Paper cutting/receiving machine

A paper splicing machine and paper cutting technology, which is applied in stacking receiving devices, sending objects, thin material processing, etc., can solve the problems of high labor intensity, restricting productivity, slow speed, etc., and achieve the effect of precise cutting paper size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

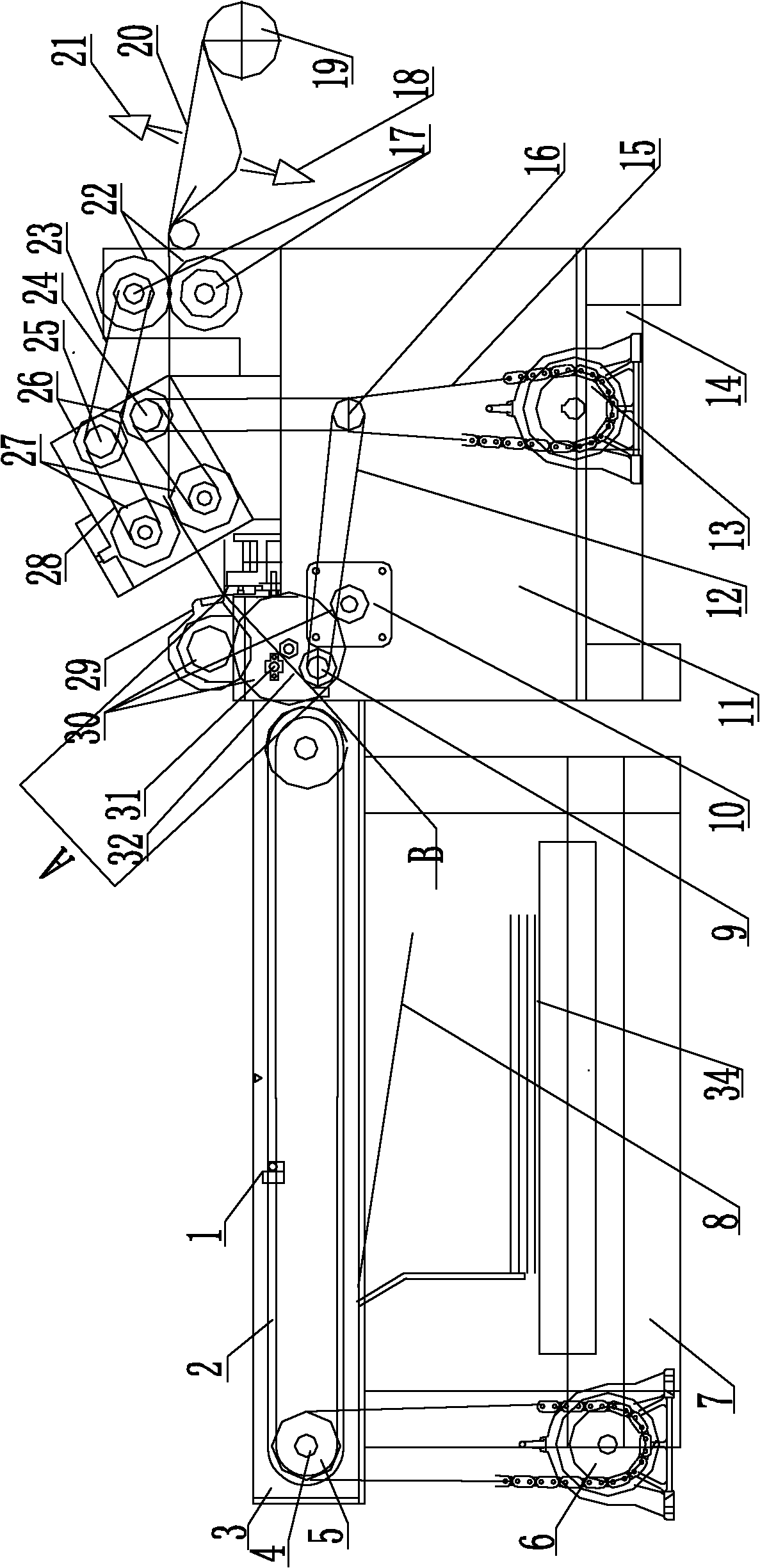

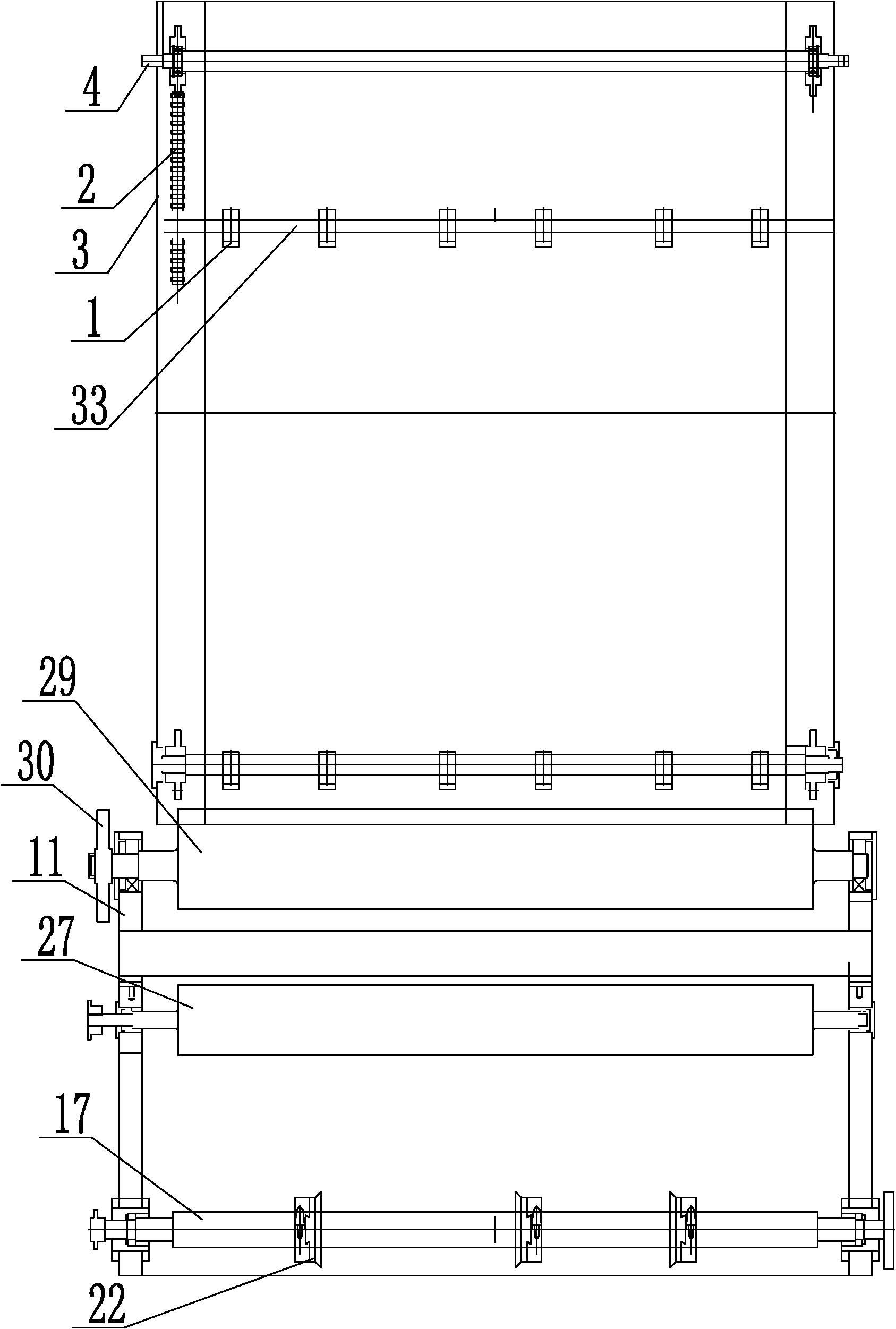

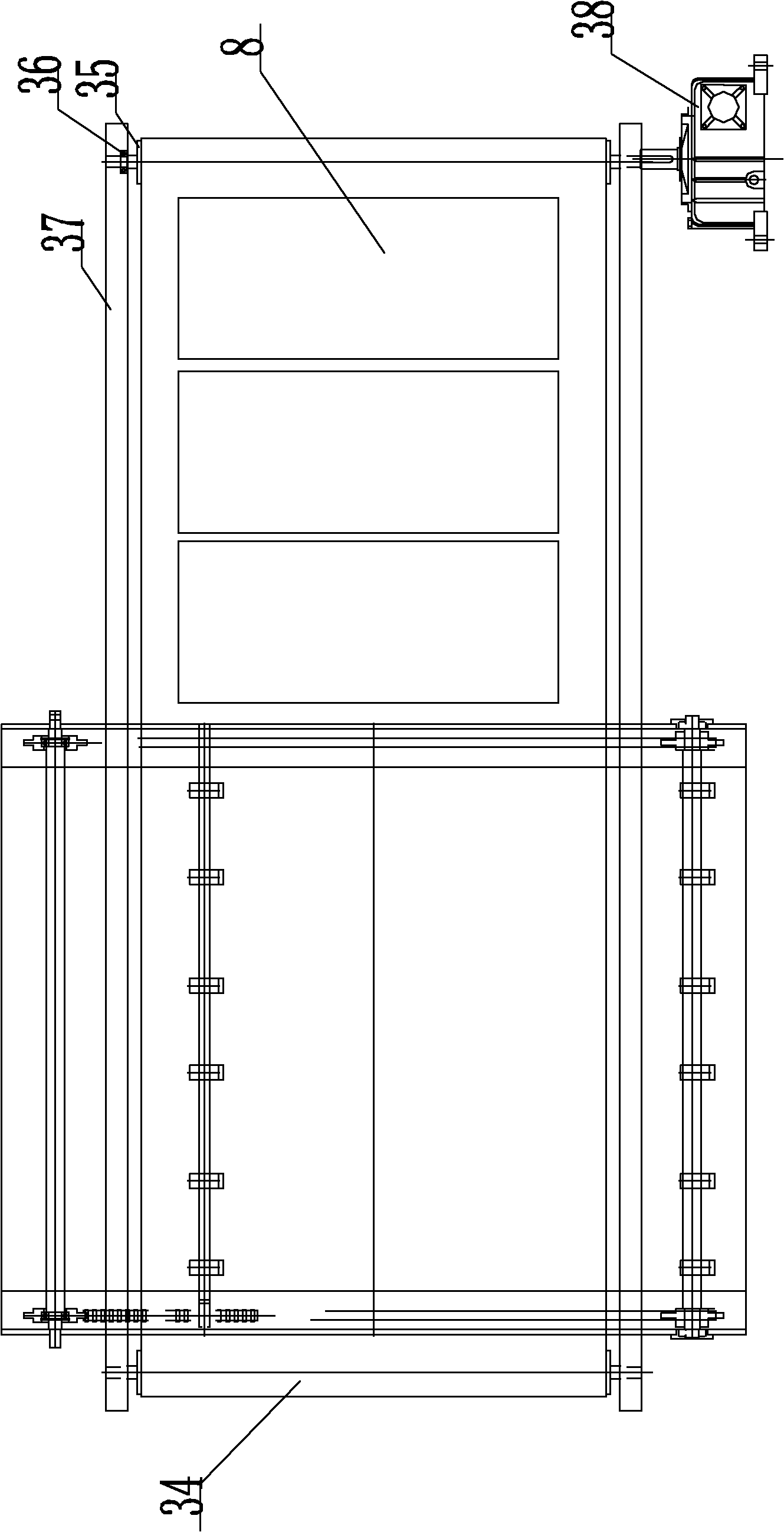

[0019] See figure 1 with figure 2 , figure 1 It is a schematic diagram of the structure of the paper cutting and splicing machine of the present invention. figure 2 for figure 1 Top view. The paper cutting and splicing machine of the present invention is composed of three parts: a paper feeding and cutting part, a paper receiving part and a transverse output belt 34.

[0020] The paper feeding and cutting part is mainly composed of paper cutting foot 14, paper cutting wall board 11, reversing gear 26, paper pulling shaft 9, pressure paper bar 31, pressure paper 32, circular cutter 29, circular cutting Knife gear 30, servo motor 10, reversing gear 26, first short bridge shaft 24, second short bridge shaft 25, chain with paper conveyor 28, bridge shaft 16, transmission bridge shaft variable frequency motor 13, The paper transmission shaft chain 12, the longitudinal slitting knife shaft 17, the longitudinal slitting knife 22, the longitudinal slitting knife shaft chain 23, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com