Lost pattern casting method

一种消失模铸造、模型的技术,应用在铸造成型设备、铸型、铸型成分等方向,能够解决恶化环境、砂型强度不足、铸件铸造缺陷等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

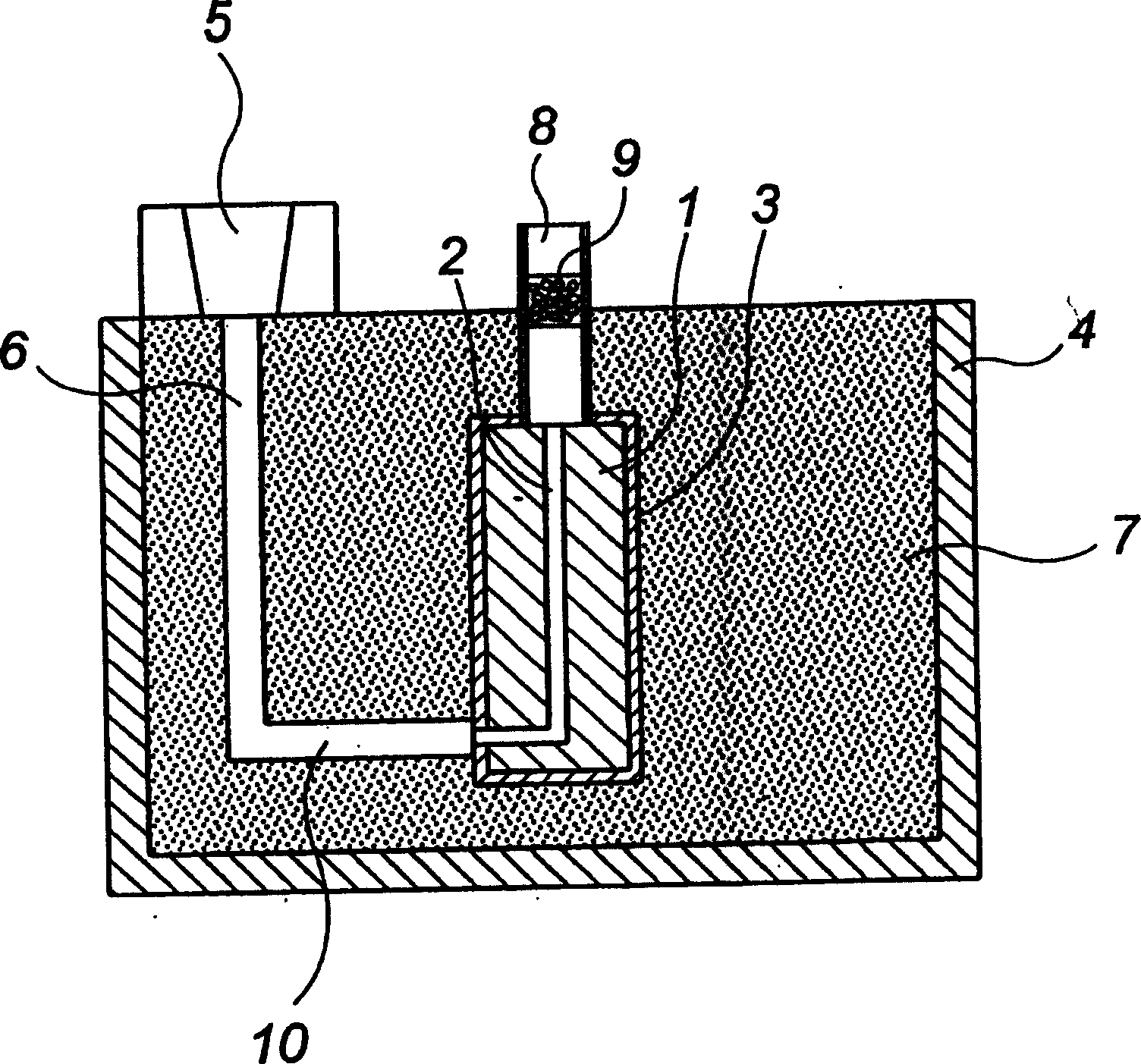

[0077] like figure 1 as shown (however, sample 3 as Figure 9 shown), install the Figure 4~6 The foam models shown (all made of styrofoam) were subjected to lost pattern casting. Below, will Figure 4 The member of the sample is used as sample 1, and the Figure 5 The member of the sample is used as sample 2, and the Image 6 The component is used as sample 3.

[0078] In sample 2, the size of the hollow portion 51, in Figure 5 The x-direction is 100 mm, the y-direction is 60 mm, and the z-direction is 155 mm, and the dimensions of the protrusion 52 are 50 mm in the x-direction, 20 mm in the y-direction, and 20 mm in the z-direction.

[0079] In addition, in Sample 3, the dimensions of the cavities 1 and 3 are 200 mm in width × 130 mm in length and 275 mm in depth, and the dimensions of cavity 2 are 200 mm in width × 140 mm in length and 275 mm in depth (thickness of the outer frame and the division part is 25 mm). ).

[0080] Figure 7 The form of the through hole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com