Method for longitudinally slitting fibrous web using longitudinal splitting machine

A technology of fiber web and slitting machine, which is applied in the direction of winding strip, thin material processing, sending objects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

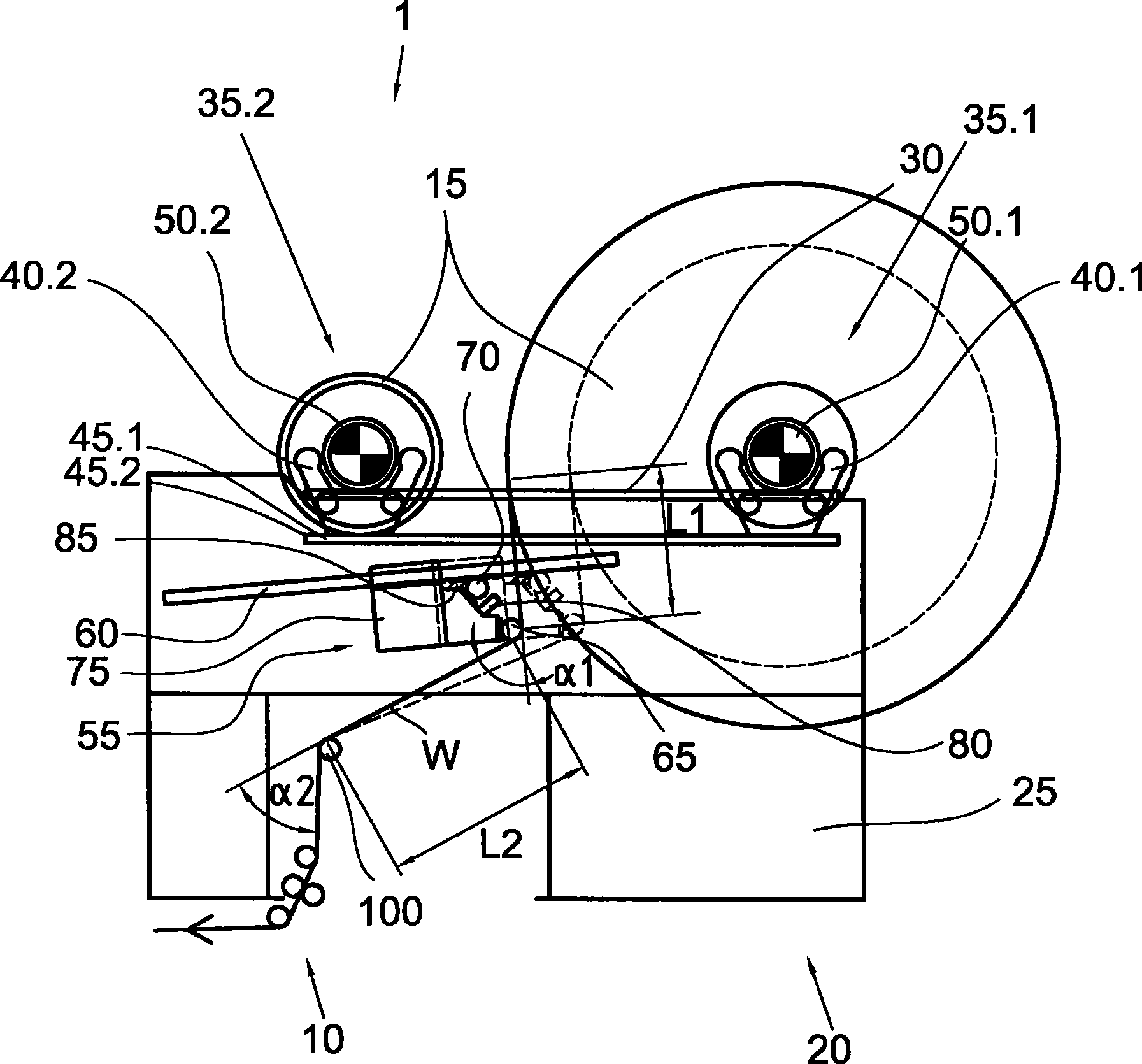

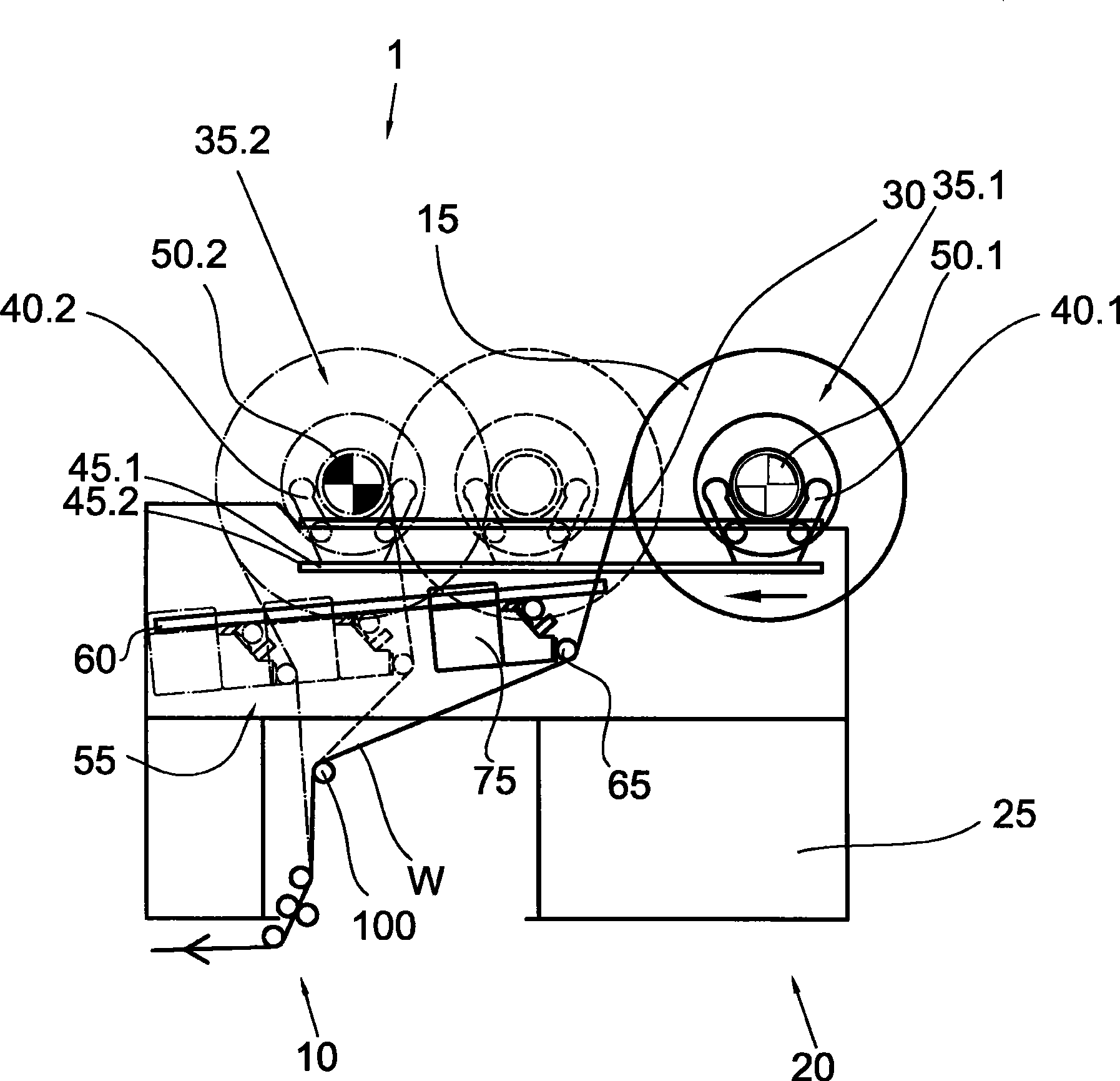

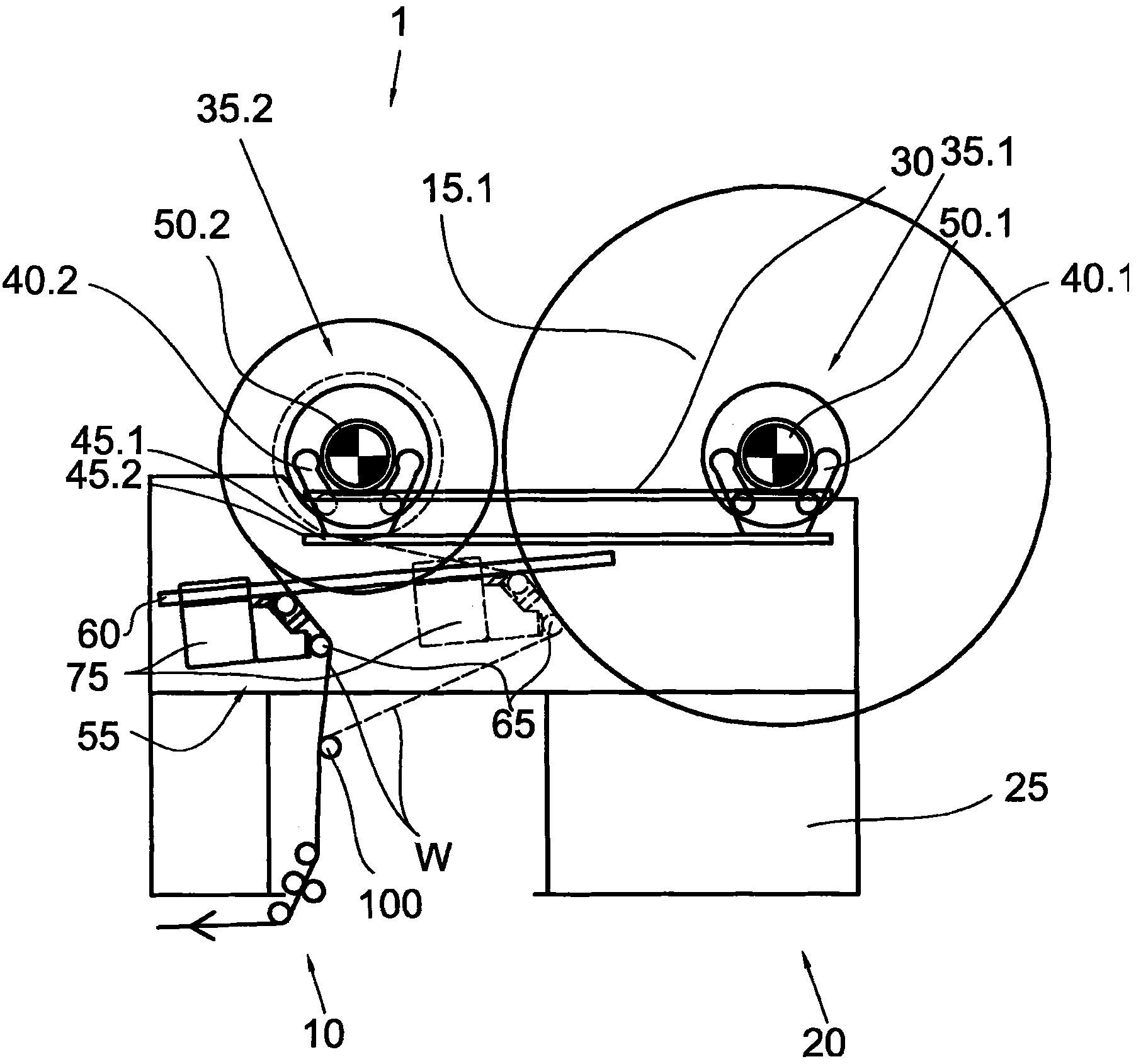

[0022] According to an embodiment of the present invention, in figure 1 A side view of the cutting section 10 of the longitudinal web slitting machine 1 and the subsequently arranged unwinding device 20 for the machine roll 15 is schematically shown in FIG. Part of the web unwinder that functionally belongs to the longitudinal slitter is not shown for the sake of clarity of the drawing. The unwinding device comprises a frame 25 supported on a base (not shown). A plurality of rails 30 are arranged in parallel and in the same direction on the machine frame 25 , so that the machine reels 15 are supported in the same manner via bearings at both ends of the reel shaft (only one is shown). The unwinding device comprises a first unwinding station 35.1 and a second unwinding station 35.2 at which, in the illustrated embodiment, fixed drives 50.1 and 50.2 are provided. The two drives are provided with motors and connection means (not shown) by means of which the motors can be connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com