Sheel metal stacker

A stacker and sheet technology, applied in the field of metal sheet packaging machinery, can solve the problems of sheet material quality, high labor intensity, damage to the use effect of sheet materials, etc., achieves neat stacking, reduces labor intensity, The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

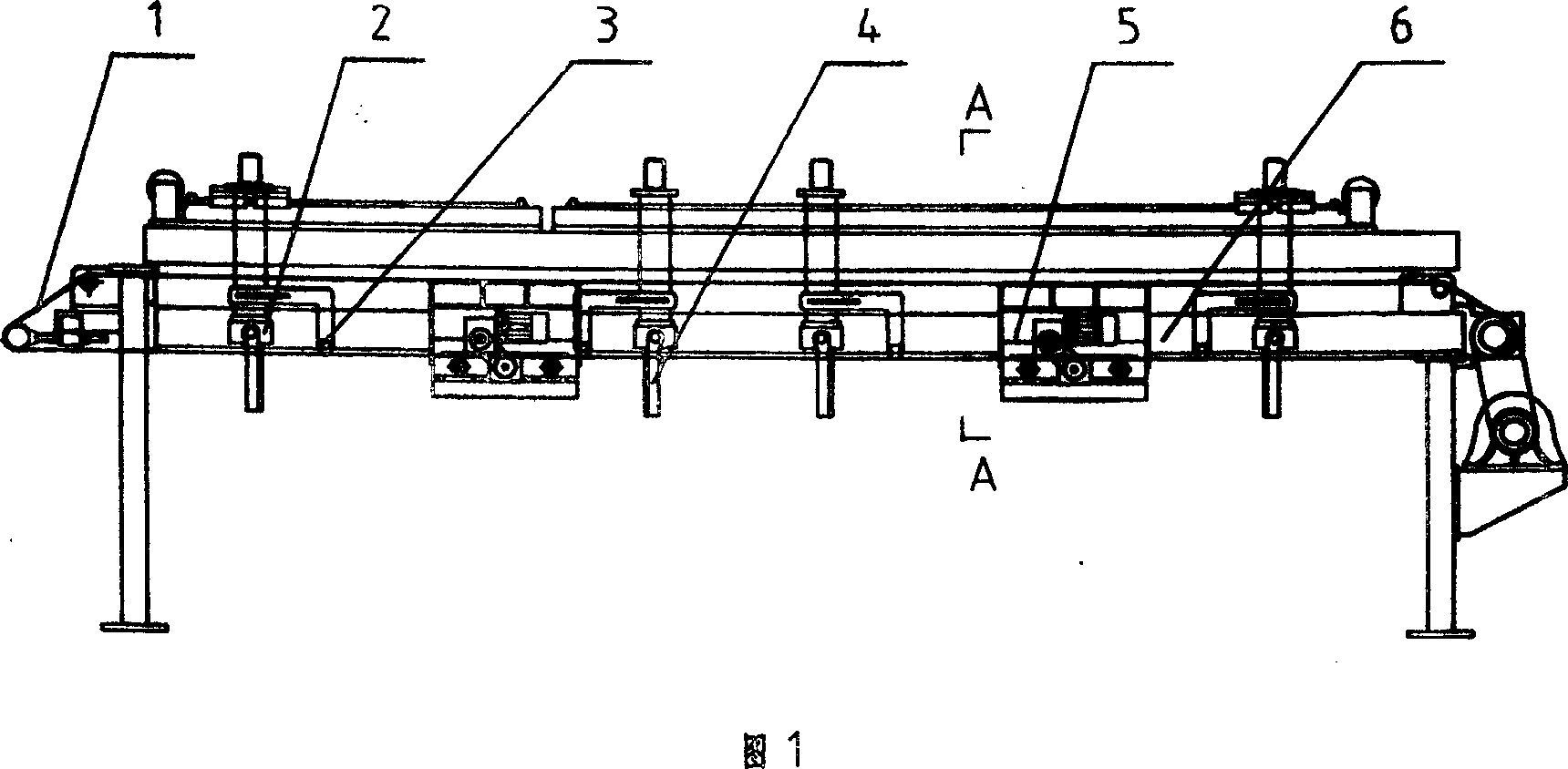

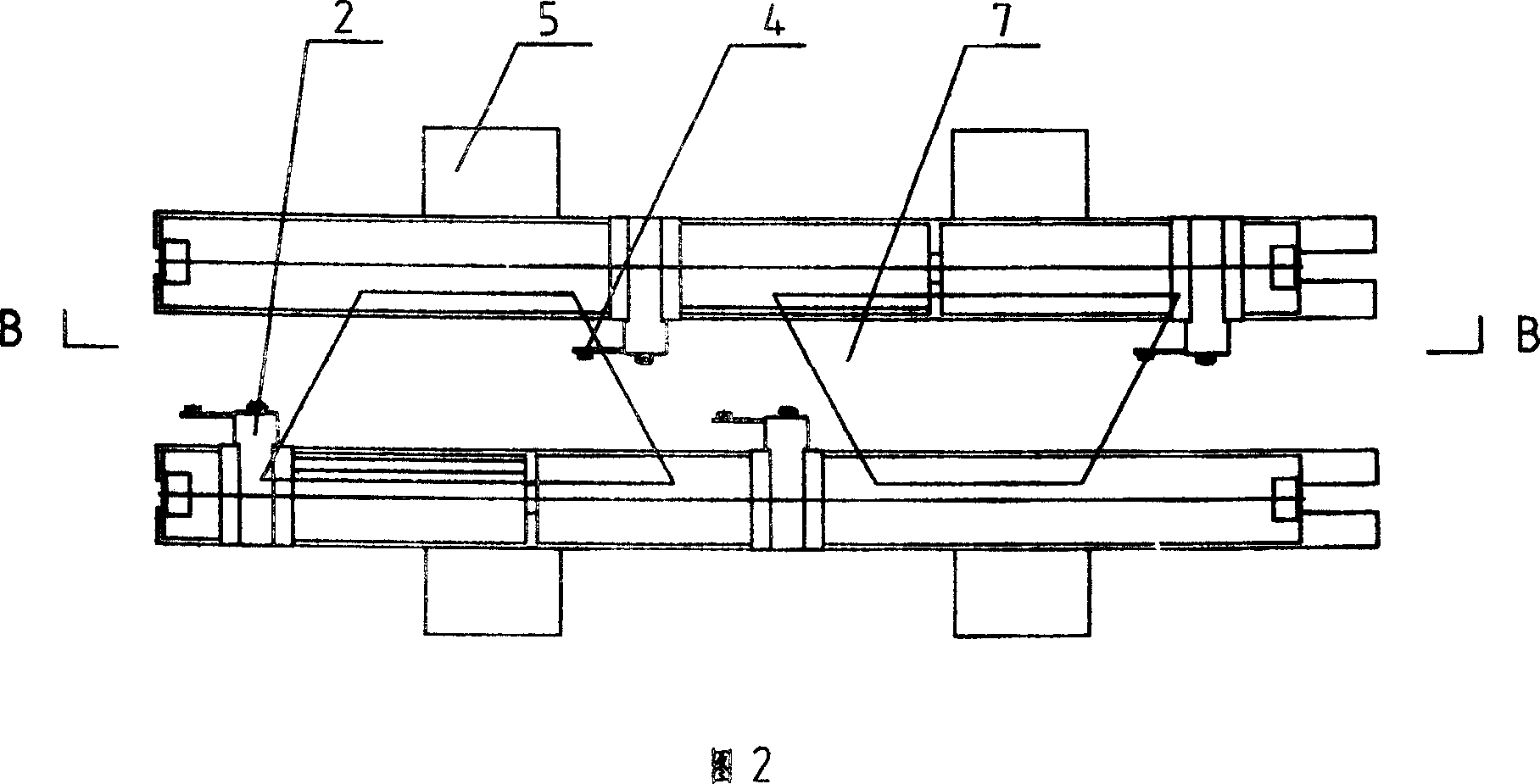

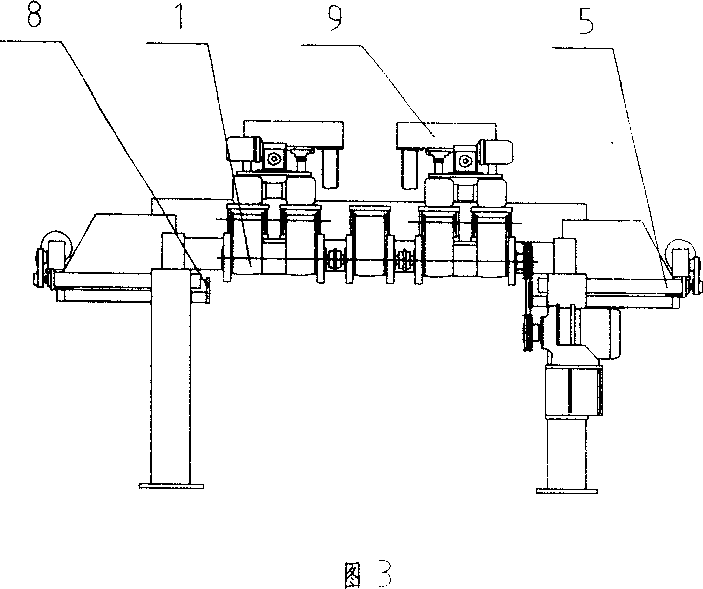

[0024] As shown in the figure, in the present invention, the two longitudinal beams are located on the lower side of the feed port, and a side stopper 8 perpendicular to the longitudinal beam is respectively provided. The stopper 8 is plate-shaped, and the midpoint of its plate surface is on the above-mentioned axis; the two side stoppers 8 are horizontally coaxially arranged to connect the shafts of the respective cylinders 11, and each cylinder 11 is fixed on each cylinder frame 5, and each cylinder Frame 5 is connected with frame by each guide rail, and each cylinder frame 5 is respectively provided with driving device, can realize the adjustment of three directions of side stopper 8X, Y, Z.

[0025] A certain distance is staggered on the two longitudinal beams, and an end stopper 4 is respectively arranged on the inner side of the two longitudinal beams. The aforementioned two side stoppers 8 are located in the middle of the two end stoppers 4. Holes are set at the top, fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com