Method of slicing thin bamboo

A manufacturing method and planing technology, which is applied in the manufacture of thin wood chips, manufacturing tools, furniture accessories, etc., can solve the problems of many processing procedures, the utilization rate of bamboo is less than 20%, and cumbersome processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Concrete embodiment of the present invention and processing step are as follows:

[0015] 1. Cross-cut the bamboo with a larger diameter into a certain length of bamboo;

[0016] 2. Bamboo segments are softened in hot water at 70-90°C for several hours;

[0017] 3. On the rotary cutting machine, the bamboo section with the shape of a round table is processed into a cylinder by rotating the circle;

[0018] 4. Split the cylindrical bamboo tube longitudinally into 3 to 4 pieces of equal arc length;

[0019] 5. Remove the inner section of the bamboo block;

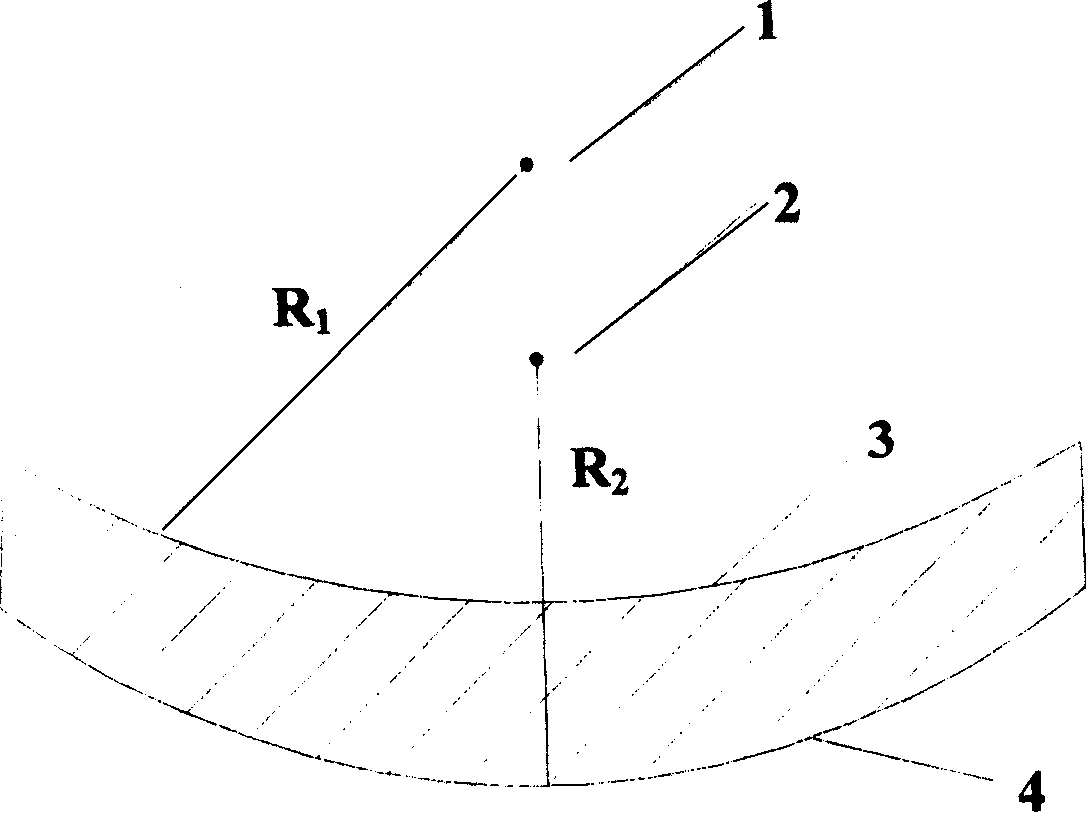

[0020] 6. Milling the inner surface of the bamboo block into an arc-shaped bamboo block with the same radius of curvature as the outer arc surface;

[0021] 7. After cooking and bleaching, dry to a moisture content of about 12%;

[0022] 8. Glue and age the arc surface of the bamboo block;

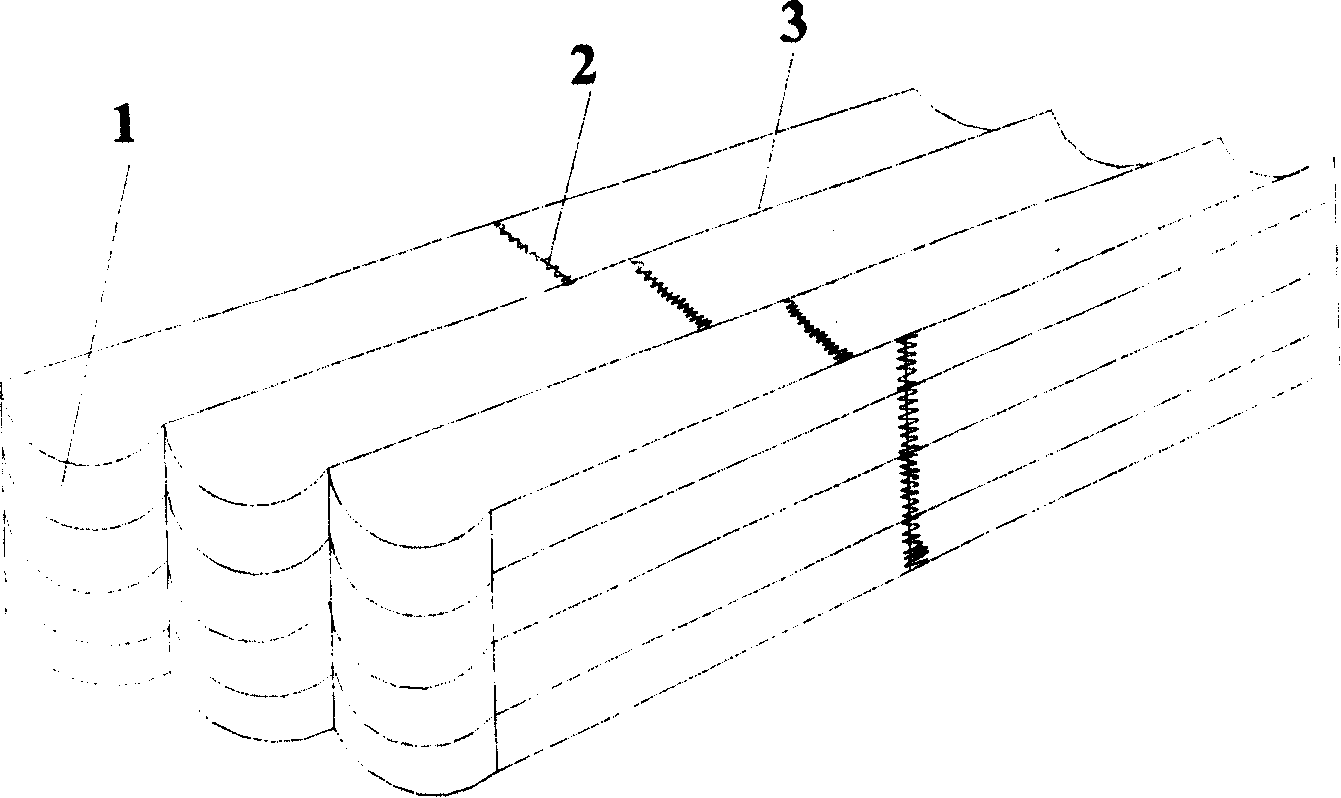

[0023] 9. A number of arc-shaped bamboo blocks with equal curvature radii are stacked vertically and parallel to form a blan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com