Patents

Literature

40 results about "Longitudinal splitting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

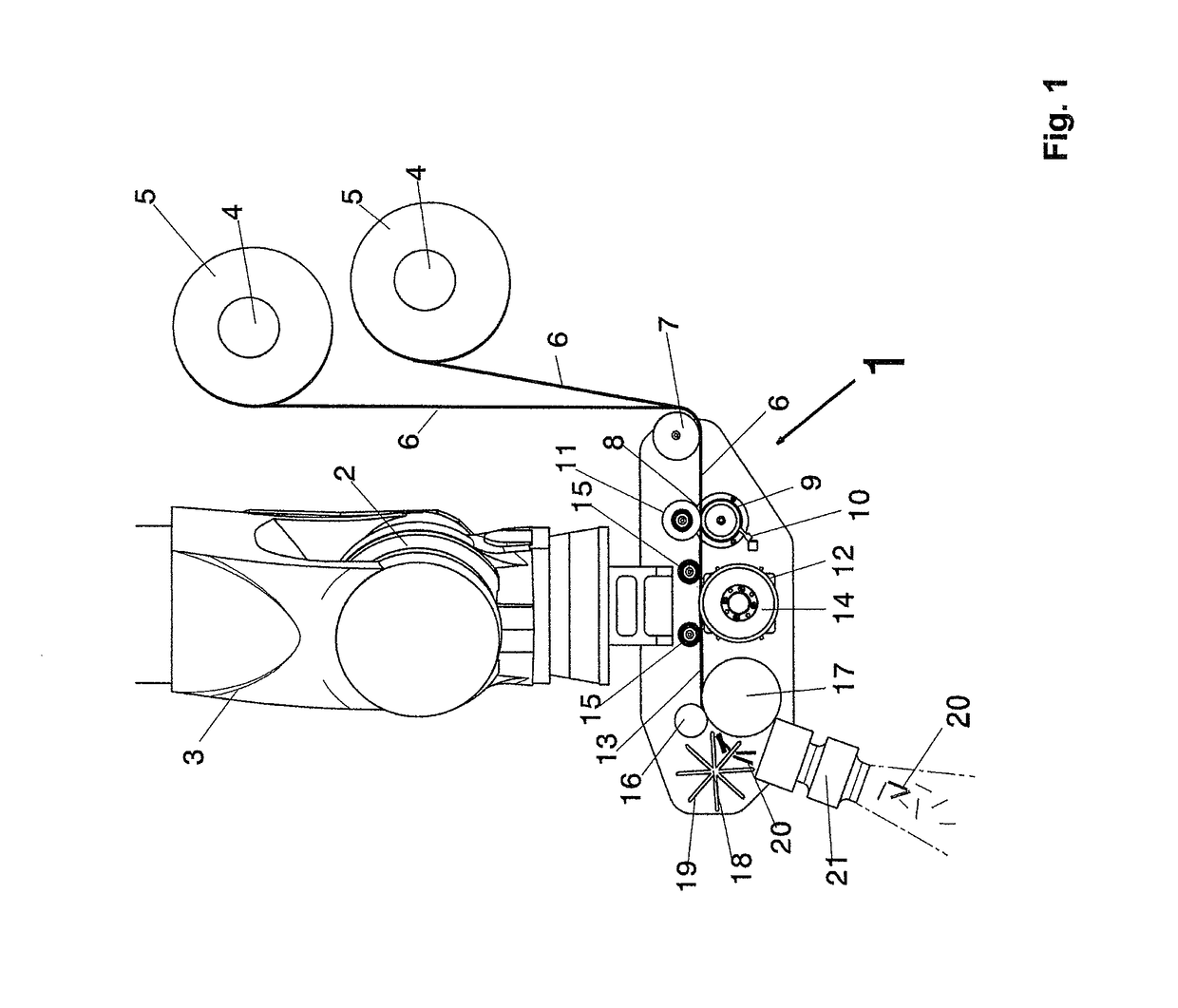

Method and Assembly for Confocal, Chromatic, Interferometric and Spectroscopic Scanning of Optical, Multi-Layer Data Memories

InactiveUS20080151253A1Reliable read-outHighly stable over the long termRadiation pyrometryInterferometric spectrometryFiberDiffraction order

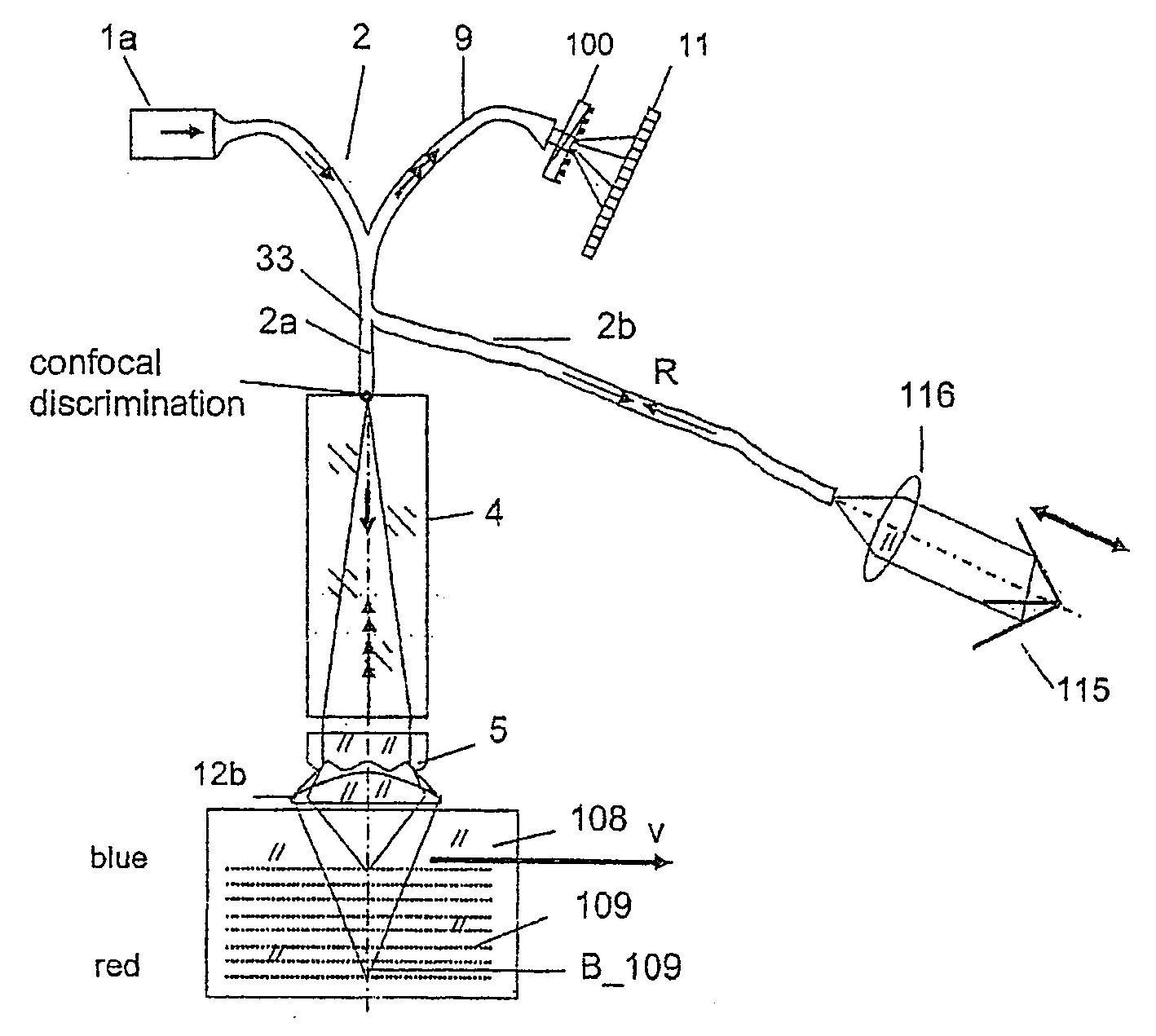

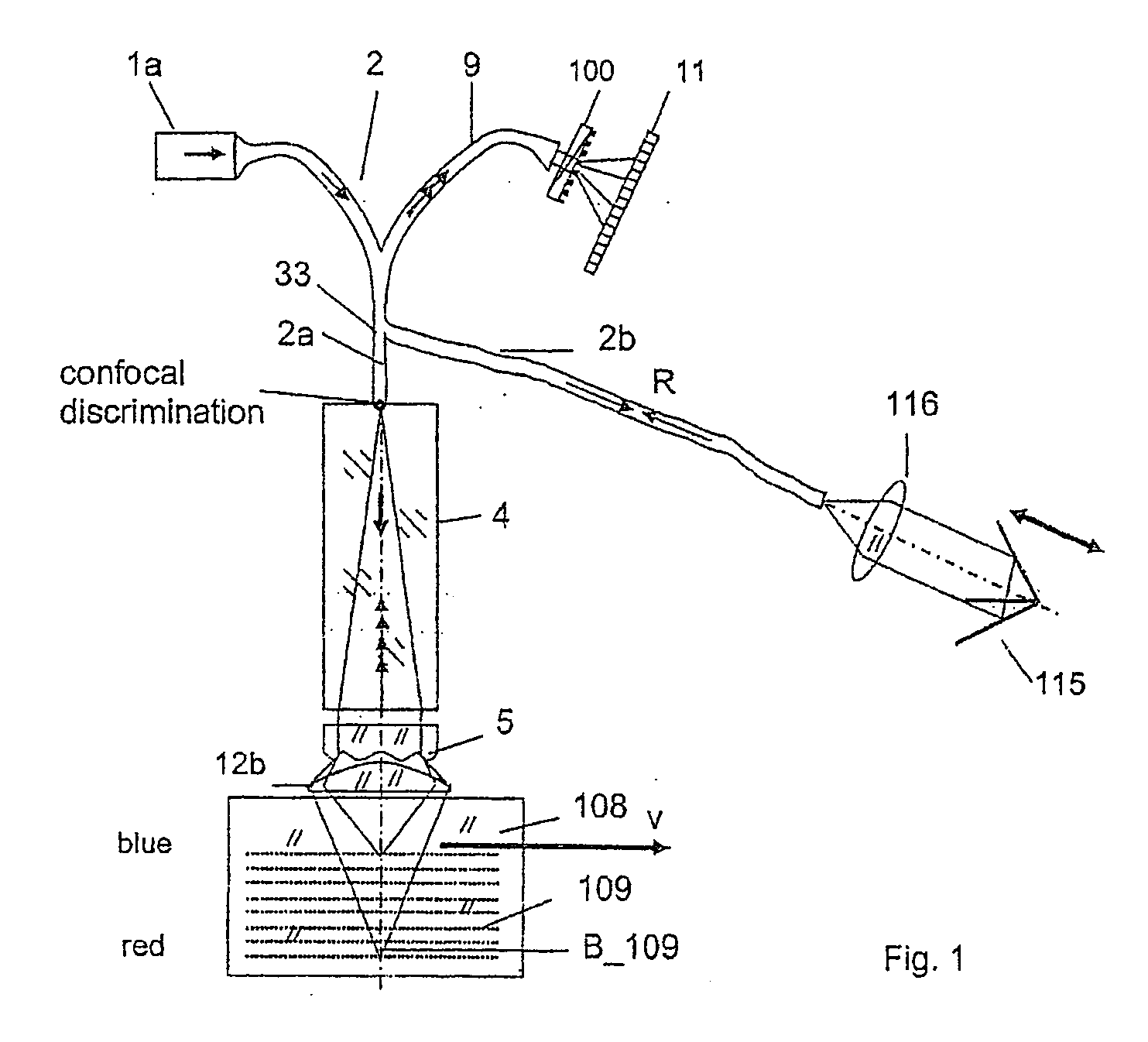

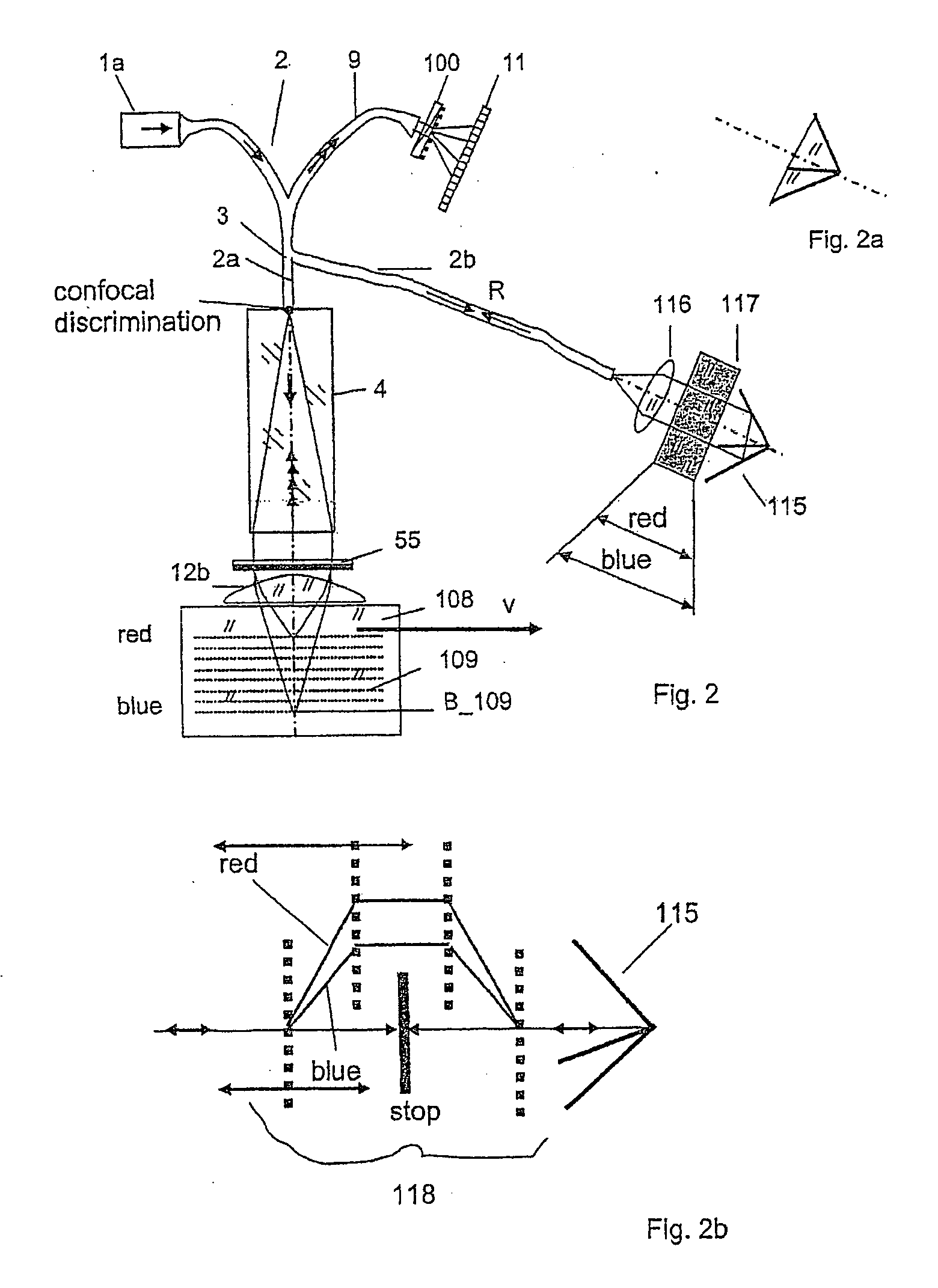

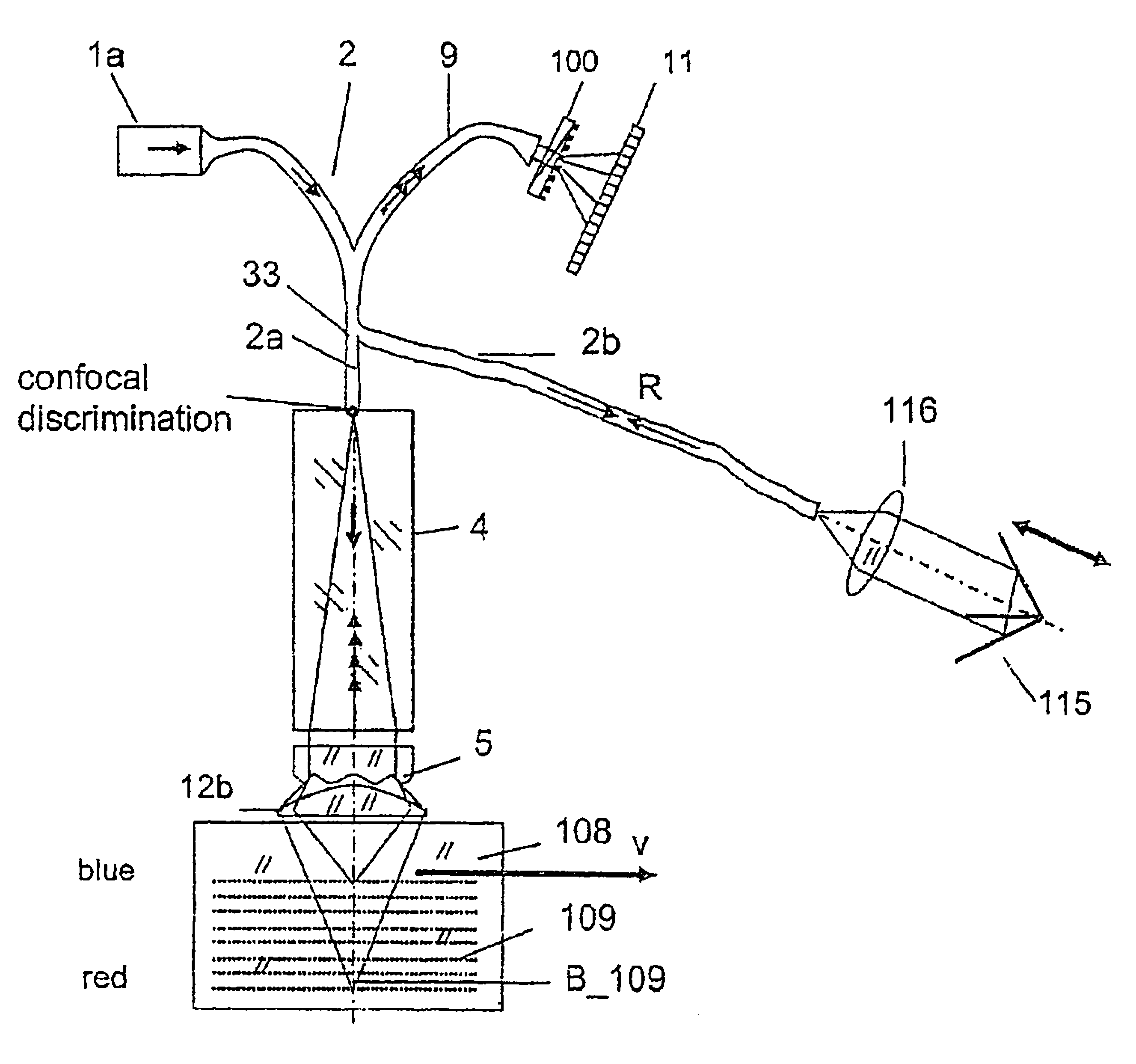

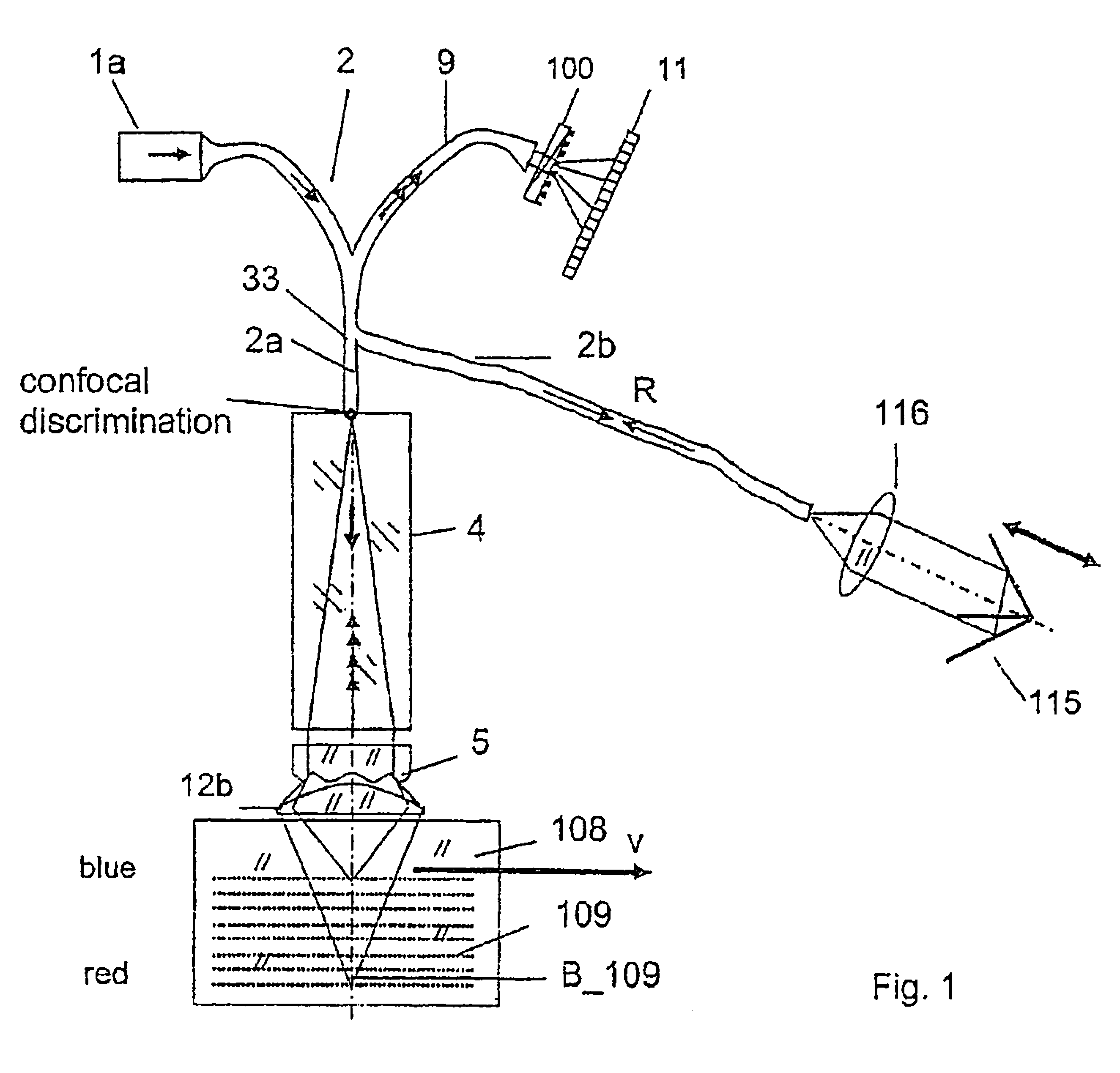

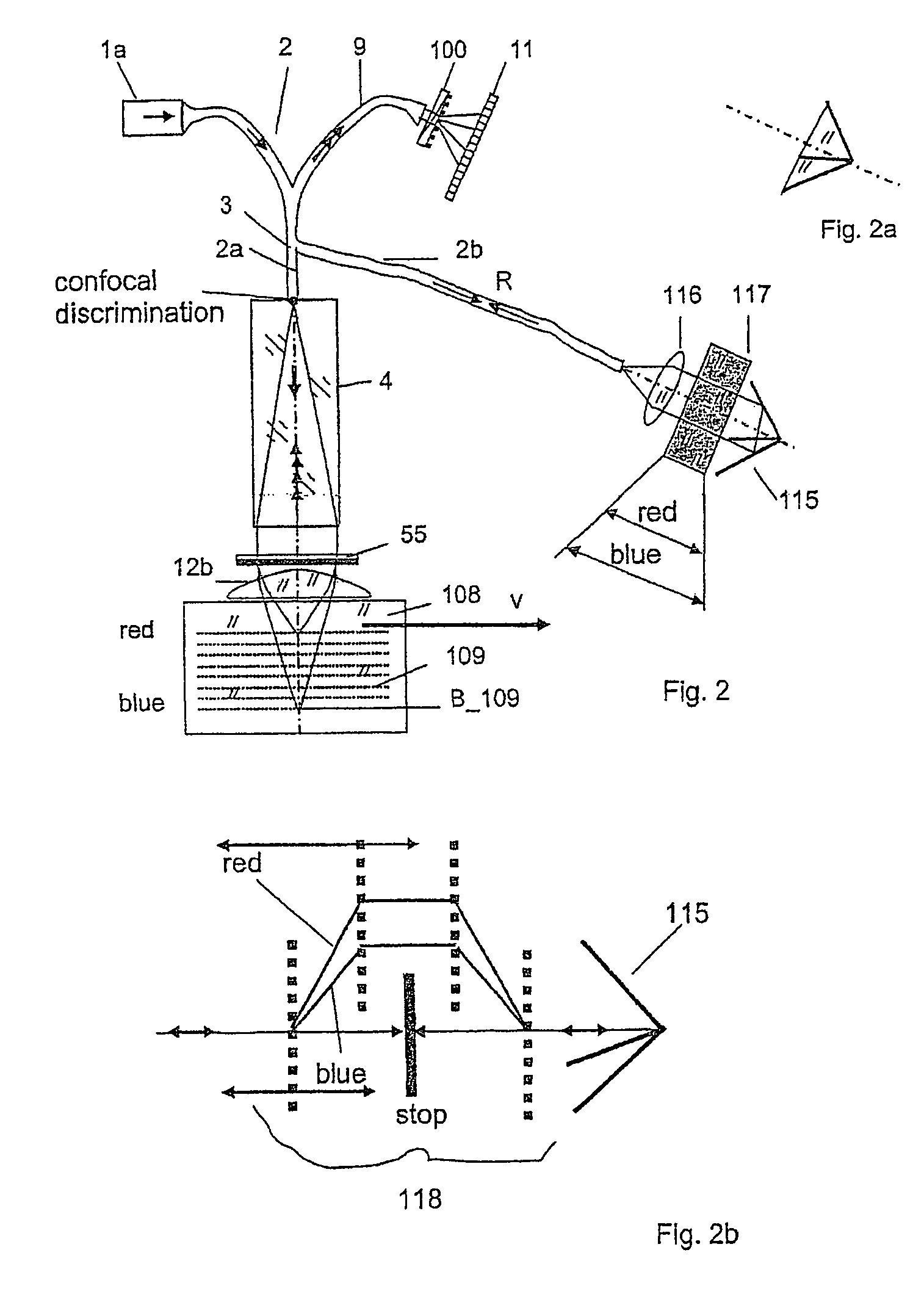

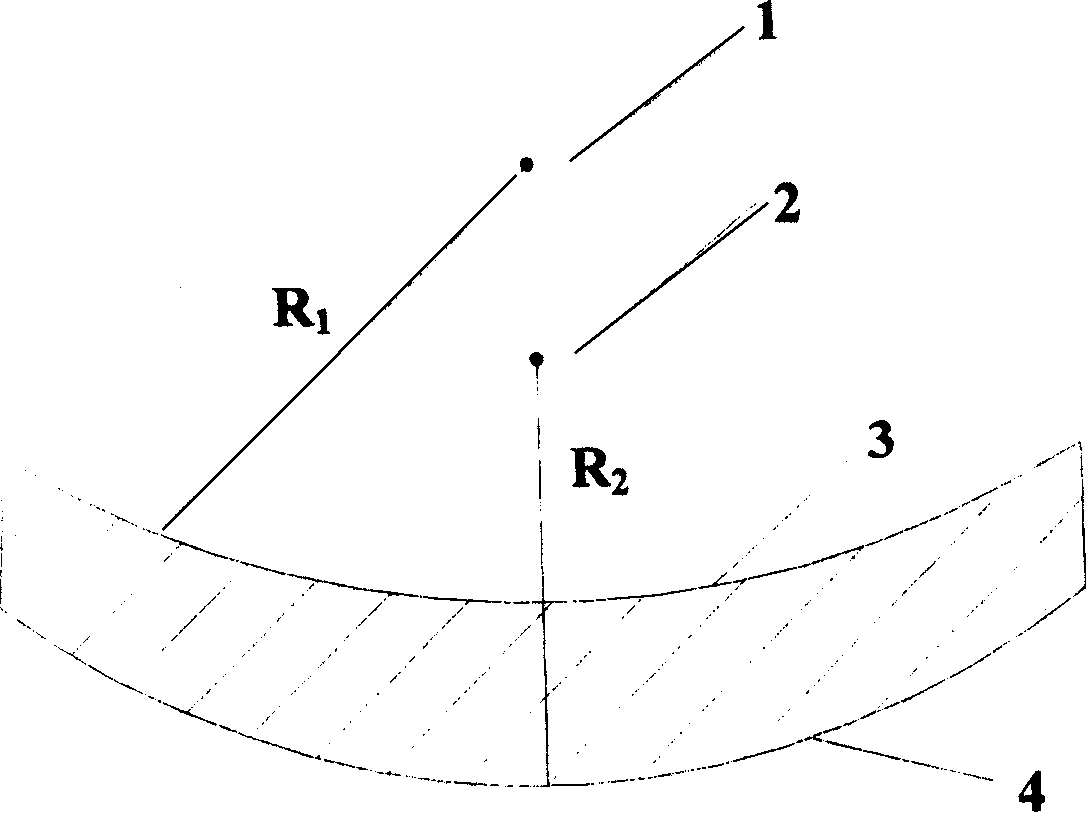

An interferometric confocal method and assembly for terabyte volume optical data memories couples two-beam spectral interferometry to chromatic confocal technology and permits a longitudinal splitting of foci in the memory volume, with the foci having limited diffraction. A spectrometer is located downstream of the interferometer with confocal discrimination in the beam path. A diffractive optical zone lens (DOZE) with a usage of the first diffraction order is introduced into the interferometric beam path to achieve longitudinal chromatic splitting. The interferometer can be a fibre-coupled interferometer with a retroreflector in the fibre-coupled reference arm and with wavelength-dependent optical path difference modification by dispersion or diffraction. The optical path difference in the interferometer is set so that easily detectable wavelets are formed from detectable interferograms by spectral analysis.

Owner:UNIV STUTTGART

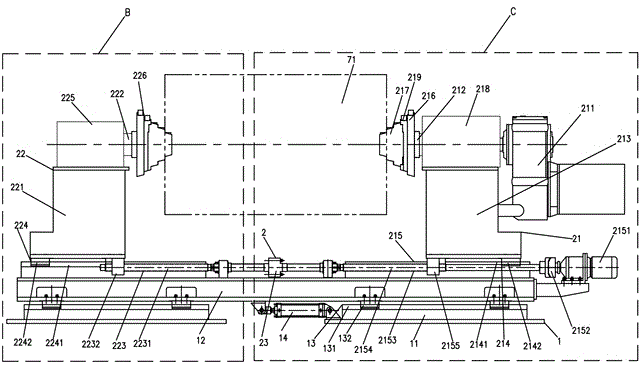

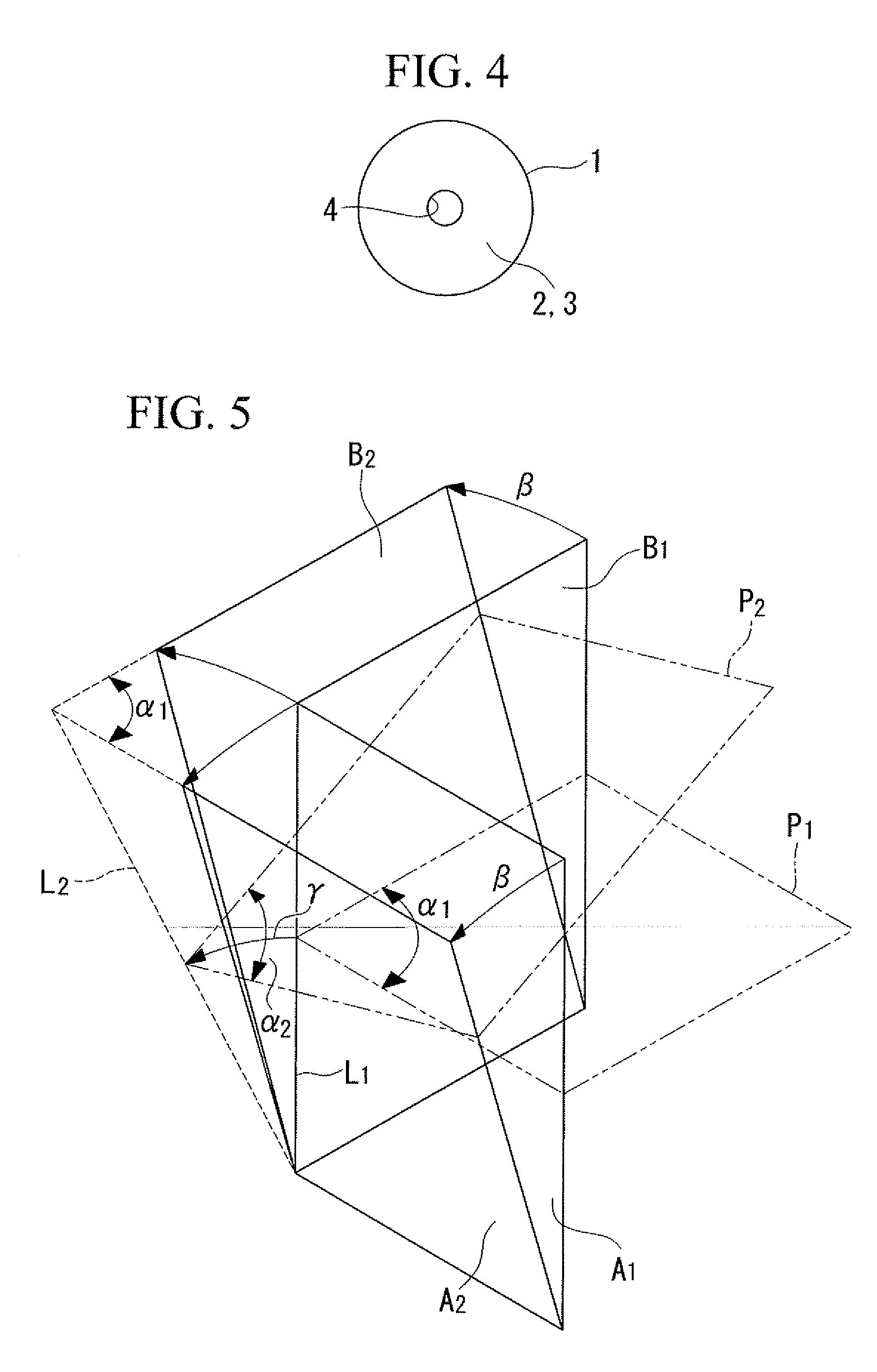

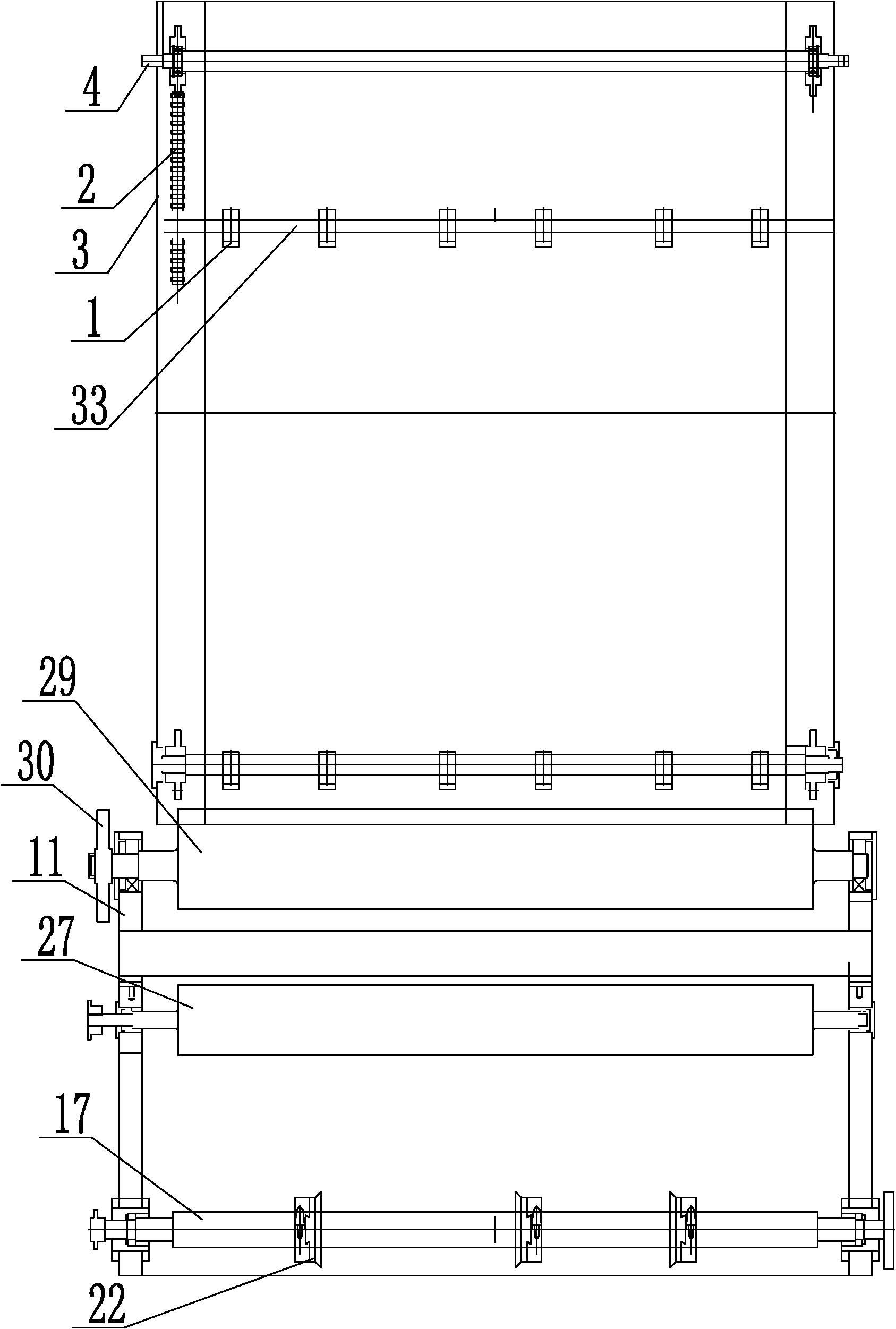

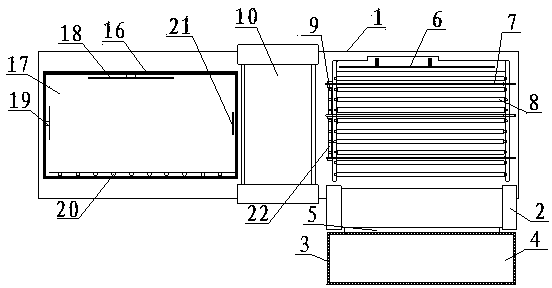

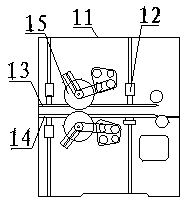

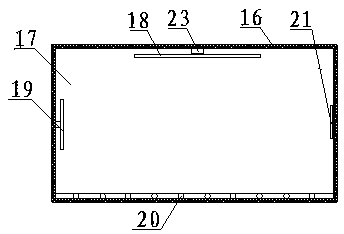

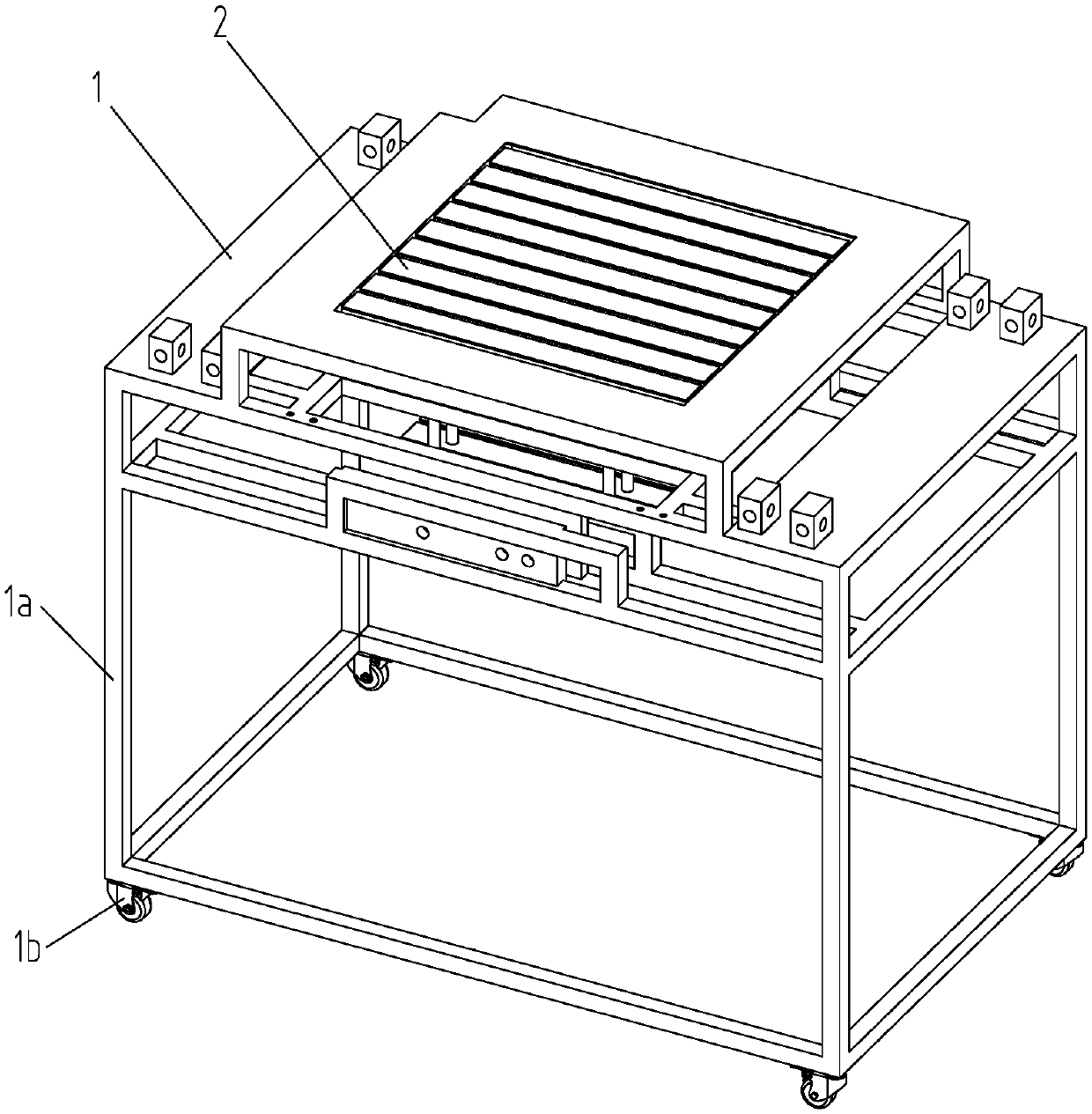

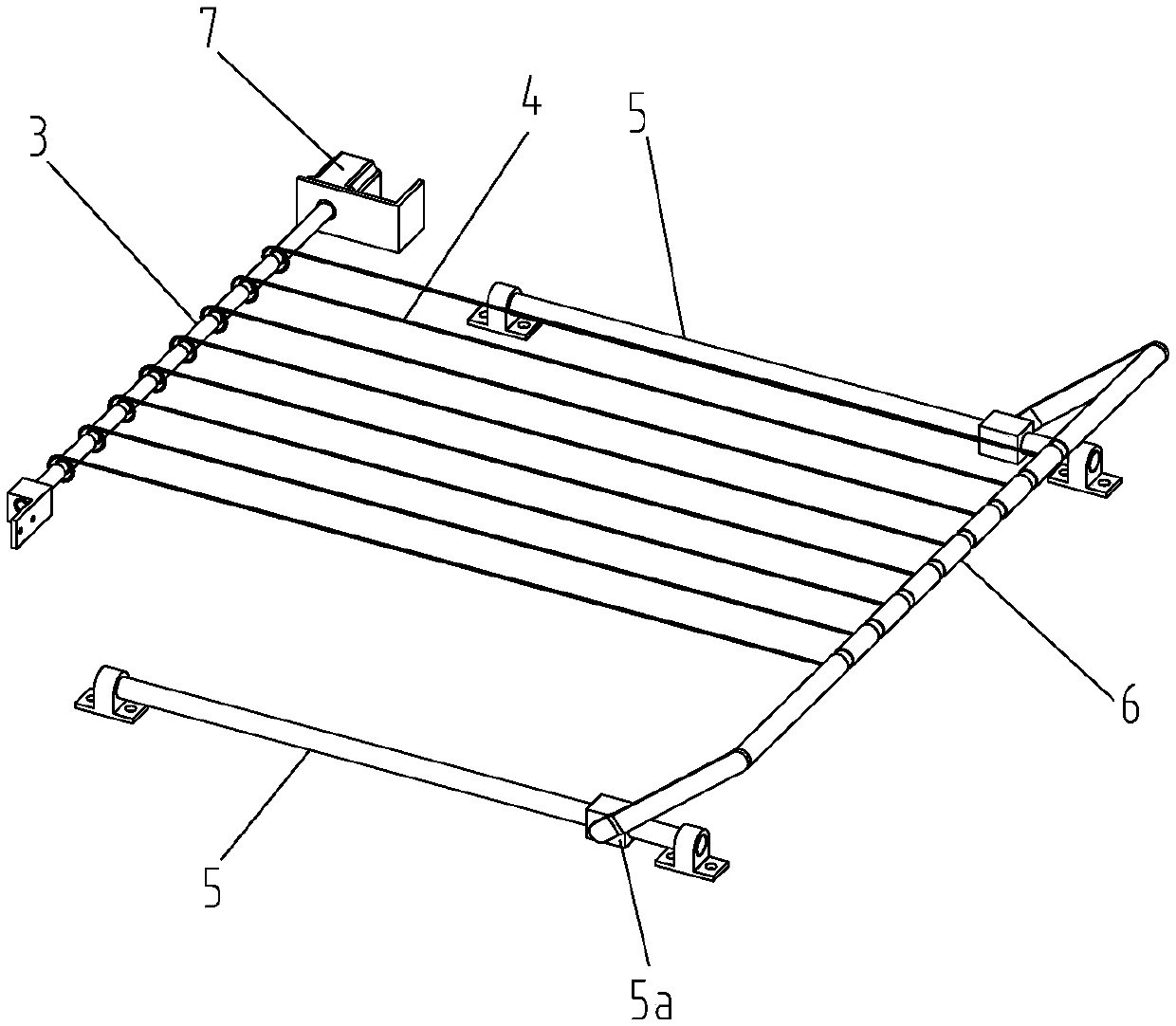

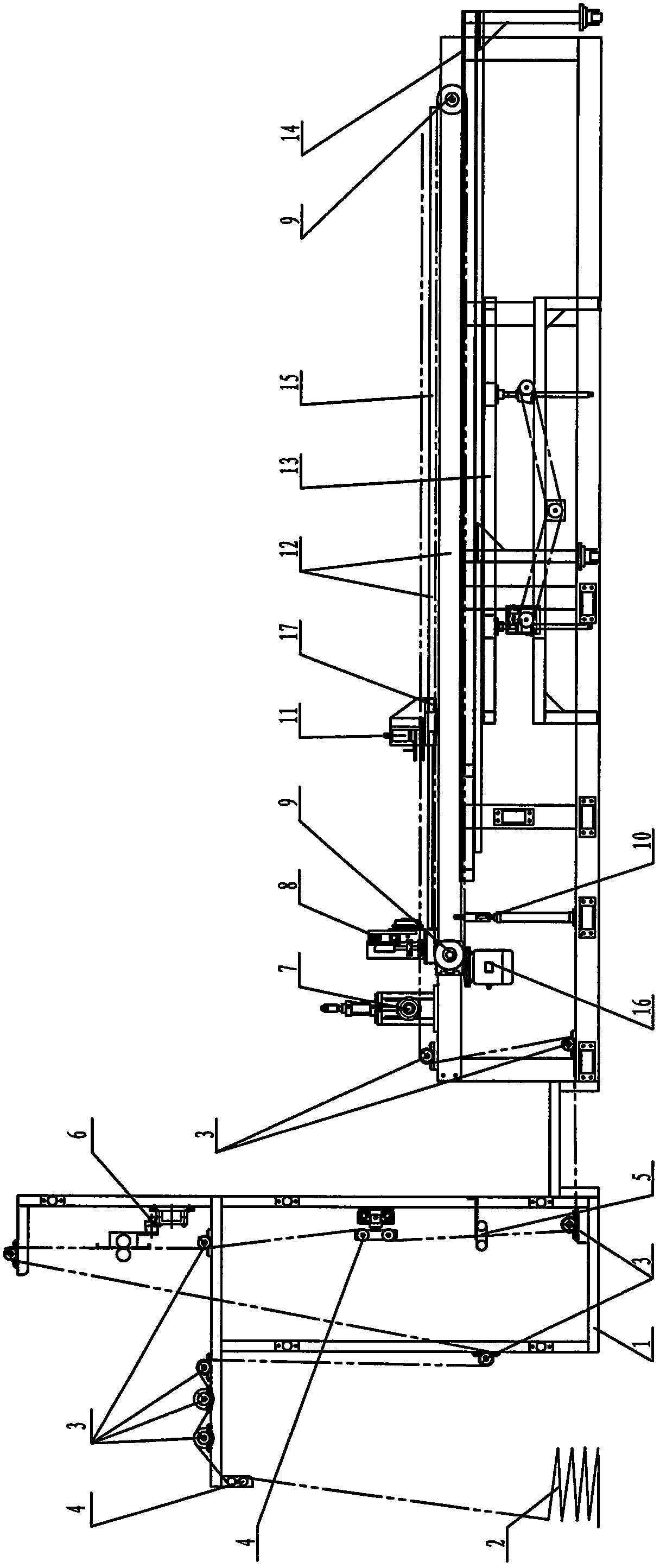

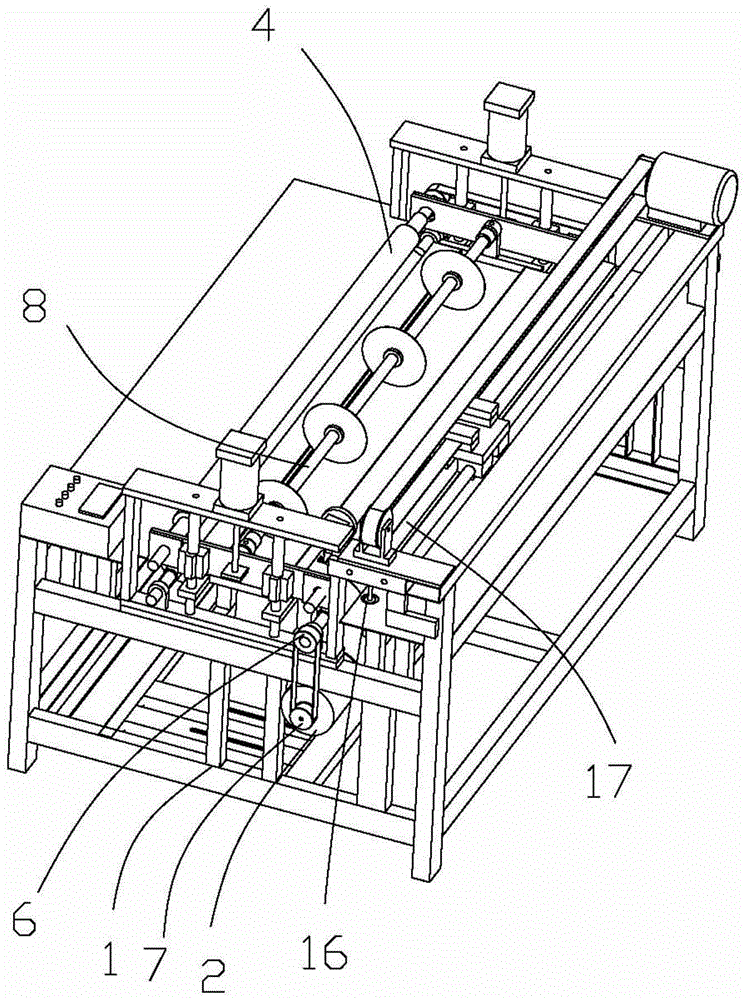

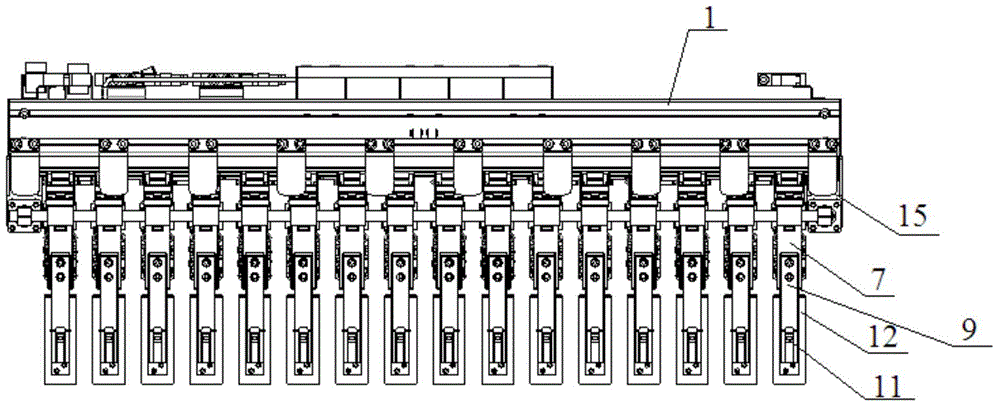

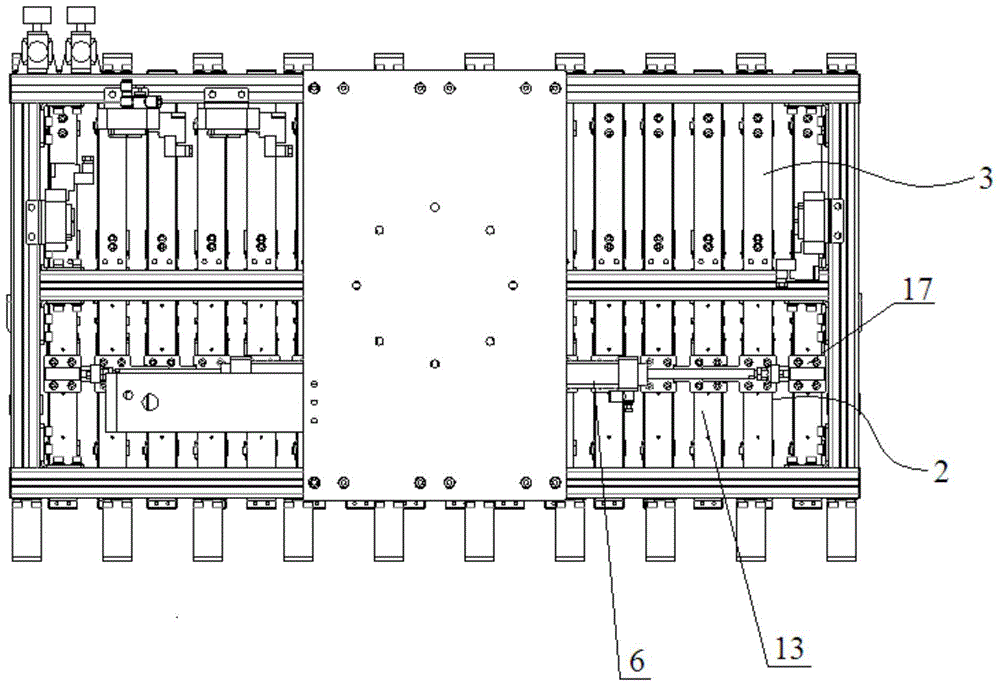

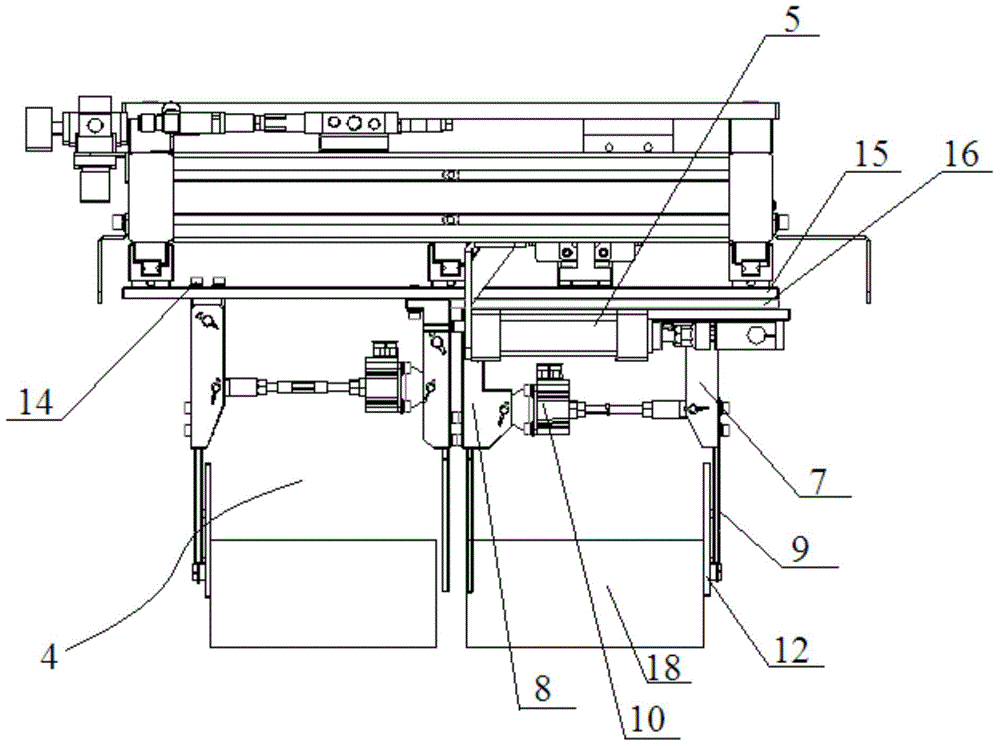

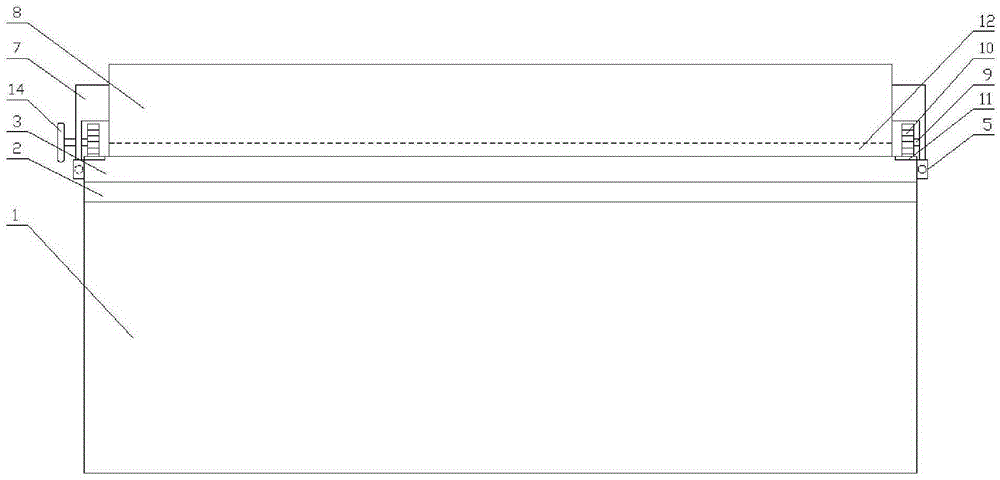

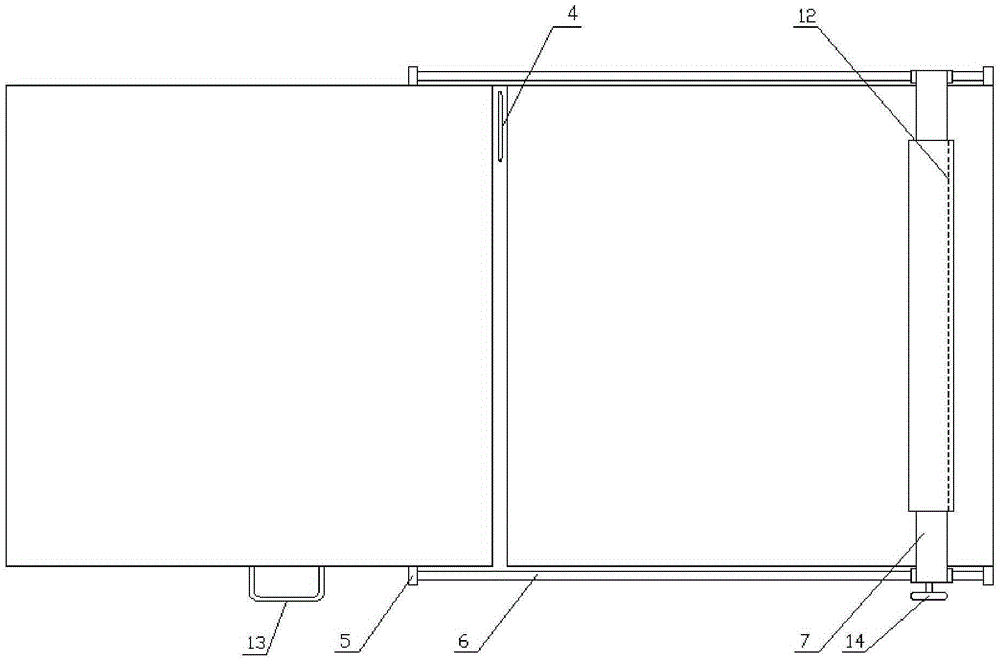

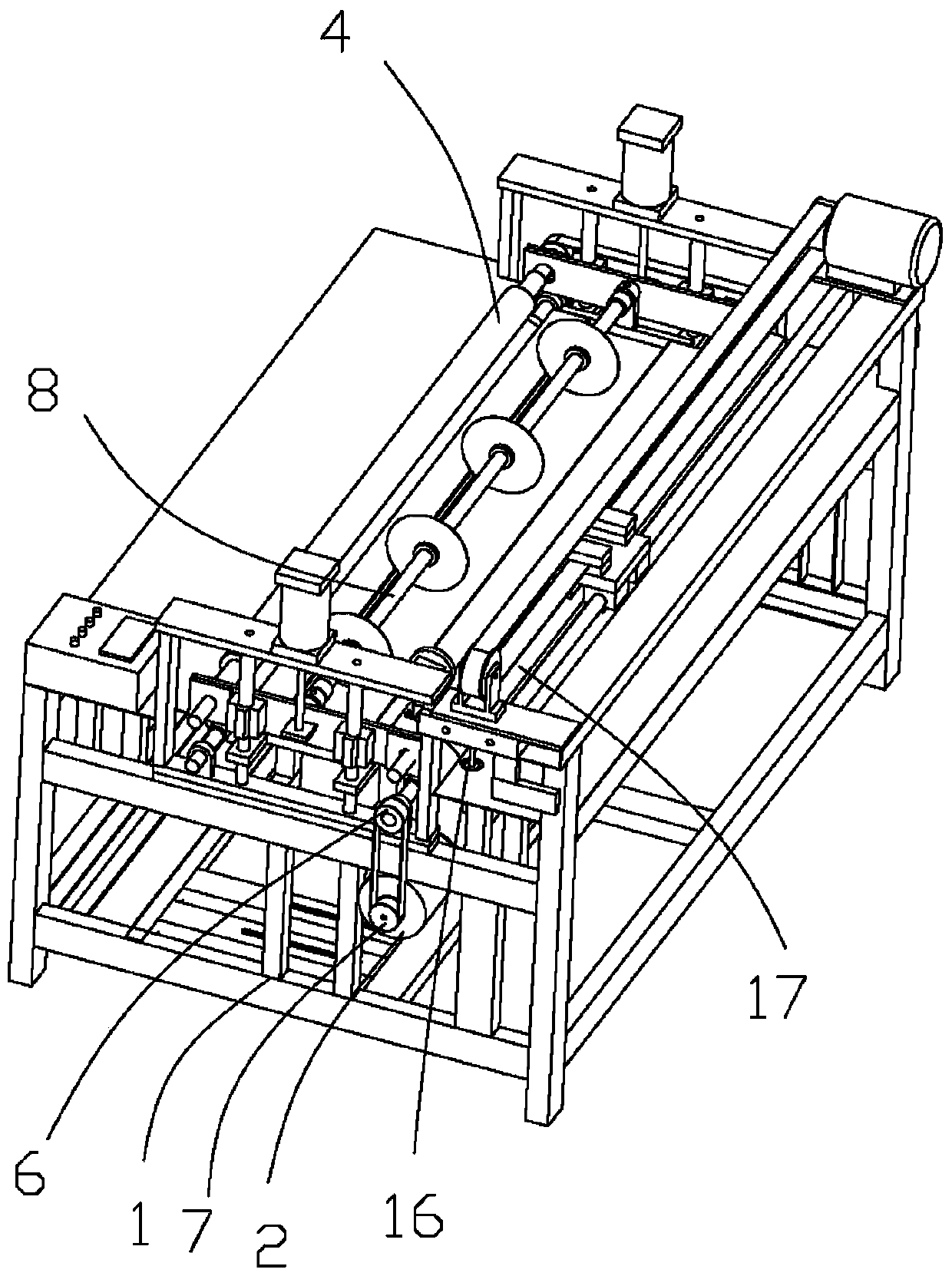

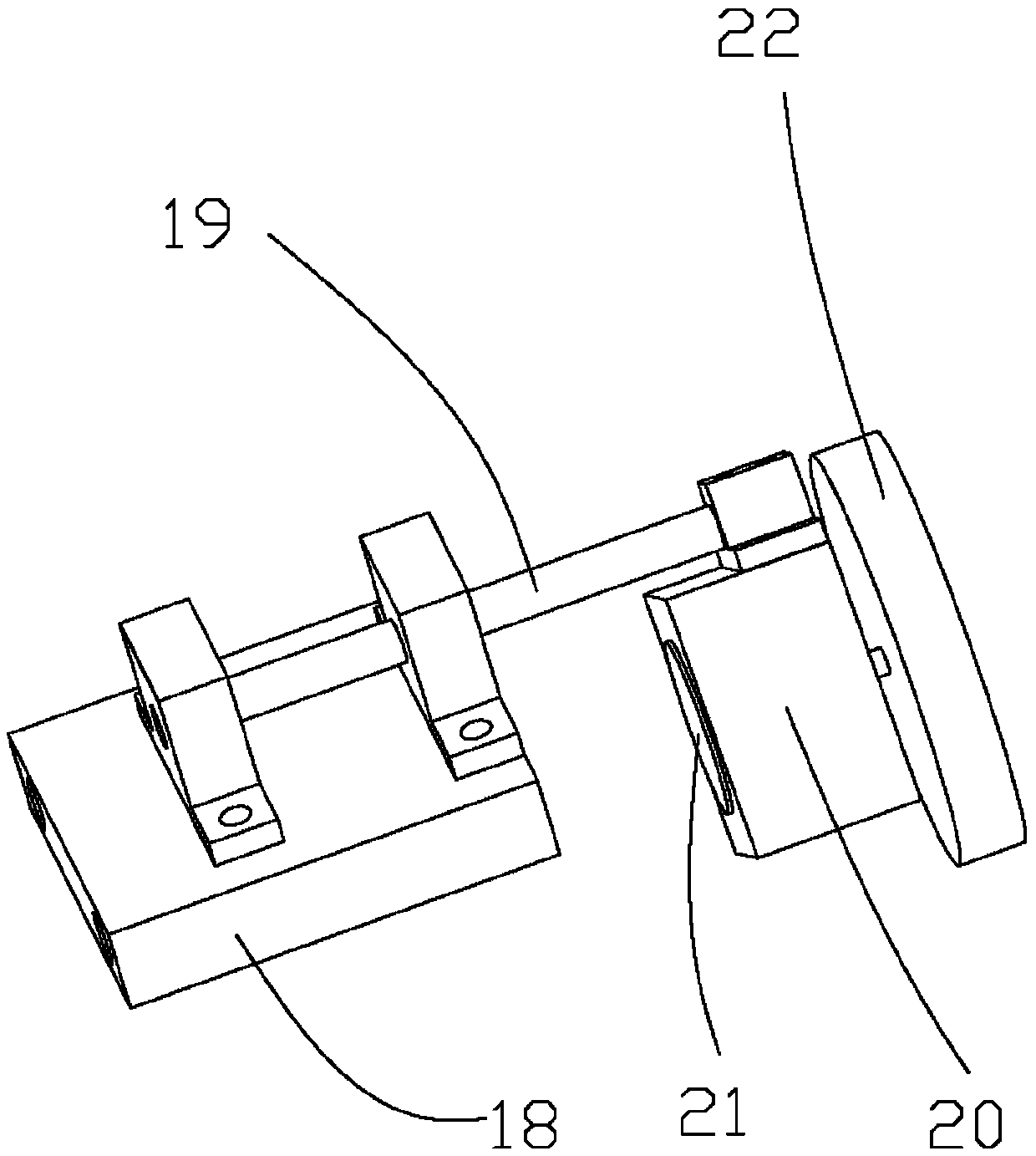

Wide-width aluminum strip double-axis coiling and longitudinal splitting machine

ActiveCN104150266AGuaranteed uptimeAdjustable distanceArticle deliveryWebs handlingLongitudinal splittingEngineering

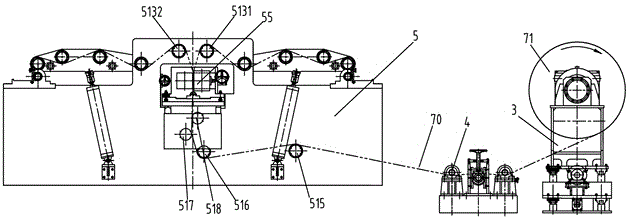

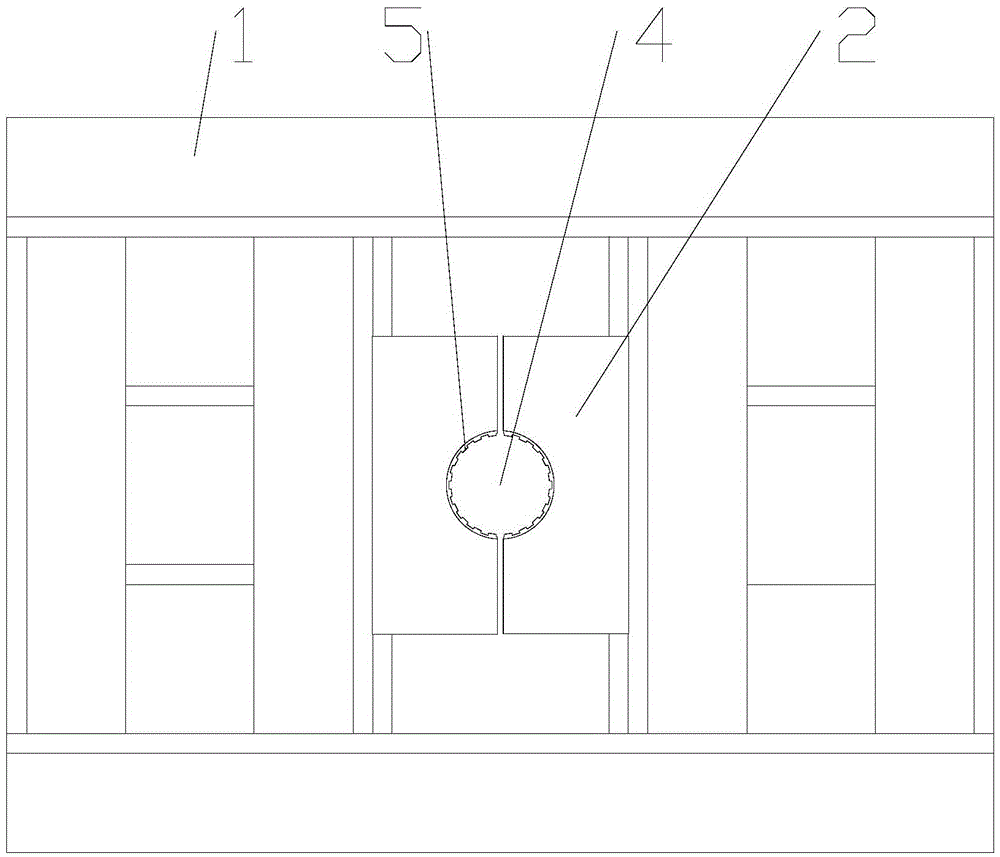

The invention discloses a wide-width aluminum strip double-axis coiling and longitudinal splitting machine. The wide-width aluminum strip double-axis coiling and longitudinal splitting machine comprises an uncoiling machine, an adjustment device and a main machine. The uncoiling machine, the adjustment device and the main machine are arranged in one plane and sequentially connected according to the order. The uncoiling machine comprises an uncoiling base and an uncoiling driving device. The uncoiling driving device is arranged on the top face of the uncoiling base. The adjustment device comprises a first base, a pair of steering mechanisms, an adjustment mechanism and a centering detection device. The steering mechanisms are fixedly arranged at the two ends of the top face of the first base respectively. The adjustment structure is arranged in the position right between the steering mechanisms. The centering detection device is arranged on the side face of one of the steering mechanisms. The main machine comprises a machine frame, a pair of rocker arm devices, a guide rail supporting device, a pair of winding devices and a splitting device. The wide-width aluminum strip double-axis coiling and longitudinal splitting machine is stable in running, wide in machining range, high in universality, low in cost and high in efficiency.

Owner:镇江龙源铝业有限公司

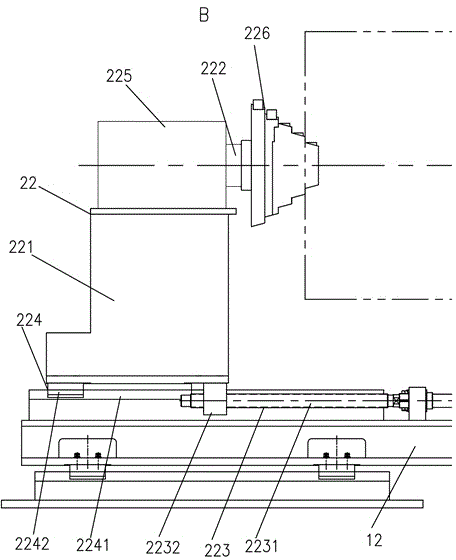

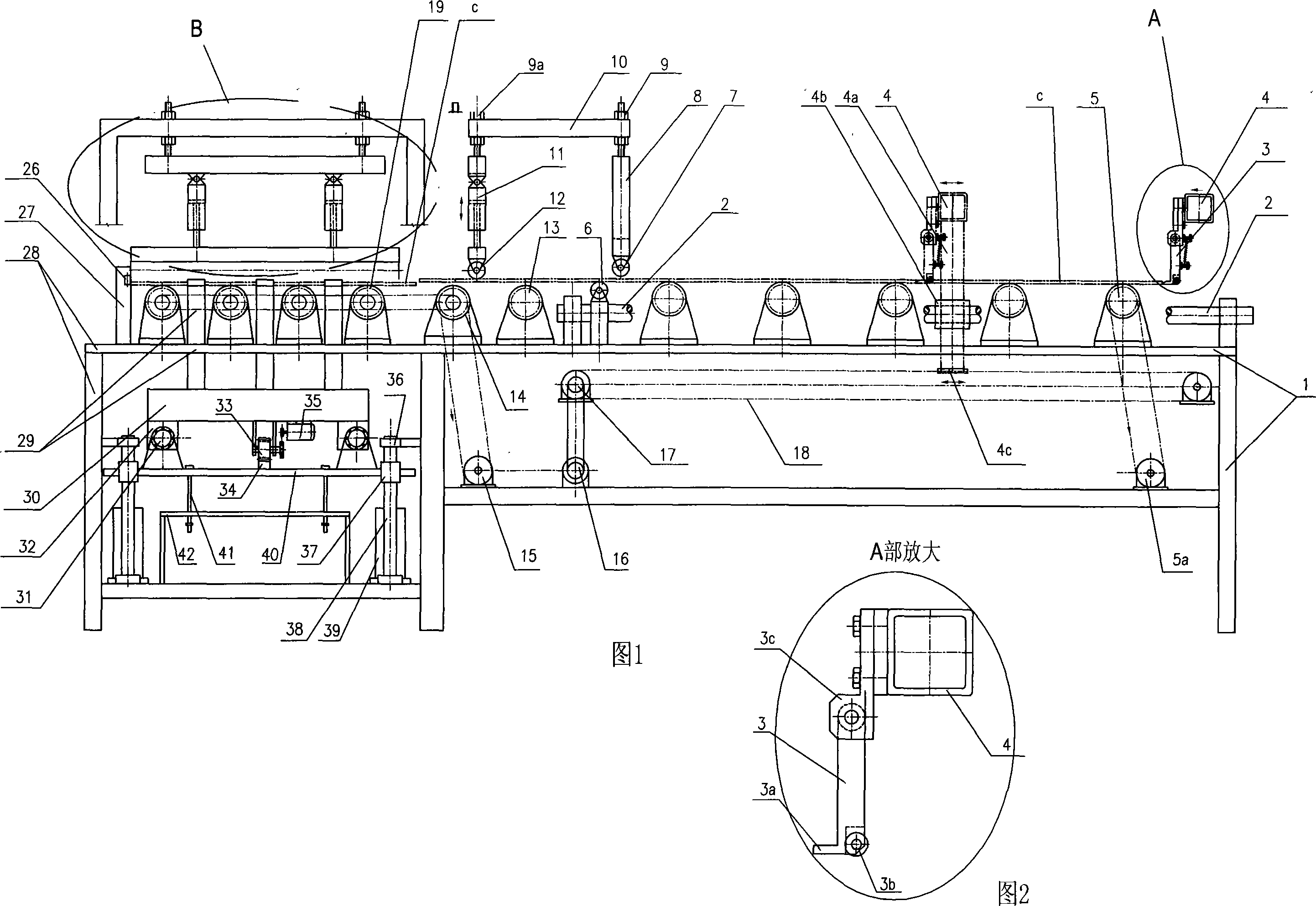

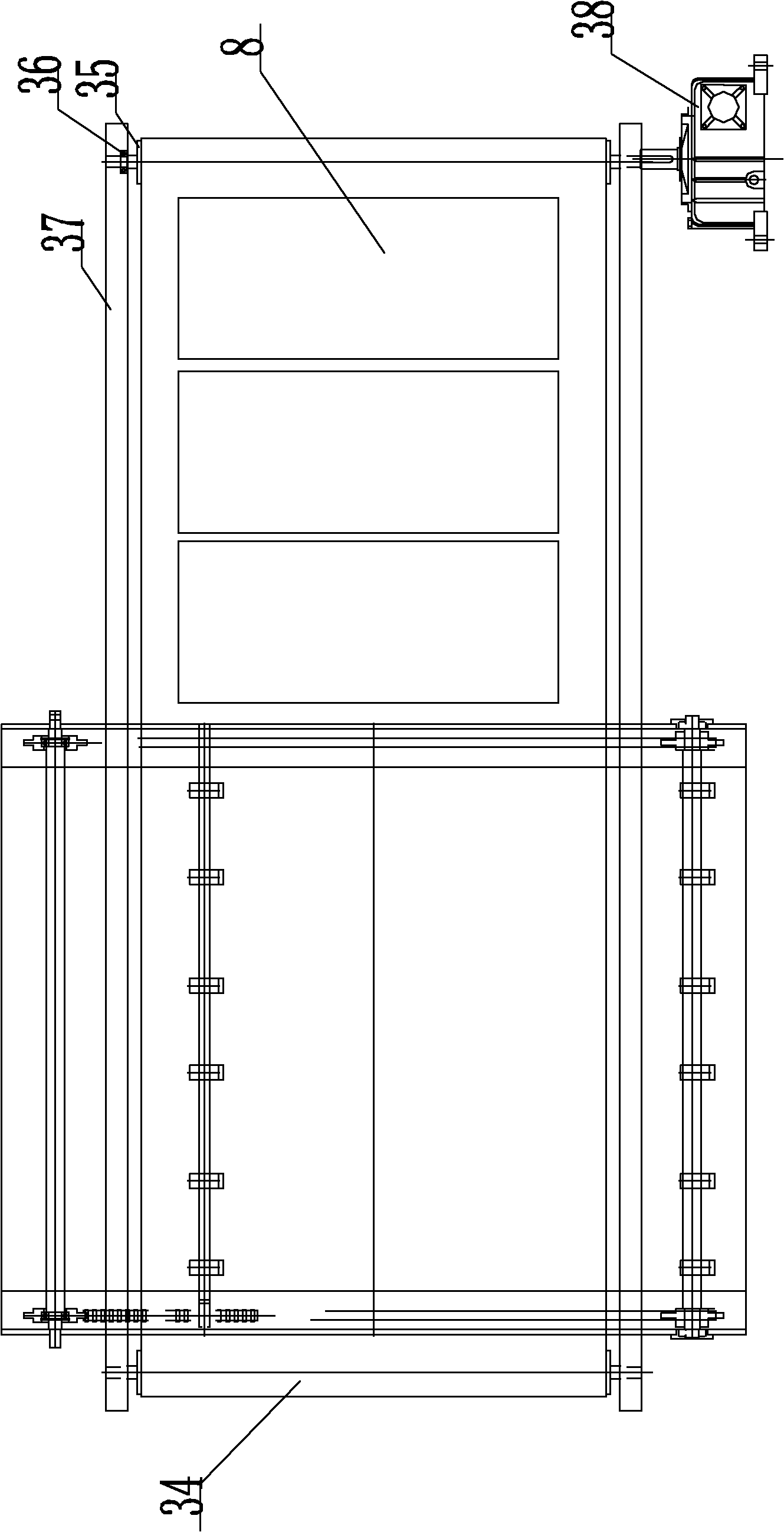

Flat glass on-line severing machine

InactiveCN101125730AHigh degree of automationImprove efficiencyGlass severing apparatusGlass productionFlat glassLongitudinal splitting

The invention relates to a splitting machine used in plate glass production line and is characterized in that the splitting machine comprises a transverse splitting part and a longitudinal splitting part. In the transverse splitting part, a transverse frame (1) is provided with a transverse roller (5) and a transverse beam (4); the transverse beam (4) is connected with a transverse jack device (3); the end of the transverse frame (1) is provided with transverse splitting devices (6) and (12). In the longitudinal splitting part, a longitudinal frame(28) is provided with a transverse roller(19) and longitudinal splitting devices(B) same with transverse splitting devices, a transverse frame (28) is internally provided with an elevator (40), on which a moving platform (30) is arranged; a gear (33) matched with a gear rack (34) is connected under the moving platform (30) while a longitudinal flake jack device (29) is arranged on the moving platform (30). The invention has the advantages that the device can be directly applied in the plate glass production line and matched with a cutting table, has high automatization and efficiency, can cut and split glass into the size required according to the requirements of the users, reduces labor intensity and greatly reduces cost.

Owner:郑书法

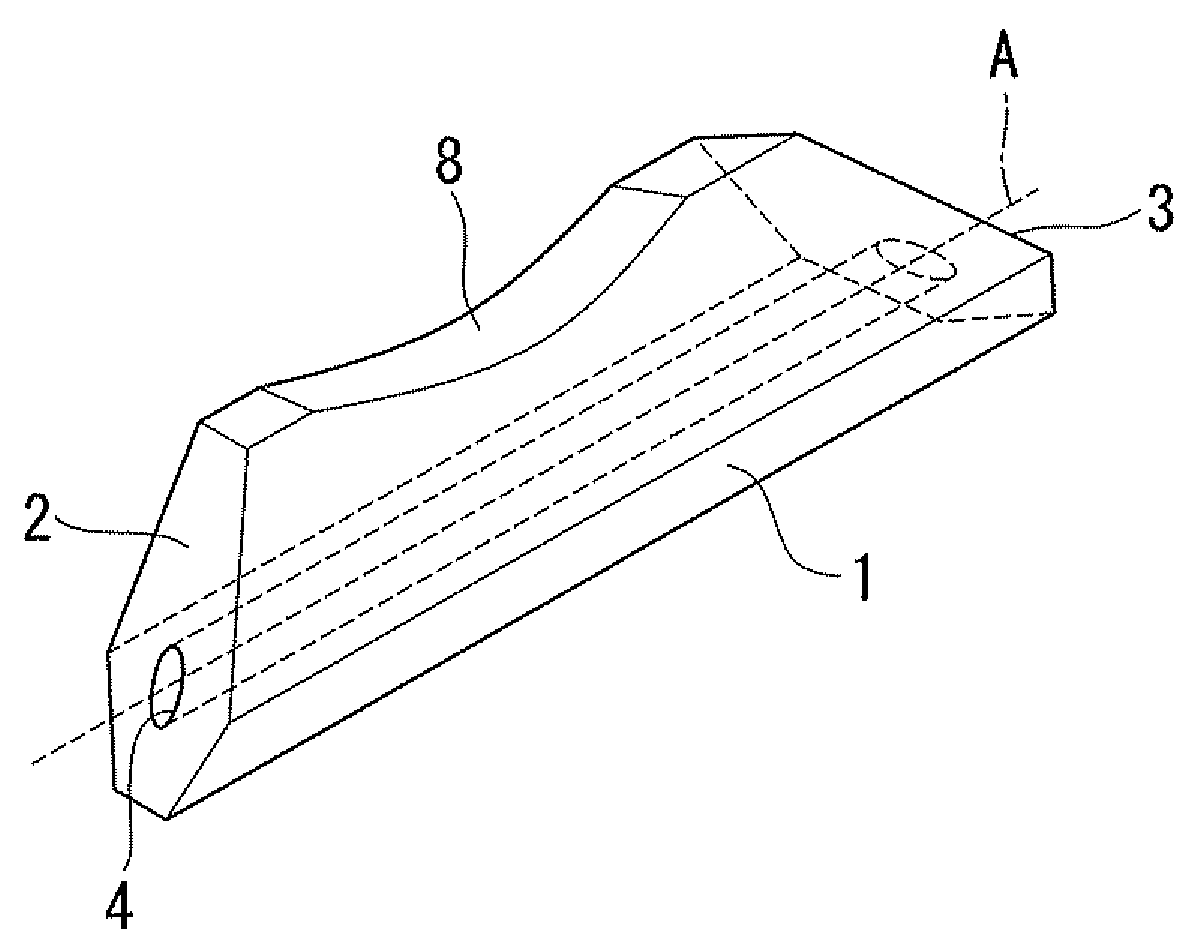

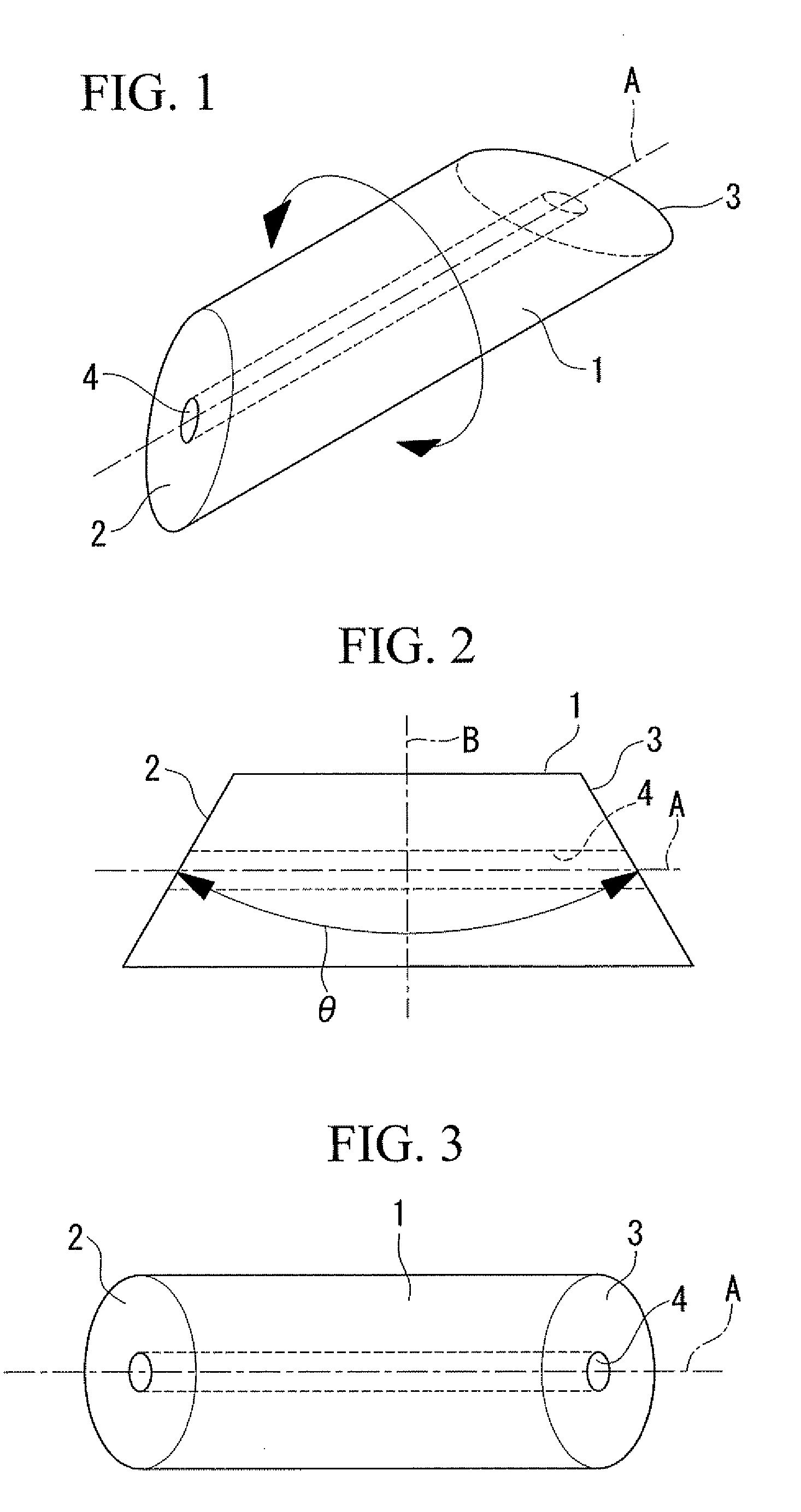

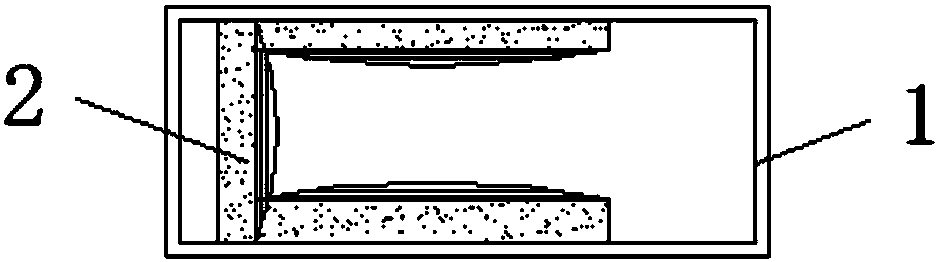

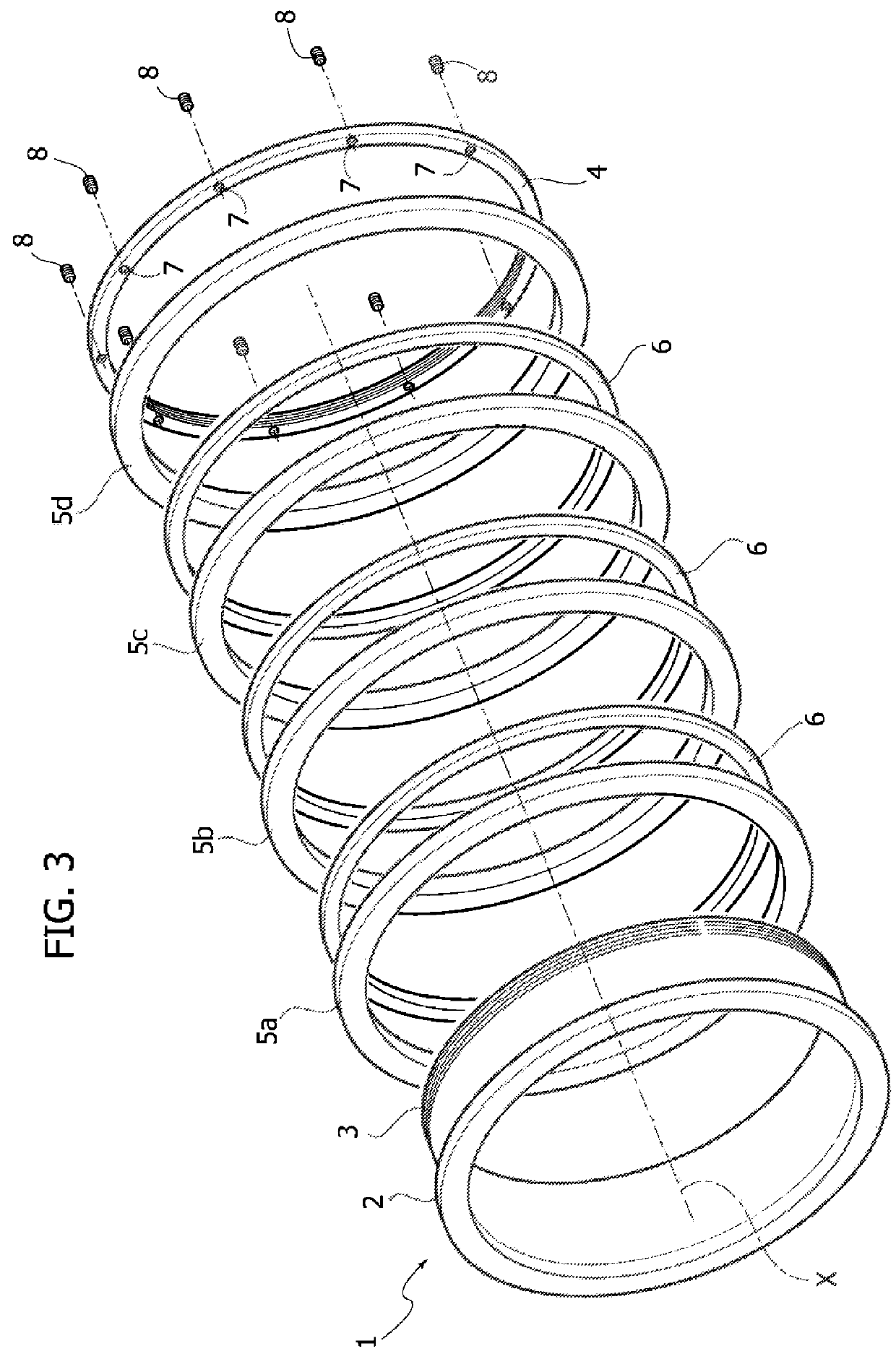

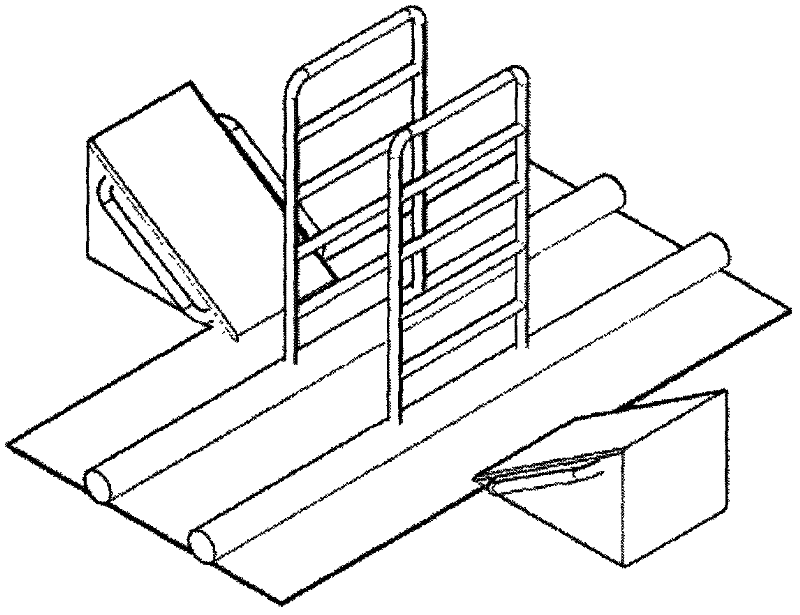

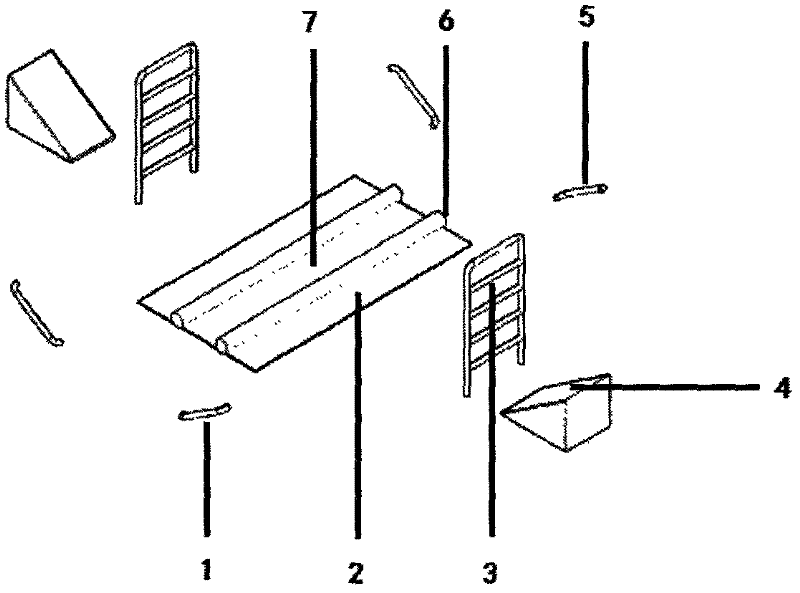

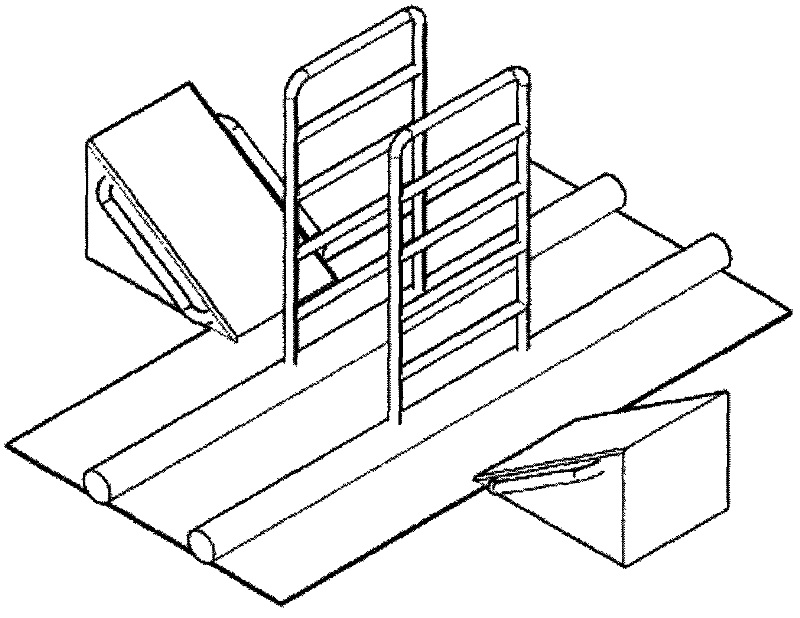

Spinous process spacer

InactiveUS20090198278A1Avoid displacementEasy to shapeInternal osteosythesisJoint implantsLongitudinal splittingEngineering

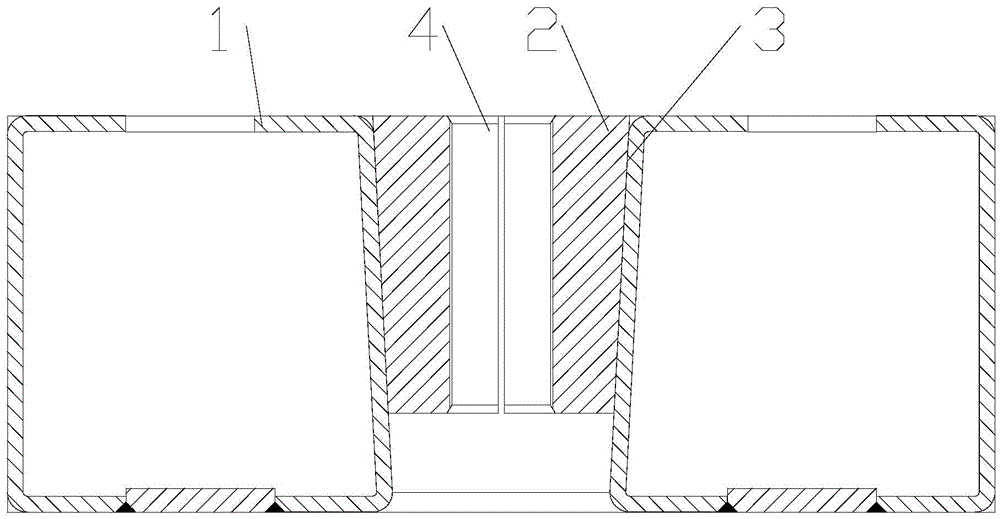

To provide a spinous process spacer that can be stably inserted and fixed between split faces of a split spinous process in a gapless manner, without made-to-order production for each patient. There is provided a spinous process spacer (1) for insertion between split halves of a spinous process resulting from longitudinal splitting of the spinous process, wherein the spinous process spacer is formed in an approximately cylindrical shape and the opposite end faces (2, 3) thereof are constituted by planes which mutually form a fixed angle.

Owner:OLYMPUS TERUMO BIOMATERIALS

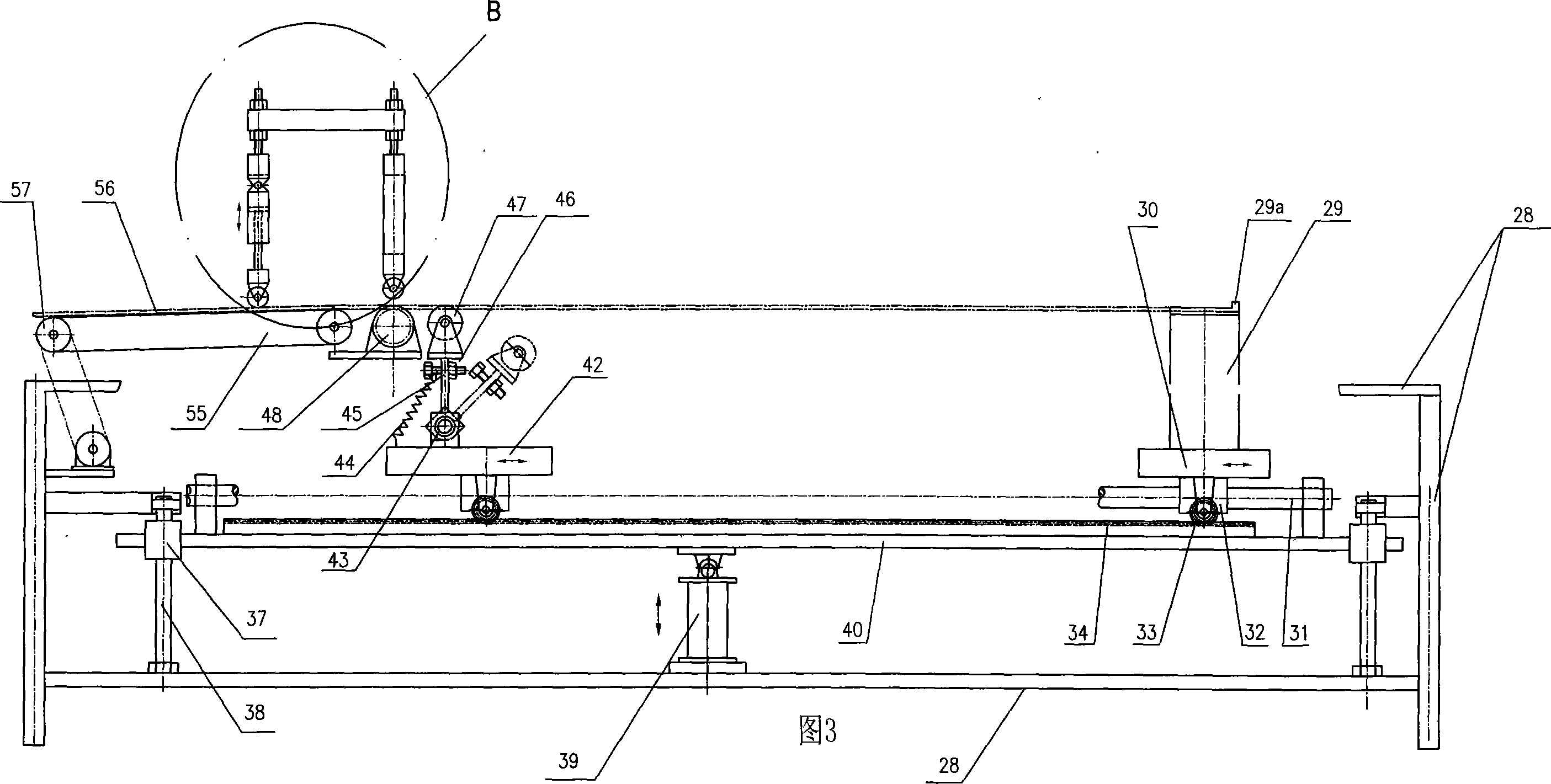

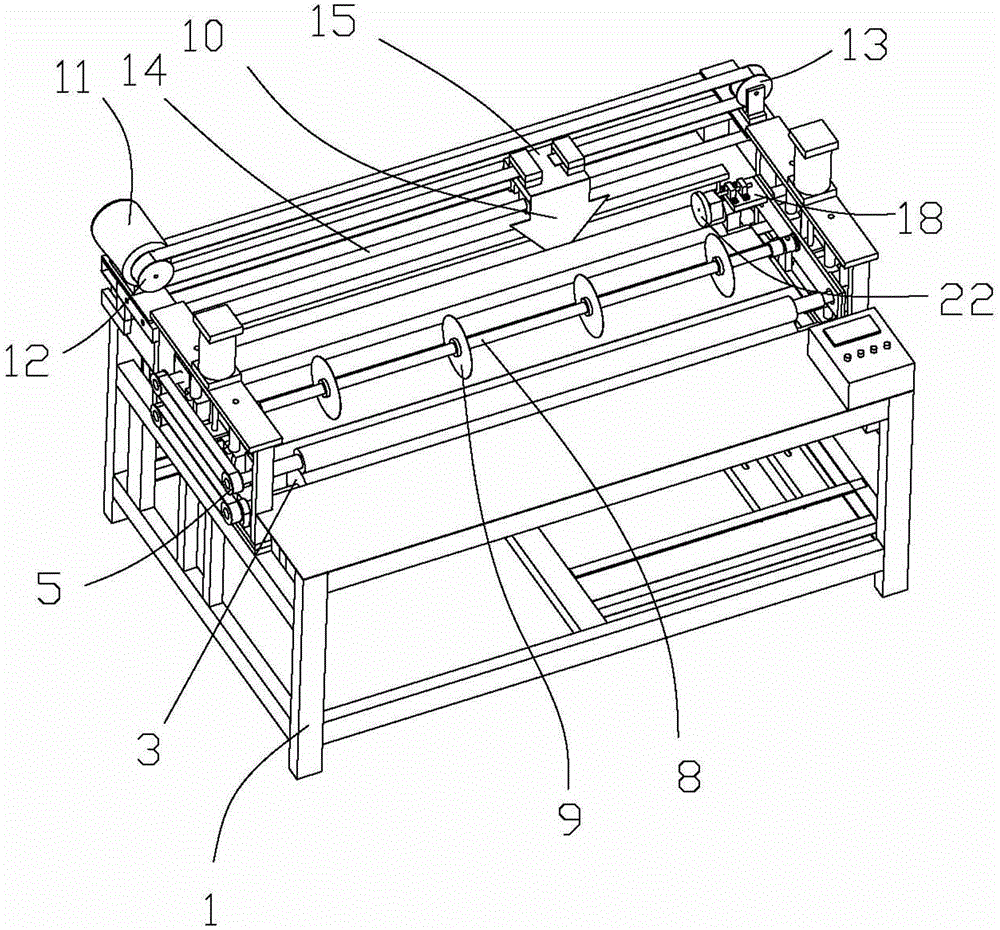

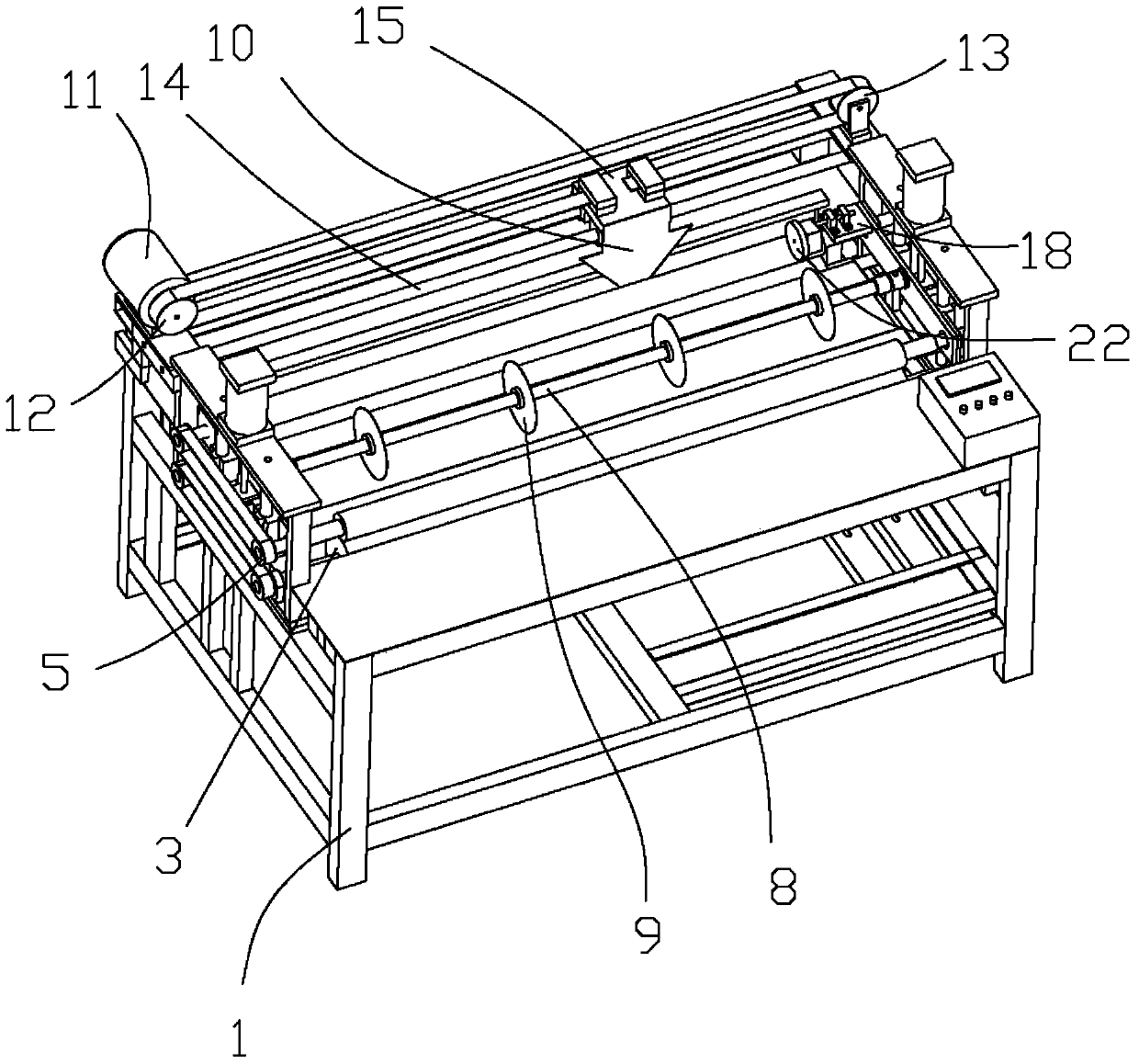

Paper cutting/receiving machine

InactiveCN102060205APrecise cut paper sizeNeatly stackedPile receiversArticle deliveryRolling paperLongitudinal splitting

The invention relates to a paper cutting / receiving machine, which comprises a paper conveying / cutting part, a paper receiving part and a transverse output belt (34), wherein the paper conveying / cutting part comprises a paper cutting foot (14), a paper cutting wallboard (11), a reversing gear (26), a paper drawing shaft (9), a paper pressing strip crossbar (31), a paper pressing strip (32), a round cutter (29), a round cutter gear (30), a servo motor (10), a reversing gear (26), a first short bridge axle (24), a second short bridge axle (25), a chain (28) with a paper conveying rubber roller, a bridge axle (16), a transmission bridge axle variable-frequency motor (13), a transmission paper drawing shaft chain (12), a longitudinal splitting cutter shaft (17), a longitudinal splitting cutter (22), a chain (23) with a longitudinal splitting cutter shaft, an upper photoelectric switch (21) and a lower photoelectric switch (18); and the paper receiving part comprises a paper receiving foot (7), a paper receiving wallboard (3), a seam (1), a seam mounting strip (33), a paper receiving chain (2), a paper receiving chain wheel shaft (4), a paper receiving chain wheel (5) and a transmission paper receiving shaft variable-frequency motor (6). Through the invention, the single-corrugated paper formed by a single-corrugated machine or roll paper is cut off and then automatically stacked.

Owner:赵祖良

High integrity polyester strapping

Polyester strapping made from polyester and less than 3% by weight of a polyolefn additive exhibits improved resistance to longitudinal splitting when the strapping is later placed under tension in packaging reinforcement applications. The polyolefin improves the longitudinal split resistance of the strapping without facilitating unwanted longitudinal stretch of the polyester strapping when under tension. The polyolefin additive may be combined with other conventional additives, or may be used alone in order to minimize costs.

Owner:SIGNODE IND GRP

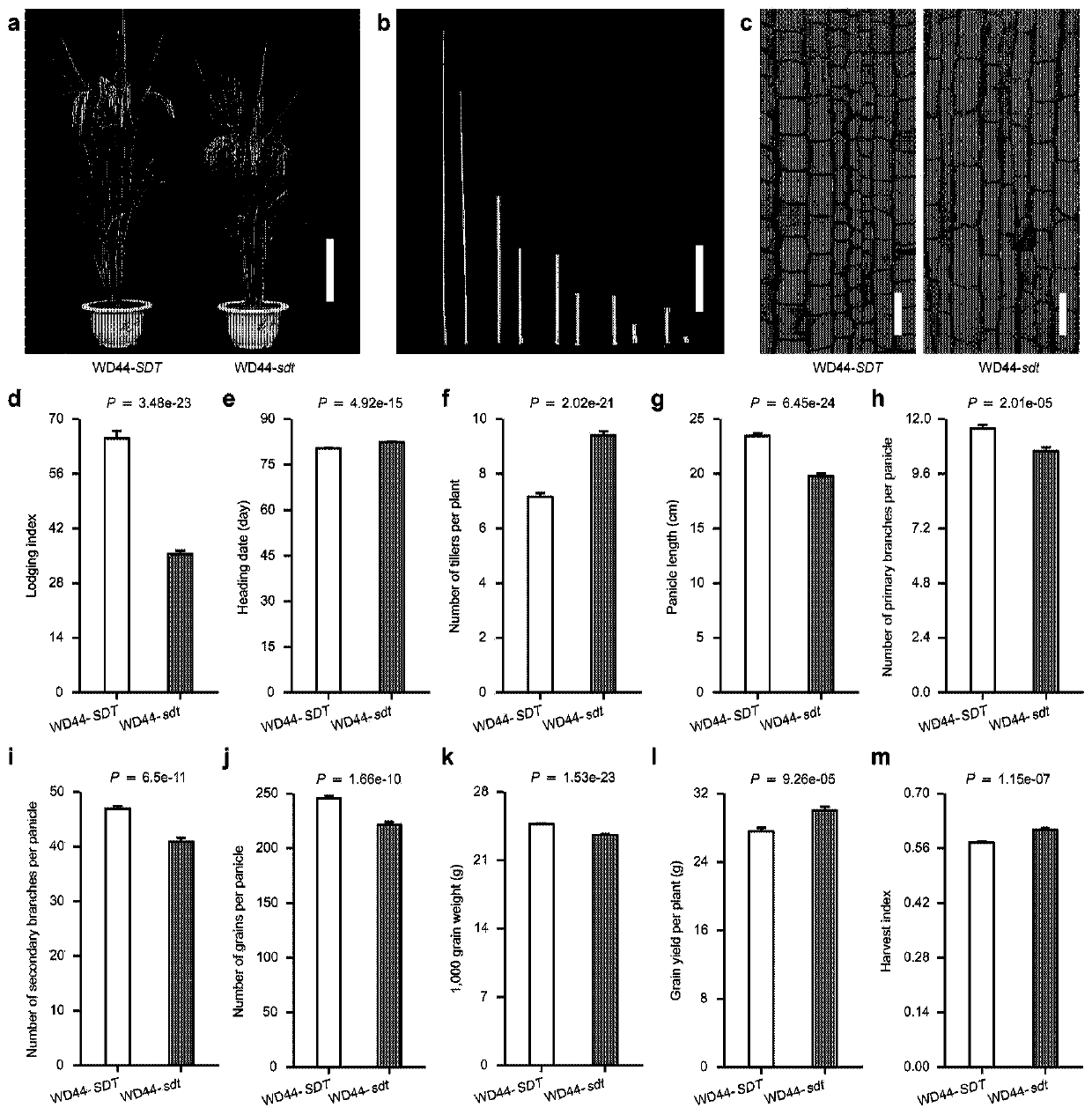

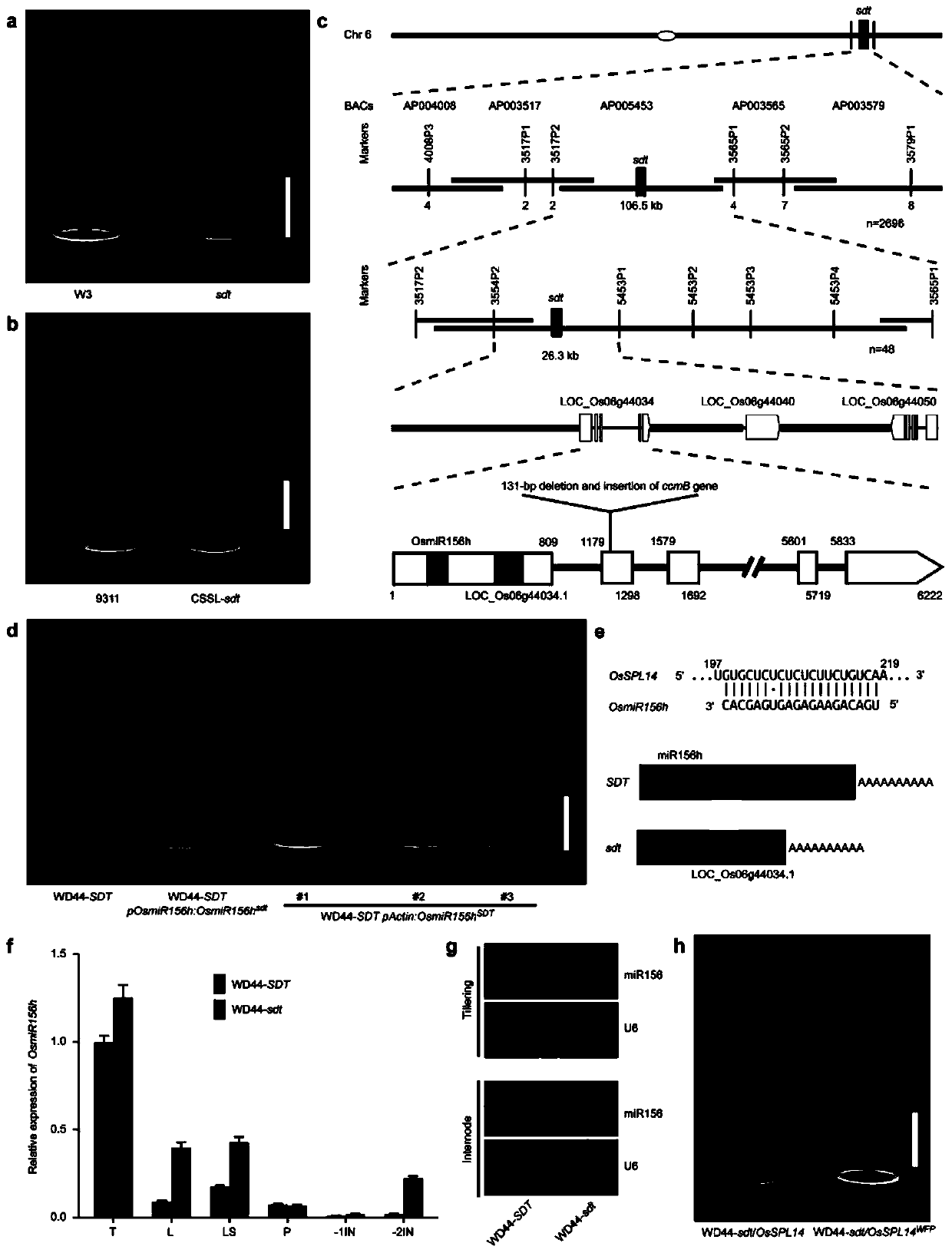

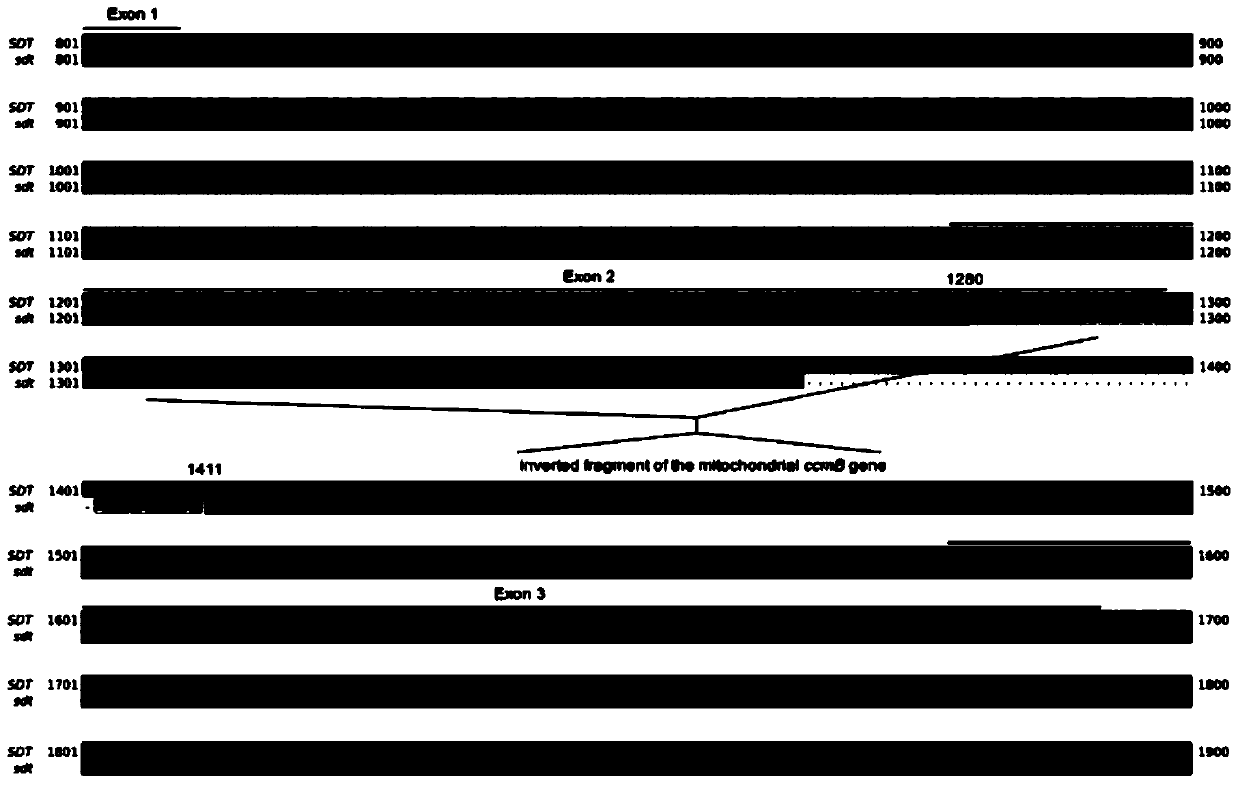

Gene for controlling Oryza sativa plant height, enhancing lodging resistance, increasing effective tiller number and yield and its application

The invention discloses an SDT (semi dwarf and high-tillering) gene for decreasing Oryza sativa plant height, enhancing lodging resistance, increasing tiller number and yield, and its application. The SDT gene coding is OsmiR156h. In semi dwarf and high-tillering SDT Oryza sativa mutant, the length of the mRNA 3'-UTR transcribed from the SDT gene is shorter than that of the 3'-UTR transcribed from a wild type SDT gene, resulting in high SDT gene transcription level than expression level of the wild type SDT gene. Genetic analysis shows that SDT is a semidominant mutation, which can inhibit longitudinal splitting of stem cells to control the internode length and plant height, thereby improving the lodging resistance of Oryza sativa; at the same time, the SDT gene can increase effective tiller number of Oryza sativa, thereby improving grain number and yield per spike. The present invention for the first time improves that the control on the length of 3'-UTR of mRNA transcribed from the OsmiR156h gene can change the expression level of gene, thereby realizing the application prospect of the cultivation of excellent varieties of Oryza sativa.

Owner:INST OF GENETICS & DEVELOPMENTAL BIOLOGY CHINESE ACAD OF SCI

Pneumatic-tyre

A pneumatic tire is provided in the tread portion with a circumferential row (Rm) of middle tread elements (6), wherein each of the middle tread elements (6) is divided into four elemental blocks (6A1,6A2,6B1,6B2) having different configurations, by three splitting grooves, and the three splitting grooves are: a longitudinal splitting groove (9) extending between the lateral main grooves (5): an axially inner lateral splitting groove (10) extending axially outwardly from the axially inner circumferential main groove (3) beyond the longitudinal splitting groove (9) and terminating before the axially outer circumferential main groove (4); and an axially outer lateral splitting groove (11) extending axially inwardly from the axially outer circumferential main groove (4) beyond the longitudinal splitting groove (9) and terminating before the axially inner circumferential main groove (3).

Owner:SUMITOMO RUBBER IND LTD

Paperboard splitting unit

ActiveCN103770151AAffect cutting efficiencyExtended service lifeMetal working apparatusArticle feedersLongitudinal splittingHigh volume manufacturing

A paperboard splitting unit comprises a rack, a longitudinal splitting machine, a transverse splitting machine, a feeding mechanism, a guide plate mechanism, a small board splitting machine and a material collecting platform, wherein the feeding mechanism is connected with the longitudinal splitting machine, the longitudinal splitting machine is connected with the transverse splitting machine, one end of the guide plate mechanism is connected with the transverse splitting machine, the other end of the guide plate mechanism is connected with the small board splitting machine, the small board splitting machine is connected with the material collecting platform, and the longitudinal splitting machine, the transverse splitting machine, the feeding mechanism, the guide plate mechanism and the small board splitting machine are arranged on the rack. The paperboard splitting unit can be used for consecutive production of longitudinal cutting and transverse cutting, is high in production efficiency, and capable of meeting requirements of volume production, and feeds and collects materials automatically in the splitting process so as to effectively reduce the intensity of manual labor and reduce damage caused by manual transfer. Meanwhile, cutting knives in the small board splitting machine are arranged, side by side, on an upper bracket and a lower bracket and split at the same time, so that unevenness, of splitting faces of a honeycomb paperboard, caused by single distribution of cutting knives is effectively reduced, and the splitting quality is improved.

Owner:HUNAN HUAWANG TECH

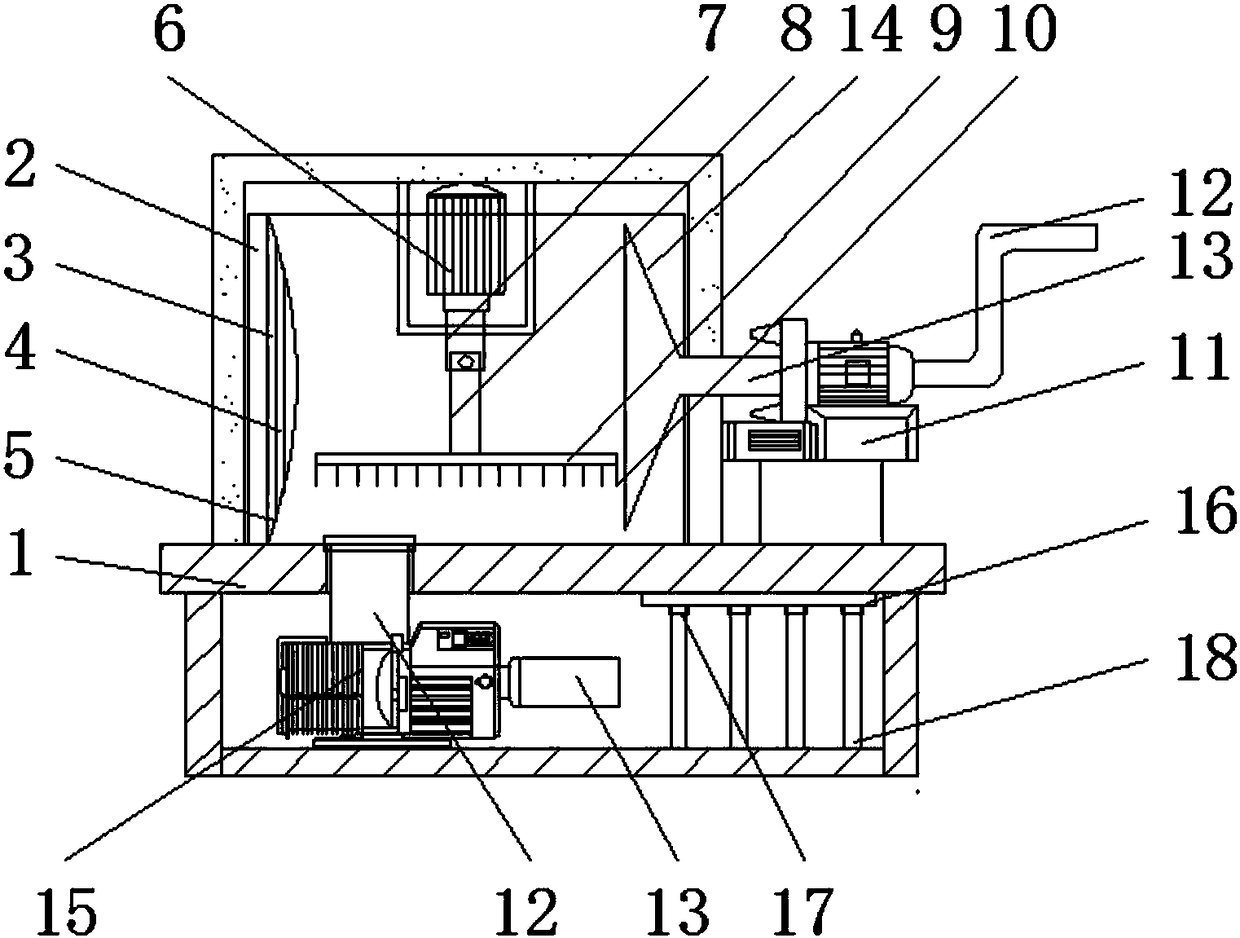

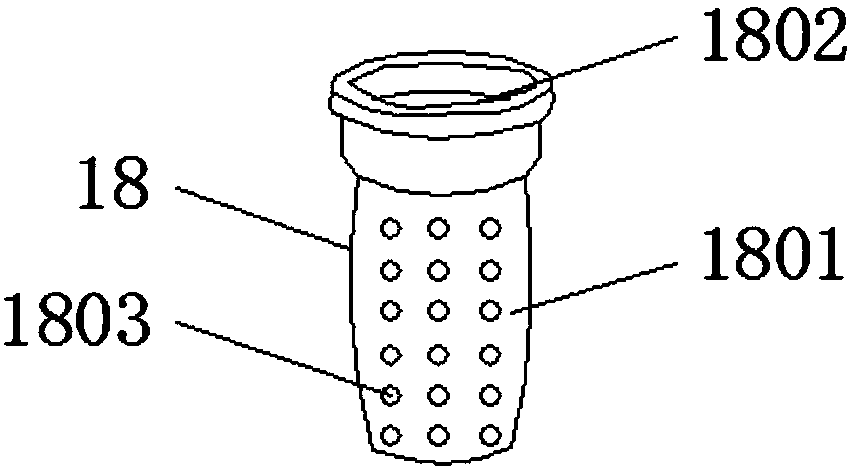

Steamed sponge cake splitting machine

InactiveCN105364986ASlitting process hygieneEasy to operateMetal working apparatusLongitudinal splittingEngineering

The invention provides a steamed sponge cake splitting machine. The steamed sponge cake splitting machine comprises a machine frame. A tray used for containing a steamed sponge cake is arranged in the middle of the machine frame. The tray is composed of a plurality of movable carriers which are transversely arranged in parallel, and gaps are formed between the movable carriers respectively. Jacking devices used for jacking the movable carriers one by one are arranged on the portion, below the tray, of the machine frame. A transverse splitting device and a longitudinal splitting device which are used for cutting the steamed sponge cake are arranged on the portion, above the tray, of the machine frame. According to the steamed sponge cake splitting machine, the steamed sponge cake is divided into a plurality of transverse cake strips through the transverse splitting device firstly, then the transverse steamed sponge cake strips are jacked one by one through the jacking devices respectively, and then the transverse steamed sponge cake strips are cut into small rhombic cake blocks through the longitudinal splitting device; due to the fact that slender splitting lines are used for transverse splitting and longitudinal splitting, the appearance of the steamed sponge cake is prevented from being damaged during splitting; in addition, the splitting process is sanitary, the splitting operation is easy, the labor intensity of workers can be effectively relieved, and the working efficiency is improved.

Owner:GUANGXI POLYTECHNIC

High integrity polyester strapping

Polyester strapping made from polyester and less than 3% by weight of a polyolefin additive exhibits improved resistance to longitudinal splitting when the strapping is later placed under tension in packaging reinforcement applications. The polyolefin improves the longitudinal split resistance of the strapping without facilitating unwanted longitudinal stretch of the polyester strapping when under tension. The polyolefin additive may be combined with other conventional additives, or may be used alone in order to minimize costs.

Owner:SIGNODE IND GRP

Method and assembly for confocal, chromatic, interferometric and spectroscopic scanning of optical, multi-layer data memories

InactiveUS7876446B2Reliable read-outHighly stable over the long termRadiation pyrometryInterferometric spectrometryDiffraction orderData memory

Owner:UNIV STUTTGART

Crystallizer casting powder for continuous casting of high-carbon abrasion-resisting steel

InactiveCN106077545AReduce crackingReduce the incidence of steel breakoutAlkalinityLongitudinal splitting

The invention relates to crystallizer casting powder for continuous casting of high-carbon abrasion-resisting steel. The crystallizer casting powder comprises, by weight percent, 7.5%-33.5% of CaO2, 27%-34% of SiO2, 2%-7% of Al2O3+MgO, smaller than 5% of Fe2O3, 2%-8% of F, 4.5%-10.5% of R2O, 3.5%-9.5% of C, 0.8%-1.3% of CaO / SiO2, and the balance impurities. Except C, calculating and burdening are conducted according to the above components, then the components are evenly mixed, pelletizing is conducted, and the components are fed into an electric furnace to be evenly melted; and after cooling crushing, the components are screened, a corresponding carbon framework material is added, then ball milling and slurrying are conducted, and finally, finished casting powder is obtained through atomizing, granulating and drying. The alkalinity of the casting powder is low and ranges from 0.8 to 1.3, and the casting powder is stable in performance in the using process. In the continuous casting process of high-carbon abrasion-resisting steel, the casting powder can effectively control and balance heat transfer of a primary blank shell in a meniscus region to the crystallizer wall through a slag film, and the probability of recessing, longitudinal splitting and other surface defects of a cast blank can be effectively lowered; and meanwhile lubrication of a liquid slag film to the primary blank shell can be guaranteed, bonding and bonding bleed-out are avoided, stable and smooth continuous casting is facilitated, and the continuous casting efficiency is improved.

Owner:西峡县恒基冶材有限公司

Intelligent full-automatic cloth pulling, splitting and cutting machine

PendingCN108238479ANo pollutionHigh degree of automationSevering textilesFolding thin materialsFiberLongitudinal splitting

The invention discloses an intelligent full-automatic cloth pulling, splitting and cutting machine. The intelligent full-automatic cloth pulling, splitting and cutting machine comprises a rack, cloth,cloth guiding rolls, cloth tensioners, a centralizer, an opposite-site flattening device, a longitudinal splitting device, a transverse cutting device, synchronizing wheels, a chemical fiber ironingand cutting device, a cloth pulling device, left and right side plates, a lifting platform, a movable cloth containing platform, a linear sliding support, a servo motor A, sliding blocks, cutter shaftsliding block brackets, a right-angle motor bracket, a right-angle motor, cutter shaft gears, cutter shaft bearings, air cylinders A, cutter shaft sliding blocks and the like. The machine adopts a mechanical-electrical integration intelligent control technology and is high in automation degree. When the machine is used, the machine flattens and straightens the cloth according to instructions andconducts transverse cutting and chemical fiber ironing and cutting according to the length dimension, the machine is widely applied to the industries of clothing, shoes and hats, home textiles and thelike, the automation degree is high, the cutting length is precise, the defects such as bevel edges and swing angles are not generated, time and labor are saved, the working efficiency is high, no noise is generated, the environment is not polluted, and the economic benefit is increased.

Owner:YANCHENG XIEHE MACHINERY

Bamboo chip longitudinal splitting slicer dust removal device

InactiveCN108312264AImprove cleanlinessEasy to installDispersed particle filtrationBark-zones/chip/dust/waste removalLongitudinal splittingSprayer

The invention discloses a bamboo chip longitudinal splitting slicer dust removal device. The bamboo chip longitudinal splitting slicer dust removal device comprises a workbench and a brush. A dust collecting plate is arranged at the upper left end of the workbench. A first hook-and-loop fastener, a second hook-and-loop fastener and EVA super glue are fixed to the outer end of the dust collecting plate. A drive motor is arranged above the workbench, a rotation shaft is connected to the other end of the drive motor, a telescopic rod is fixed to the other end of the rotation shaft, and a brush roller is arranged at the other end of the telescopic rod. The brush is arranged on the outer side of the brush roller. An air blower and a suction fan are arranged between the upper right end and the lower end of the workbench. A sprayer is arranged at the other end of the air inlet pipe, an installing plate is fixed to the position on the right of the suction fan, and a cloth bag dust removal device body is arranged at the outer end of the installing plate. According to the bamboo chip longitudinal splitting slicer dust removal device, the brush is arranged at the other end of the rotation shaft and the other end of the telescopic rod in a rotating and lifting manner, scraps and fragments at the gap positions in the workbench are conveniently swept, and the work intensity of workers can bebetter relieved.

Owner:黄国贞

EPE (expand aple poly ephylene) foam cutting machine

ActiveCN104128948ASimple structureImprove cutting accuracyMetal working apparatusLongitudinal splittingEngineering

The invention discloses an EPE (expand aple poly ephylene) foam cutting machine which is characterized by comprising a main frame. A first motor, a transverse cut-off mechanism for cutting off raw materials, a longitudinal splitting mechanism for splitting the raw materials, at least two bottom rolls and at least two press rolls matched with the bottom rolls correspondingly are arranged on the main frame. The first motor is connected with one bottom roll through a first drive mechanism to drive the bottom roll to rotate. Besides, a compressing mechanism for compressing the raw materials is also arranged on the main frame.

Owner:杭州勤诚塑料包装材料有限公司

Method of slicing thin bamboo

InactiveCN100384604CSimple production processHigh yieldVeneer manufactureWood veneer joiningEngineeringLongitudinal splitting

A technology for making thin bamboo sheet used as the veneer of artificial board or furniture includes such steps as providing a long large-diameter bamboo segment, spinning cutting, longitudinal splitting, longitudinal milling to become arc bamboo strips, coating resin, longitudinal and parallel laminating, die pressing, longitudinal and transverse splicing, and horizontal planing.

Owner:赵仁杰

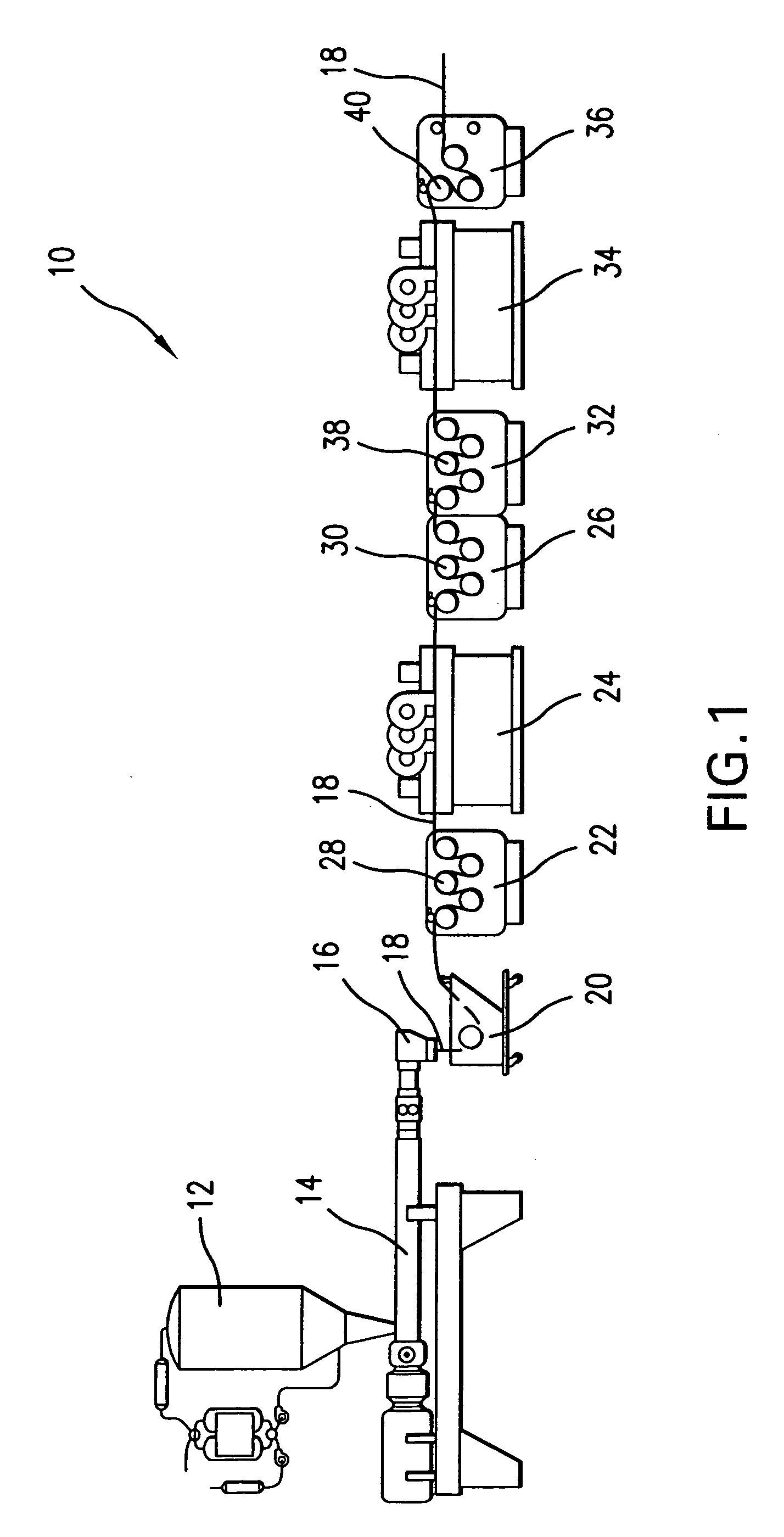

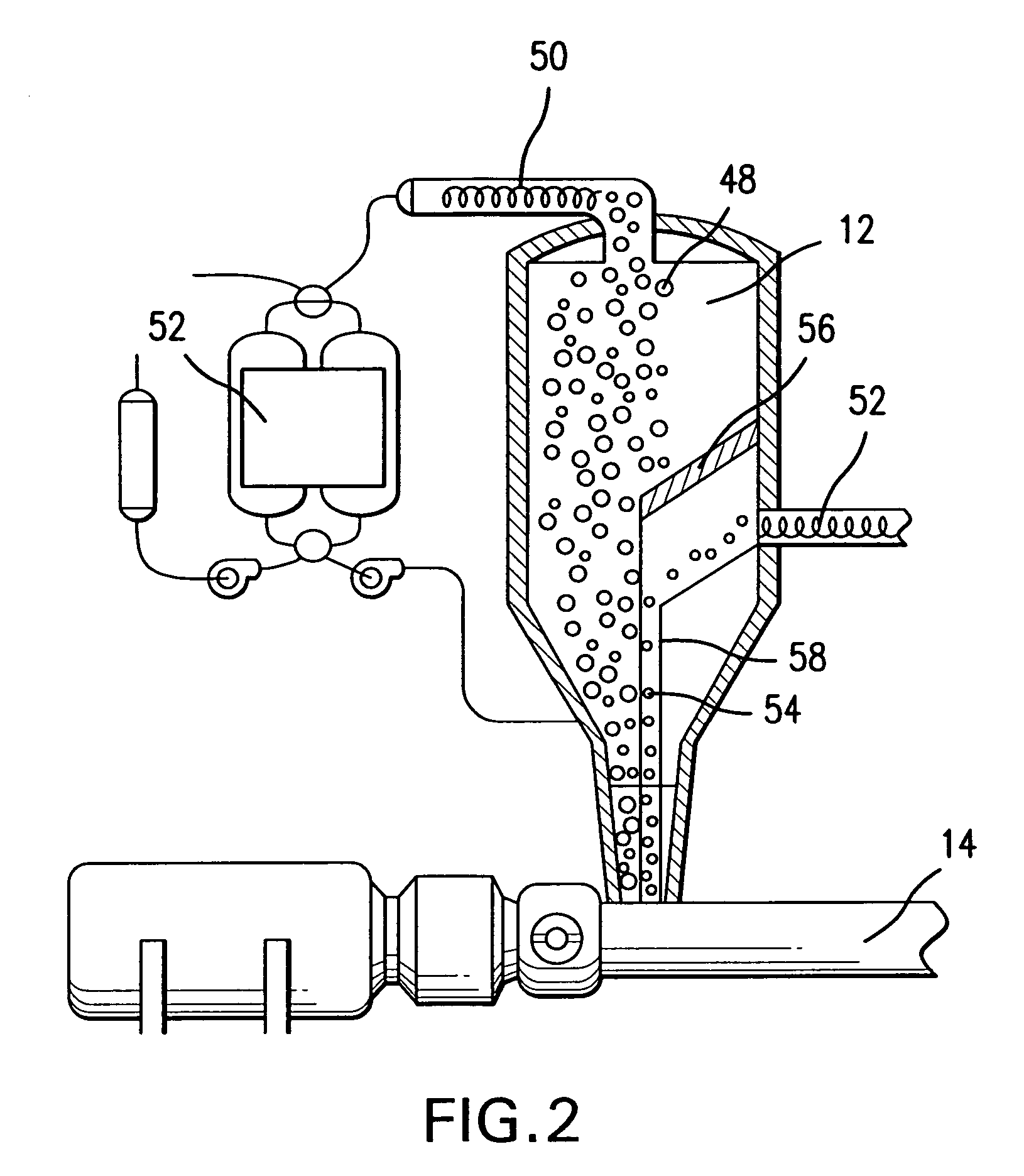

Multiple rotary knife for longitudinal splitting of webs

InactiveUS9227334B2Extended service lifeEasy to manufactureMetal working apparatusLongitudinal splittingEngineering

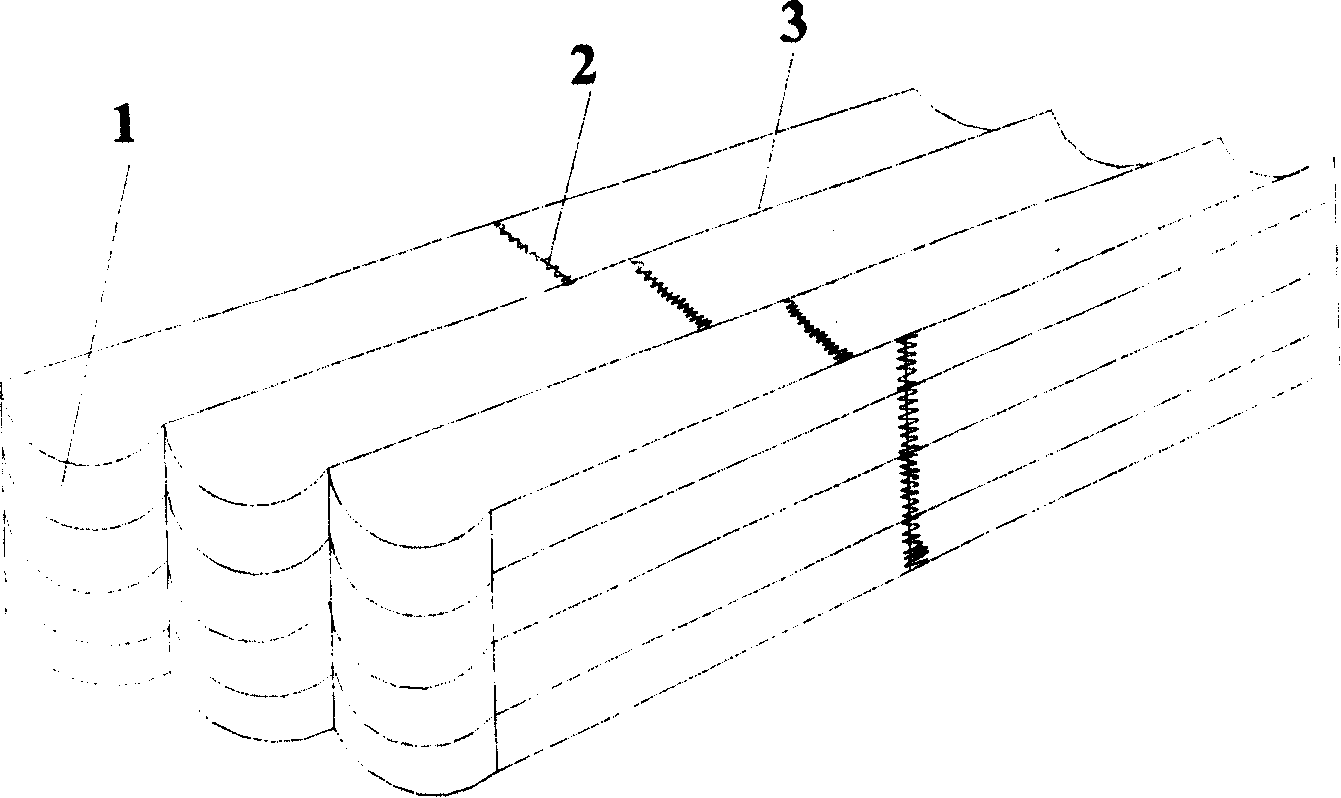

A multiple rotary knife for longitudinal splitting of webs, includes a generally cylindrical annular body bearing a plurality of circumferential blades spaced apart. The circumferential blades are formed by continuous hard-metal rings mechanically fixed axially to the annular body.

Owner:TURMOND

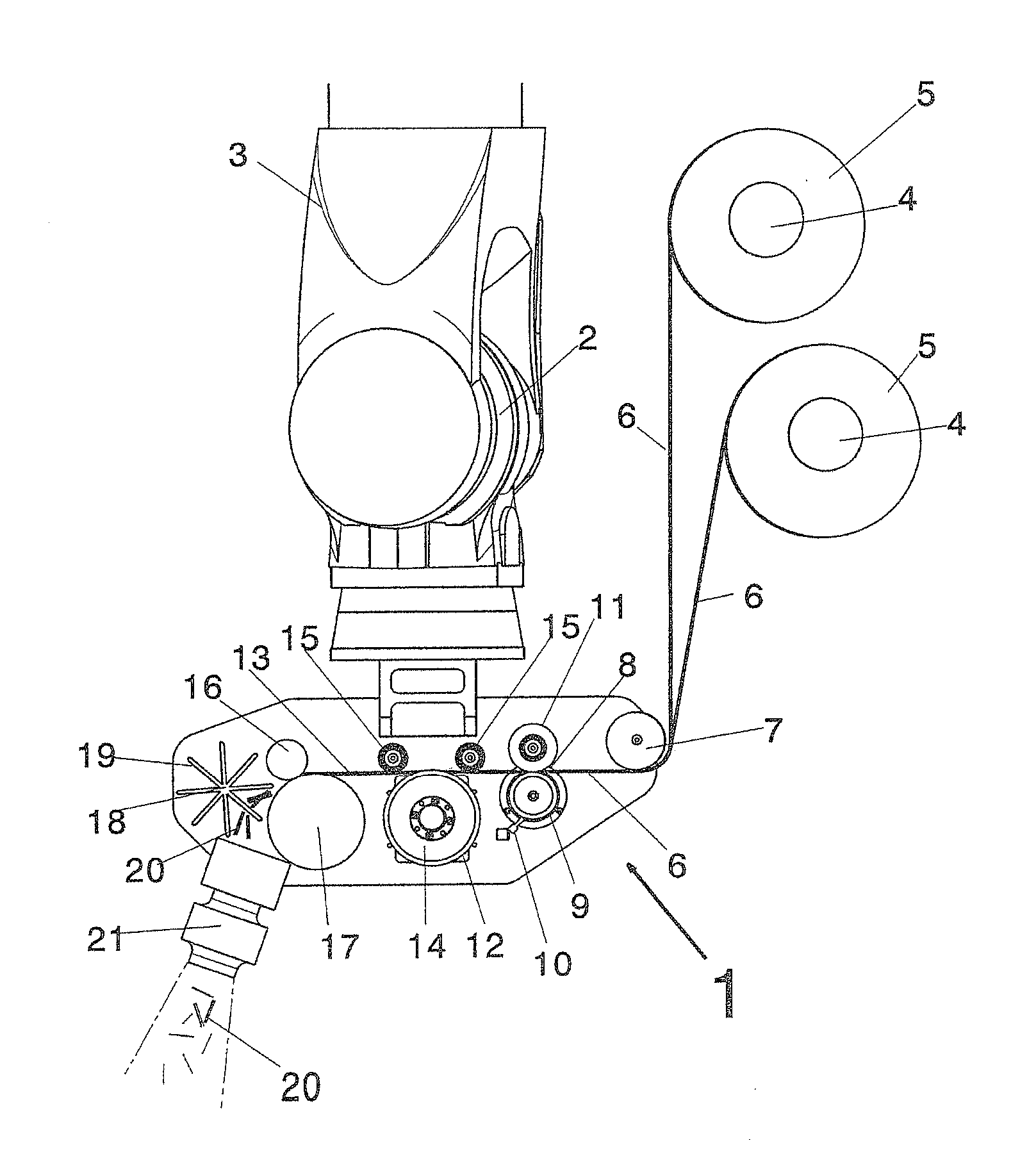

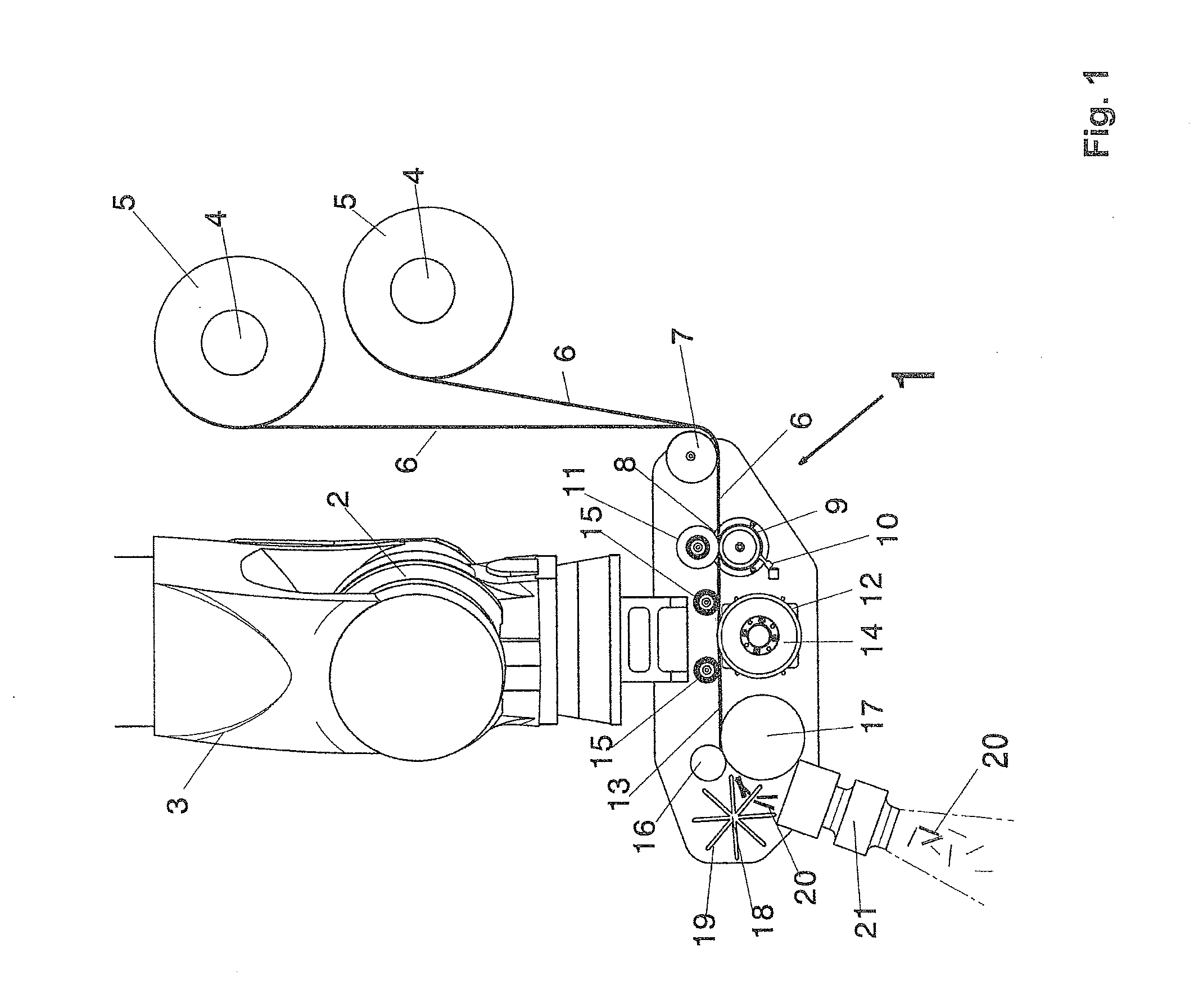

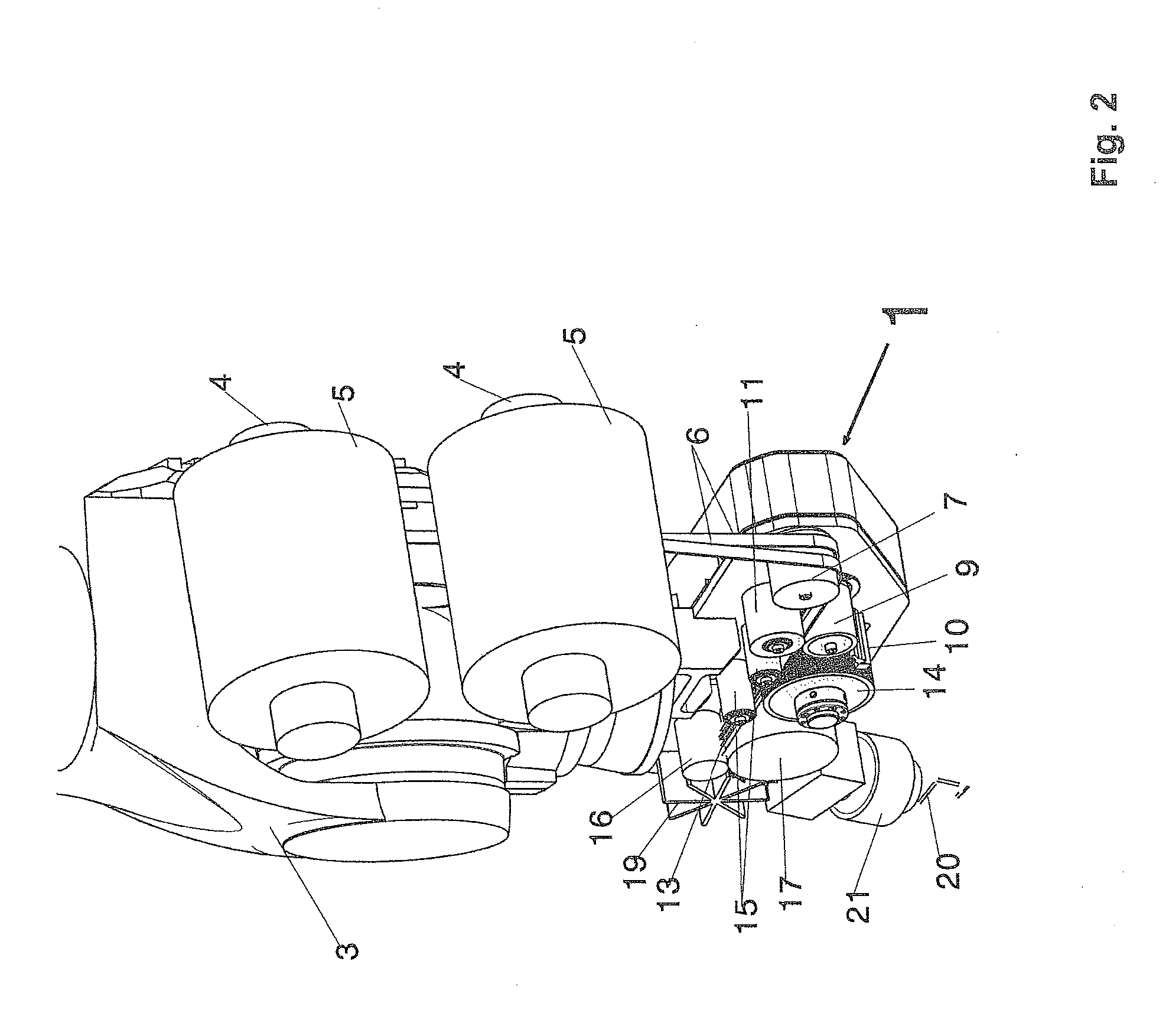

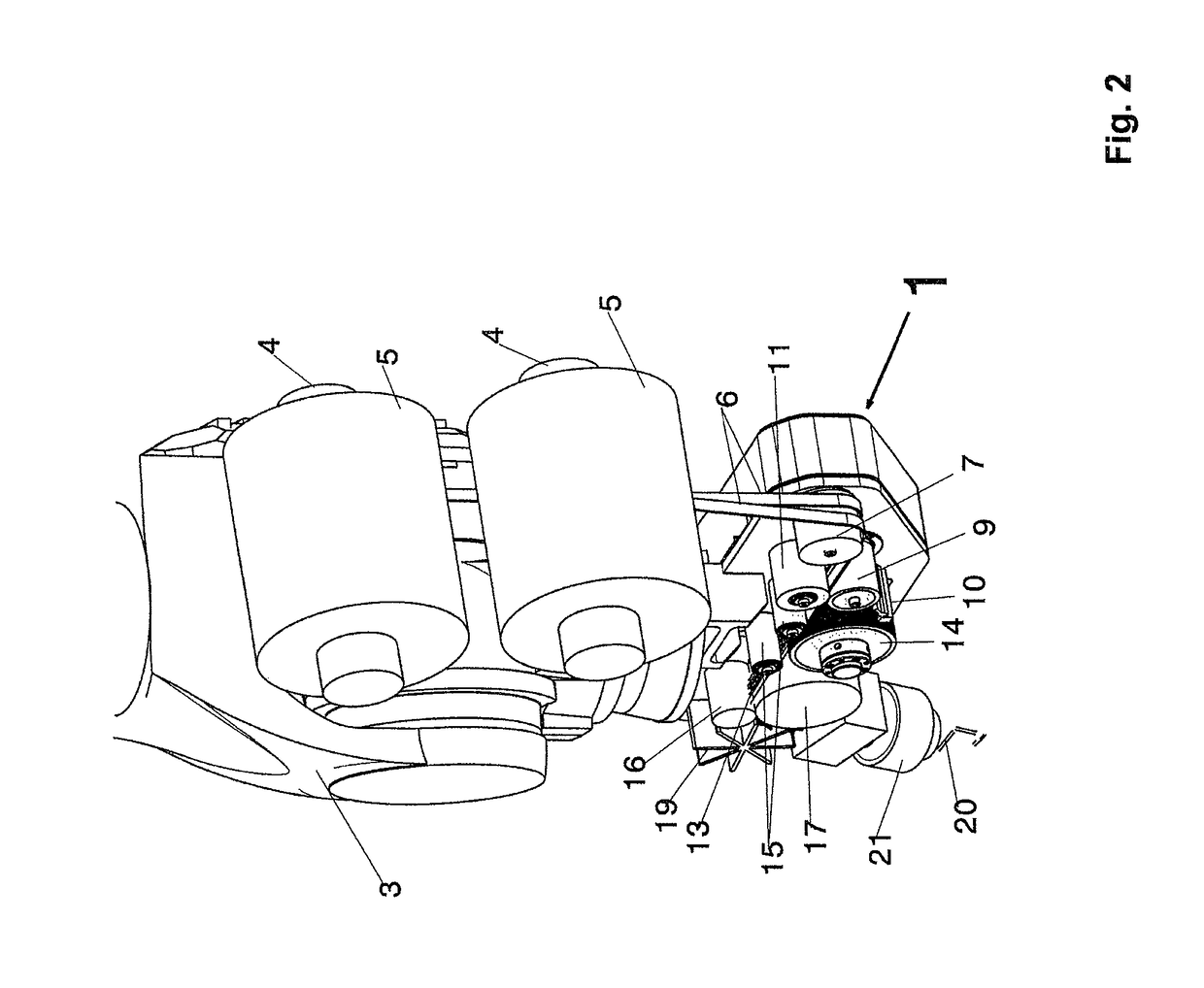

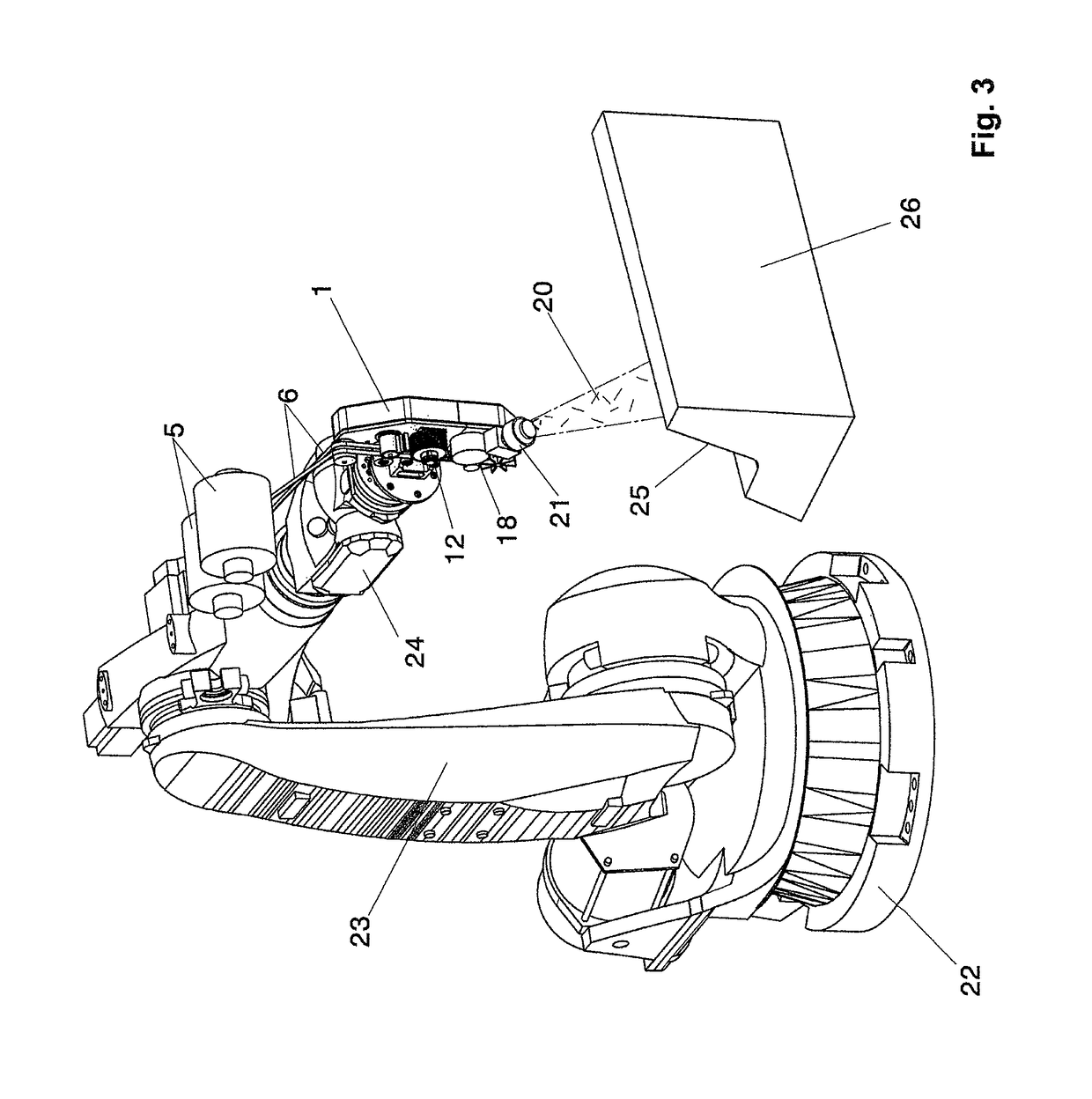

Deposition device for controlled deposition of reinforcing fiber bundles

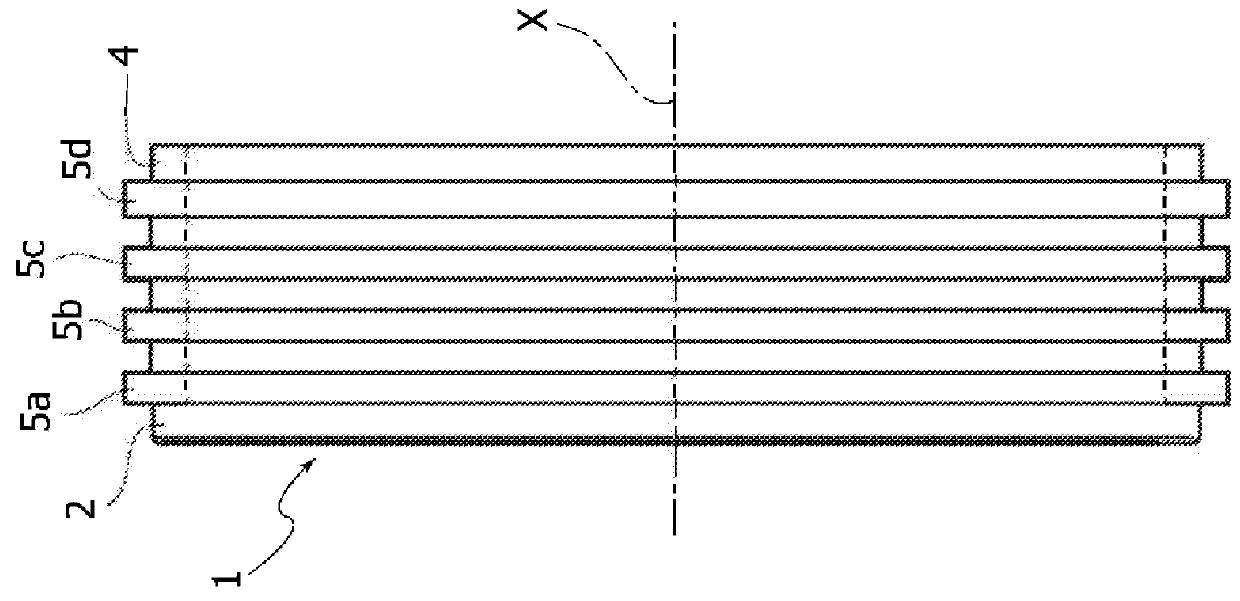

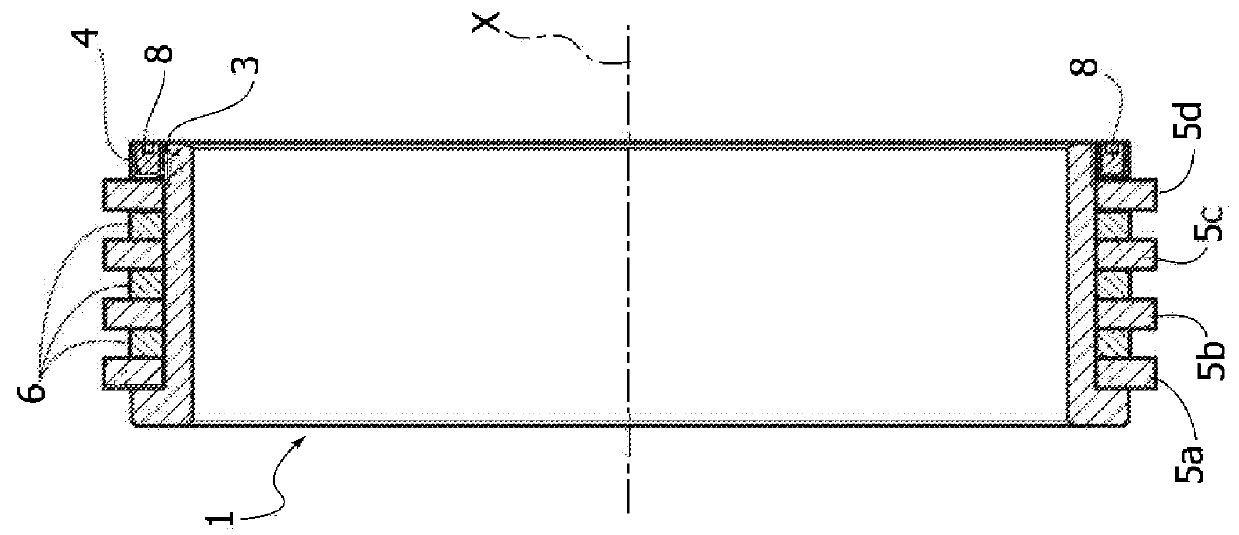

ActiveUS20150298163A1High fiber volume percentageReduce in quantitySpraying apparatusPretreated surfacesFiber bundleLongitudinal splitting

A deposition device for controlled deposition of reinforcing fiber bundles on a surface, including a deposition head and a controllable positioning unit, means for providing at least one strand of reinforcing fibers provided with a binder, and a first conveying device, arranged on the deposition head conveys the at least one strand to the deposition head, wherein, when viewed in the conveying direction, means for spreading the at least one strand are arranged on the deposition head, and the deposition head has a second conveying device arranged after the first conveying device, a longitudinal splitting device, arranged between the first and second conveying devices, with at least one splitting element for splitting the at least one strand along the longitudinal extension thereof into two or more partial strands, and a cut-to-length unit arranged after the second conveying device for cutting-to-length the two or more partial strands into fiber bundles.

Owner:TEIJIN CARBON EURO GMBH

Light double-row green brick tongs

ActiveCN105800322ASimple structureEasy to controlStacking articlesDe-stacking articlesLongitudinal splittingBrick

The invention relates to light double-row green brick tongs. The light double-row green brick tongs comprise a front-row clamping plate unit, a rear-row clamping plate unit, a longitudinal splitting and integrating air cylinder and a transverse splitting and integrating air cylinder which are arranged on a rack. Each of the front-row clamping plate unit and the rear-row clamping plate unit comprises a plurality of rows of clamping plate sets. The longitudinal splitting and integrating air cylinder drives the front-row clamping plate unit to move front and back so as to adjust the distance between the front-row clamping plate unit and the rear-row clamping plate unit. The transverse splitting and integrating air cylinder drives the clamping plate sets in the front-row clamping plate unit and the clamping plate sets in the rear-row clamping plate unit to transversely move, and adjusts the distance between the adjacent clamping plate sets. Each clamping plate set comprises a movable clamping plate fixing plate, a fixed clamping plate fixing plate and a clamping air cylinder, wherein the movable clamping plate fixing plate and the fixed clamping plate fixing plate are oppositely arranged front and back, and the clamping air cylinder drives the movable clamping plate fixing plate and the fixed clamping plate fixing plate to open and close to clamp green bricks. Compared with the prior art, the light double-row green brick tongs have the beneficial effects of being simple in structure, easy to control, small in weight and the like, by means of the tongs, the production efficiency can be improved, and power consumption can be reduced as well.

Owner:SHANGHAI TRIOWIN INTELLIGENT MACHINERY CO LTD

Method for producing fiber preforms

Described is a method for producing a fiber preform by deposition of reinforcing fiber bundles onto a surface including: supplying at least one continuous strand of reinforcing fibers provided with a binder to a deposition head, spreading the at least one strand in a spreader unit and conveying using a first conveying device to a longitudinal splitting device, cutting the at least one strand in the longitudinal splitting device along the longitudinal extension thereof into at least two partial strands by means of a splitting element, conveying the partial strands by means of a second conveying device to a cut-to-length unit, cutting the partial strands by means of the cut-to-length unit into reinforcing fiber bundles, and depositing the reinforcing fiber bundles onto a surface and / or reinforcing fiber bundles deposited on the surface and fixing the reinforcing fiber bundles to form the fiber preform.

Owner:TEIJIN CARBON EURO GMBH

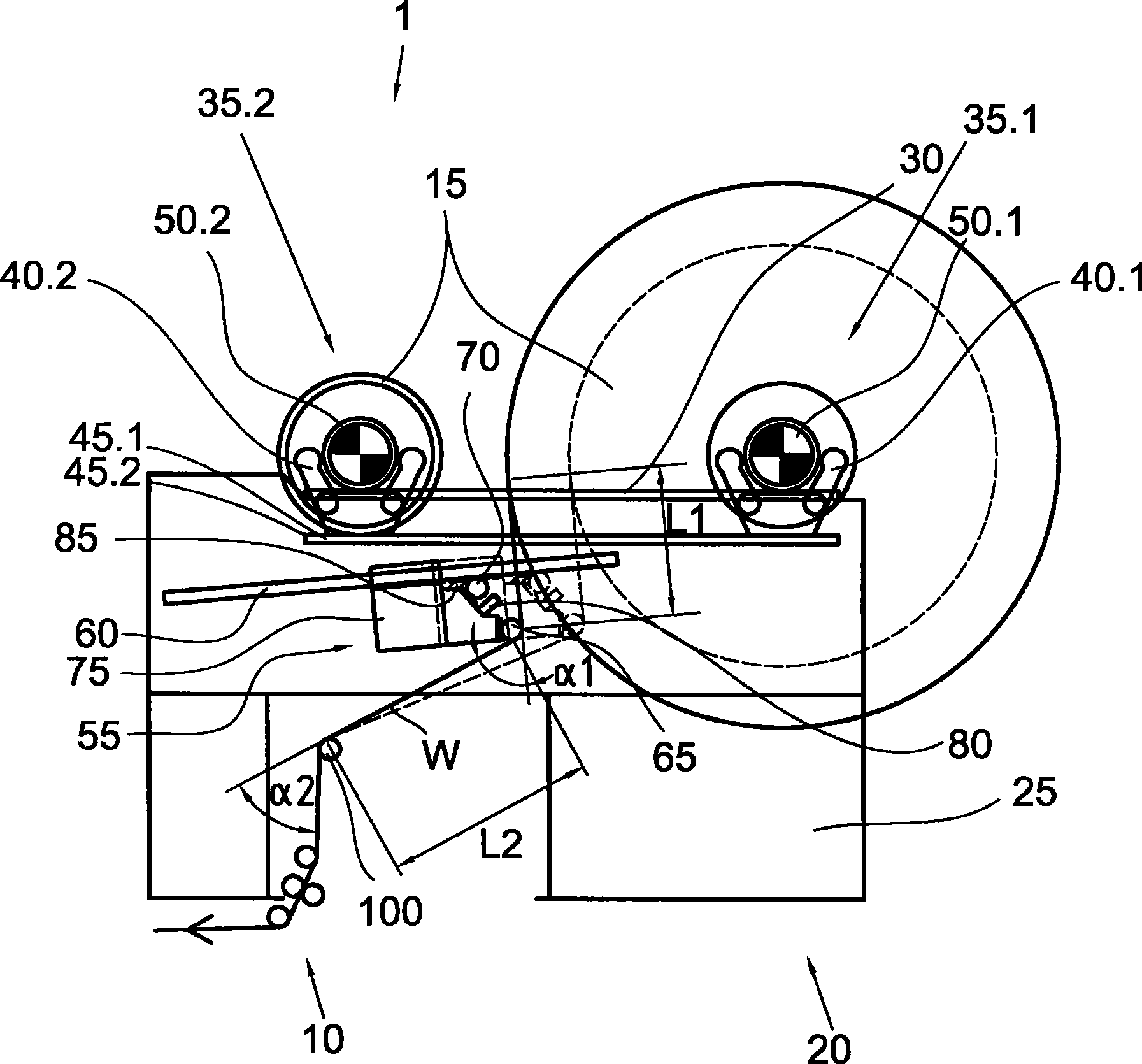

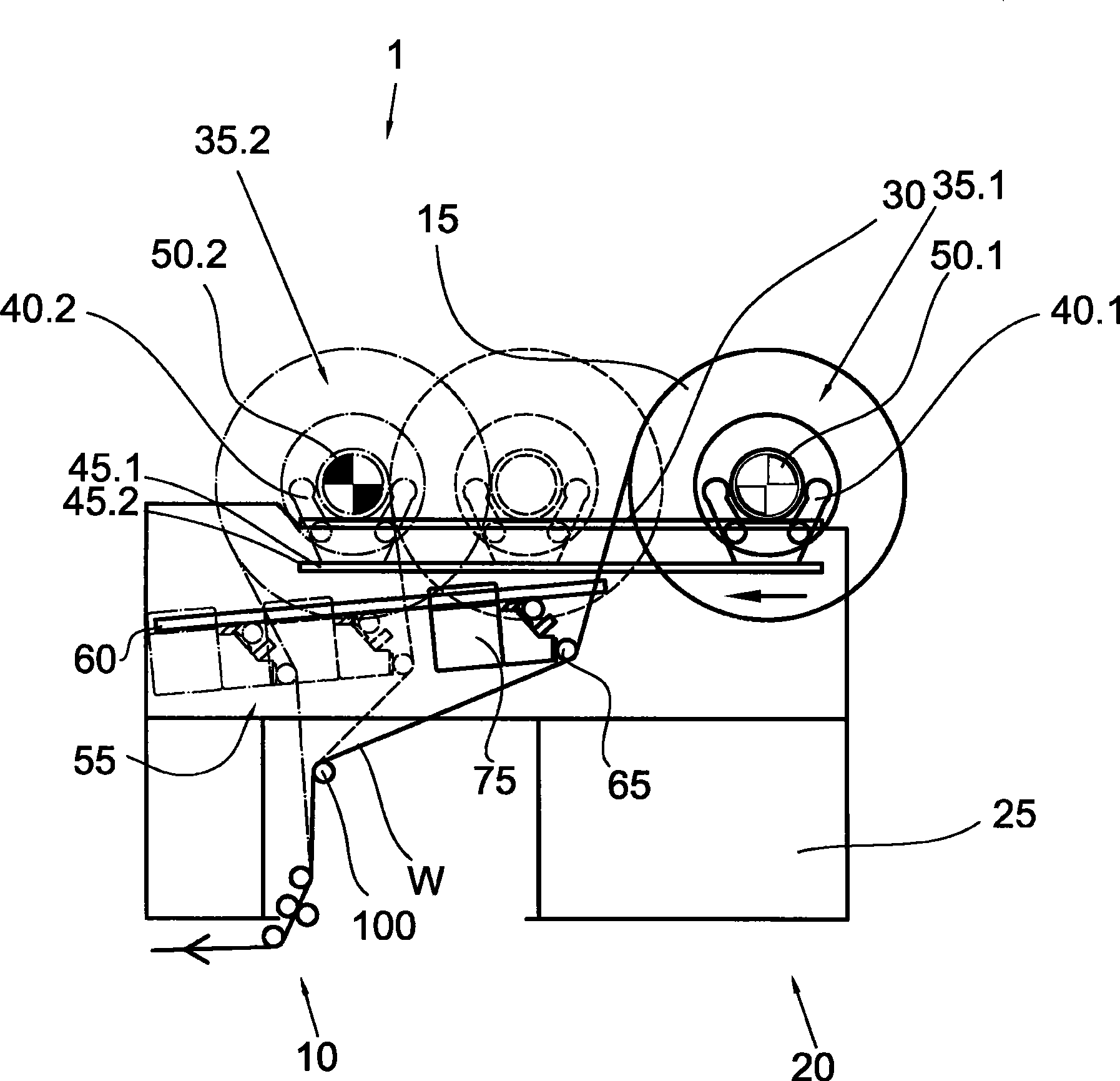

Method for longitudinally slitting fibrous web using longitudinal splitting machine

ActiveCN101407290BImprove efficiencyShorten the timeArticle deliveryWebs handlingLongitudinal splittingMachine

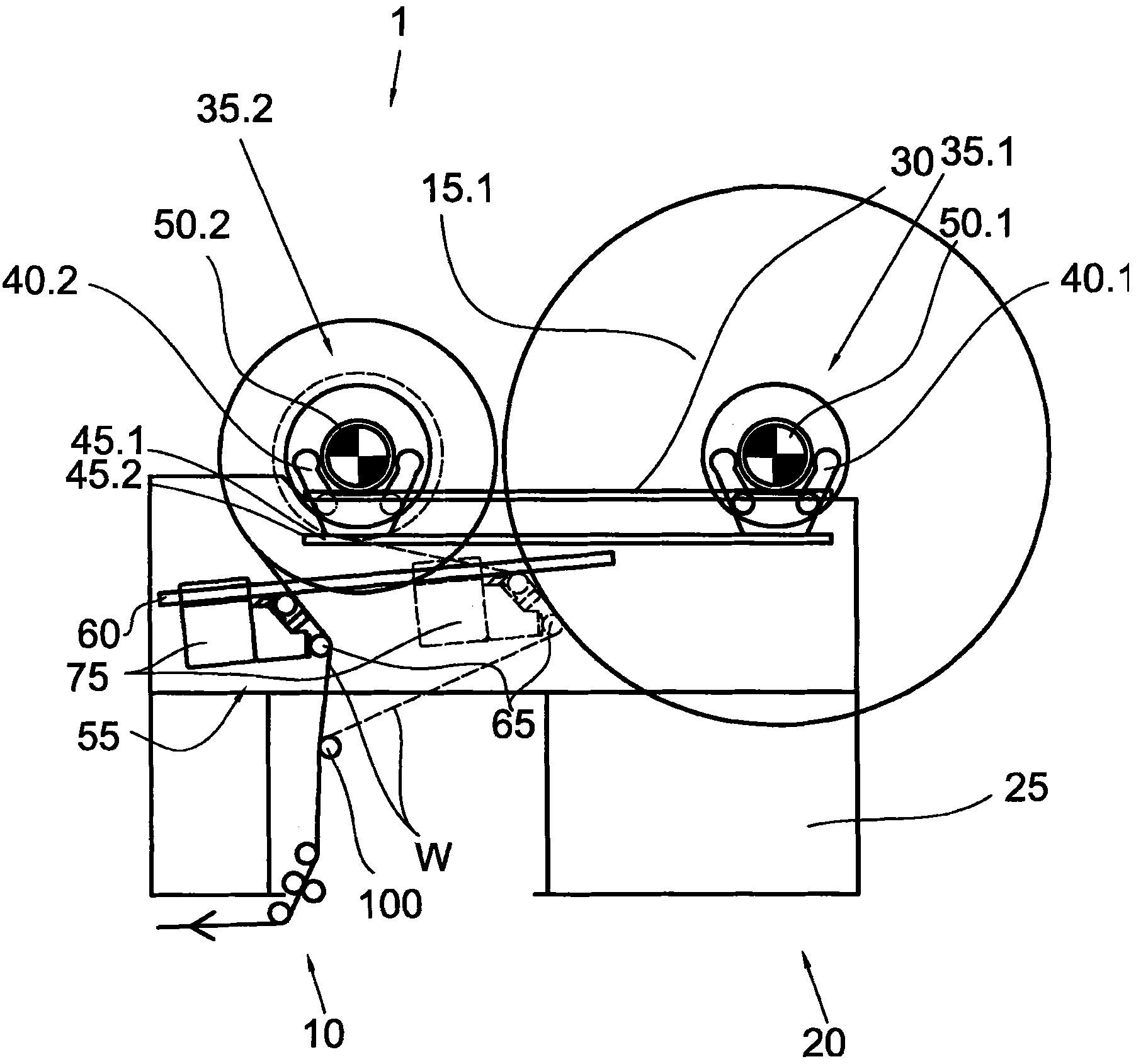

The invention relates to a method using a longitudinal cutter for longitudinally splitting a fiber web, wherein, by executing re-rolling of a predetermined length, the web (W) which is cut into part web by the longitudinal cutter is rolled up to a part of web roll with a predetermined diameter. The method involves rolling a machine roll (15) up to a predetermined diameter in a primary rolling station (35.1). The machine roll is shifted to a secondary rolling station (35.2), and a machine roll change is implemented during connection of a fiber web (W) arriving from the new machine roll with a web arriving from an old machine roll that is connected with a splitting connection. The machine roll is shifted from the primary rolling station to the secondary rolling station during the roll change of a longitudinal cutter. An independent claim is also included for an arrangement for slitting a longitudinal cutter of a fiber web.

Owner:METSO PAPER INC

Drill rod puller

InactiveCN105604510AReliable liftingSimple structureBorehole/well accessoriesLongitudinal splittingPetroleum engineering

The invention discloses a drill rod puller. The drill rod puller comprises a transverse beam frame and a slip, wherein the slip is arranged in the middle of the transverse beam frame; the contact surface between the slip and the transverse beam frame is an inclined plane and an included angle is formed between the contact surface and the vertical direction; a clamping hole through which a drill rod passes is formed in the middle of the slip; the slip is in a longitudinal splitting form; and the drill rod is tightly clamped by the slip and the transverse beam frame which are wedged through the inclined plane. The drill rod puller disclosed by the invention has the advantages of simple structure, low manufacture cost, and convenience for operation; the drill rod can be reliably pulled; the drill rod puller is small in size, can be mounted in site and also can be used in a complicated utilization environment so that the drill rod puller has relatively great flexibility.

Owner:ZHENJIANG BAOCHENG GROUTING EQUIP

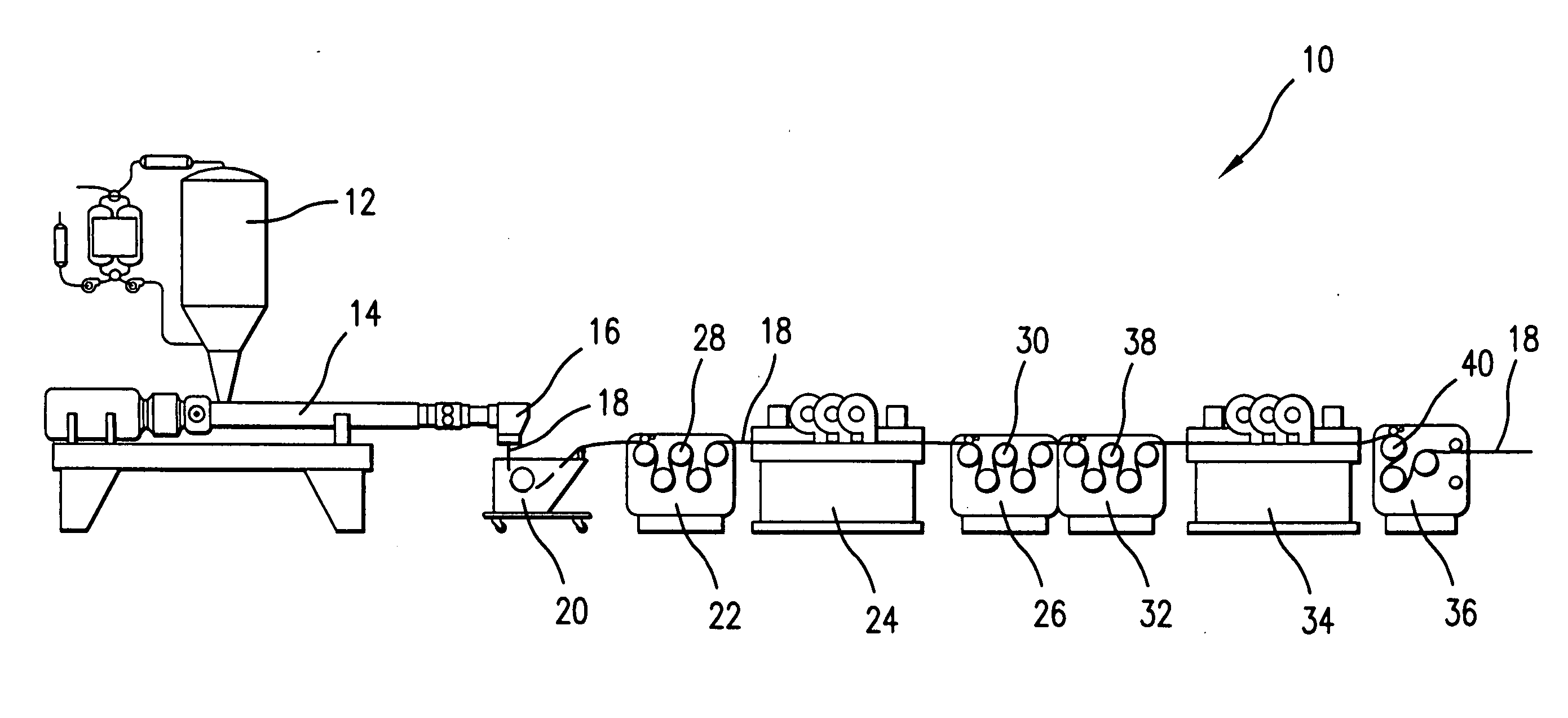

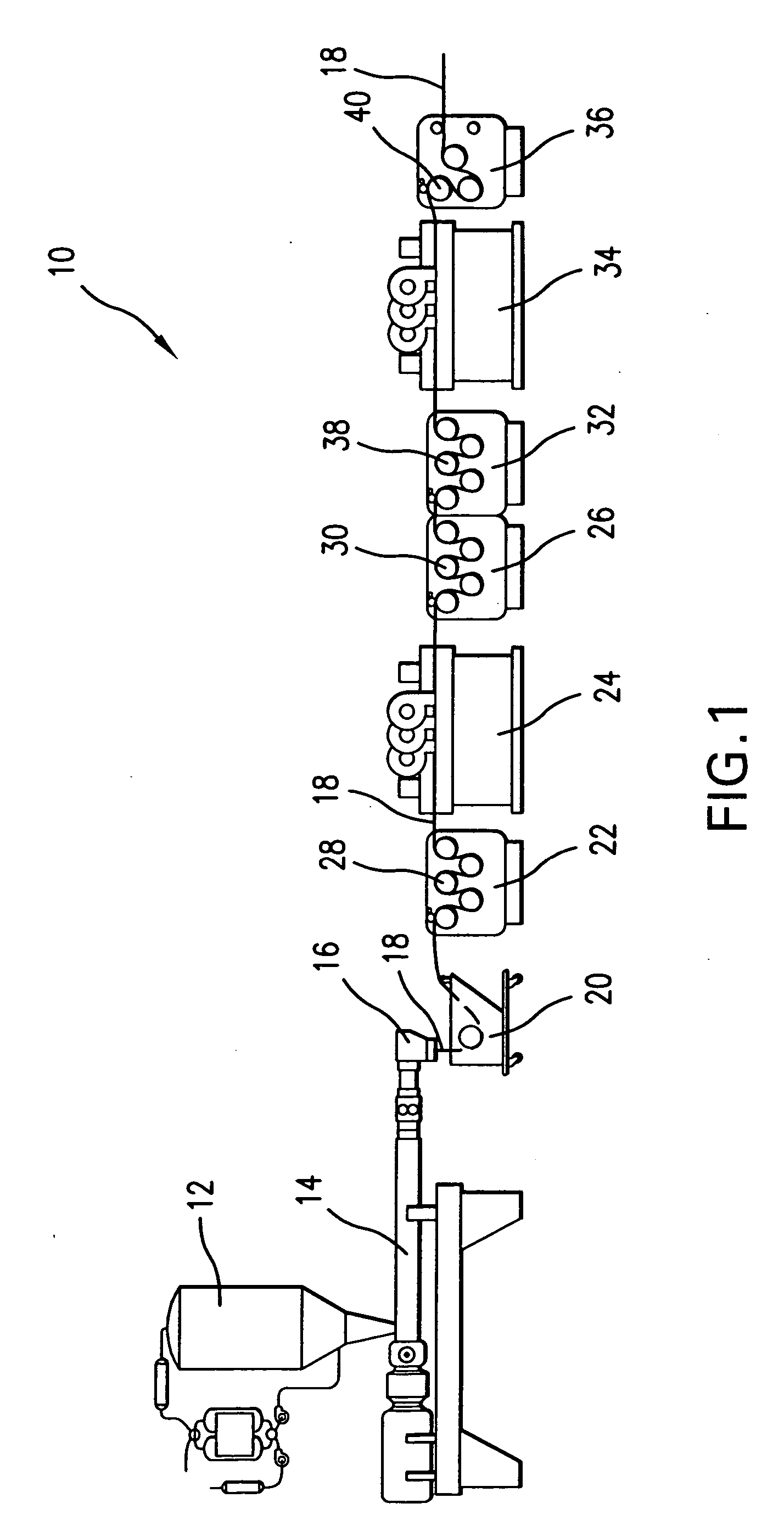

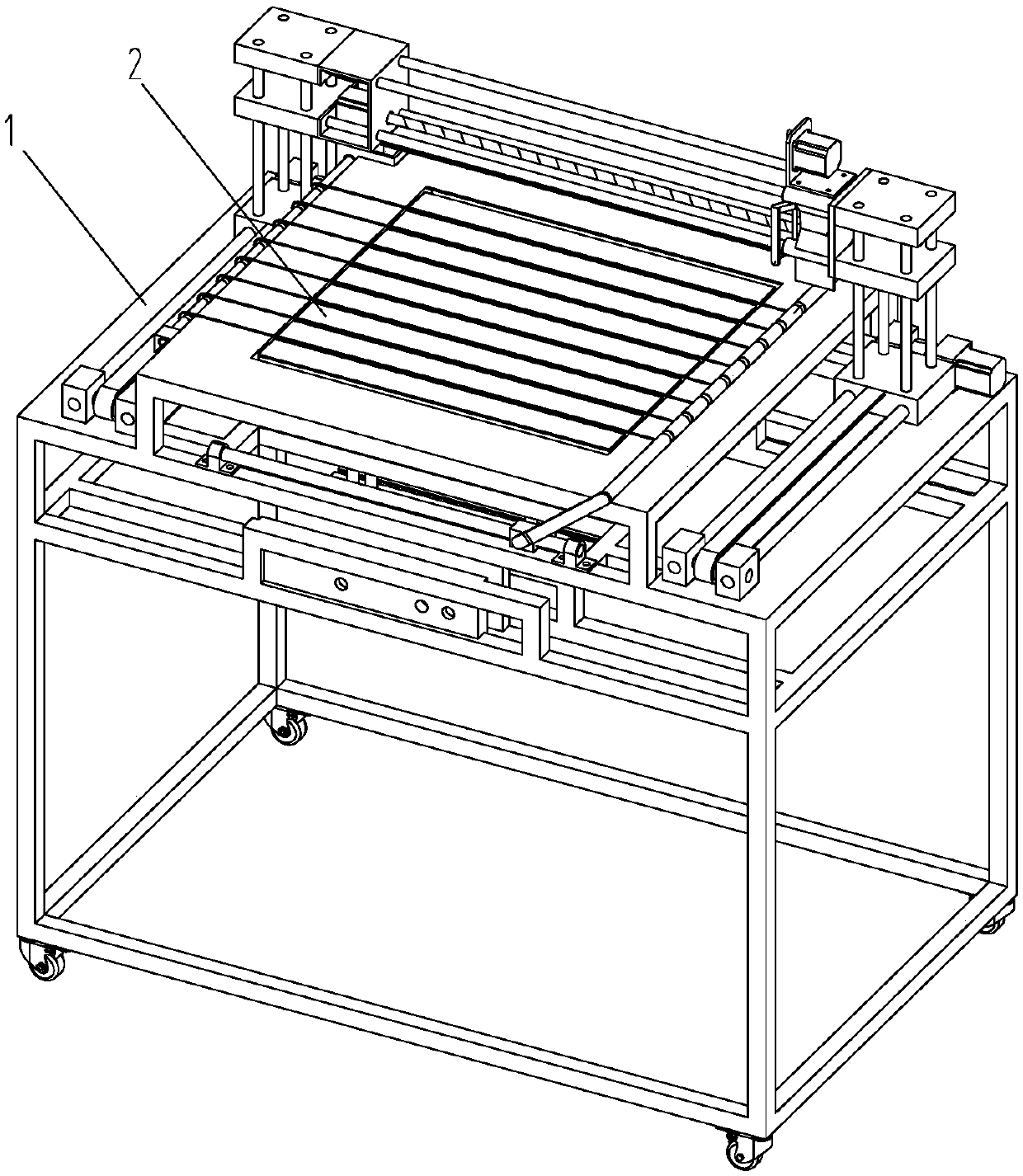

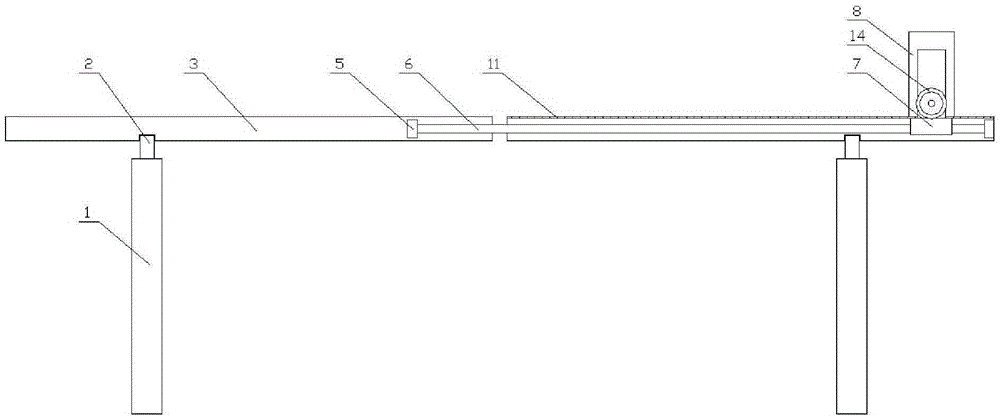

Novel corrugated board production line

ActiveCN102220722BSimple configurationEfficient configurationPaper-making machinesProduction lineCardboard

The invention provides a novel corrugated board production line. The production line is characterized in that the production line is formed by a No.1 single machine (1), a No.2 single machine (2), a No.3 single machine (3), a quadruplex preheater (4), a gummer (5), a double-sided machine (6), a drying and cooling machine (7), a longitudinal splitting machine (8), a transverse splitting machine (9), a board collecting frame (10) and a No1. elevator (11) which are arranged in sequence; and a board conveyor (14), a longitudinal and transverse splitting machine (12) and a board collecting frame II (13) are arranged in sequence and connected to an idle No.1 single machine (1) to form another technonoly production line are positioned at the right or left end of the production line. The production line has the following advantages: two different products can be simultaneously produced along two process flow directions; one production line completes the functions of two production lines; the equipment utilization ratio and the production efficiency are high; the equipment input is low; and resource waste is avoided.

Owner:QUJING QIANKUN PAPER

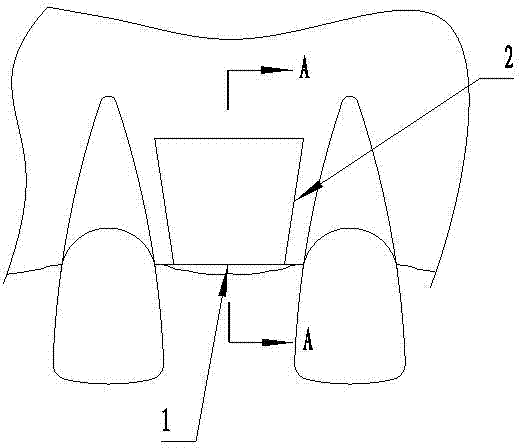

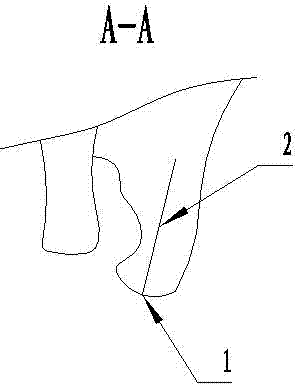

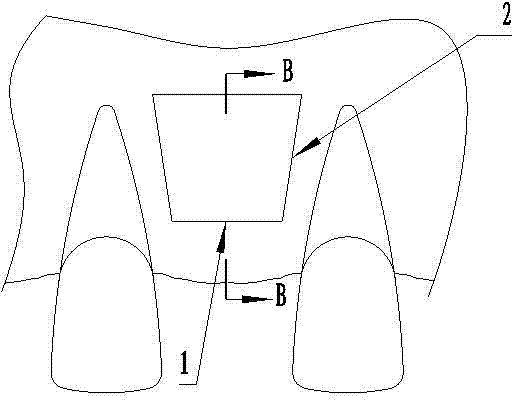

Improvement of bone splitting carried out below lip-cheek crest in oral implantation

InactiveCN103494649AAvoid breakingImprove initial stabilityDental implantsLongitudinal splittingQuadrate bone

The invention provides an improvement of bone splitting carried out below a lip-cheek crest in oral implantation. The improvement is characterized in that a splitting inlet is located in the lip-cheek crest, and the starting point of a bone splitting line is designed at the near-root end of a concave area of a lip-cheek side bone. The bone splitting method includes the following steps: a horizontal bone splitting cut line is formed at the near-root end of the concave area of the bone through an ultrasonic bone knife, two longitudinal splitting lines are additionally and respectively formed in a near cut, a distant cut and a middle cut, the bone splitting is carried out through the horizontal cut line, and meanwhile an implant, bone implantation powder and a bone cover membrane are implanted. Usually, a Biogide bone membrane is used for covering when Bio-oss bone powder is implanted. The situation that a bone plate is broken in the bone concave area in the splitting process is avoided, the implantation direction of the implant can be in an ideal position, the condition that the implant is supported by sufficient bones around the implant is guaranteed, and retaining of bone cortex of the crest facilitates stability in the early stage.

Owner:福建医科大学附属口腔医院

Double leg flexibility trainer

InactiveCN102641576AIncrease enthusiasmImprove tensile propertiesGymnastic exercisingLongitudinal splittingForward sliding

The invention relates to a double leg flexibility trainer; flexibility is one of physical qualities; good flexibility is base for learning technical actions; at present, less equipment related to the flexibility training is seen; practitioners stretch ligaments through traditional forward leg-bending and straddling seat when training leg crossing flexibility; because there is no forward sliding force when practitioners sit on ground, effects are not good; in a longitudinal splitting area 7, practitioners help two handle rods 3 on left and right sides by two hands, two legs split front and back, a hip is opened longitudinally to split and train a longitudinal split. Practitioners sit on a sliding inclined plate 4 by bending legs behind the body, two hands respectively help a left handle 1 and a right handle, two legs split greatly and tiptoes face upwards, inner sides of two feet slide on a forward leg-bending and transversely-straddling foot blocking rod to perform longitudinal splitting training.

Owner:EASTERN GANSU UNIVERSITY +2

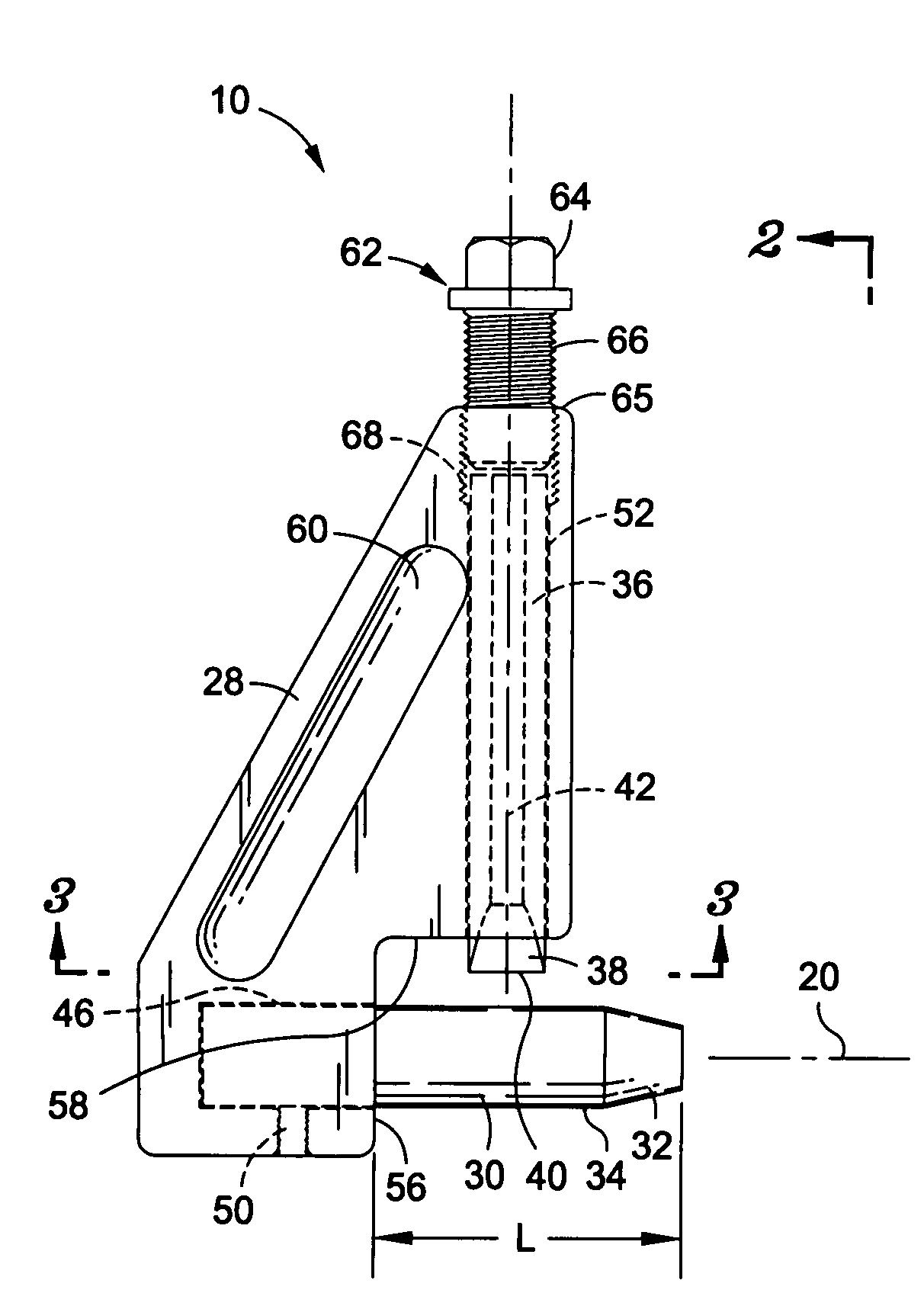

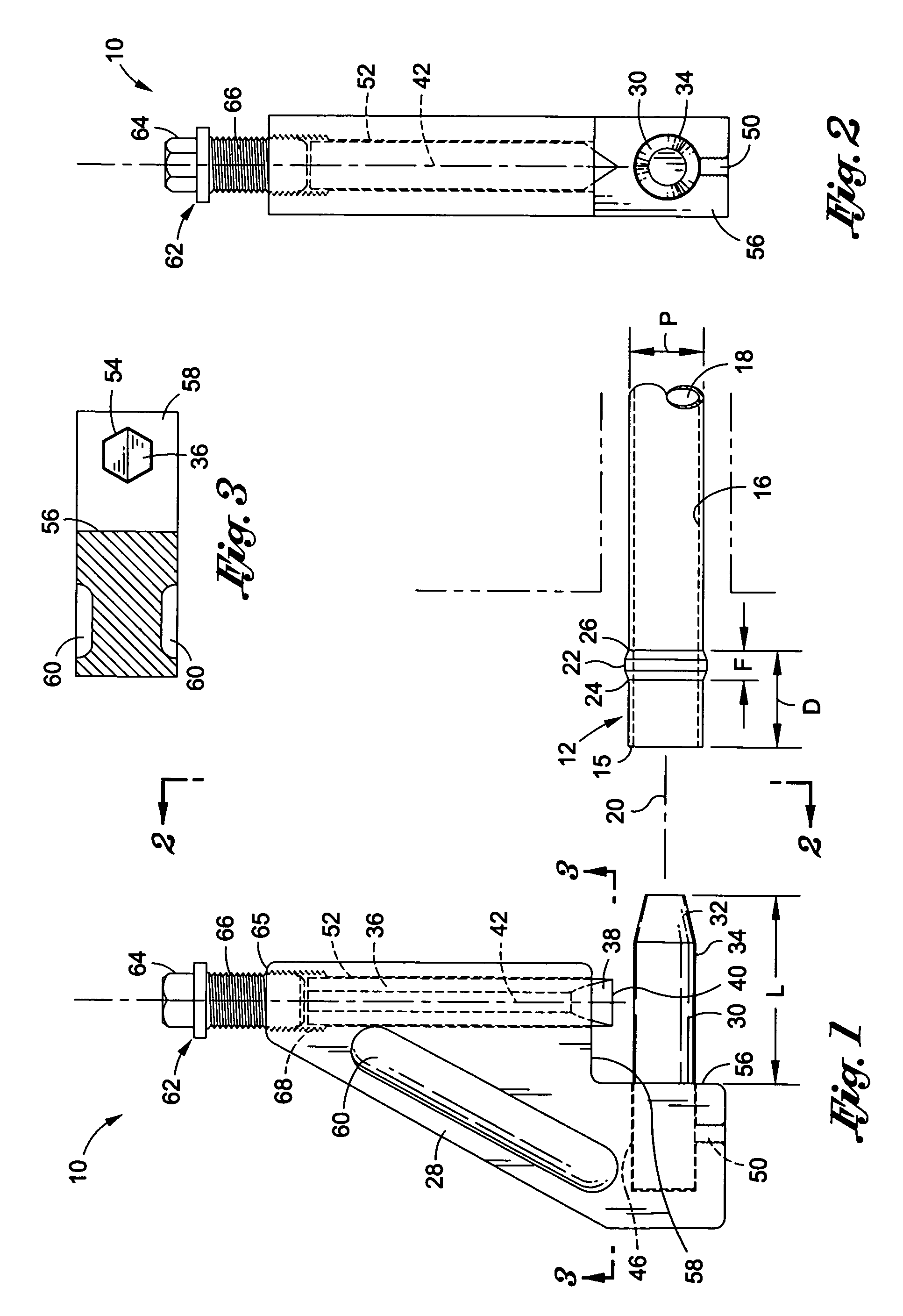

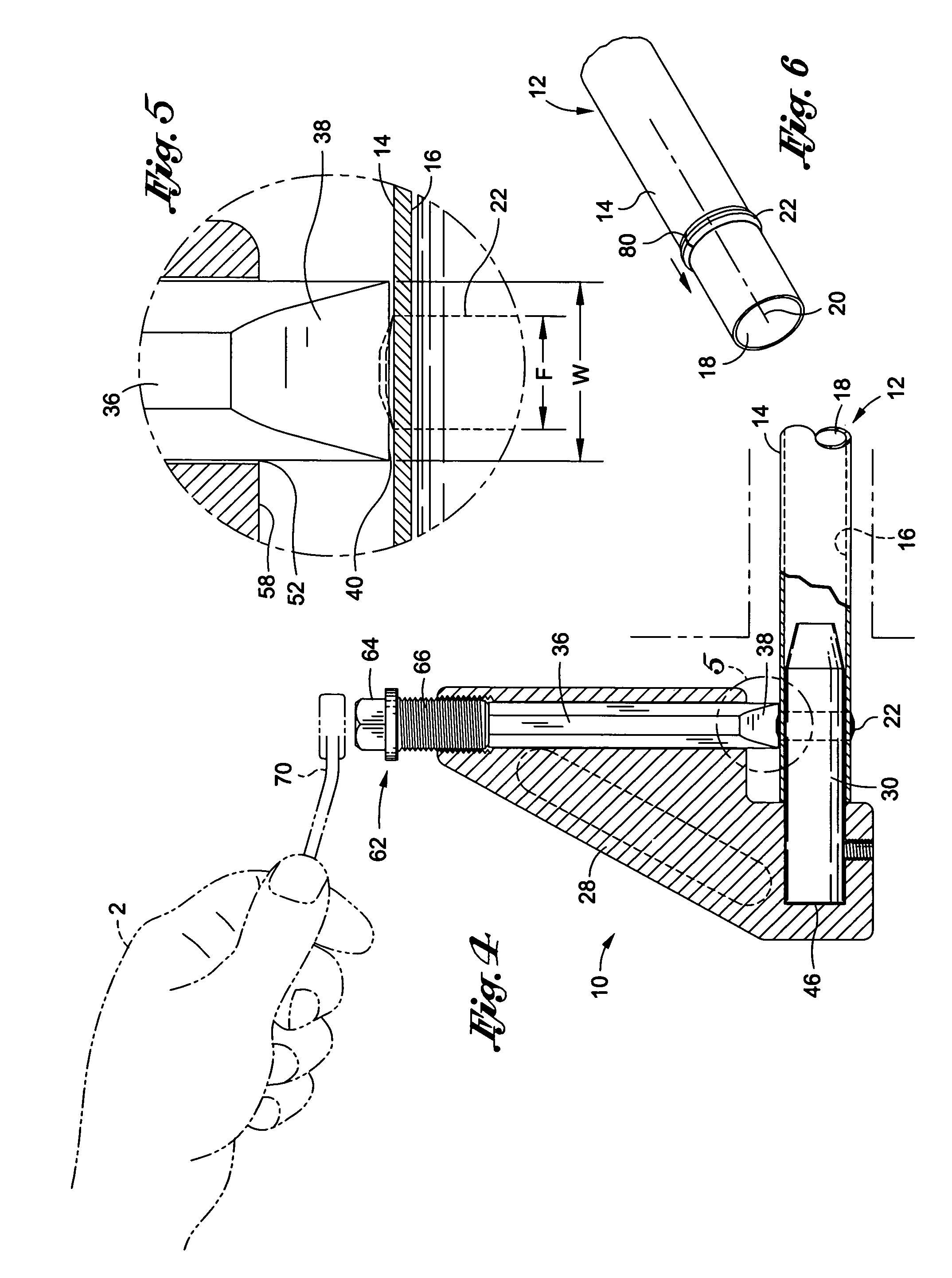

Compression sleeve splitter and removal tool

ActiveUS8209835B2Easy to disassembleReduce deformation or damageTube shearing machinesMetal working apparatusLongitudinal splittingEngineering

There is provided a splitting tool for use with a pipe defining a longitudinal pipe axis. The pipe includes an outer wall and an inner wall defining a pipe channel. A ferrule is circumferentially disposed about the outer wall. The splitting tool includes a pipe support member defining an outer periphery that is substantially complimentary in shape to the inner wall. The pipe support member is insertable within the pipe channel to extend at least through the ferrule and to provide radial support to the inner wall. The splitting tool additionally includes a splitter member operatively connected to the pipe support member. The splitter member defines a longitudinal splitting axis that is substantially perpendicular to the pipe axis when the pipe support member is inserted within the pipe channel. The splitter member is moveable along the splitting axis to radially engage with and pierce the ferrule.

Owner:HUFFER BRIAN J +1

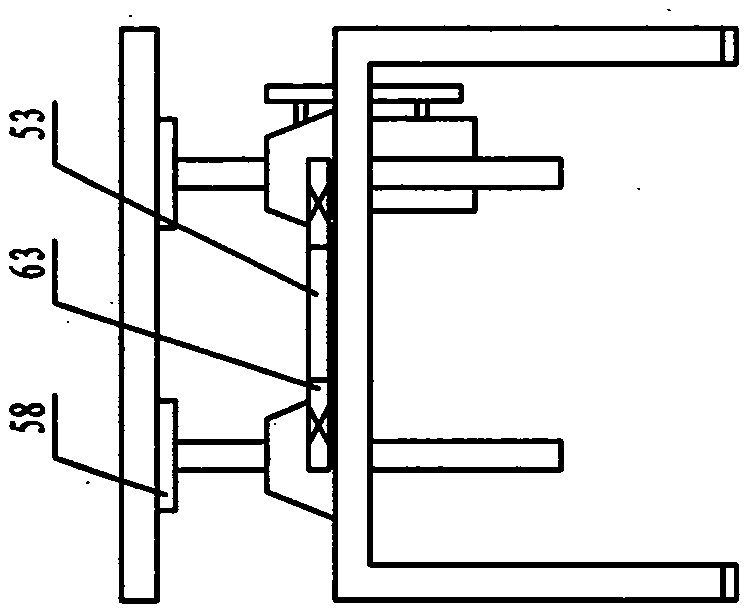

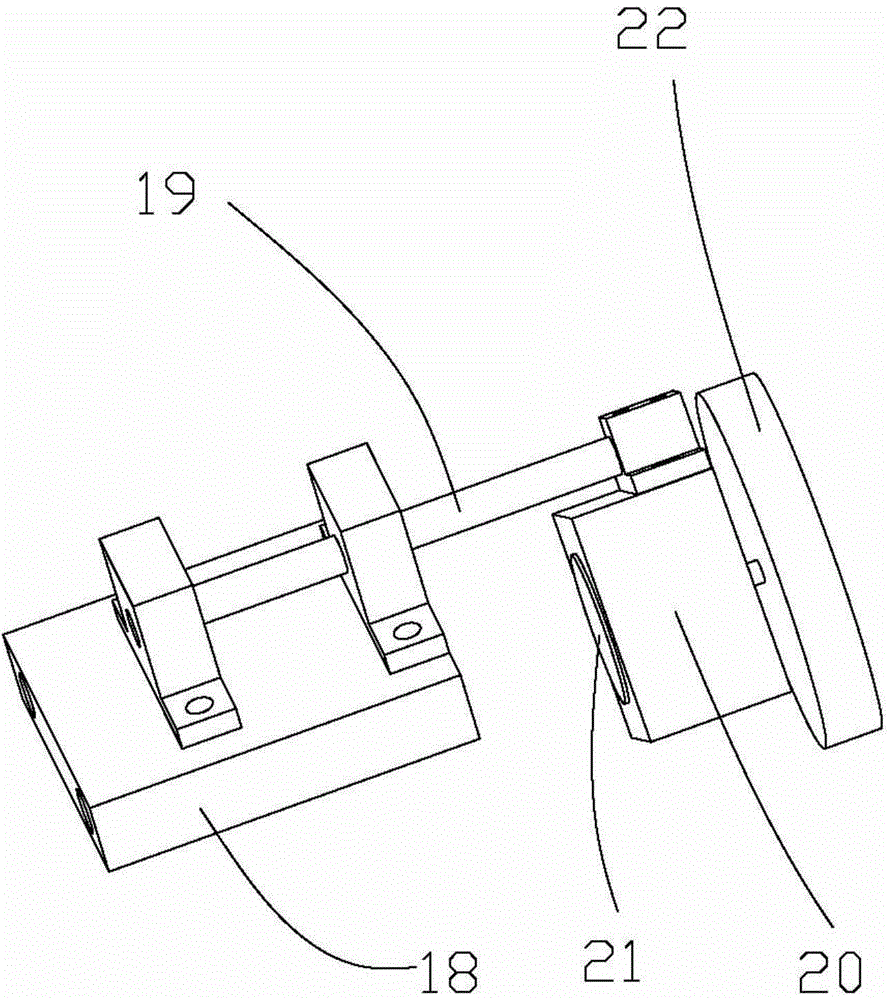

Longitudinal splitting machine

InactiveCN106799763ASmooth transmissionEasy to operateMetal working apparatusLongitudinal splittingDrive shaft

The invention provides a longitudinal splitting machine comprising two side supporting plates. Guide rails are arranged at the top ends of the side supporting plates. Feeding plates are slidably connected on the guide rails correspondingly. The feeding plates are arranged oppositely. A cutting knife is arranged in a gap between the feeding plates. Supporting seats are oppositely arranged between the transverse side faces of the feeding plates. Guiding shafts are fixedly connected between the supporting seats. Side brackets are slidably connected on the guiding shafts. A pressing plate is fixedly connected between the side brackets. Driving shafts are rotatably connected on the side faces of the side brackets. The front ends of the driving shafts penetrate through the side brackets and are connected with gears. Racks are transversely arranged on the two sides of the feeding plates. The gears are engaged with the racks. The longitudinal splitting machine has the beneficial effects that the structure is simple, operation is convenient and fast, and the adaptability of operation of cutting sheet materials with different widths is improved.

Owner:TIANJIN WANGUO POLYMER MATERIALS CO LTD

A pearl cotton cutting machine

ActiveCN104128948BSimple structureImprove cutting accuracyMetal working apparatusLongitudinal splittingEngineering

Owner:杭州勤诚塑料包装材料有限公司

Longitudinal slitting machine for wide aluminum strip double shaft coiling

ActiveCN104150266BGuaranteed uptimeAdjustable distanceArticle deliveryWebs handlingLongitudinal splittingEngineering

The invention discloses a wide-width aluminum strip double-axis coiling and longitudinal splitting machine. The wide-width aluminum strip double-axis coiling and longitudinal splitting machine comprises an uncoiling machine, an adjustment device and a main machine. The uncoiling machine, the adjustment device and the main machine are arranged in one plane and sequentially connected according to the order. The uncoiling machine comprises an uncoiling base and an uncoiling driving device. The uncoiling driving device is arranged on the top face of the uncoiling base. The adjustment device comprises a first base, a pair of steering mechanisms, an adjustment mechanism and a centering detection device. The steering mechanisms are fixedly arranged at the two ends of the top face of the first base respectively. The adjustment structure is arranged in the position right between the steering mechanisms. The centering detection device is arranged on the side face of one of the steering mechanisms. The main machine comprises a machine frame, a pair of rocker arm devices, a guide rail supporting device, a pair of winding devices and a splitting device. The wide-width aluminum strip double-axis coiling and longitudinal splitting machine is stable in running, wide in machining range, high in universality, low in cost and high in efficiency.

Owner:镇江龙源铝业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com