Light double-row green brick tongs

A brick and light technology, which is applied in the field of light double-row brick grippers, can solve the problems of cumbersome control operation and complicated device structure, and achieve the effects of reducing power consumption, improving production efficiency, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

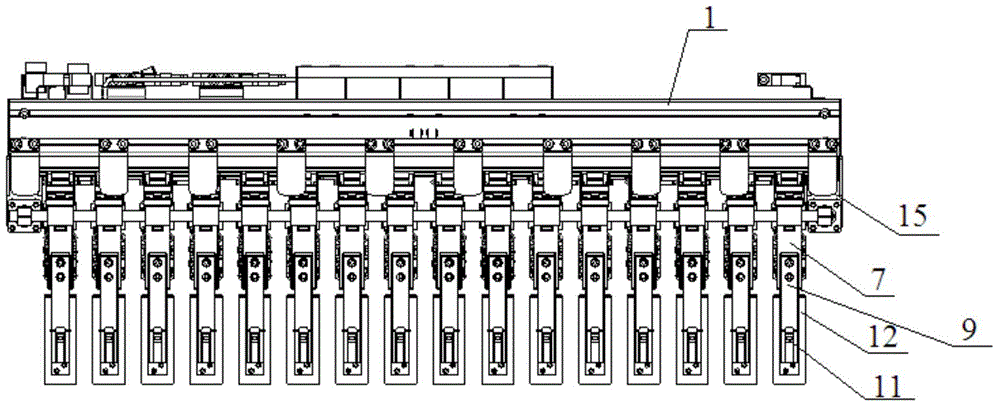

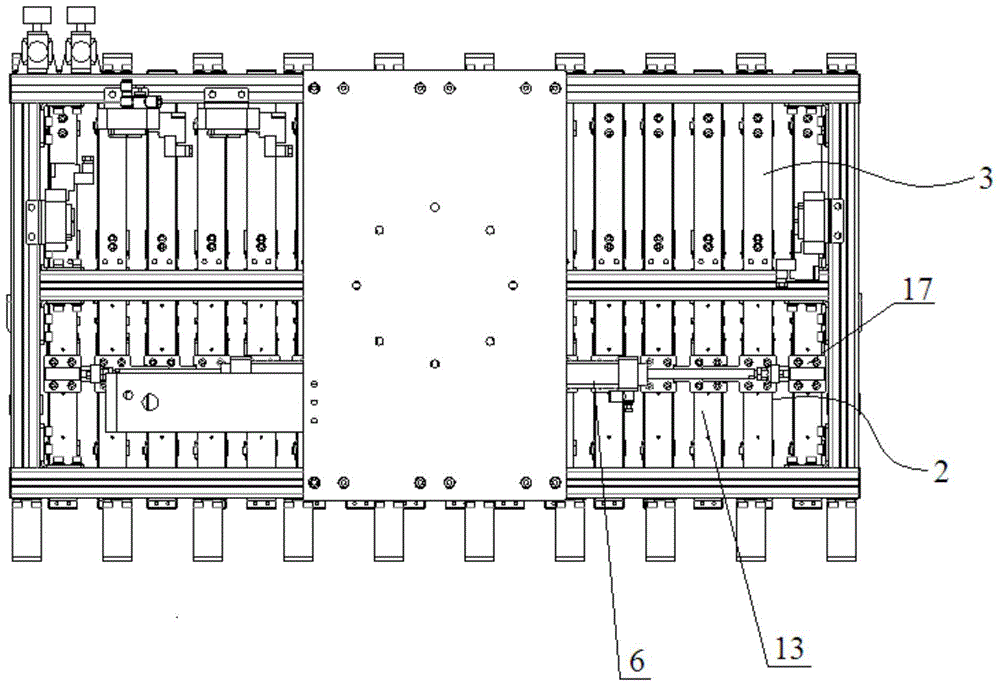

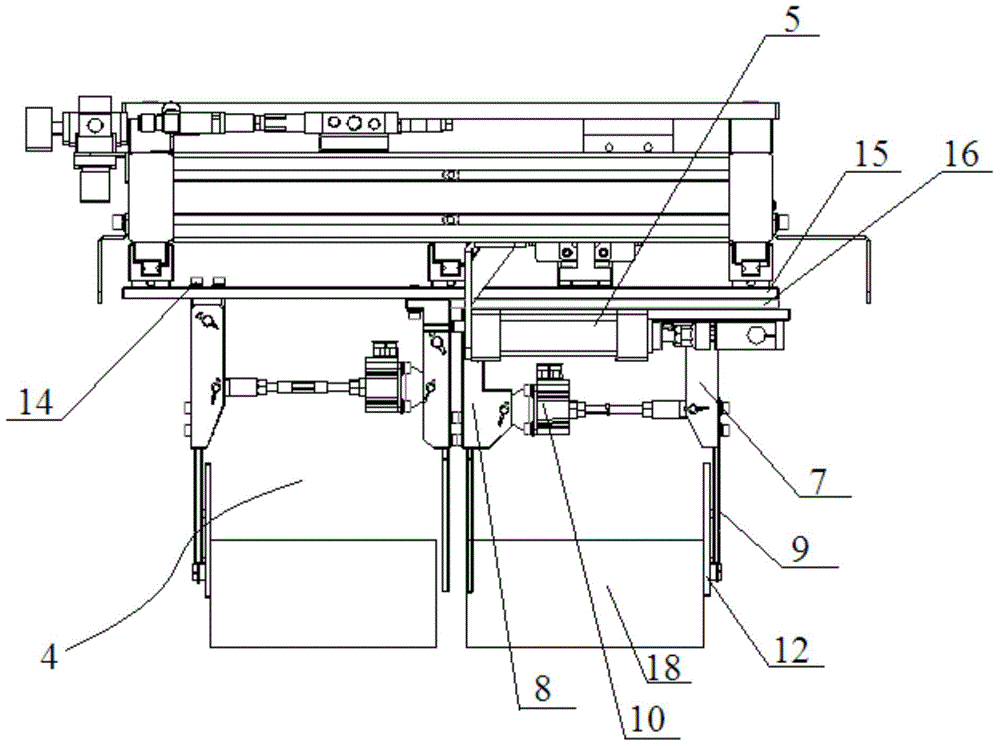

[0028] A lightweight double row adobe gripper such as Figure 1 ~ Figure 3 As shown, it includes front row splint unit 2, rear row splint unit 3, longitudinal splitting cylinder 5 and horizontal splitting cylinder 6 arranged on frame 1, and front row splint unit 2 and rear row splint unit 3 all contain several components. The splint group 4 arranged in the row, the longitudinal split cylinder 5 drives the front row splint unit 2 to move back and forth to adjust the distance between the front row splint unit 2 and the rear row splint unit 3; the horizontal split cylinder 6 drives the front row splint unit 2 Move laterally with each splint group 4 in the rear splint unit 3, and adjust the distance between adjacent splint groups 4.

[0029] The splint group 4 includes a moving splint fixing plate 7 and a fixed splint fixing plate 8 which are arranged oppositely. , the piston rod of the clamping cylinder 10 is connected with the movable splint fixed plate 7, and the clamping cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com