Automatic cutting equipment of aluminum profile

A technology for automatic cutting and aluminum profiles, which is applied in the direction of shearing machine equipment, metal processing equipment, shearing devices, etc., and can solve problems that are not in line with economic benefits, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

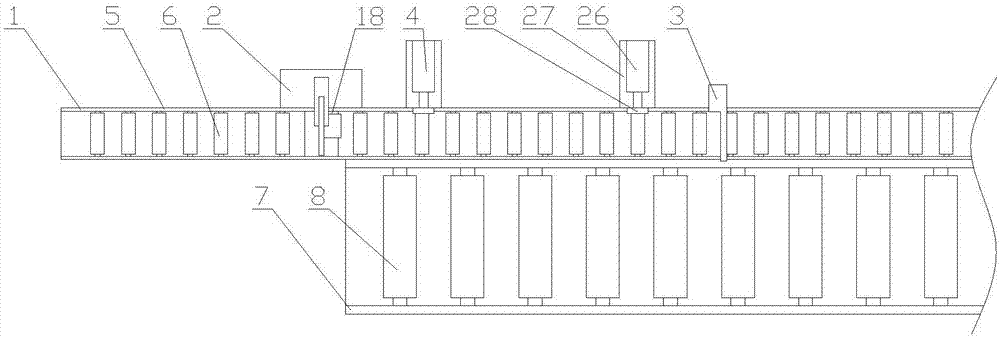

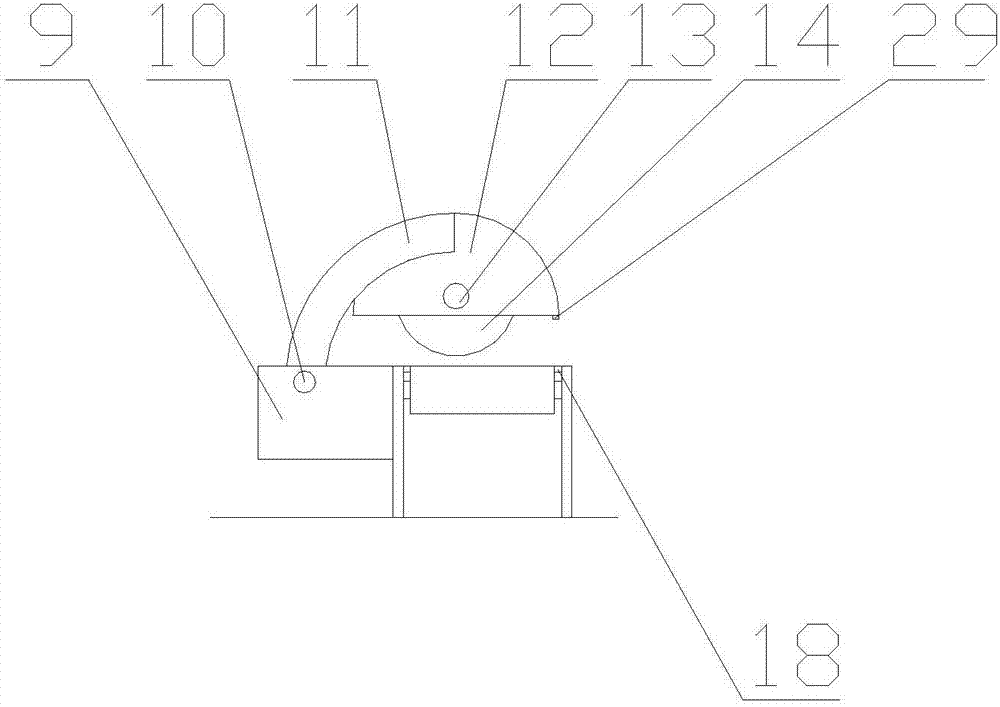

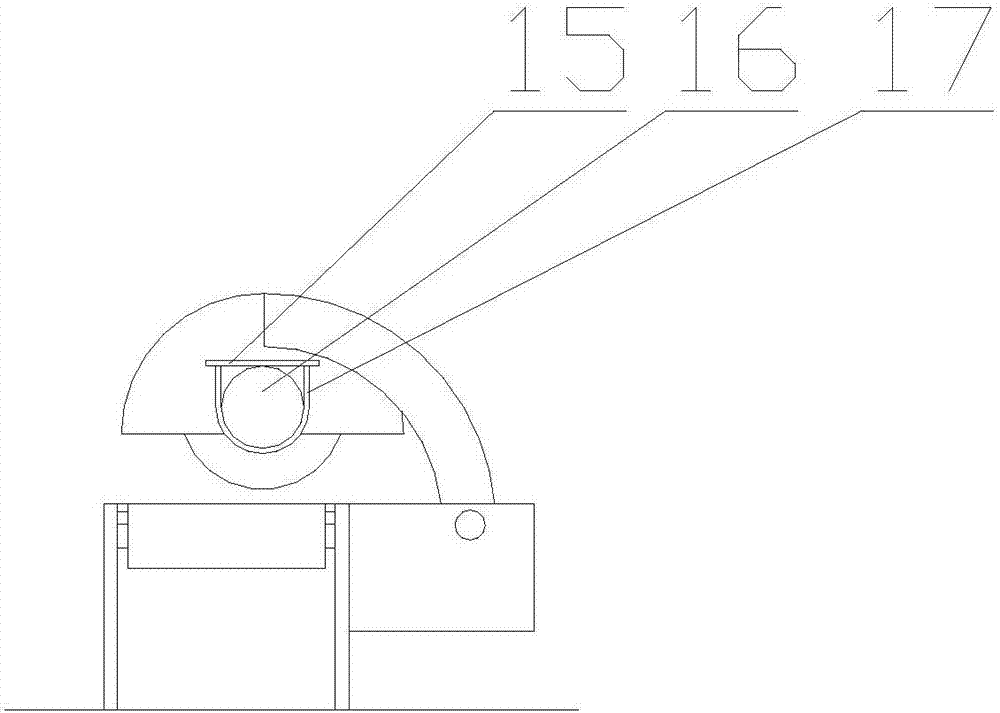

[0021] As shown in the figure, an automatic aluminum profile cutting equipment includes a transmission track 1, a cutting machine 2, a distance component 3 and a blanking component 4; the transmission track 1 is located at the front end of the discharge port of the hot extrusion molding machine, Extending forward in the factory building, it is used to convey the cut aluminum profiles; the cutting machine 2 is located on one side of the conveying track 1, and is fixedly connected with the edge of the conveying track 1, and is used for performing cutting action; The distance component 3 is located in front of the cutting machine 2 and at the edge of the conveying track 1, on the same side as the cutting machine 2, and slides freely along the conveying track 1, It is used to determine the length of the aluminum profile; the blanking assembly 4 is located on one side of the conveying track 1, on the same side as the cutting machine 2 and the distance assembly 3, and is fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com