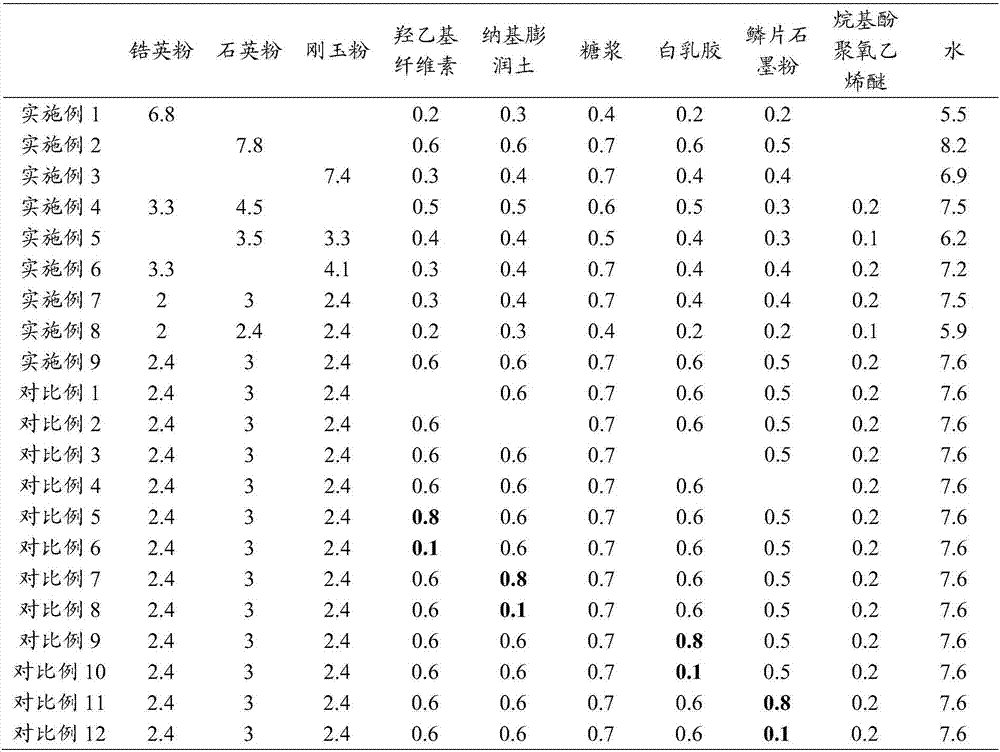

The invention discloses evaporative pattern casting coating and a preparation method and using method thereof. The evaporative pattern casting coating comprises the following components of, by weight, 68-78 parts of refractory aggregate, 2-6 parts of hydroxyethyl cellulose, 3-6 parts of sodium bentonite, 4-7 parts of syrup, 2-6 parts of white emulsion and 2-5 parts of crystalline graphite powder. All the raw materials of the evaporative pattern casting coating are reasonably blended by weight, and the evaporative pattern casting coating has the characteristics of high strength and good stripping quality. The surface of an evaporative pattern casting prepared through the evaporative pattern casting coating is good in quality and free of sand inclusion or sand burning, the coating can be automatically stripped from the surface of the casting after the casting is unpacked, and the workload of later peeling-off and grinding of the casting is lowered.

Owner:CHANGGAO ELECTRIC GROUP CO LTD

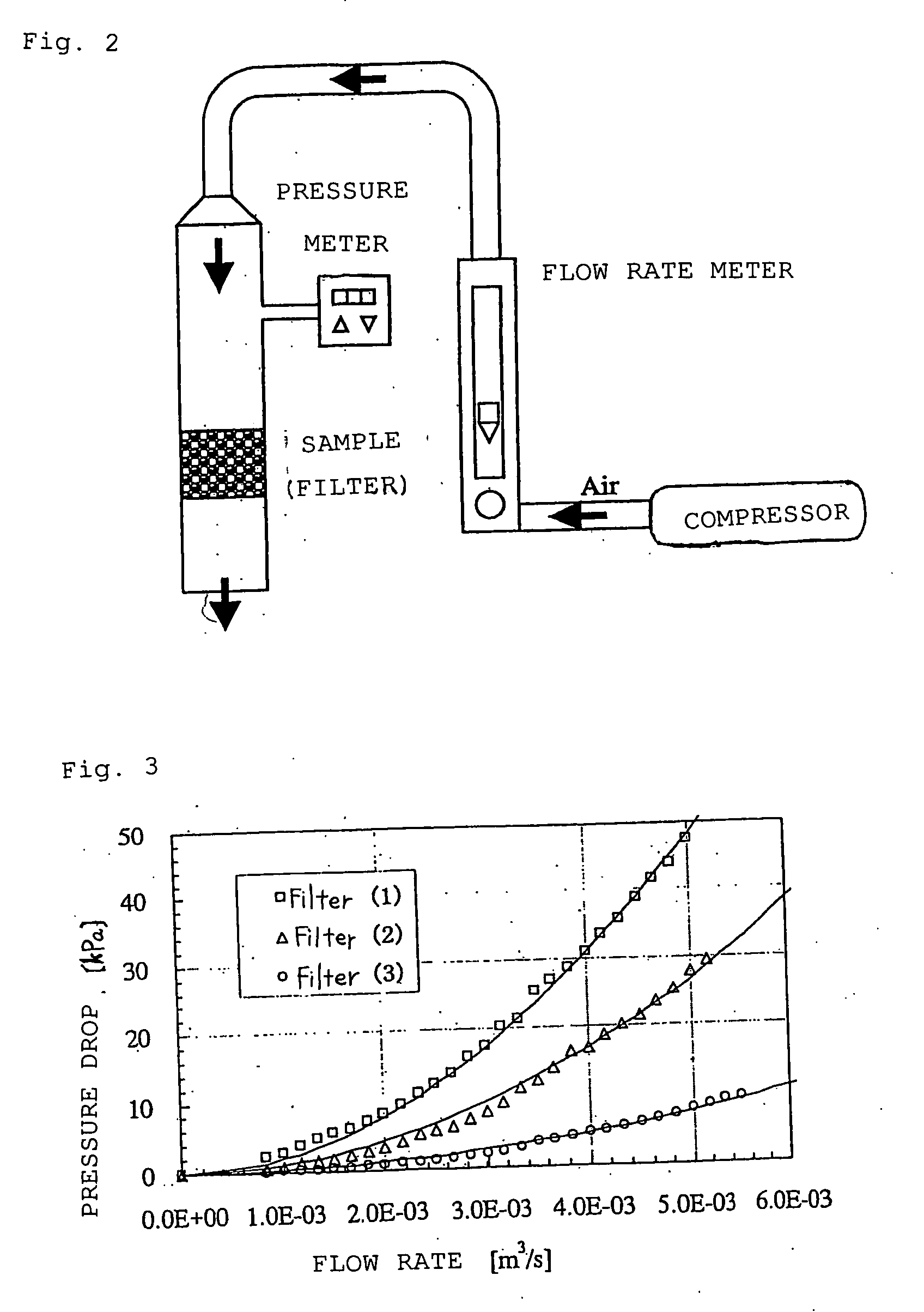

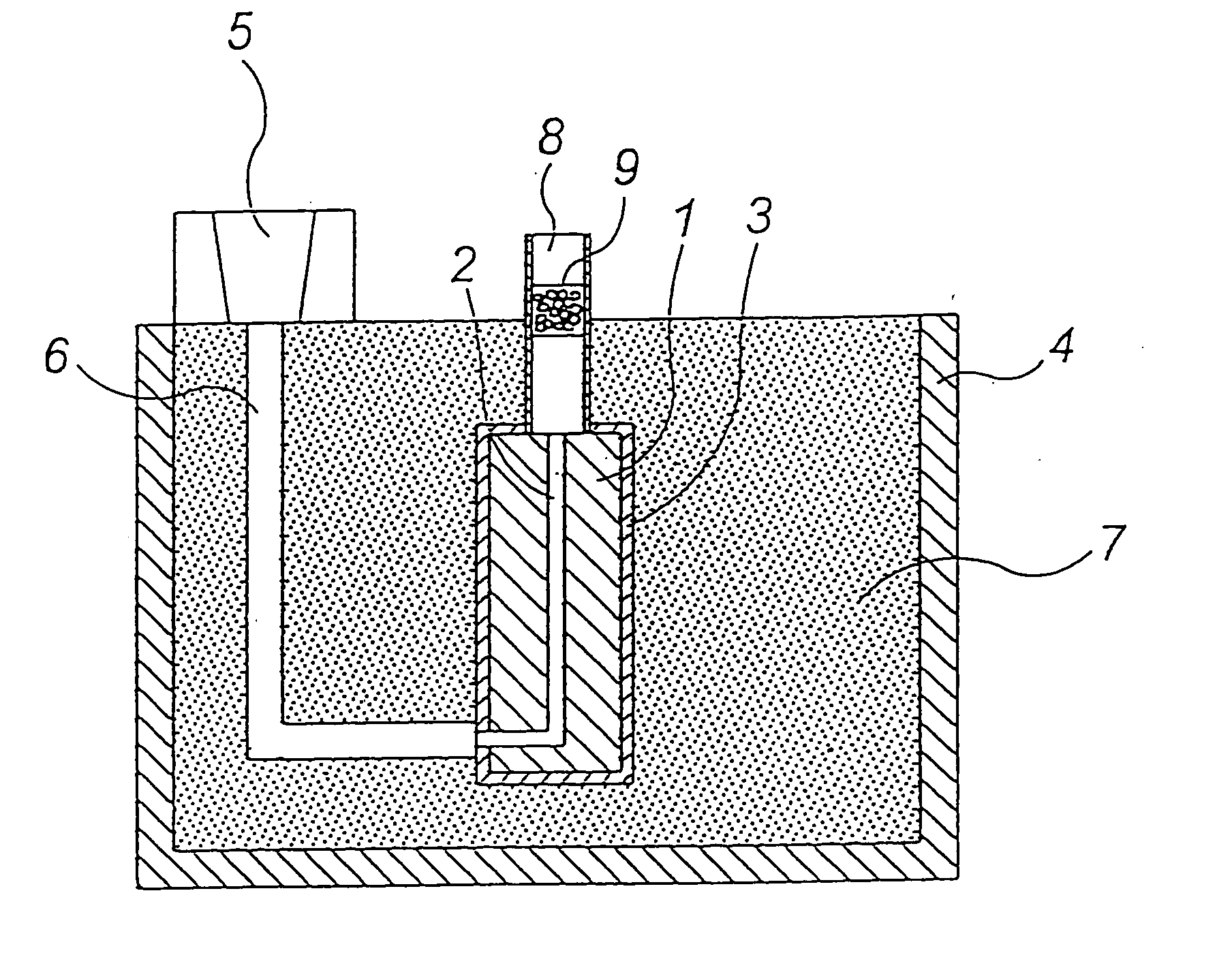

Lost pattern casting method

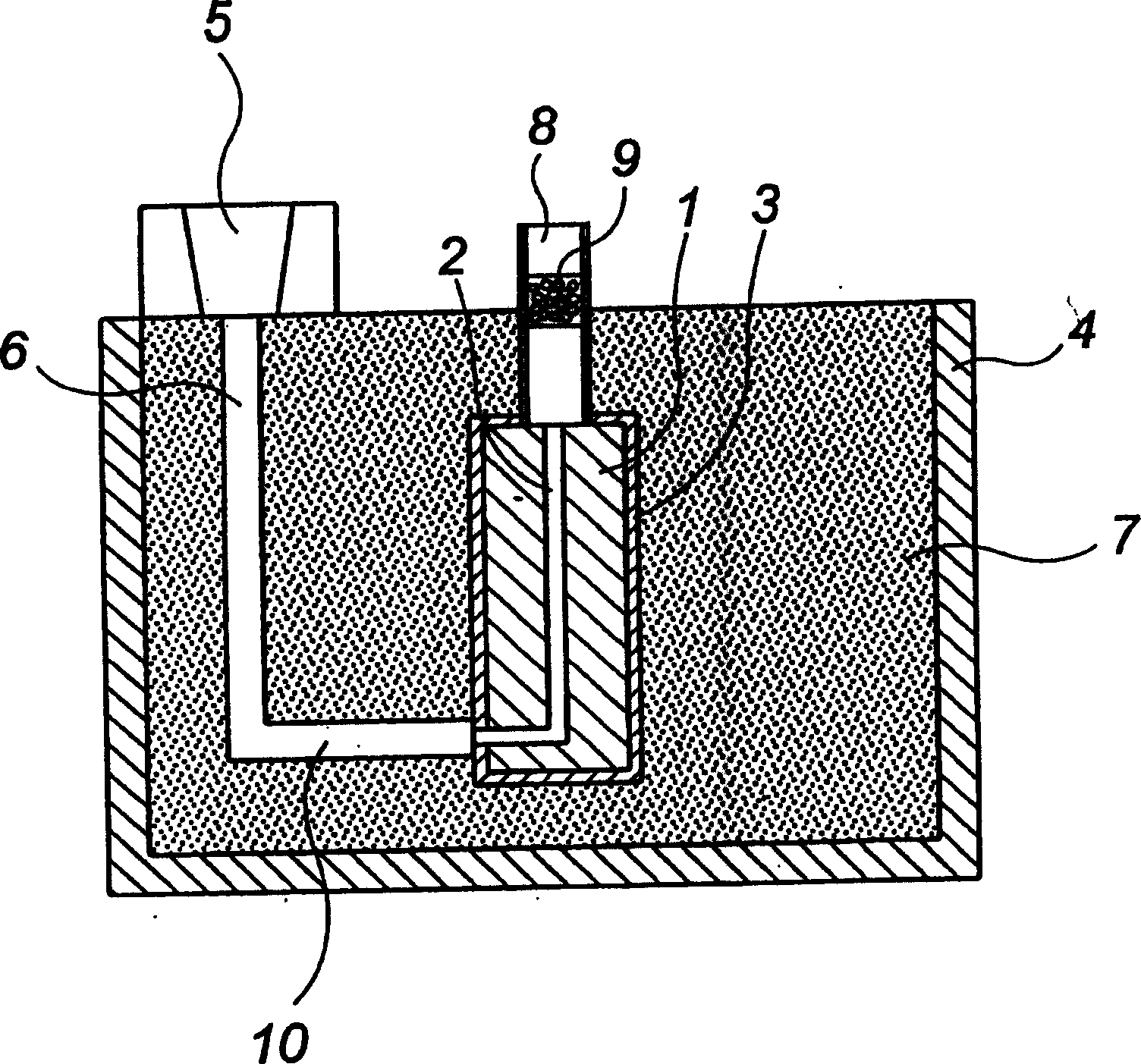

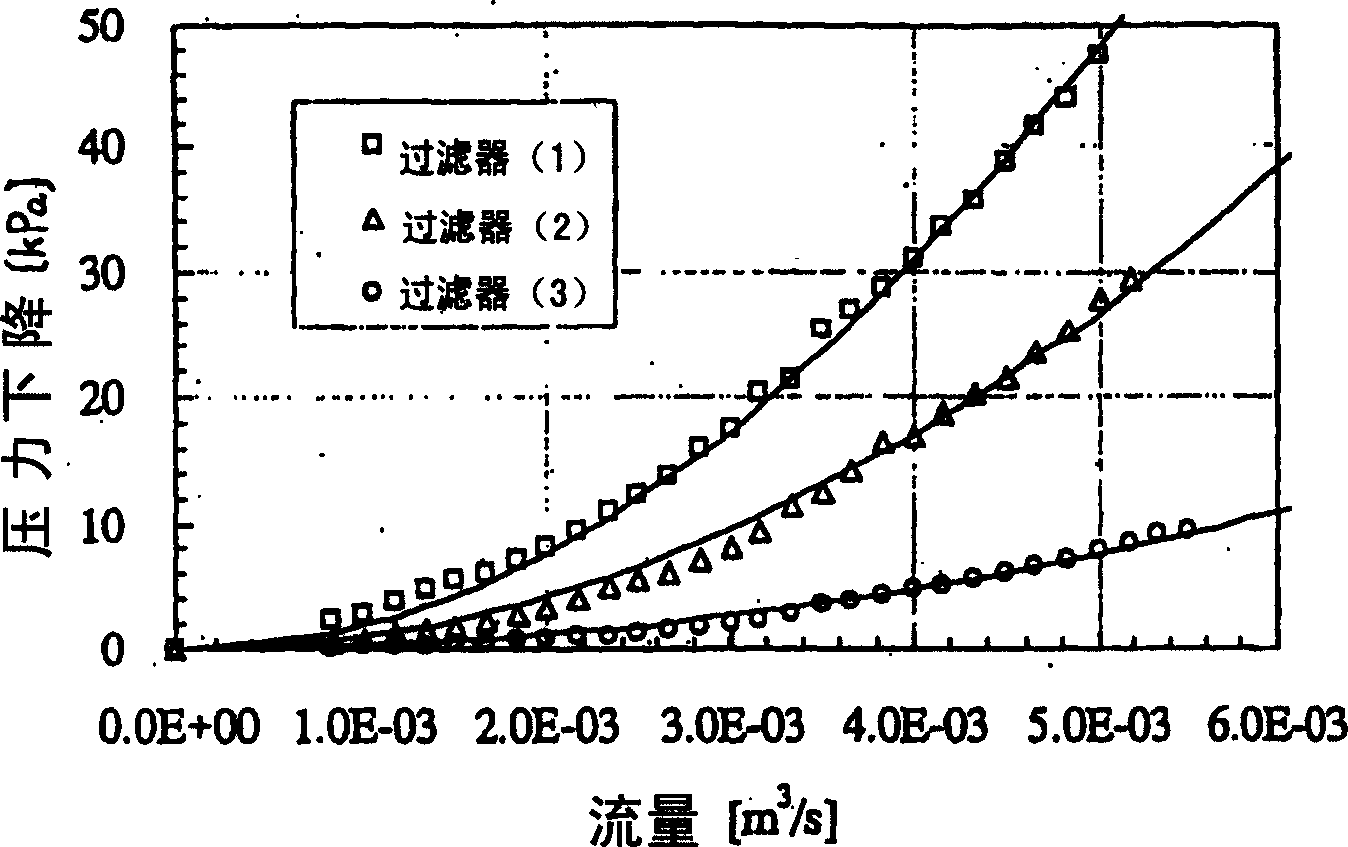

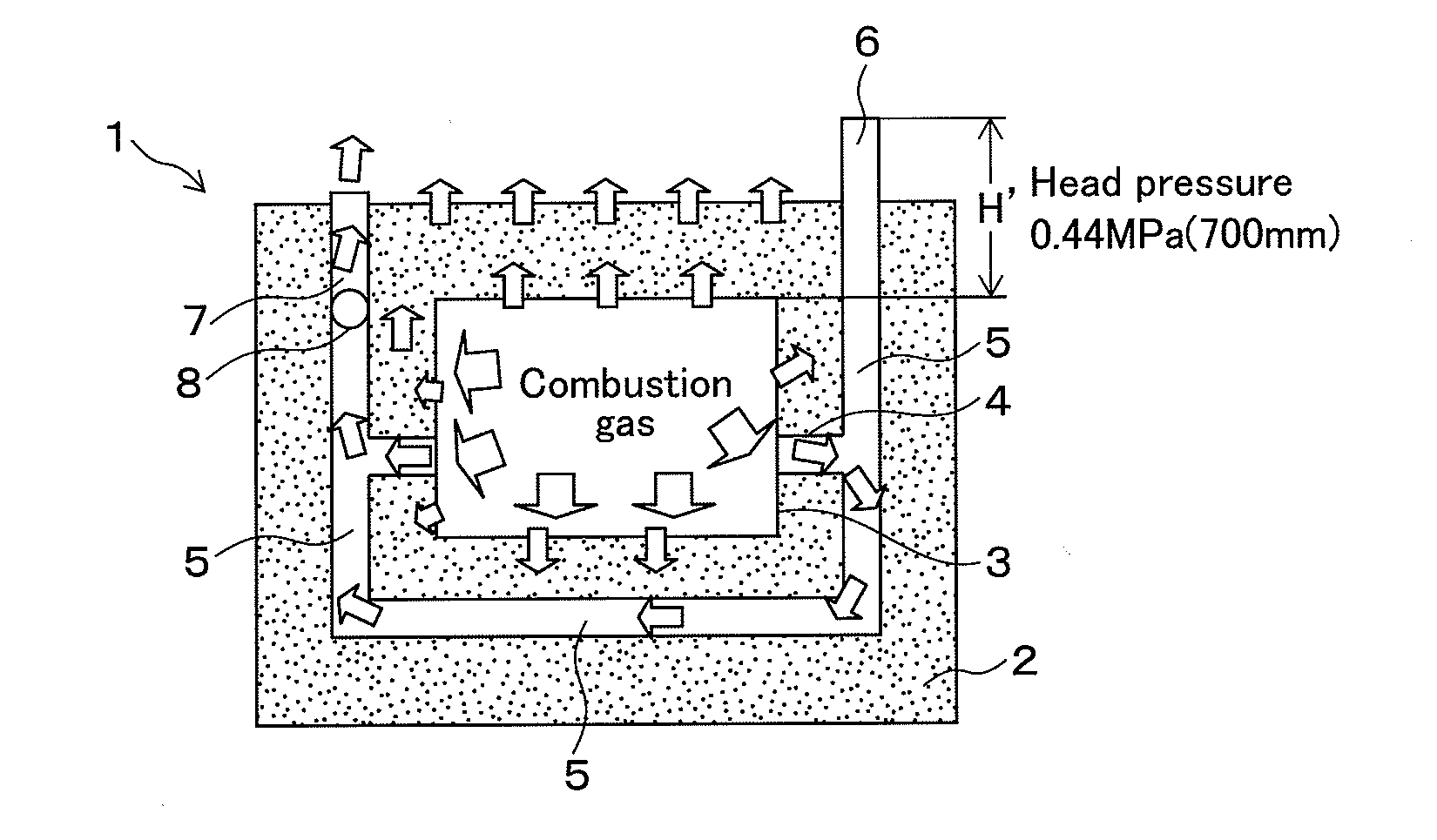

Provided is an evaporative pattern casting process wherein a casting process plan capable of attaining the optimal discharge of generated gas can easily be decided. The present invention is an evaporative pattern casting process for casting a product, which comprises pouring a molten metal in a mold in which a pattern made of an expanded synthetic resin is embedded in molding sand, and evaporating the pattern with the molten metal, while gas generated by evaporation of the pattern is discharged outside the mold through a discharging passage comprising a discharged gas suppressing means, wherein the ventilation of the discharging passage is controlled on the basis of the material and the shape of the pattern and the kind of the molten metal and the temperature of the molten metal.

Owner:KAO CORP

Evaporative pattern casting magnesium alloy and smelting method thereof

The present invention relates to a evaporative pattern casting special-purpose magnesium alloy and its smelting method. It is characterized by that in the formula of magnesium alloy the content of zinc is reduced, the contents of Al and Mn elements are properly regulated, and the mixed rare earth RE richly containing Ce and elements of Ti and C are added so as to fine the crystal grains of evaporative pattern casting magnesium alloy, reduce its dispersed shrinkage defect and improve its casting property and mechanical property.

Owner:SHANGHAI AIERSI LIGHT ALLOY

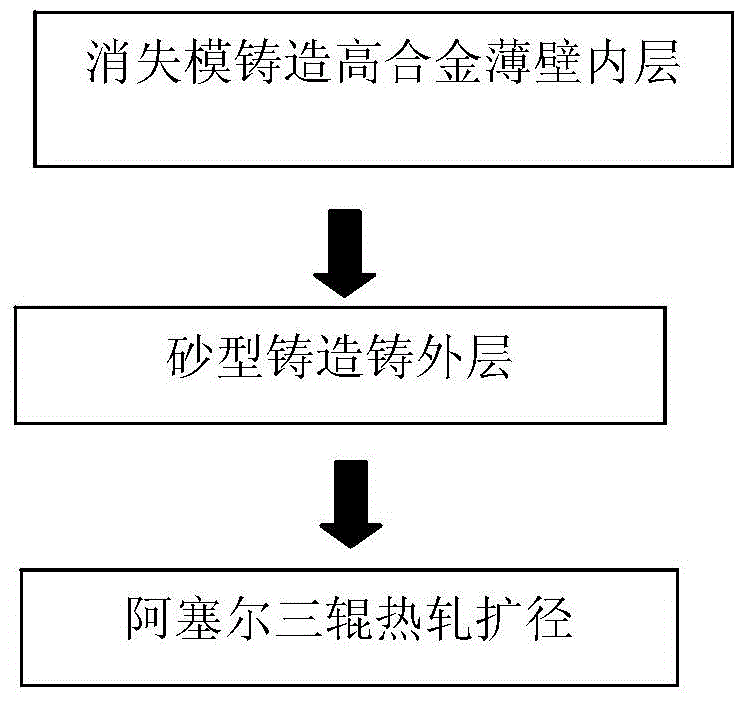

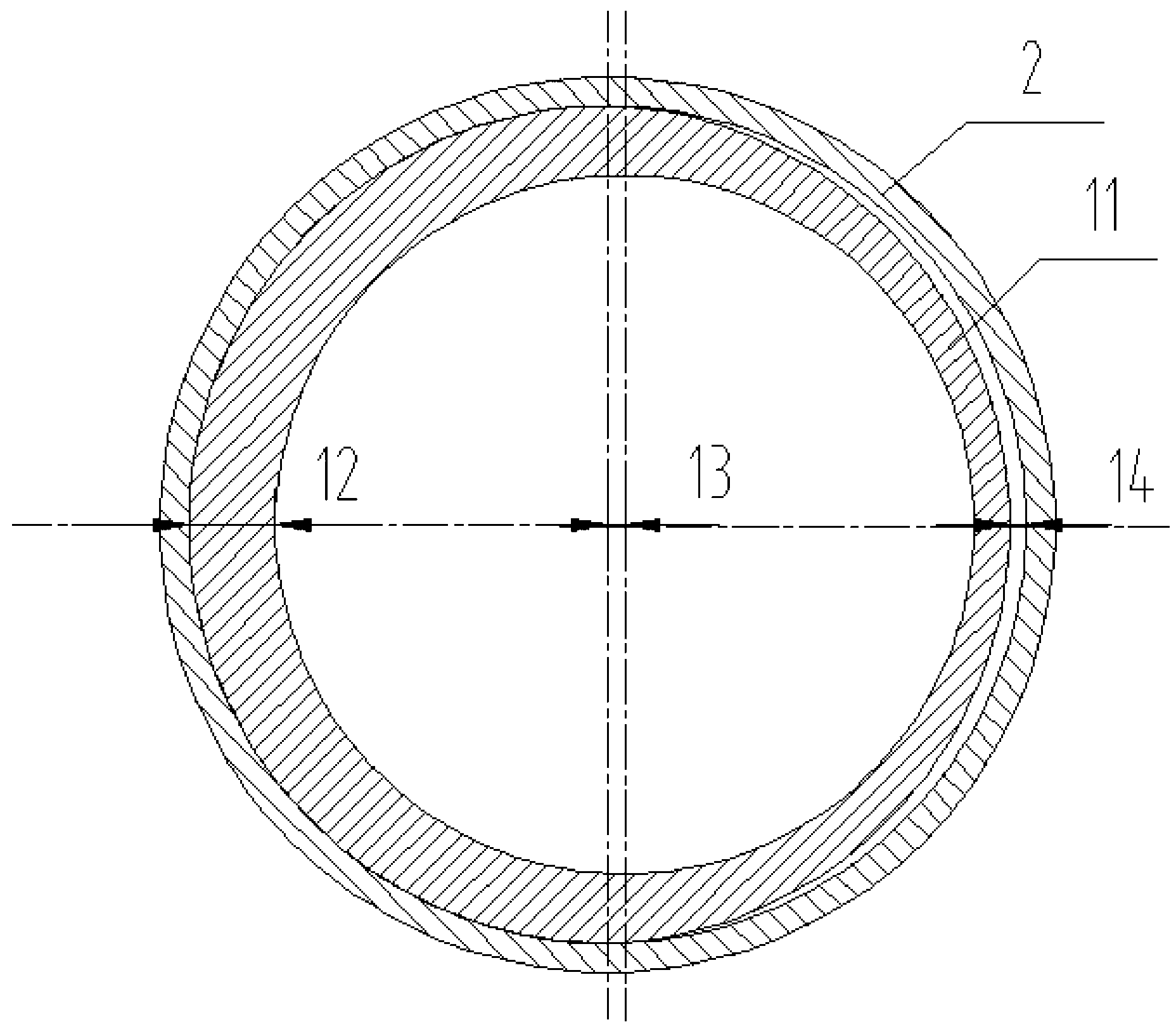

Method for preparing composite pipe by expanding secondary pouring dual-metal pipe billets

The invention discloses a method for preparing a composite pipe by expanding a secondary pouring dual-metal pipe billet. The secondary pouring dual-metal pipe billet is manufactured by the following steps: by adopting an evaporative pattern casting process, pouring to obtain an inner-layer thin-walled high-alloy corrosion-resistant pipe billet, and by adopting a sand casting method, pouring to obtain an outer-layer carbon steel pipe billet, thereby obtaining the dual-metal pipe billet. The expanding process is characterized by comprising the following steps: by adopting the dual-metal pipe billet prepared by secondary pouring, performing three-roller hot-rolling expanding deformation, thereby obtaining the dual-metal composite pipe. According to fusion of the inner and outer layers of metals in the casting process and plastic deformation in the hot-rolling expanding process, the dual-metal composite pipe with good metallurgical bonding property can be obtained. According to the dual-metal composite pipe disclosed by the invention, the high-precision inner-layer metal surface is obtained by virtue of the evaporative pattern casting process, and the inner-layer metal thickness is controllable; and moreover, due to the three-roller hot-rolling expanding process, high-strength metallurgical bonding among the inner and outer layers of metals is realized, the inner-layer surface precision is high, the ellipticity is high, and the wall thickness precision is high.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

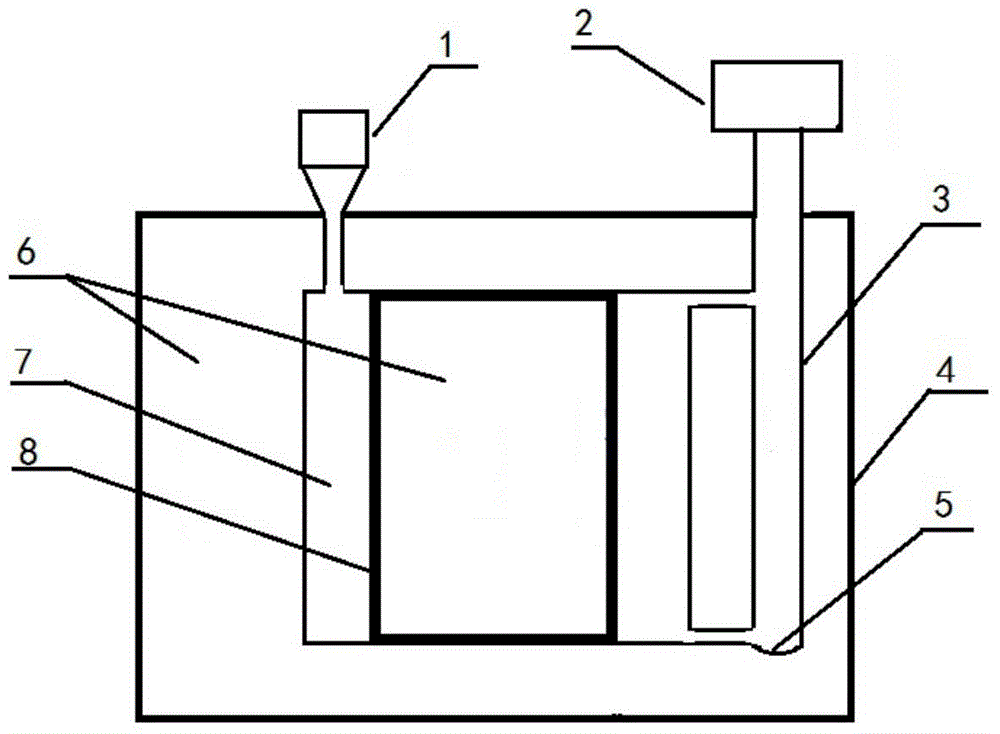

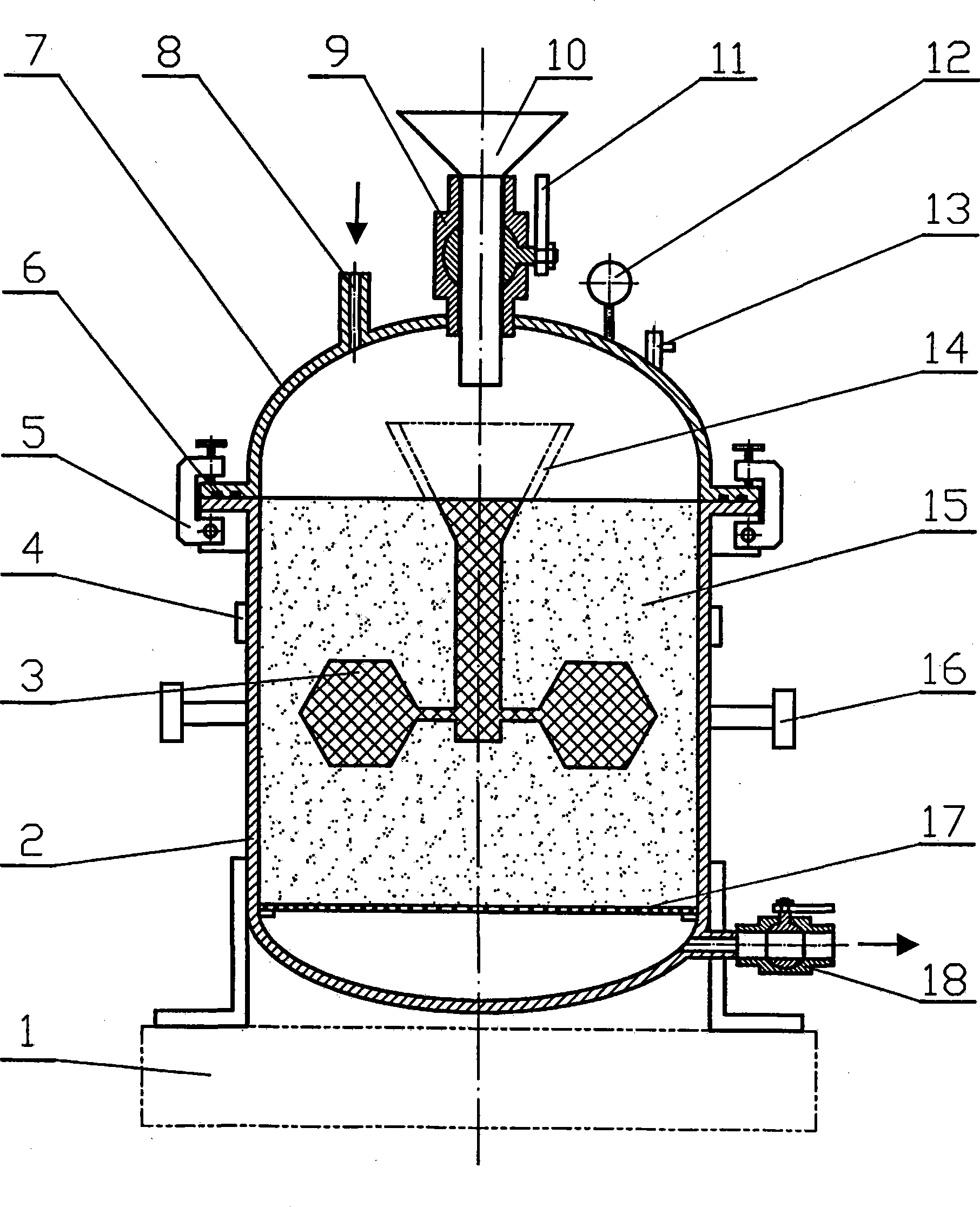

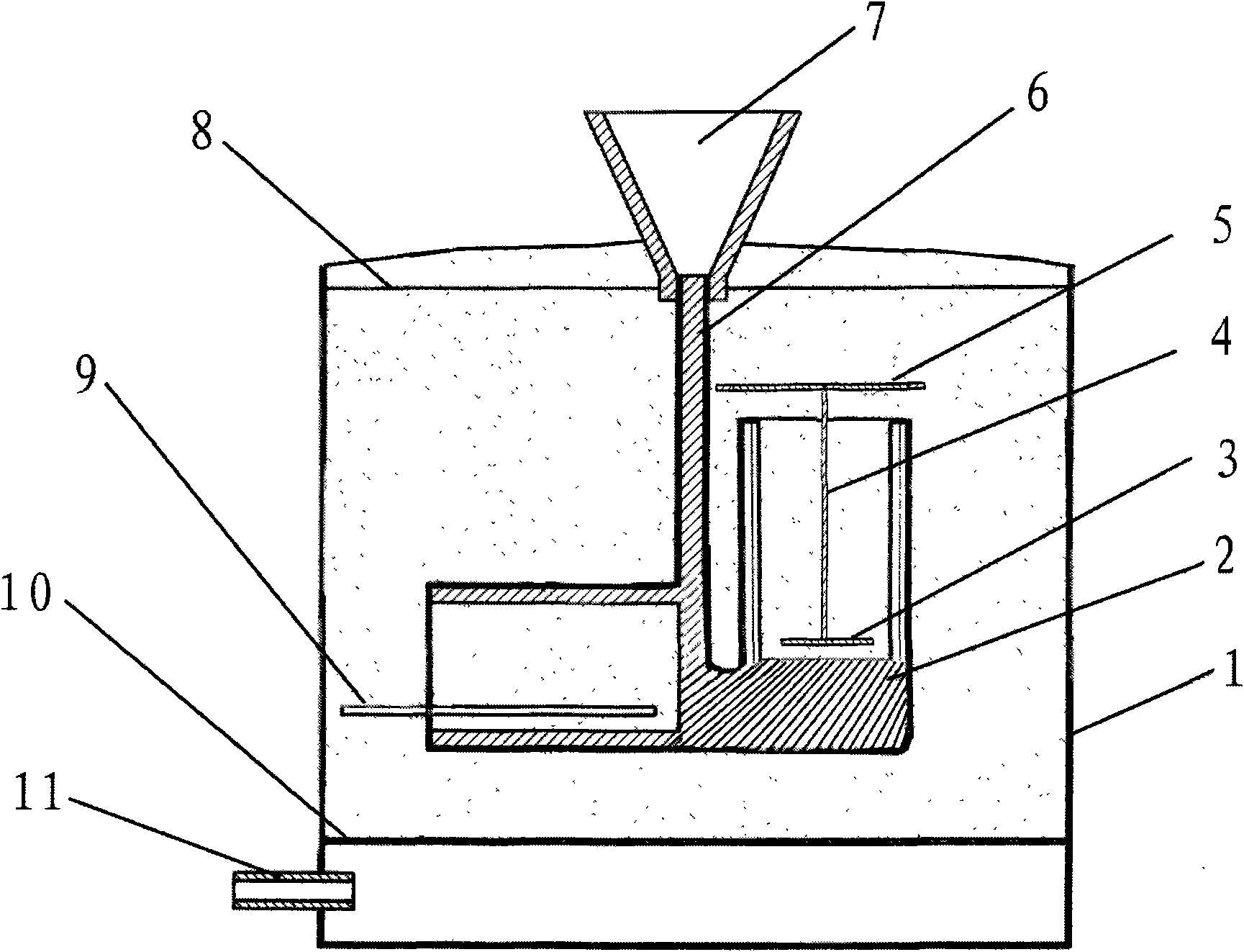

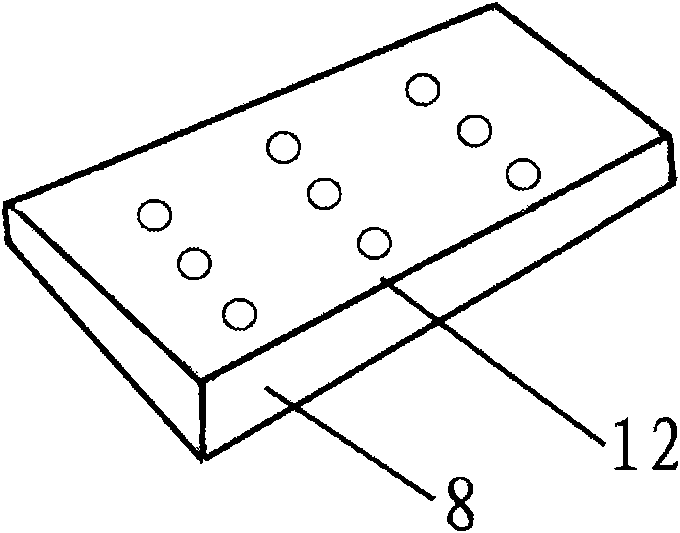

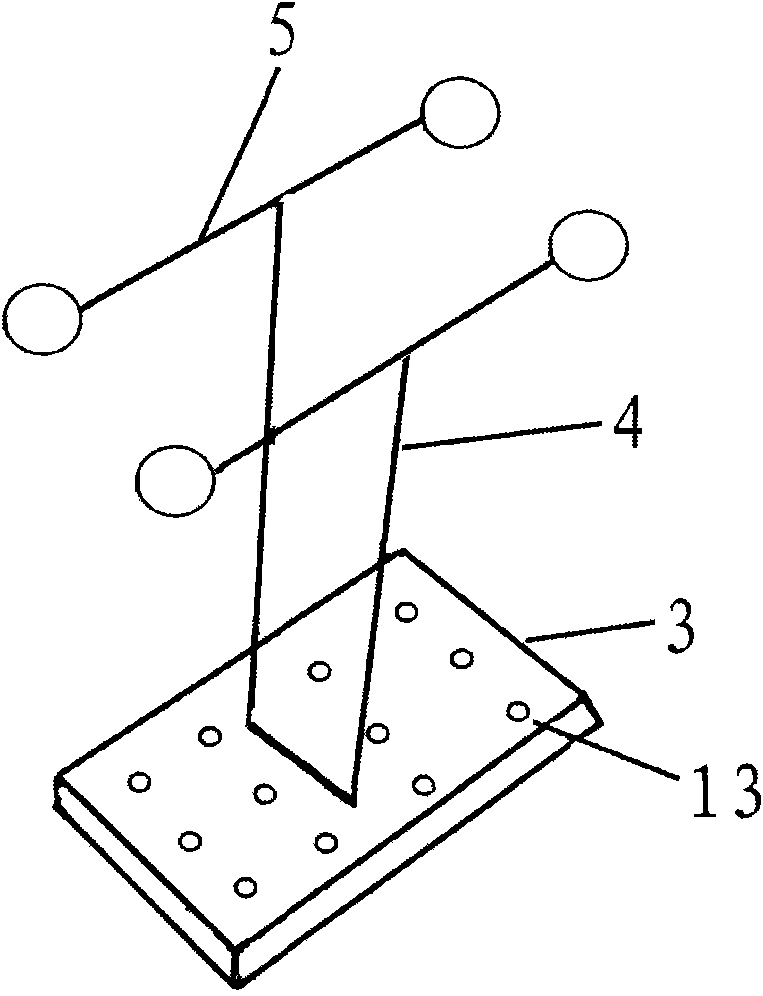

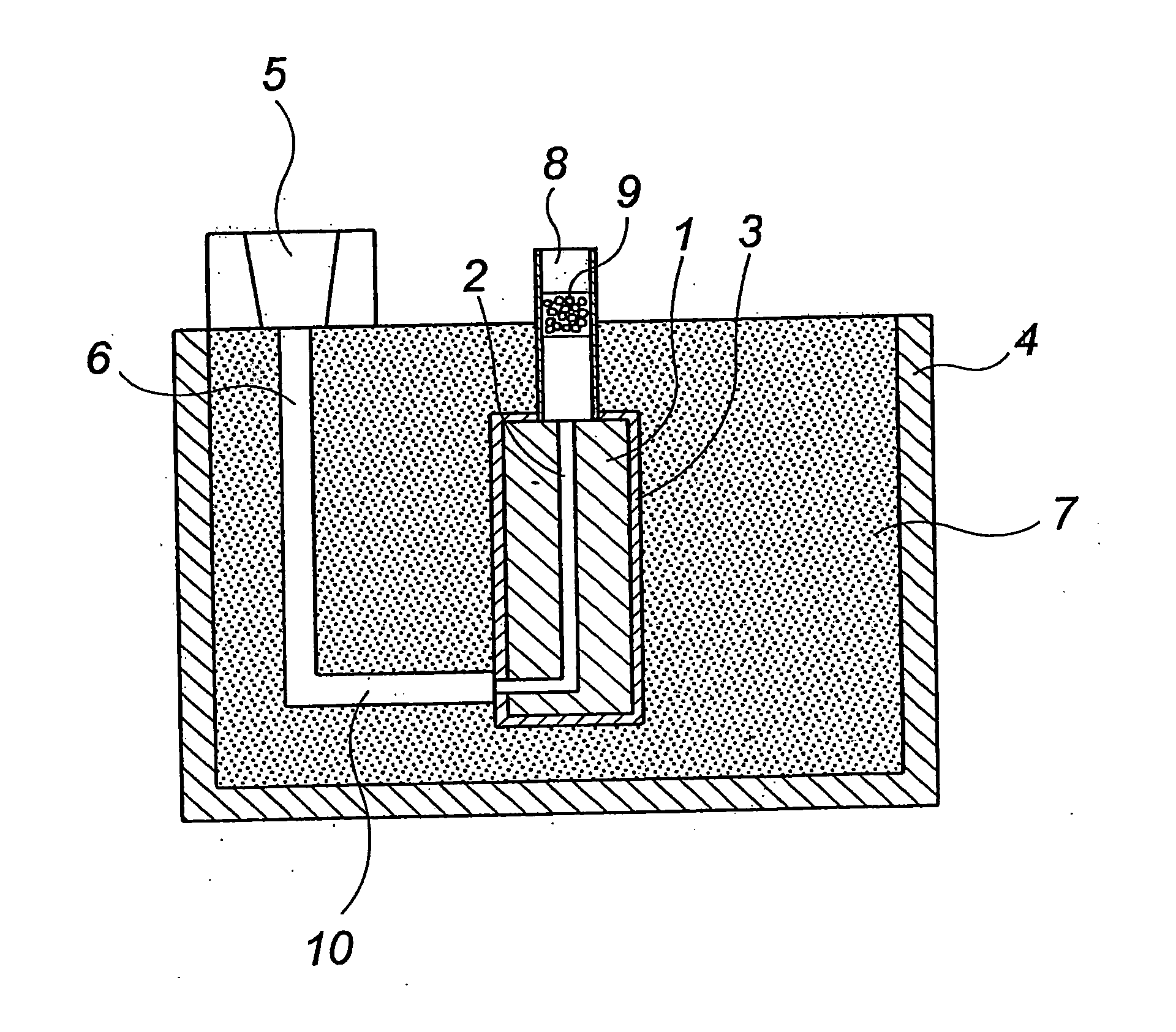

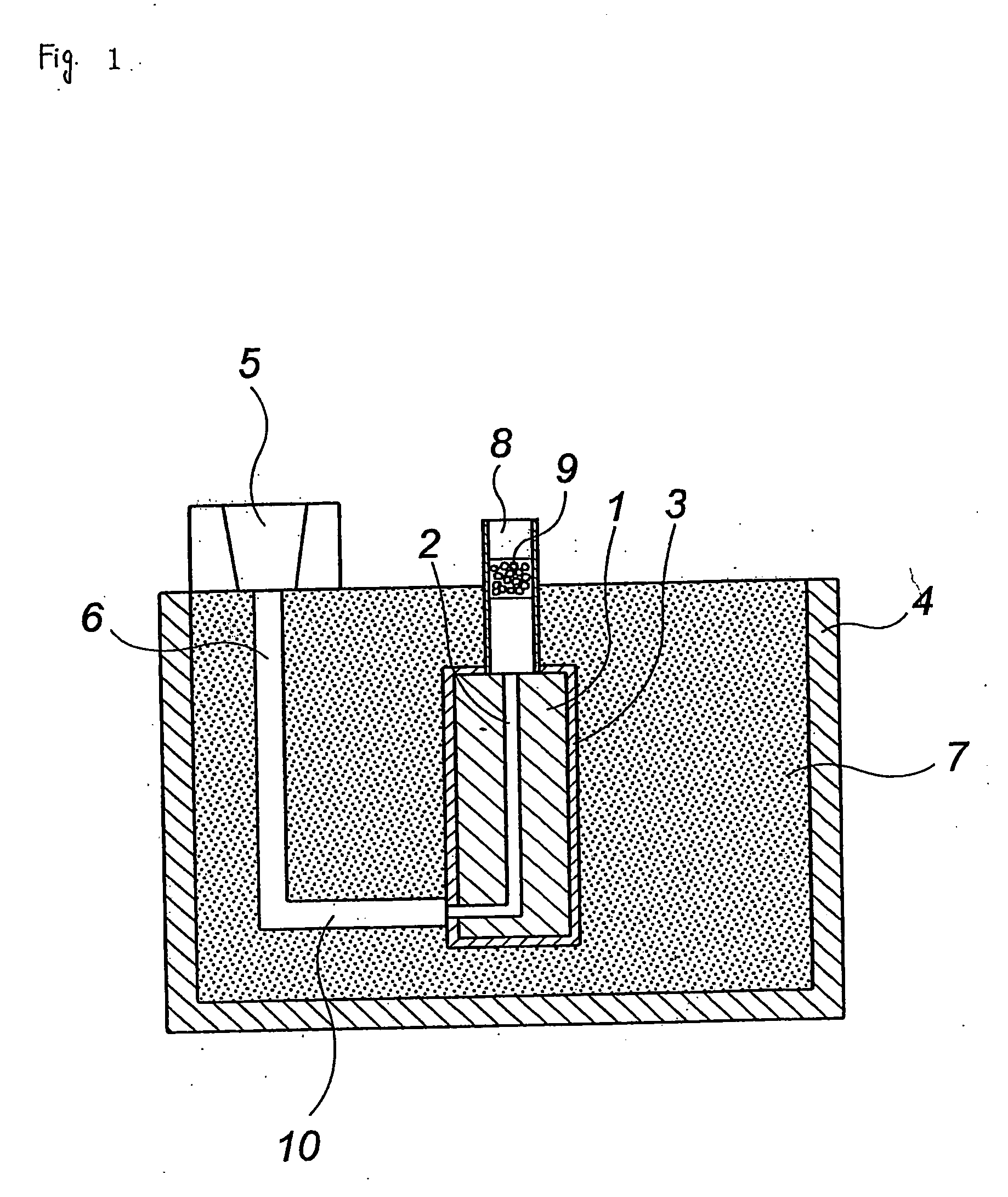

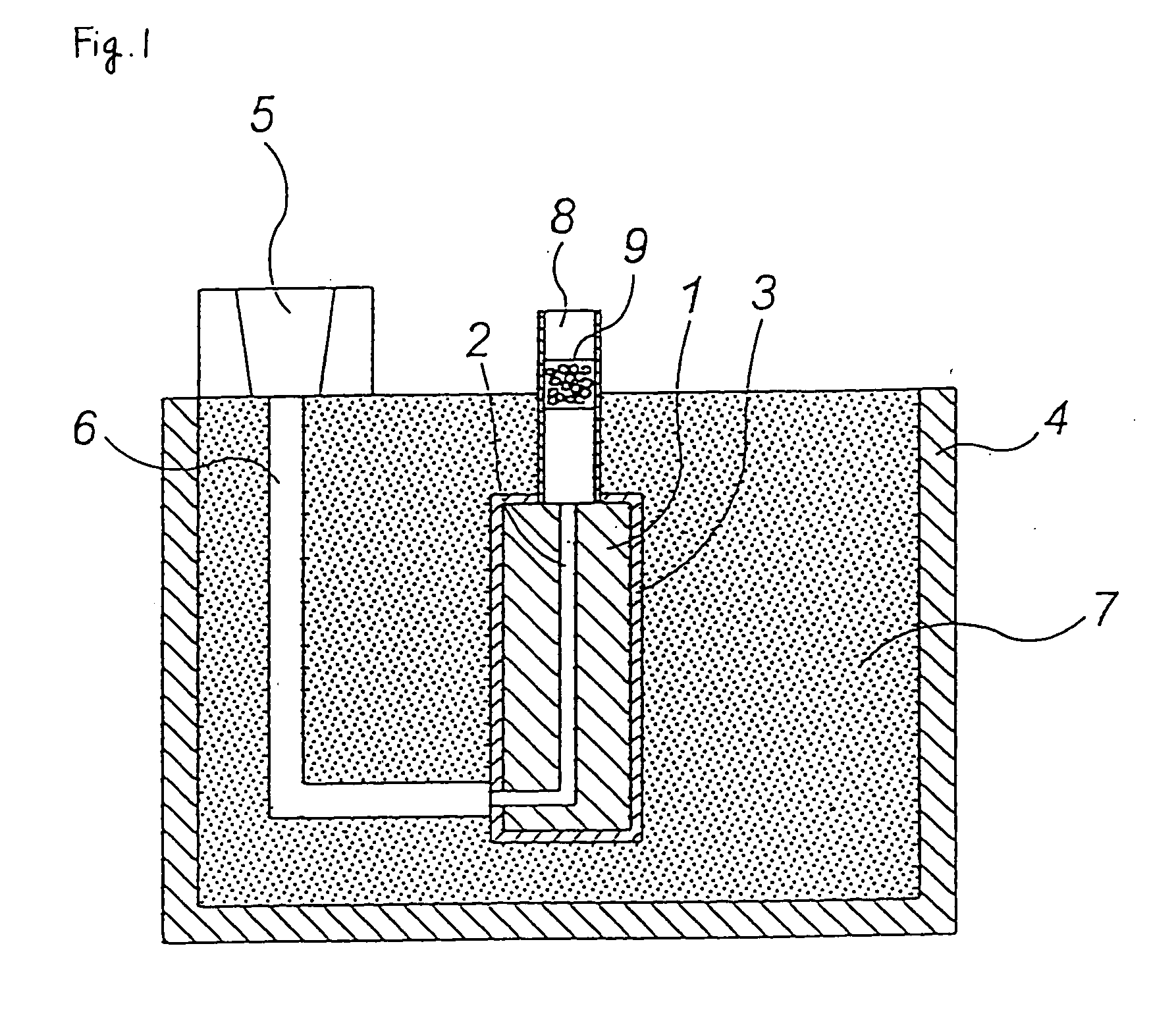

Aluminium alloy or magnesium alloy evaporative-pattern casting compression solidification method and device thereof

InactiveCN101391298AHigh densityGrain refinementFoundry mouldsFoundry coresExhaust valve5005 aluminium alloy

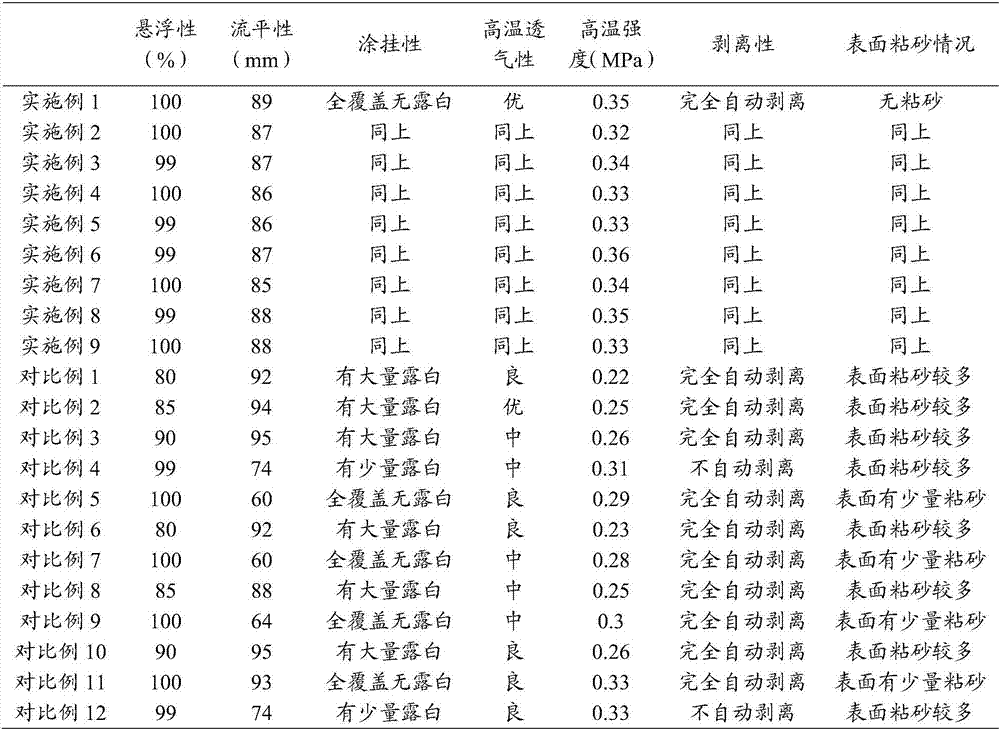

The invention relates to an aluminium alloy or magnesium alloy lost mould casting pressuring solidification method and a device thereof, and the invention belongs to the field of special precision casting. The aluminium alloy or magnesium alloy lost mould casting pressuring solidification method comprises compacting, vacuuming, pouring, pressuring and depressurizing. A pressure resistant sand box of the device is a cylinder-shaped container, the bottom is provided with an exhaust valve, and the inner lower part or the side wall is provided with a ventilation interlayer; the upper surface of a cover of the pressure resistant sand box is respectively provided with a switch valve, a safety valve and a pressure gauge; and the side surface of the pressure resistant sand box or the cover of the pressure resistant sand box is provided with an intake pipe. The aluminium alloy or magnesium alloy lost mould casting pressuring solidification method can obviously reduce casting defects of shrinkage cavity, shrinkage porosity, and the like in aluminium alloy lost mould casting, can effectively reduce pinhole in the aluminium alloy, enhances density of the casting, thins alloy crystal grains, and improves the surface quality and mechanical property of the aluminium alloy or magnesium alloy lost mould casting. The device simplifies lost mould casting pressuring solidification technique, and low production cost, convenient operation, good sealing effect, short sealing time of the sand box and fast pressuring speed.

Owner:HUAZHONG UNIV OF SCI & TECH

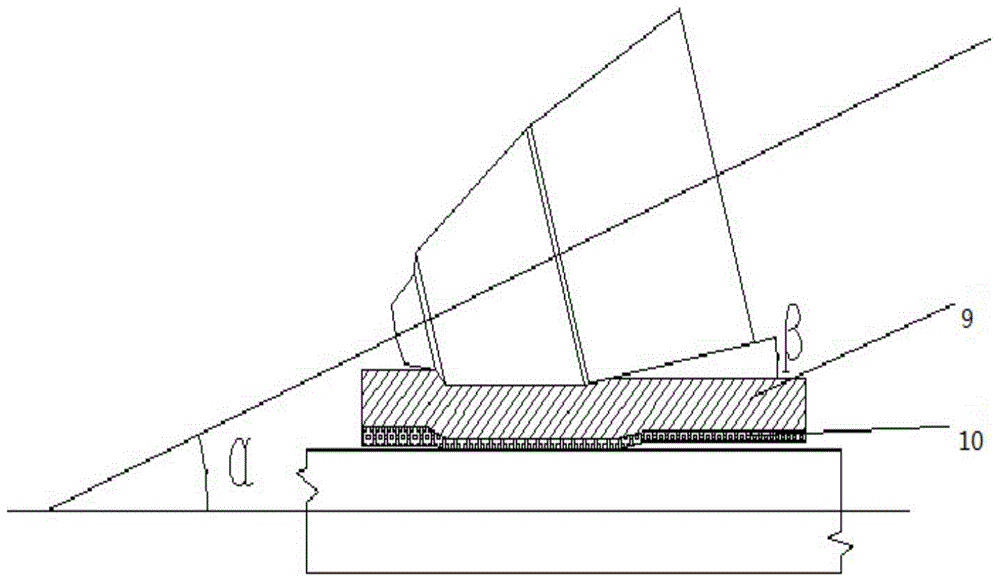

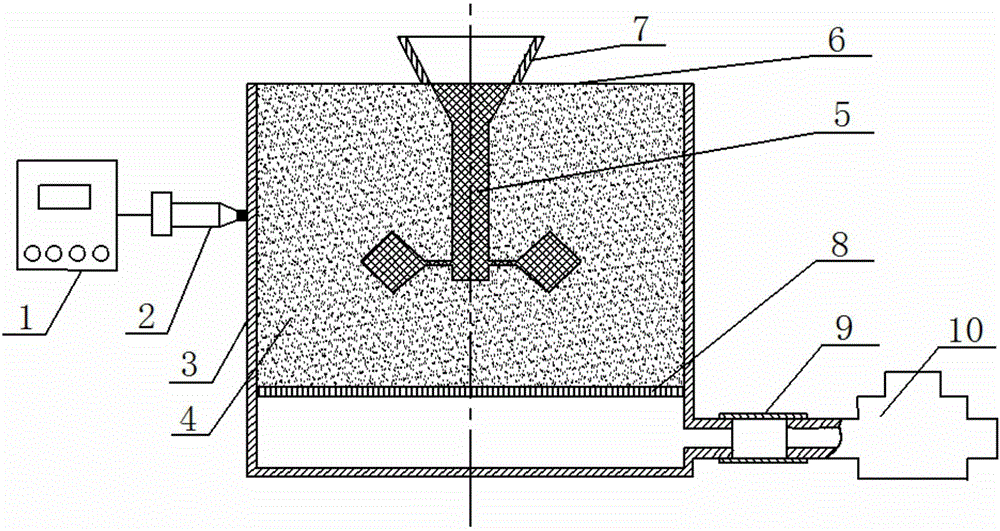

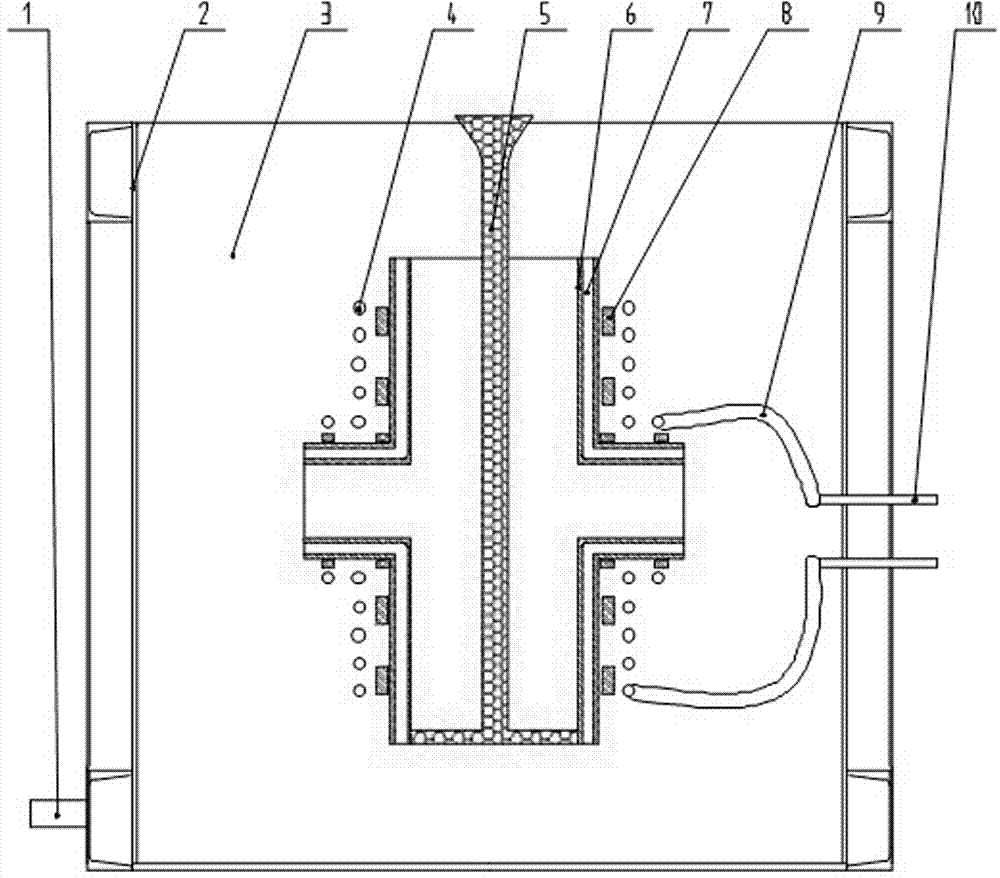

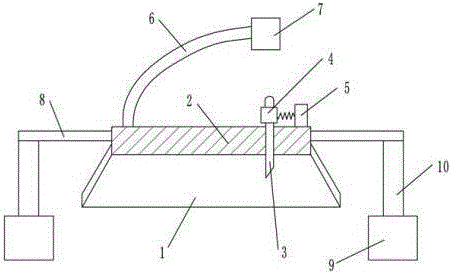

Evaporative pattern casting method and device for ultrasound vibration resin self-hardening sand

ActiveCN105834362ASolve the collapsed boxSolve the carburization defectFoundry mouldsMoulding machinesBox modelingUltrasonic vibration

The invention provides an evaporative pattern casting method and device for ultrasound vibration resin self-hardening sand and belongs to the field of special precision casting. The method includes the steps that dry sand used in traditional evaporative pattern casting is changed into resin self-hardening sand, an ultrasonic wave generation system is introduced, a sine signal generated by an ultrasonic wave generator is converted into high-frequency mechanical vibration through an ultrasonic wave amplitude-variable bar connected with the ultrasonic wave generator, and high-frequency mechanical vibration acts on a sand box wall auxiliary resin self-hardening sand evaporative pattern modeling. The method includes the steps of manufacturing a foamed plastic model, painting a coating, performing sand box modeling, performing ultrasonic wave compaction, performing vacuumizing, burning the foamed plastic model through flames, performing vacuum negative-pressure pouring and performing the shakeout working procedure. By the adoption of the evaporative pattern casting method and device for ultrasound vibration resin self-hardening sand, the defects of sand crushing and recarburization can be overcome remarkably, the problems that most of castings are each of a dendrite structure, shrinkage and loosening are generated, and mechanical property is lower are solved, and the functions of grain refining, gas discharging and segregation reduction can be achieved.

Owner:GUANGXI UNIV

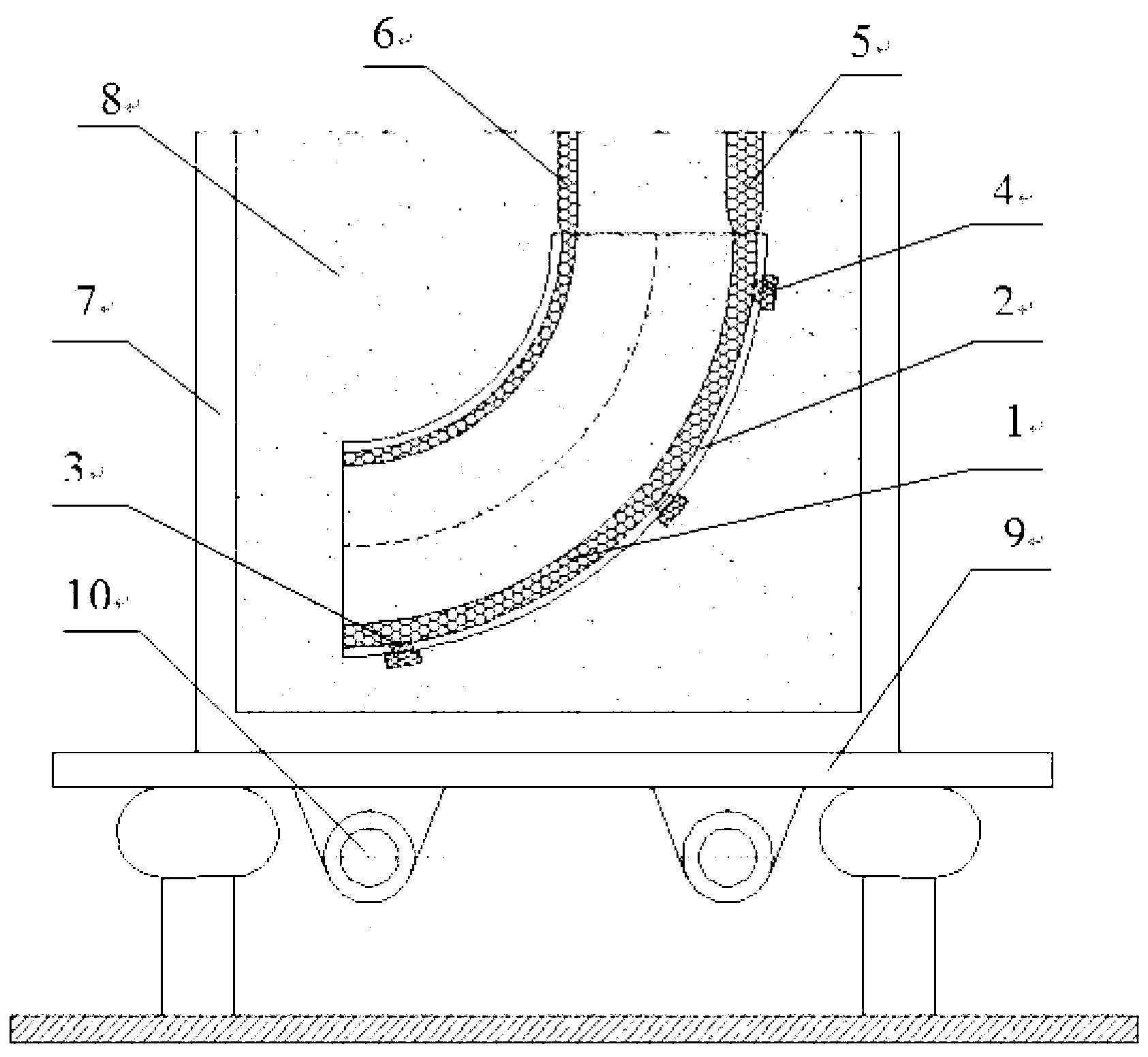

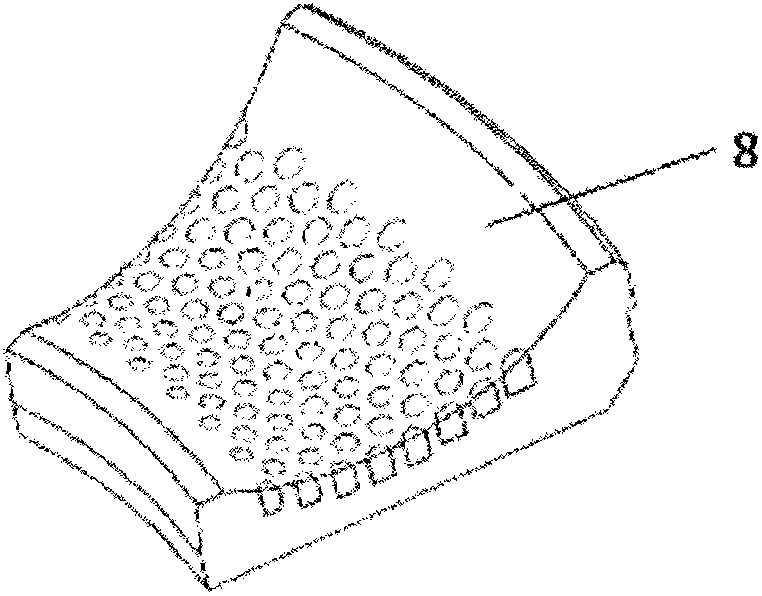

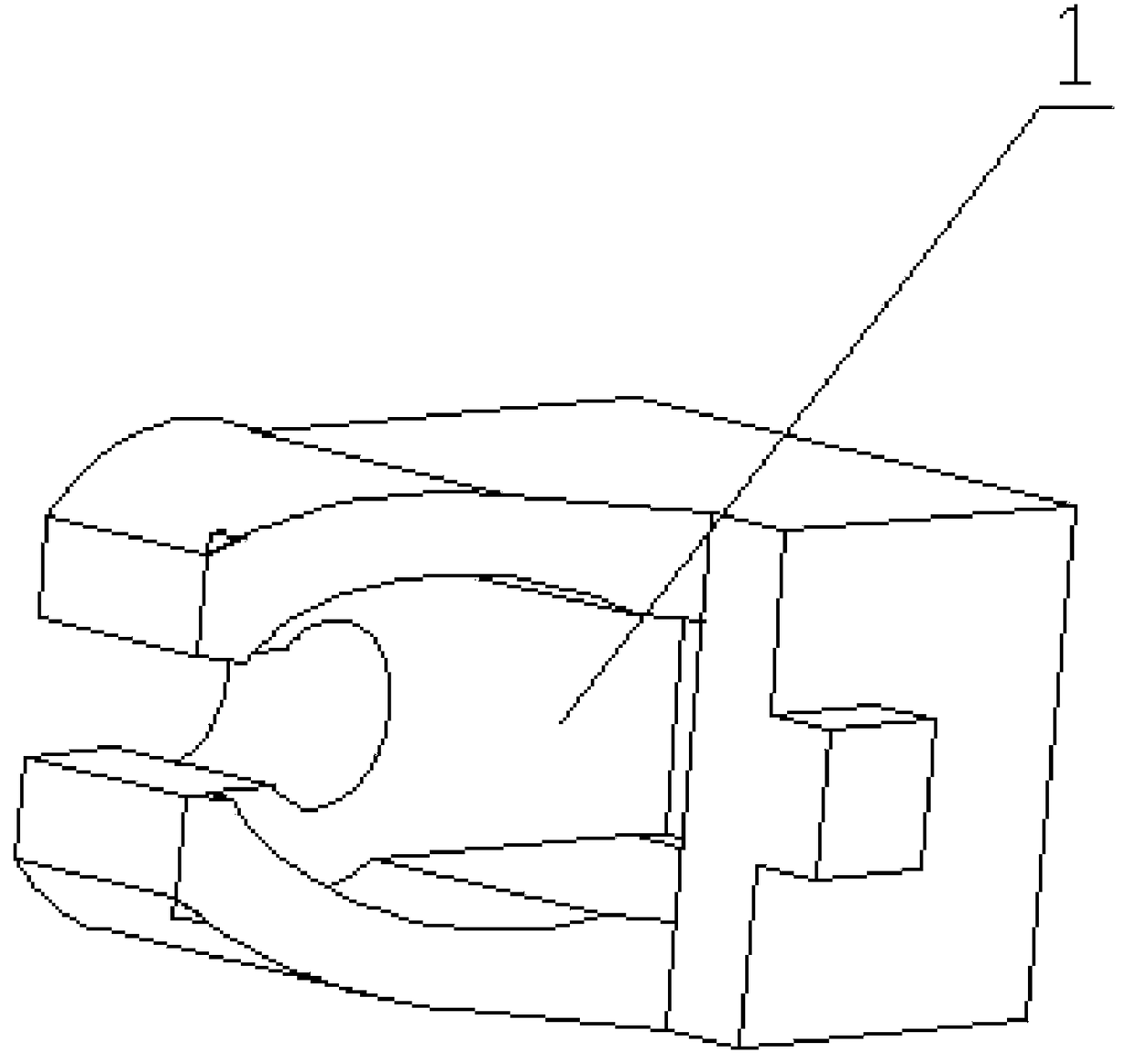

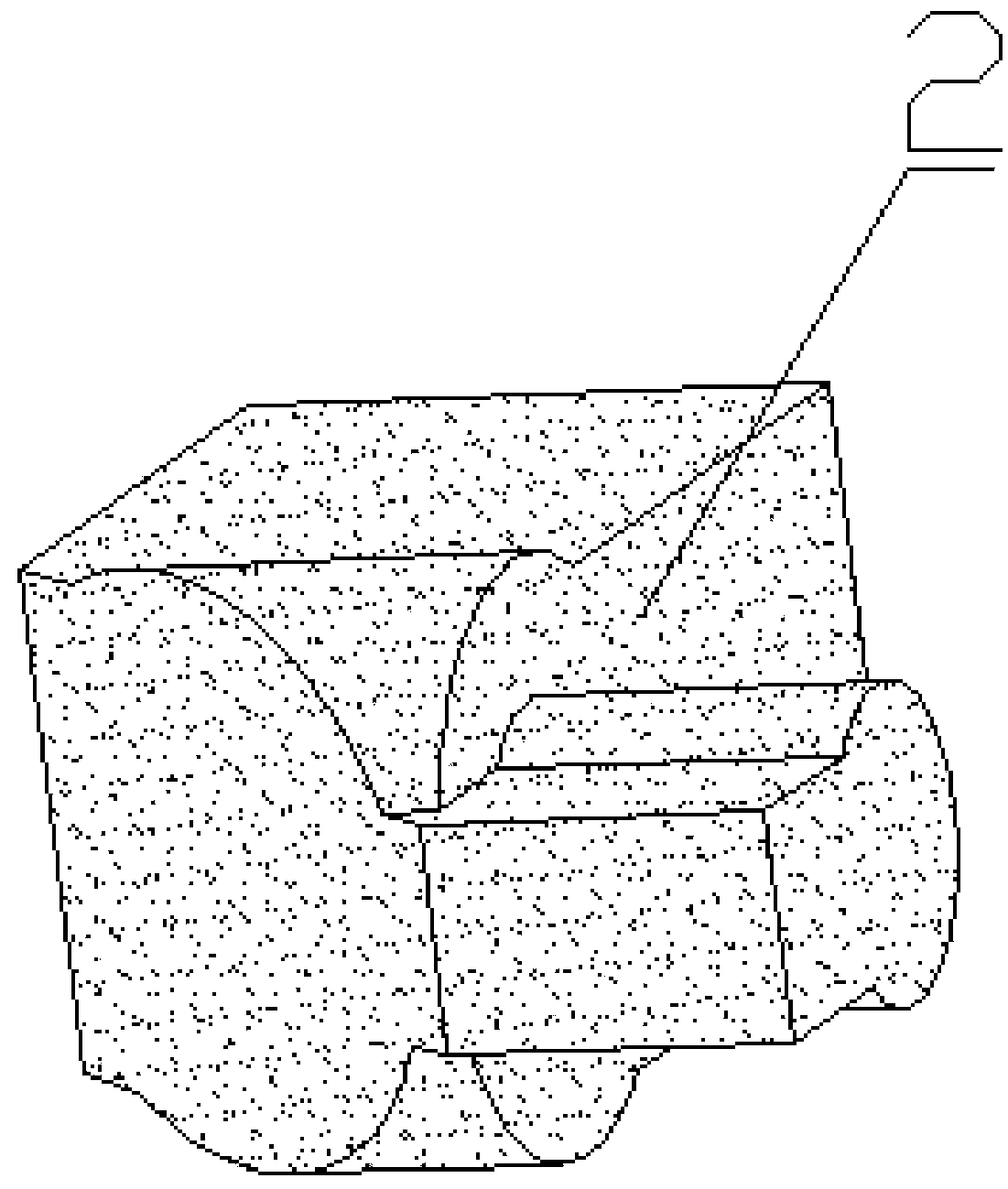

Bi-metal bent pipe manufacturing process based on evaporative pattern casting and vibration pouring

InactiveCN103008544AImprove bindingEliminate shrinkage gapsFoundry mouldsFoundry coresWear resistantWear resistance

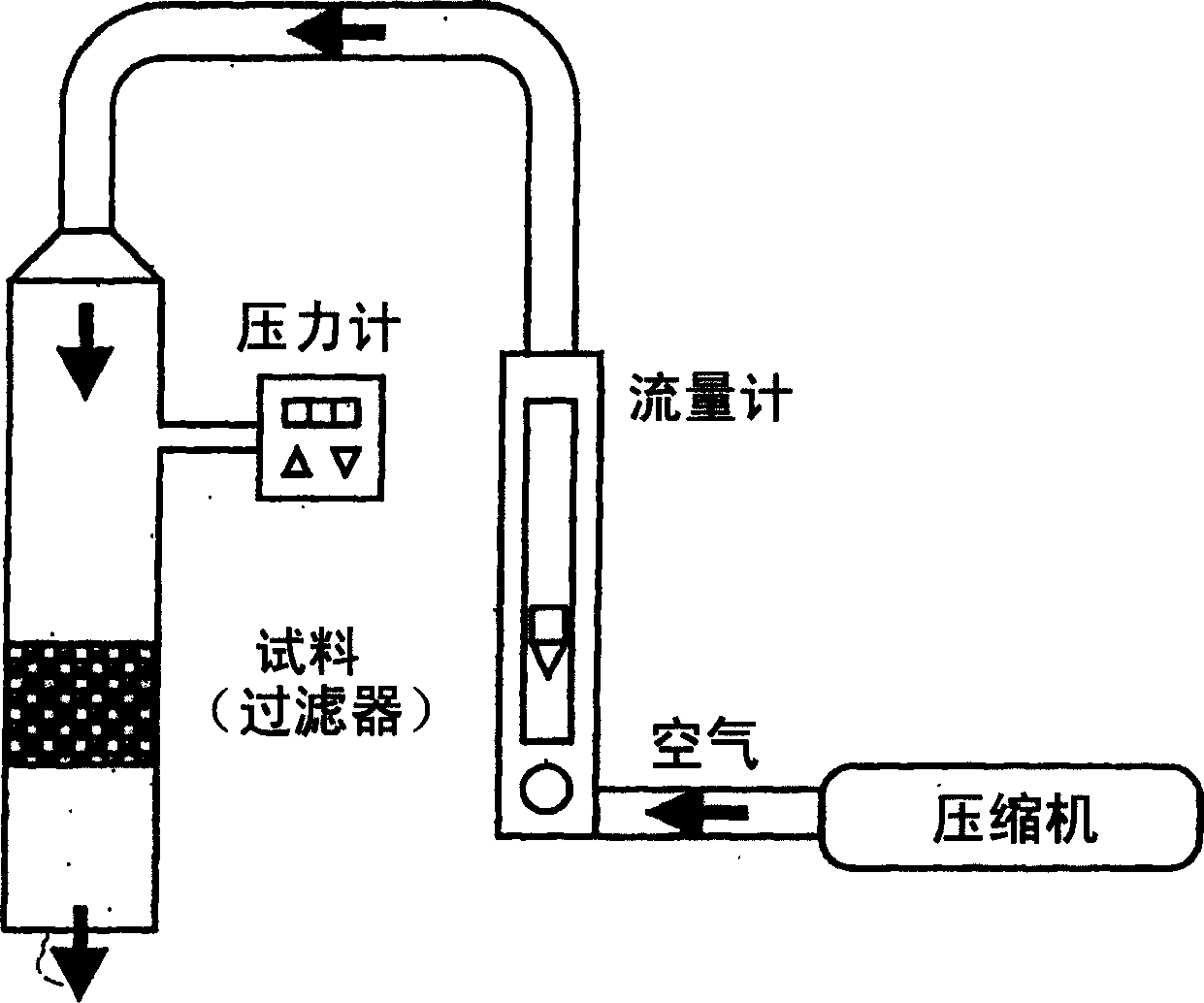

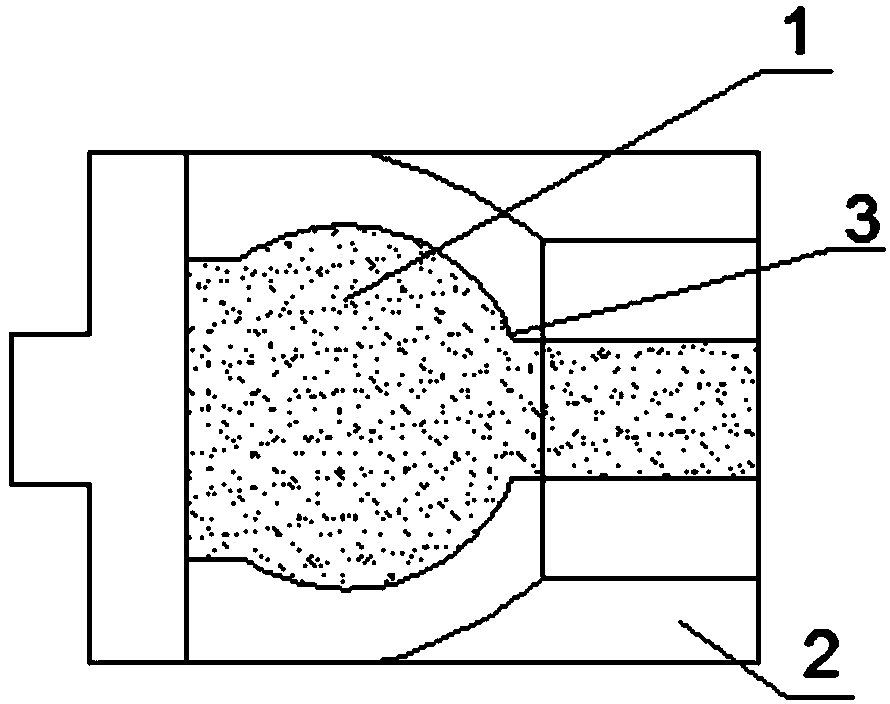

The invention discloses a bi-metal bent pipe manufacturing process, which includes: assembling a foam pattern (1) of a bi-metal bent pipe lining and an outer steel pipe (2) that has through-holes (3) drilled on an outside wall, and plugging the through-holes (3) with foam bodies (4) so as to form a combined foam pattern; bonding the combined foam pattern with a pouring system (5) for foam molding of an evaporative pattern and a vent hole (6) to form an overall pattern, and placing the overall pattern in a sand box to conduct sand filling and molding; burning off the foam pattern in the overall pattern, then putting the sand box on a vibration pouring jolting platform to perform vibration pouring, carrying out heat preservation for some time, and then opening the box to clear up the casting, thus finishing manufacturing the bi-metal bent pipe. The process provided in the invention adopts non-vacuum vibration casting. The lining of the manufactured bi-metal composite bent pipe has a more compact and wear resistant texture, and the mechanical and metallurgical bonding degree outside the composite bent pipe is high, so that the outside toughness and wear resistance of the bi-metal bent pipe are effectively improved, the service life is prolonged, and the production cost of the bi-metal bent pipe is effectively reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

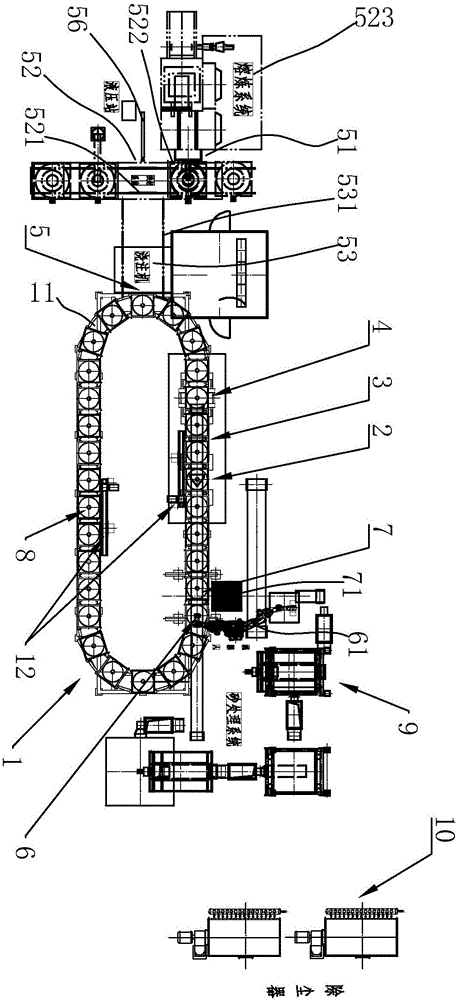

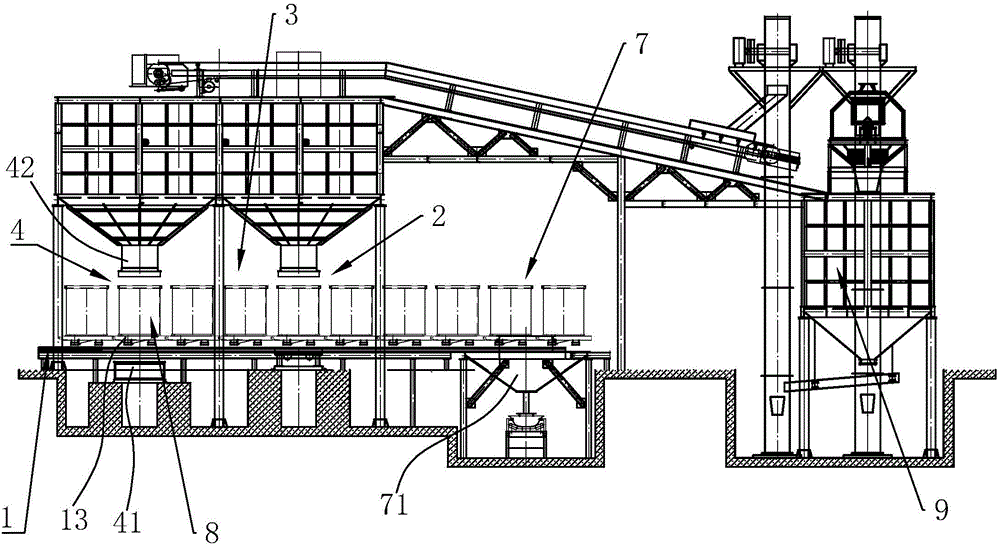

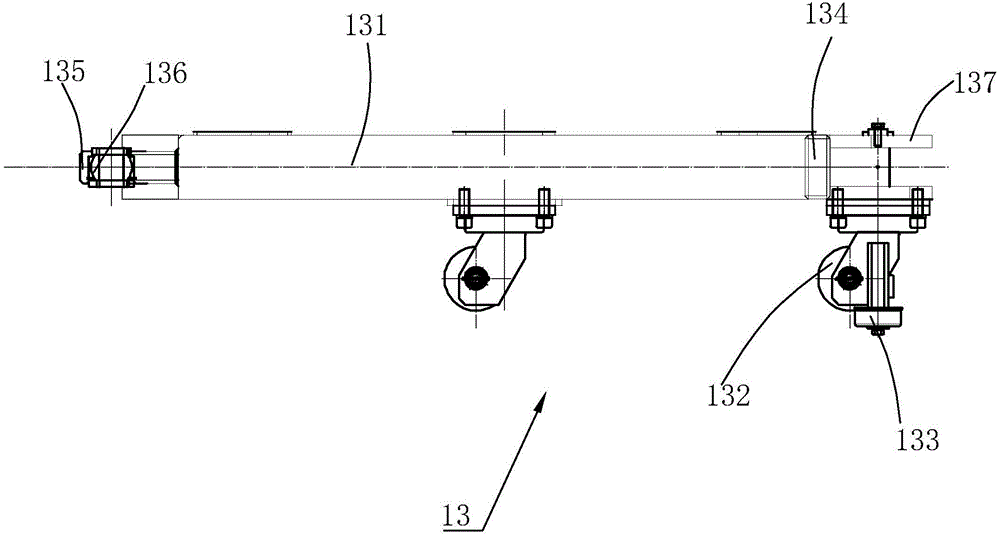

High-efficiency and energy-saving aluminum alloy evaporative pattern casting production line

The invention discloses a high-efficiency and energy-saving aluminum alloy evaporative pattern casting production line. The high-efficiency and energy-saving aluminum alloy evaporative pattern casting production line comprises a sand box automatic circular line, wherein a plurality of box bearing carts which move along a conveying line and are used for bearing sand boxes are arranged on the sand box automatic circular line; the sand boxes are borne on the box bearing carts; the box bearing carts sequentially pass through a bottom sand adding station, a model cluster storing station, a sand filling and modeling station, a pouring station, a casting discharging station and a sand falling station on the conveying line through a servo box pushing system; the pouring station comprises a pouring machine and a tundish changing system; a casting taking robot for taking out castings in the sand boxes is arranged at the casting discharging station; and a bottom-dump type sand falling device for dumping molding sand in the sand boxes from the bottoms of the sand boxes is arranged at the sand falling station, or a box turning machine is adopted for automatically turning over the boxes to finish the sand falling. The production line has the characteristics of high degree of automation, high production efficiency, stability, reliability, energy conservation, environment friendliness and the like.

Owner:北京天哲消失模铸造技术有限公司

Molding sand for die casting

ActiveCN105312485AReduce health risksImprove reusabilityFoundry mouldsFoundry coresDie castingLost-foam casting

The invention relates to molding sand for die casting. The molding sand is composed of quartz sand, limestone sand, chromium ores, zircon sand and emery. The molding sand is suitable for evaporative pattern casting, not prone to adhesion to sand, settlement shrinkage or earthworm cracking and low in cost, the reusability and collapsibility are good, and hidden dangers to health of workers are reduced.

Owner:广西博白县三田机械制造有限公司

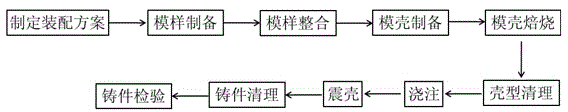

Method for preparing overall shell mold by utilizing vaporizing combustion of mold shell roasting pattern

The invention provides a method for preparing an overall shell mold by utilizing vaporizing combustion of mold shell roasting pattern. The method comprises the following steps: preparing a plastic mold by adopting an injection molding method, splicing and assembling the plastic mold to form an overall pattern, and coating, sanding, drying and hardening the overall pattern, thus obtaining a solid mold shell; roasting the obtained mold shell, wherein the pattern disappears due to vaporizing combustion, thus obtaining an overall shell mold; and finally, cleaning and pouring the obtained shell mold, thus obtaining the casting. The method is high in applicability, the complexity of the cast alloy types and casting structures is not limited, the processes of investment casting and dewaxing are reduced, the production cycle is shortened, and the production efficiency is improved. In the process of manufacturing the shell mold, a phenolic resin is not used as an adhesive, and the problems of pungent smell and subskin blowholes of castings in the process of casting and pouring the shell mold are solved. The pattern disappears before pouring due to roasting and vaporizing combustion of the mold shell, the defects of evaporative pattern casting steel casting recarburization and iron casting wrinkled skin are overcome, and the casting quality is improved.

Owner:沃尔曼科技张家港有限公司

High-strength and high-tenacity excavator bucket tooth and production method thereof

The invention provides a high-strength and high-tenacity excavator bucket tooth. The preparing material of the excavator bucket tooth, namely martensite / austenite multi-phase low-alloy wear-resistant steel, comprises the following components in a percent by mass: 0.25-0.35 of C, 0.4-0.6 of Si, 0.9-1.1 of Mn, 0.85-0.95 of Cr, 0.3-0.4 of Mo, 0.05-0.10 of Cu, 0.10-0.20 of Ni, 0-0.01 of P, 0-0.01 of S and the balance of Fe and unavoidable impurities. The production method comprises the following steps: 1), smelting; 2), adopting evaporative pattern casting molding; 3), after finishing pouring, when a casting is cooled to 840-900DEG C, air-cooling the casting to a room temperature; 4), heating the obtained casting to 840-900DEG C and carrying out austenization; 5), then, placing the casting in a salt bath furnace at a temperature of 230-350DEG C and carrying out quenching; 6), then, rapidly transferring the hot casting into a salt bath furnace at a temperature of 350-450DEG C, and carrying out carbon distribution; and 7), finally quenching the casting to a room temperature by water and obtaining the excavator bucket tooth. The obtained excavator bucket tooth is a martensite / austenite multi-phase low-alloy wear-resistant steel bucket tooth. The surface of the bucket tooth has high hardness and great wear resistance, and the inner structure can ensure great tenacity, so that the excavator bucket tooth, when is shocked, can absorb more shock energy, and the shock resistance is improved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Preparation method for tungsten carbide ceramic/heat-resisting alloy based heat-resisting and wear-resisting composite material

The invention discloses a preparation method for a tungsten carbide ceramic / heat-resisting alloy based heat-resisting and wear-resisting composite material. The preparation method comprises the following steps of: manufacturing a reinforcement body of the tungsten carbide ceramic, welding an iron nail to one end of the reinforcement body of the tungsten carbide ceramic; then plating a metal buffer layer on the surface of the reinforcement body of the tungsten carbide ceramic welded with the iron nail, manufacturing an easily-wearing part model; inserting the prepared tungsten carbide ceramics into the easily-wearing part model, keeping the iron nail outwards, casting and shaping by adopting an evaporative pattern casting process, taking out the casting piece and cutting off the iron nail; polishing the working surface by a diamond sand wheel flatly, performing heat treatment on the work piece. The reinforcement phase of the composite material is uniform in distribution, large in controllable range of volume percent, small in interface residual stress, small in hot influence zone and good in combination; the composite material tungsten carbide ceramic with the thickness of 10-15 mm are located at the surface layer of the working surface of the easily-wearing part and can be used for manufacturing the room-temperature or high-temperature heat-resisting and wear-resisting easily-wearing part in mine, building, metallurgy, electricity and other fields.

Owner:泰州市永昌冶金科技有限公司

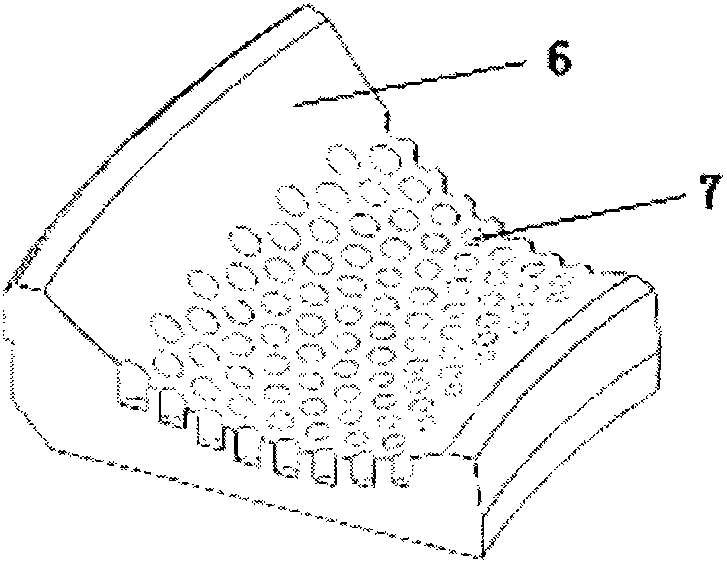

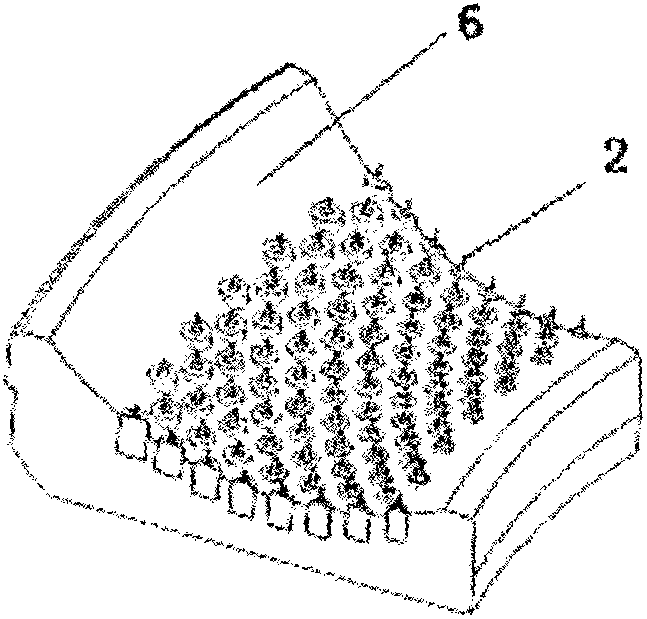

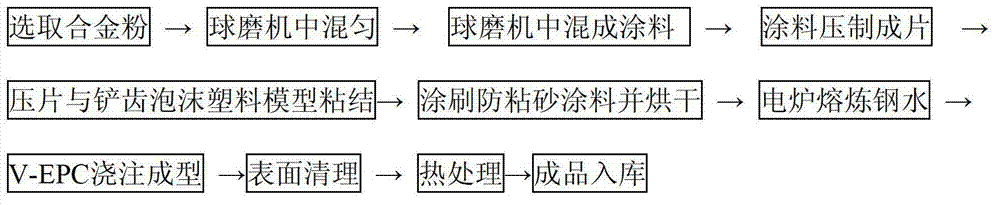

Method for preparing TiC+Al2O3 particle-reinforced steel-based surface-recombined excavator form-relieved tooth

InactiveCN102921923AImprove wear resistanceExtended service lifeFoundry mouldsFoundry coresElectric arc furnaceExpanded polystyrene

The invention relates to a method for preparing a TiC+Al2O3 particle-reinforced steel-based surface-recombined excavator form-relieved tooth. The method disclosed by the invention comprises the following steps: preparing an alloy powder coating by using titanium dioxide, iron scale powder, aluminium powder, ferrotitanium powder, carbon powder and an organic binder; pressing the alloy powder coating into pieces, and adhering the pieces to two working tooth surfaces of a foamed plastic EPS (expanded polystyrene) model of the excavator form-relieved tooth; then, preparing an EPS appearance of the form-relieved tooth through externally coating an anti-sticking sand coating and drying; and smelting molten steel in a medium-frequency induction furnace or an electric-arc furnace, and carrying out casting moulding by using a V-EPC vacuum evaporative pattern casting method. Through testing, in the prepared particle-reinforced steel-based surface-recombined excavator form-relieved tooth, a composite layer and a steel substrate form a metallurgical combination state; the composite layer is dense in organization, and the thickness of the composite layer can reach more than 3 mm; the surface hardness HRC of the composite layer can be greater than or equal to 53; and compared with similar excavator form-relieved teeth which are not subjected to surface composition, the service life of the excavator form-relieved tooth can be prolonged by 2-3 times.

Owner:JIANGSU UNIV

Method for preventing evaporative pattern casting blind hole crush

InactiveCN101628321APrevent collapsePlay a supporting roleFoundry mouldsFoundry coresDry sandPlastic film

The invention discloses a method for preventing evaporative pattern casting blind hole crush, which comprises steps of: putting dry sand of a sand box which is compacted into an evaporative pattern mould of a blind hole, horizontally putting a member into the evaporative pattern mould with horizontal blind holes and inclined blind holes and near to the lower part; adding dry sand to an extraction end member and compacting dry sand; putting a layer of dry sand in the mould with vertical blind holes, simultaneously putting an I-shaped member, and then adding and compacting dry sand till the whole evaporative pattern blind holes is externally and internally filled with dry sand; leaving a white foam straight pouring gate between the evaporative pattern mould and the top surface of the dry sand; sealing the top of the dry sand of the sand box with a plastic film, laying a water pouring cup, opening a vacuum pump to cause the negative value to reach technology required value and casting, finally obtaining formed blind hole casting. The practical problem of the evaporative pattern casting blind hole crush is completely solved by putting the member or the I-shaped member with supporting or hanging type sand function into the evaporative pattern casting blind hole. The method is suitable for blind hole casting processing of deeper large-scale members.

Owner:HEBEI HAIYUE WEAR RESISTANT MATERIAL TECH

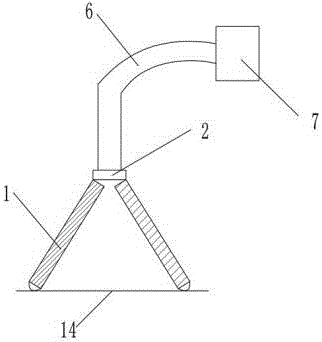

Process for induction heating gasification expanded polystyrene (EPS) evaporative pattern casting

ActiveCN102764853AImprove inner qualityImprove pressure resistanceFoundry mouldsFoundry coresVacuum pumpingExpanded polystyrene

The invention discloses a process for an induction heating gasification expanded polystyrene (EPS) evaporative pattern casting and relates to the technical field of evaporative pattern casting. The process comprises steps of 1) producing a model, wherein the model comprises a casting head system and a casting model; 2) placing the model in a sand box and performing sand-filling and molding; 3) performing vacuum-pumping; 4) casting; and 5) cooling and taking out a casting. The modification includes that the step 2 comprises that an embedded cold iron ring and an induction coil are arranged on the periphery of a casting model of the model, and the induction coil is connected with a copper pipe electrode which is arranged on the side wall of the sand box; and an induction heating gasification casting model process is added between the step 3 in which the vacuum-pumping is performed and the step 4 in which the casting is performed, i.e., the induction oil is energized, the embedded cold iron ring is heated by the induction coil, and the casting model around cold iron is gasified. The process has the advantages that the induction heating embedded cold iron ring is used for gasifying the casting model, a die cavity is formed in the casting model, metal liquid is casted, the quantity and positions of EPS module residues are controlled, and the internal quality and pressure-resistant performance of the casting are improved.

Owner:HANDAN HUIQIAO COMPOSITE MATERIAL TECH CO LTD

High-strength and high-tenacity low-alloy wear-resistant steel excavator bucket tooth and preparing method thereof

ActiveCN105568142APromote formationHigh surface hardnessSoil-shifting machines/dredgersWear resistantAlloy

The invention provides a high-strength and high-tenacity low-alloy wear-resistant steel excavator bucket tooth and a preparing method thereof. The preparing material of the excavator bucket tooth, namely austenite / martensite multi-phase low-alloy wear-resistant steel, consists of the following components in a percent by mass: 0.40-0.60 of C, 0.6-1.2 of Si, 0.8-1.2 of Mn, 0.25-0.35 of Cr, 0.30-0.50 of Mo, 0.40-0.60 of Cu, 0.2-0.3 of Re, 0-0.01 of P, 0-0.01 of S and the balance of Fe and unavoidable impurities. The preparing method comprises the following steps: 1), smelting; 2), adopting evaporative pattern casting molding; 3), after finishing pouring, when a casting is cooled to 800-900DEG C, air-cooling the casting to a room temperature; 4), heating the obtained casting to 820-860DEG C and carrying out austenization; 5), carrying out quenching; 6), taking out the casting after the surface of the casting is cooled to 200-320DEG C; and 7), immediately transferring the hot casting into a 260-330DEG C heat holding furnace, carrying out bainite isothermal transformation, and then taking out and air-cooling the casting. The surface of the obtained excavator bucket tooth has high hardness and great wear resistance, and the inner structure can ensure great tenacity, so that the excavator bucket tooth, when is shocked, can absorb more shock energy, and the shock resistance is improved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

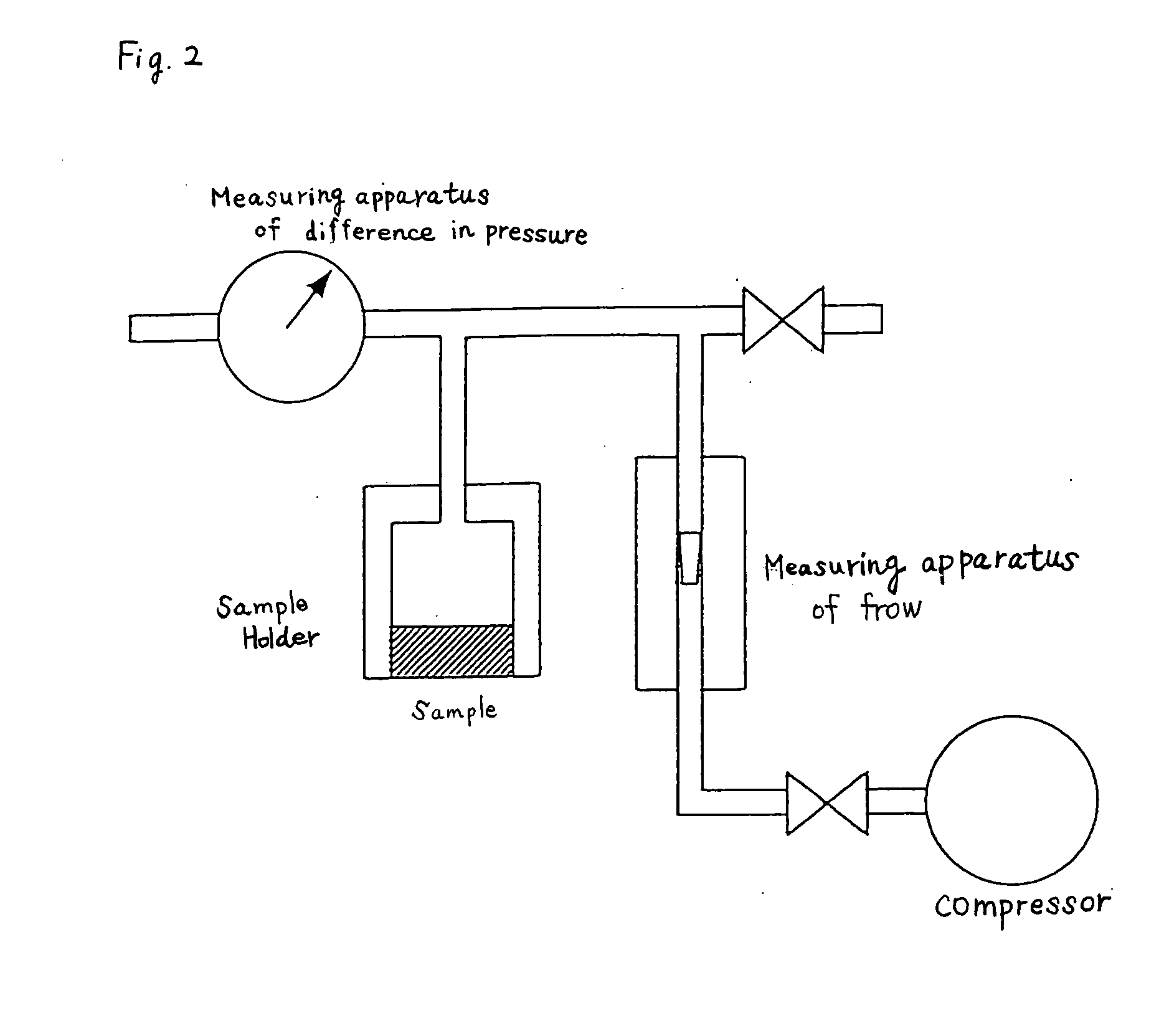

Sublimation pattern casting method

Provided is an evaporative pattern casting process wherein a casting process plan capable of attaining the optimal discharge of generated gas can easily be decided. The present invention is an evaporative pattern casting process for casting a product, which comprises pouring a molten metal in a mold in which a pattern made of an expanded synthetic resin is embedded in molding sand, and evaporating the pattern with the molten metal, while gas generated by evaporation of the pattern is discharged outside the mold through a discharging passage comprising a discharged gas suppressing means, wherein the ventilation of the discharging passage is controlled on the basis of the material and the shape of the pattern and the kind of the molten metal and the temperature of the molten metal.

Owner:KAO CORP

Evaporative pattern casting process preventing deformation

InactiveCN105364010AReduce labor intensityReduce consumptionFoundry mouldsFoundry coresModel compositionAdhesion process

The invention discloses an evaporative pattern casting process preventing deformation. The evaporative pattern casting process comprises the steps of 1, selecting plastic foam beads; 2, manufacturing models; 3, combining the models for cluster formation; 4, carrying out vibration molding; 5, carrying out casting forming; 6, taking out castings. According to the evaporative pattern casting process, the phenomenon that in the casting process of the evaporative pattern castings, because gaps are generated in the adhesion process of a plurality of mold sheets, the castings are deformed in the pouring process can be effectively avoided, deformation can be effectively prevented, and the qualification rate of products can be increased.

Owner:YIBIN JIUDING PRECISION CASTING CO LTD

Sublimation pattern casting method

Provided is an evaporative pattern casting process which ensures that smooth casting can be carried out without blow-back of a molten metal and a molding product having an excellent casting quality is obtained. The invention relates to an evaporative pattern casting process for casting a product, which comprises pouring a molten metal into a mold provided with a pattern with a through-hole, embedded in molding sand, and evaporating the pattern with the poured molten metal, gradually exhausting the gas generated by the evaporation of the pattern to the outside of the mold through an exhausting path provided with an exhaust gas-controlling means.

Owner:KAO CORP

Casting method for preventing shrinkage porosity at thick large wall of casting

ActiveCN108273963ASolve looseSolve the shrinkage cavityFoundry mouldsFoundry coresPorosityThick wall

The invention provides a casting method for preventing shrinkage porosity at a thick large wall of a casting. The casting method comprises the steps that an evaporative pattern casting technology is adopted, a vacuum negative pressure molding method is adopted in the molding procedure, before an evaporative pattern is subjected to vacuum negative pressure molding, a chiller made from a light chillmaterial is placed in a corresponding position of the evaporative pattern according to the requirement of the casting technology, and the chiller and the evaporative pattern are bonded together. According to the casting method, the problems that the chiller utilized in a conventional molding method cannot be fixed and is liable to move during the molding compaction process, feeding cannot be carried out on the thick large wall of the casting, the chiller utilized in the conventional molding method is relatively heavy, and the pattern is liable to damage and deform are solved, the casting method for preventing shrinkage porosity at the thick large wall of the casting is provided, technological methods of adopting the light chill material and assembling the chiller in advance are adopted, and porosity and shrinkage cavity problems of the thick wall during the casting process are effectively solved.

Owner:KOCEL EQUIP

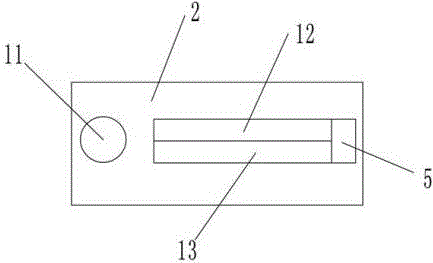

Automatic plastic film cutting device

ActiveCN106695923AAvoid enteringRealize automatic cutting workMetal working apparatusPlastic filmLost-foam casting

The invention belongs to the field of evaporative pattern casting machines, and concretely discloses an automatic plastic film cutting device, which comprises a cutting knife and a plurality of baffle plates. A covering plate is sealed on the baffle plates; a knife slot is formed in the covering plate; a first flexible plate and a second flexible plate which are opposite are horizontally arranged on the knife slot; an air suction pipe is arranged at one end of the covering plate; a sucking pump is arranged on the air suction pipe; an electromagnet is fixedly arranged at the other end of the covering plate; a magnet is arranged on a knife handle; supports are arranged at two sides of the covering plate; air cylinders are arranged under the supports, and are provided with piston rods; and the piston rods are connected with the supports. The invention provides the automatic plastic film cutting device capable of continuously automatic cutting plastic films.

Owner:CHONGQING RUITING PLASTIC

Preparation method of steel base surface composite

The invention relates to a preparation method of a steel base surface composite. The WC / high chrome steel base surface composite is prepared by vacuum-evaporative pattern casting (V-EPC).

Owner:QINGDAO GAOXIAO HEAVY IND MACHINERY MFG

Production method for preventing evaporative pattern casting deformation

ActiveCN103506576AReduce distortionHigh dimensional accuracyMoulding toolsFoundry mouldsMaterials scienceEvaporative-pattern casting

The invention relates to an evaporative pattern casting method and in particular relates to a production method for preventing evaporative pattern casting deformation. The production method is characterized by comprising the following steps: designing a tie bar, adhering, modeling, smelting and casting, and mold dismantling. The method is unique, the product yield is improved, the production cost is reduced, iron liquid filling is not influenced, and the casting quality is guaranteed.

Owner:KOCEL EQUIP

Evaporative pattern casting process

ActiveUS20120273151A1Accurate settingQuality improvementFoundry mouldsFoundry coresMetallurgyMaterials science

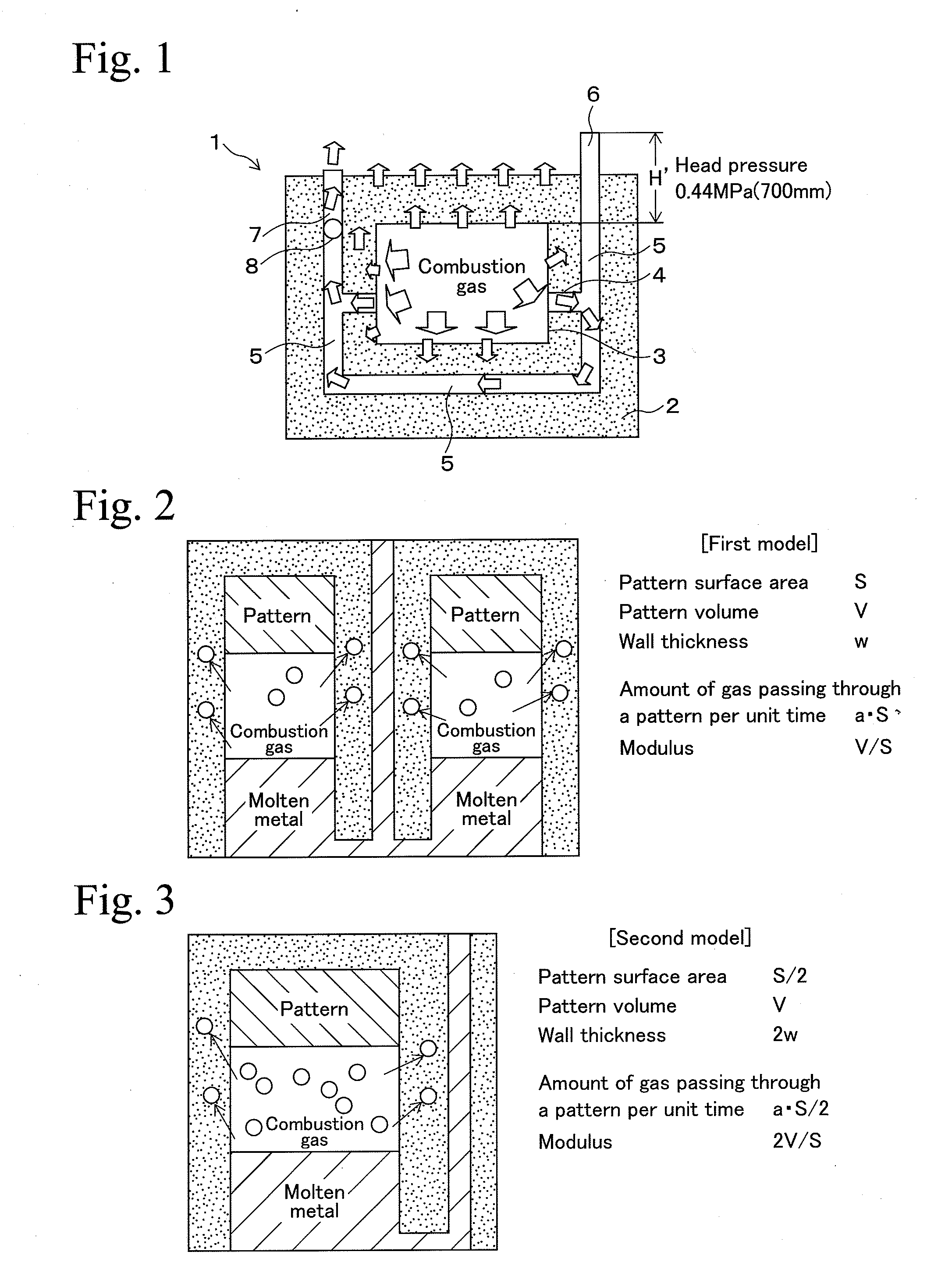

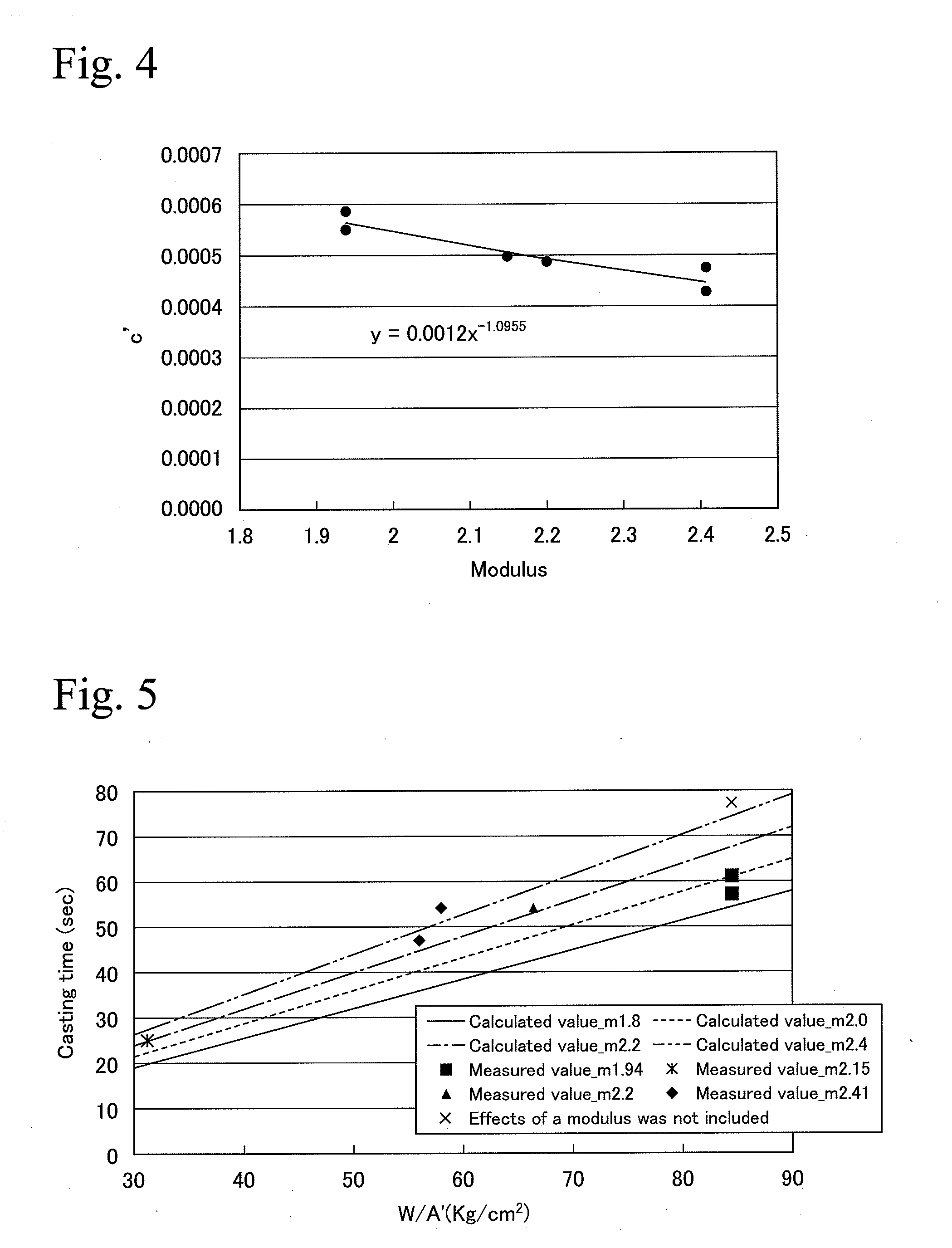

An evaporative pattern casting process includes forming a mold by burying a pattern made of resin foam in casting sand, pouring molten metal into the mold, and evaporating the pattern with the molten metal and thereby casting a product. In the evaporative pattern casting process, casting time during founding is set according to a modulus (pattern volume÷pattern surface area) of the pattern. Accordingly, the casting time in the evaporative pattern casting process is accurately set with high precision.

Owner:HONDA MOTOR CO LTD

Carbon-nanofiber-enhanced light low-carbon-residue water-based paint for evaporative-pattern casting and manufacturing method thereof

InactiveCN105522103AImprove breathabilityImprove high temperature stabilityFoundry mouldsFoundry coresWater basedCarbon fibers

The invention relates to the technical field of evaporative-pattern casting, in particular to a nano-calcium-carbonate-enhanced low-carbon-residue water-based paint for evaporative-pattern casting and a manufacturing method thereof. According to the water-based paint, high-aluminum fine powder, magnesia and brown corundum powder which are different in particle sizes are mixed to serve as a refractory aggregate, so that the water-based paint has good air permeability and high-temperature stability; a mixed suspending agent prepared from nano calcium carbonate, sodium carboxymethylcellulose and other materials can be well mixed with inorganic powder and resin emulsion, so that the fluidity and coating property of the paint are improved effectively, and dimensional stability to heating is enhanced and improved; added nano ceria has oxygen storage capacity, and oxygen can be released in the casting process, so that the oxidative combustion efficiency of plastic is improved, and carbon residues are reduced. Moreover, a coating layer produced from the manufactured paint is stable in performance when heated, not prone to collapsing and breaking, compact and breathable and capable of being stripped off and removed easily; and the number of impurities on the surfaces of manufactured castings is smaller, and quality of the manufactured castings is better.

Owner:MINGGUANG CITY LIUXIANG PUMP IND

Evaporative pattern casting process for fuel oil engine cylinder cover

InactiveCN104550721AIncrease profitOvercome the problems of many processes and heavy workloadFoundry mouldsFoundry coresEnvironmental resistanceFuel oil

The invention discloses an evaporative pattern casting process for a fuel oil engine cylinder cover. The evaporative pattern casting process comprises the following steps: a mould is manufactured by dividing a real object into multiple mould slices; an evaporative pattern casting raw material is injected into the mould to obtain an evaporative pattern casting slice similar to the real object; the mould slice is dipped with an evaporative pattern casting coating, then placed in a casting sand box, vibrated and poured so as to fuse the evaporative pattern casting slice into carbonic oxide and carbon dioxide both which are discharged to obtain a real object mould; the process can be used for overcoming the problem that an existing diesel engine and gasoline engine cylinder cover molding sand casting process is great in labor intensity, large in raw material consumption, heavy in casting weight, serious in environmental pollution, weak in redundancy degree and large in mechanical processing, and thus the evaporative pattern casting process is environmentally-friendly, the raw material is saved, the labor intensity is reduced and the performance is improved.

Owner:QINGDAO HEDELONG MACHINERY

Grapheme-oxide-contained reinforced water-based paint which can form a film easily and used for evaporative pattern casting and preparation method for grapheme-oxide-contained reinforced water-based paint

InactiveCN105057575AImprove breathabilityGood film formingFoundry mouldsFoundry coresWater basedSuspending Agents

The invention relates to the technical field of evaporative pattern casting, in particular to grapheme-oxide-contained reinforced water-based paint which can form a film easily and is used for evaporative pattern casting and a preparation method for the grapheme-oxide-contained reinforced water-based paint. According to the paint, high-alumina bauxite and quartz sand with different particle diameters serve as refractory aggregates, so that the breathability of a coating is improved. The mixed slurry of nanometer attapulgite and sodium carboxymethylcellulose serves as efficient composite suspending agents. Added grapheme oxide can be well dispersed in a solution, so that the film-forming property of the paint on the surface of a plastic pattern is improved. After carnauba wax is dispersed in the coating, the flatness of the surface of the coating is improved, and the sand prevention viscosity is improved. Besides, the carnauba wax can be melted rapidly during casting, so that the breathability of the coating is improved further. The prepared paint is easy to smear and adhere and high in utilization rate. The formed film is firm and tenacious. The dried coating is compact, breathable, good in mechanical property, not prone to sticking to sand and easy to strip after casting, does not pollute molten metal, and effectively improves the quality of a casting.

Owner:MINGGUANG CITY LIUXIANG PUMP IND

Die casting method

The invention relates to a die casting method. The die casting method includes the following steps that (1) a foam board is machined into a foam model; (2) the surface of the foam model is coated with a refractory material; (3) the foam model coated with the refractory material is dried; (4) the foam model treated in the step (3) is buried in molding sand for vibration molding; (5) liquid metal is poured under negative pressure so as to gasify the foam model; and (6) after the poured model in the step (5) is cooled, a cast part in a sand box is separated from dry sand, and the die cast part is obtained. The molding sand in the step (4) is composed of the following raw materials of quartz sand, limestone sand, chromium ores, zircon sand and emery. The die casting method is suitable for evaporative pattern casting, not prone to adhesion to sand, settlement shrinkage or earthworm cracking, low in cost and capable of reducing hidden dangers to health of workers, and the reusability and collapsibility are good.

Owner:广西博白县三田机械制造有限公司

High manganese steel sieve plate for crusher and preparation method of sieve plate

InactiveCN104988431AHigh strengthImprove wear resistanceFoundry mouldsFoundry coresSlagChemical element

The invention discloses a high manganese steel sieve plate for a crusher and a preparation method of the sieve plate. The sieve plate comprises a base plate, wherein a plurality of sieve holes are formed in the base plate; the base plate is made from high manganese steel; the high manganese steel comprises chemical element components in percentage by mass as follows: 1.25-1.45 % of C, 13.5-15.0 % of Mn, 2.5-3.5 % of Cr, 1.2-2.5 % of Si, 0.15-0.35 % of Mo, 0.35-0.55 % of B, 0.15-0.25 % of Ti, no more than 0.05 % of S, no more than 0.05 % of P and the balance of Fe. The preparation method comprises the steps of evaporative pattern preparation, modeling, smelting, slag removing, modification treatment, pouring, sand removing, water-toughening and the like. Compared with the prior art, the high manganese steel sieve plate for the crusher is manufactured by adopting high manganese steel with an evaporative pattern casting method; and the manufactured sieve plate has the advantages of excellent wear resistance, high strength, long service life, low cost and the like.

Owner:芜湖银海机械制造有限公司

Vanadium iron slag-thermal power plant coal ash evaporative pattern casting coating and preparation method thereof

InactiveCN105057578AReduce manufacturing costImprove adhesionFoundry mouldsFoundry coresIsobutanolSlag

Provided are a vanadium iron slag-thermal power plant coal ash evaporative pattern casting coating and a preparation method thereof. The vanadium iron slag-thermal power plant coal ash evaporative pattern casting coating comprises vanadium iron slag, thermal power plant coal ash, magnesia, diatomite, silicon carbide, high-bauxite fine powder, brucite, tantalum carbide, aluminum nitride, boron nitride, gamma-methacryloxy propyl trimethoxyl silane, tetra-octyl di (phosphate di-butyl laurate) titanate, isobutanol etherified melamine methyl ether resin, dicumyl peroxide, Fatty alcohol polyoxyethylene ether, vac-veova emulsion, carbon fiber, dextrin, sodium alginate, pentaerythritol, sodium benzoate, ethanol and water. The prepared vanadium iron slag-thermal power plant coal ash evaporative pattern casting coating has excellent use performance and is low in production cost, and the purposes of comprehensively recycling the vanadium iron slag and the thermal power plant coal ash and reducing production cost are achieved.

Owner:张燕

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com