Longitudinal splitting machine

A slitting machine, vertical technology, applied in metal processing and other directions, can solve problems such as inability to adjust, cannot be cut, and increase costs, and achieve the effects of easy maintenance, low cost, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

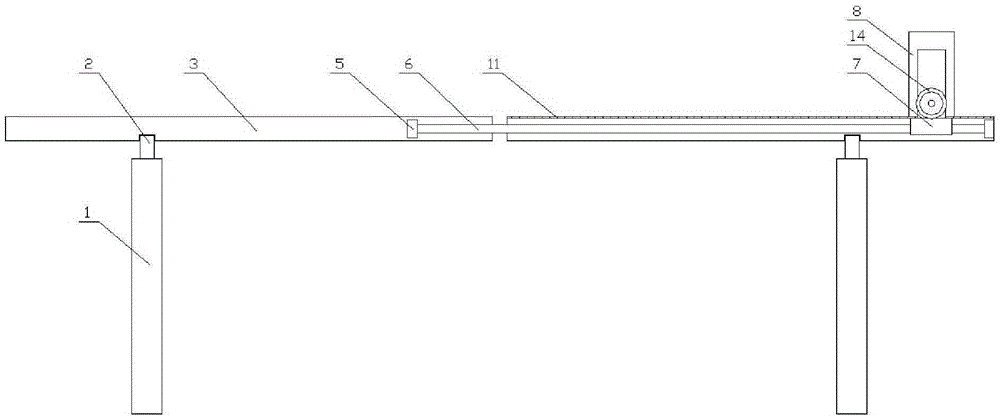

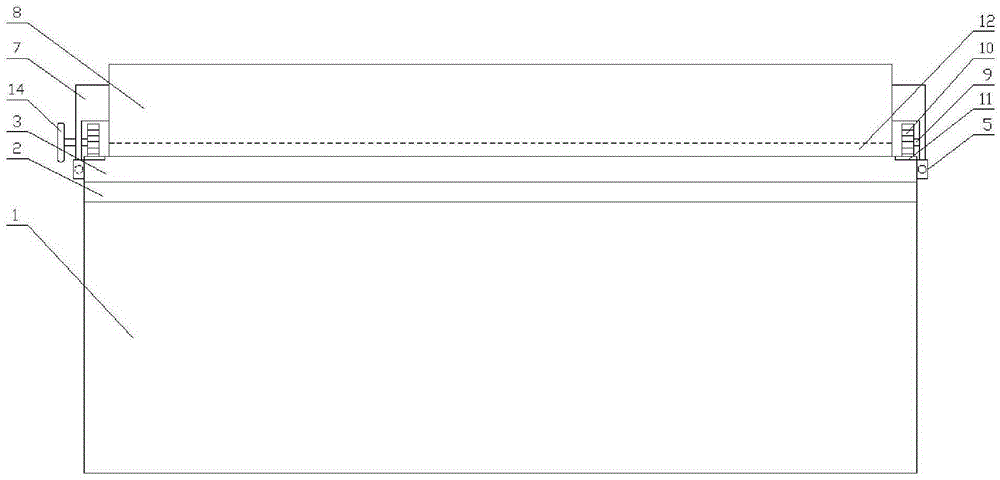

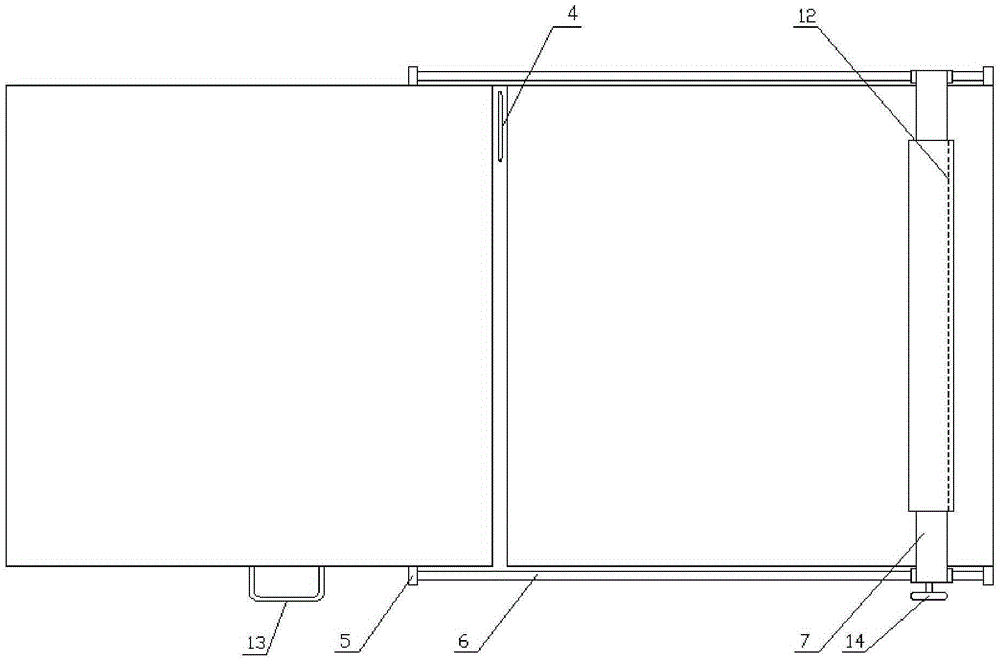

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] Such as Figure 1-Figure 3 As shown in the schematic diagram of the structure of the present invention, the present invention provides a longitudinal slitter, comprising two side support plates 1, guide rails 2 are arranged on the top ends of the side support plates 1, and feeding feeders are slidingly connected to the guide rails 2 respectively. plate 3, the feeding board 3 is arranged oppositely, a cutting knife 4 is arranged in the gap between the feeding boards 3, and a supporting seat 5 is relatively arranged between the lateral sides of the feeding board 3, and between the supporting seats 5 Guide shafts 6 are fixedly connected between them, side brackets 7 are slidably connected on the guide shafts 6, pressure plates 8 are fixedly connected between the side brackets 7, and drive shafts are rotatably connected to the side of the side brackets 7. 9. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com