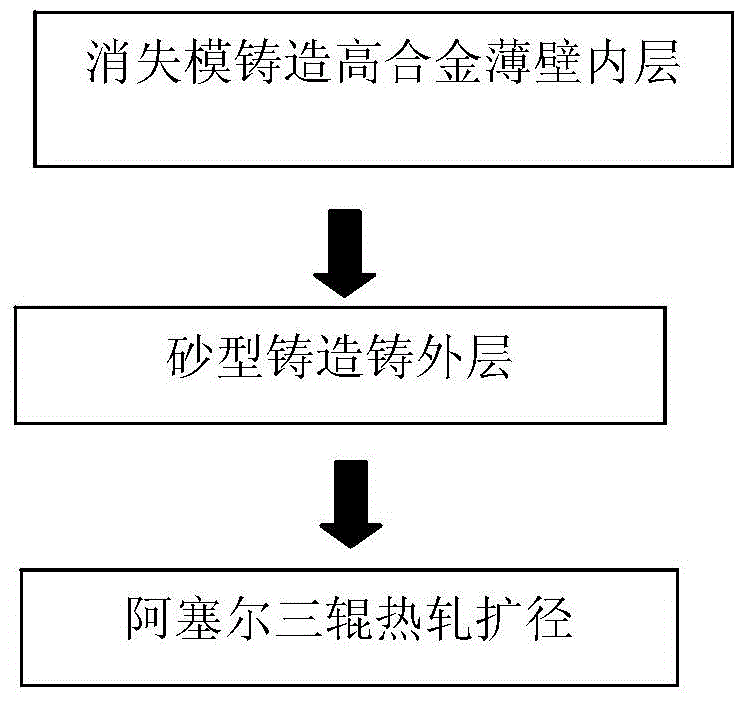

Method for preparing composite pipe by expanding secondary pouring dual-metal pipe billets

A technology of bimetallic composite pipe and bimetallic pipe, which is applied in the direction of metal rolling, metal processing equipment, manufacturing tools, etc., to achieve the effects of smooth transition of connection components, simple production process, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

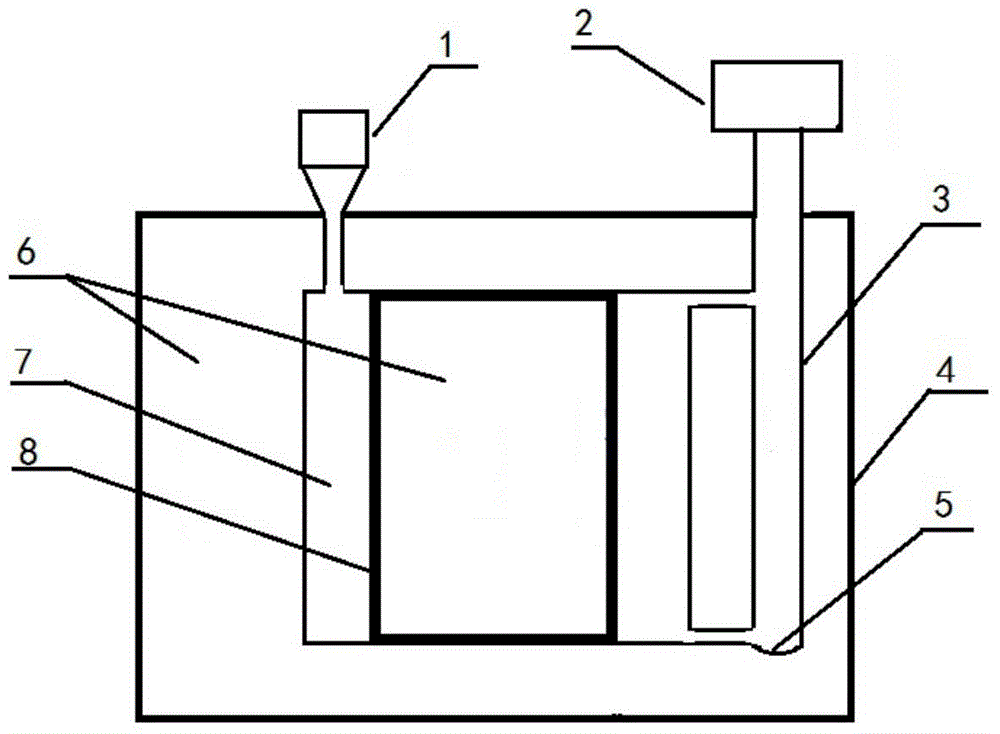

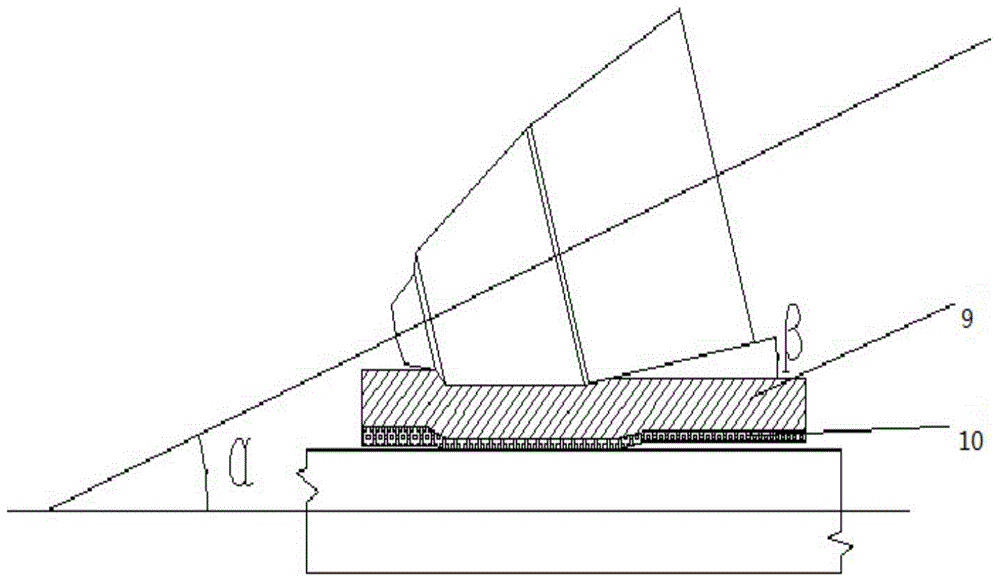

[0024] See attached figure 1 And attached figure 2 , (1) Select EPS beads with a diameter of 0.5mm, and use an intermittent steam pre-generator to prepare a thin-walled model with a density of 0.02-0.025g / cm3 at 150°C. The model size is Φ170×5mm, and the water-based paint is repeatedly coated After drying, silica sand is selected as the raw material to vibrate in the sand box 4, and high-frequency induction furnace is used to smelt high-alloy steel 12Cr. 1600°C, pouring under a negative pressure of 0.05MPa, the pouring speed is controlled at about 6kg / s, at the beginning of slow pouring, after the sprue 3 passes through, a large amount of fast pouring is performed immediately, and then slow down when the cavity 7 is about to be filled Pouring speed, after sand cleaning, a thin-walled high-alloy 12Cr tube blank is obtained, the tube blank diameter is 170mm, and the wall thickness is 5mm;

[0025] (2) Take the thin-walled high-alloy 12Cr tube billet as the core 8, adopt the m...

Embodiment 2

[0028] See attached figure 1 And attached figure 2 , (1) Select EPS beads with a diameter of 0.5mm, and use a batch steam pre-generator to prepare a thin-walled model with a density of 0.02-0.025g / cm3 at 150°C. The model size is Φ154×9mm, and the water-based paint is repeatedly coated After drying, silica sand is used as raw material to vibrate in sand, 4, and high-frequency induction furnace is used to smelt high-alloy steel 12Cr. The billet lost foam casting adopts a one-cast-one-shot pouring system, and the pouring temperature is 1600°C, pouring under a negative pressure of 0.05MPa, the pouring speed is controlled at about 6kg / s, at the beginning of slow pouring, after the sprue 3 passes through, a large amount of fast pouring is performed immediately, and then slow down when the cavity 7 is about to be filled Pouring speed, after sand cleaning, a thin-walled high-alloy 12Cr tube blank is obtained, the tube blank diameter is 154mm, and the wall thickness is 9mm;

[0029]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com