Flat glass on-line severing machine

A flat glass, breaking technology, applied in glass production, glass manufacturing equipment, glass cutting devices, etc., can solve the problems of high labor intensity, large loss, large transportation volume, etc., to reduce labor intensity, reduce waste, and automate high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

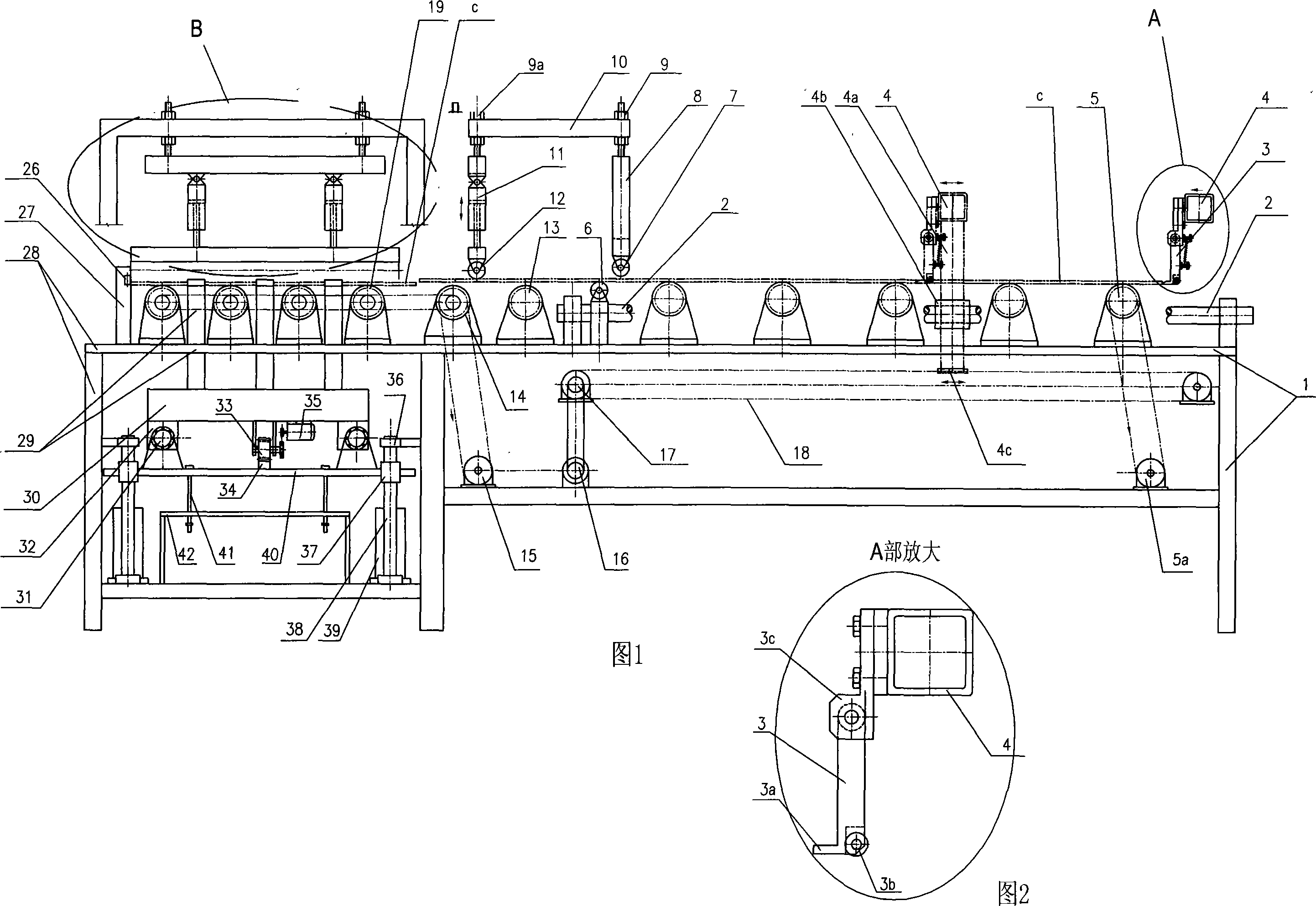

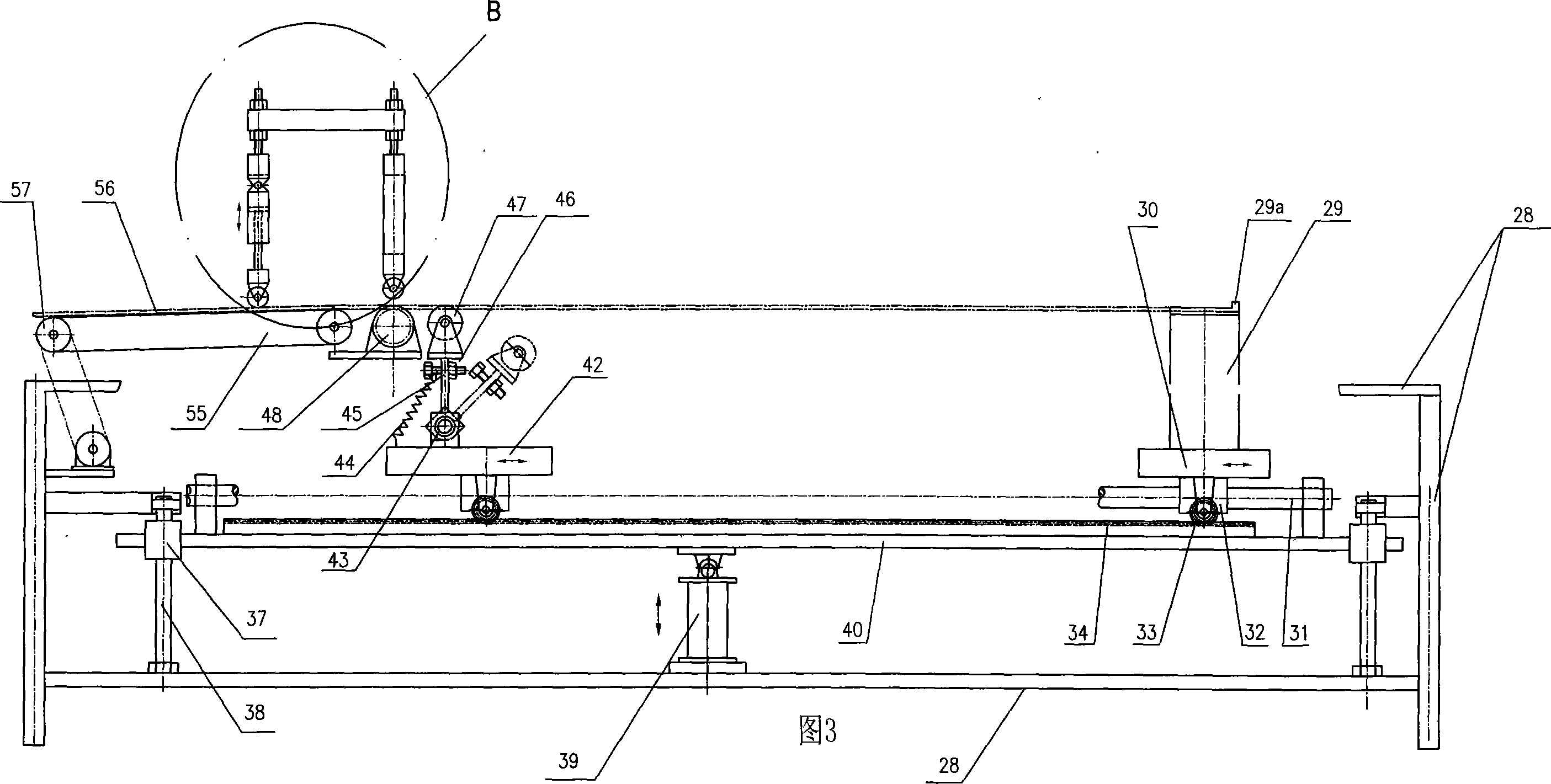

[0012] As shown in Fig. 1, Fig. 2 and Fig. 3, the present invention includes a transverse breaking part and a longitudinal breaking part.

[0013] 1. The horizontal breaking part, which includes the following three parts:

[0014] 1. Horizontal frame part: it firstly includes a horizontal frame 1, and a pair of horizontal guide rails 2 are respectively arranged on the top of the frame 1, and each horizontal guide rail 2 is connected with a linear bearing 4b, and each linear bearing 4b is respectively connected with a Support arm 4a, the upper end of support arm 4a is connected with a crossbeam 4, and the lower end is connected with a splint 4c, which is connected and matched with the timing belt 18 arranged in the transverse frame 1, and the described synchronous belt 18 is arranged in the transverse frame 1 by the Motor 16 and synchronous pulley 17 cooperate transmission. One group of pusher 3 is set on the beam 4, its structure is as shown in Figure 2, it is hinged on the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com