Novel corrugated board production line

A corrugated cardboard and production line technology, applied in papermaking, papermaking machines, textiles and papermaking, etc., can solve problems such as low production efficiency, idle equipment, and single production process flow, so as to improve production efficiency, reduce resource waste, and simplify equipment configuration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

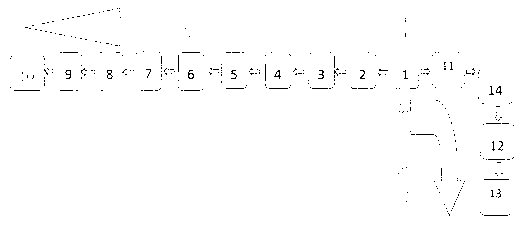

[0011] As shown in Figure 1, Figure 2, and Figure 3: the present invention consists of No. 1 single-sided machine 1, No. 2 single-sided machine 2, No. machine 6 , drying and cooling machine 7 , longitudinal slitter 8 , horizontal slitter 9 , and cardboard collecting rack I10 are arranged in sequence, and the prominent difference between it and the prior art is that: through No. Add cardboard conveyor 14, vertical and horizontal slitting machine 12, and cardboard collecting rack II 13 to connect with the idle No. 1 single-facer 1 to form another production line for process flow.

[0012] Description of each equipment in the production line:

[0013] The traditional process flow (process) of the corrugated cardboard production line is shown in Figure 3: No. 1 single-facer 1, No. 2 single-facer 2, No. 3 single-facer 3, quadruple preheater 4, gluing machine 5, Double-sided machine 6, drying and cooling machine 7, longitudinal slitter 8, horizontal slitter 9, cardboard collecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com