Five-claw self-centering clamping tool with detecting function

A self-centering clamping and functional technology, applied in the field of aluminum alloy die-casting, can solve the problems of rough, unsuitable, low efficiency, etc., and achieve the effects of convenient operation, improved accuracy and stable pressing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

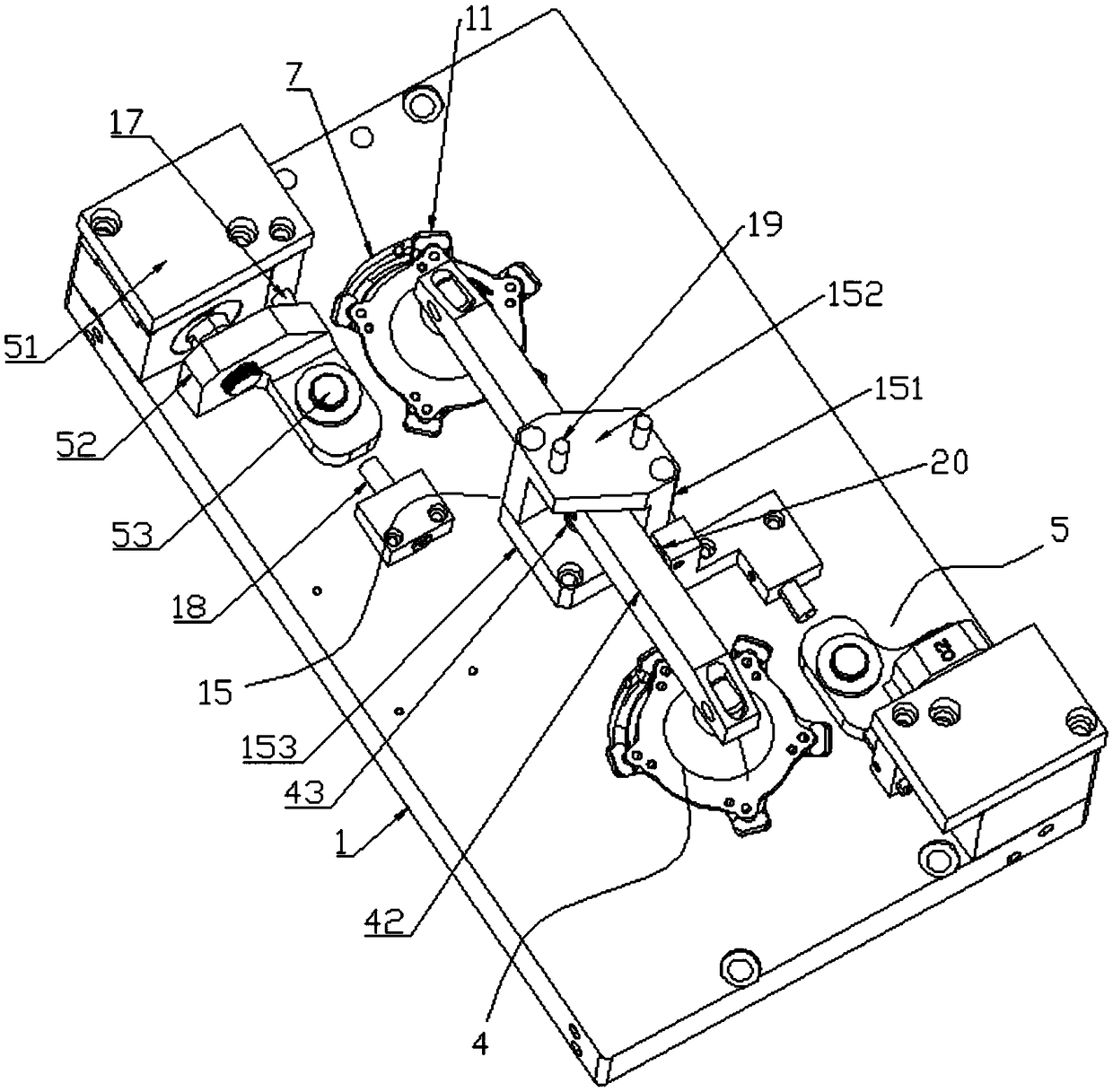

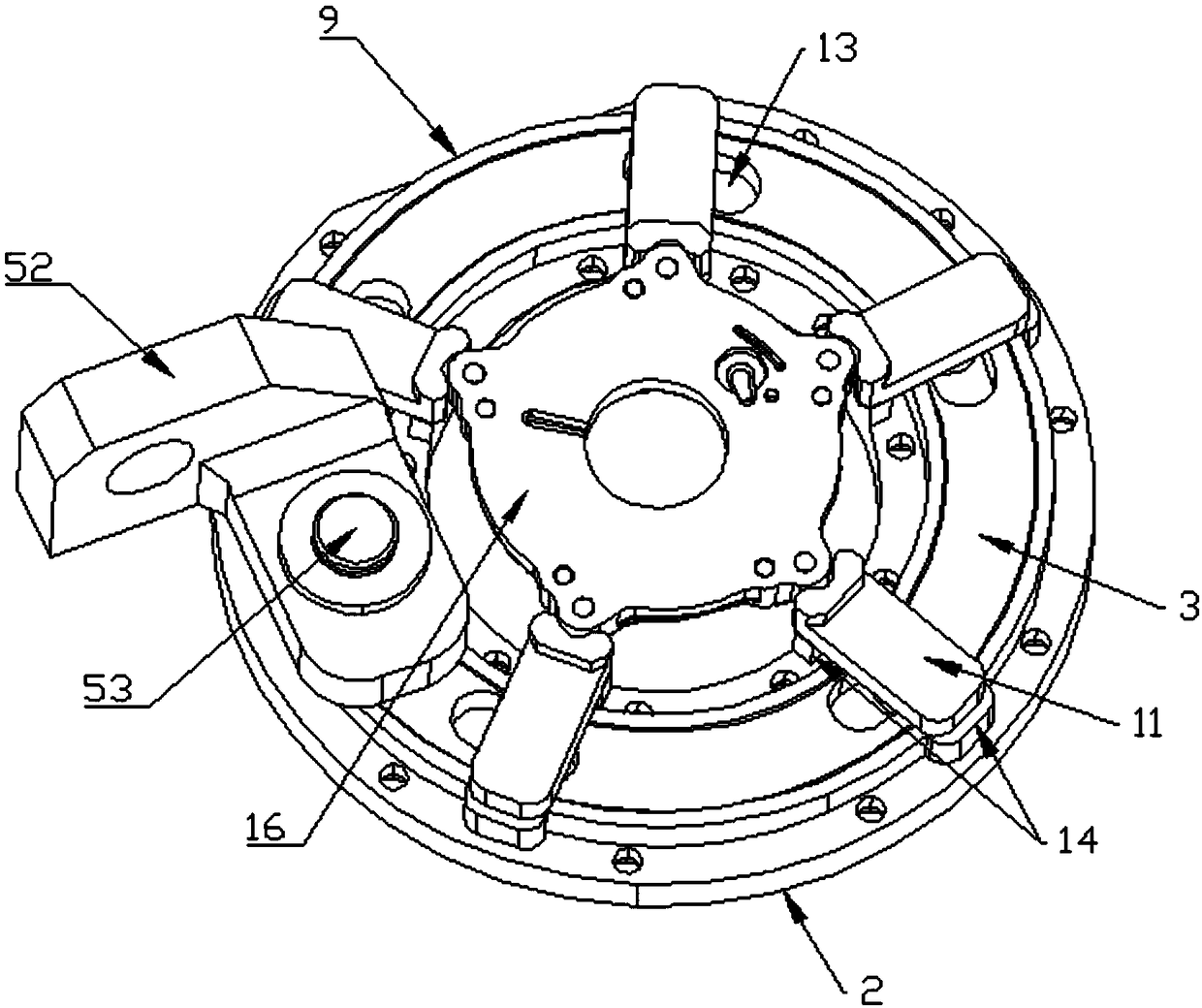

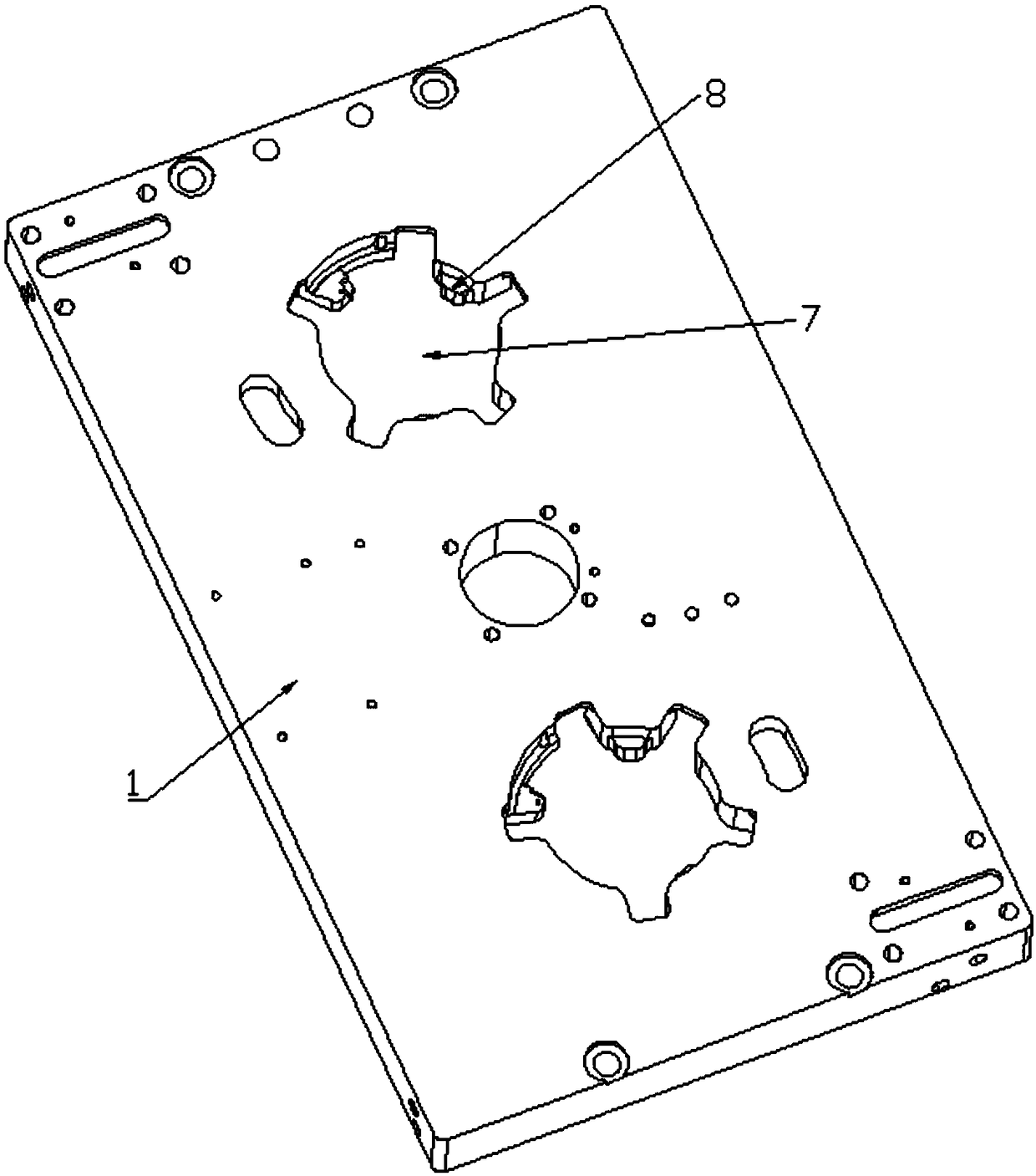

[0029] like Figure 1 to Figure 6 As shown, a five-jaw self-centering clamping tool with a detection function includes a base plate 1 and a clamping assembly, which includes a turntable seat 2, a turntable 3, a pressing assembly 4 and a pushing assembly 5. The bottom plate 1 is provided with a recessed portion 6 for installing the turntable seat 2, and above the recessed portion 6 is provided with a through product 16 placement hole 7, and the inner wall of the placement hole 7 is provided with a number of supporting bosses 8 that cooperate with the product 16, and the turntable The seat 2 is provided with an annular groove 9, the turntable 3 is rotatably connected in the annular groove 9 and is located between the bottom plate 1 and the turntable seat 2, and the bottom surface of the recess 6 is provided with five guide grooves 10, which are slidingly connected There is a collet 11, the bottom of the collet 11 is connected with a short column 12, and the turntable 3 is provid...

Embodiment 2

[0035] like Figure 1 to Figure 6 As shown, a five-jaw self-centering clamping tool with a detection function includes a base plate 1 and a clamping assembly, which includes a turntable seat 2, a turntable 3, a pressing assembly 4 and a pushing assembly 5. The bottom plate 1 is provided with a recessed portion 6 for installing the turntable seat 2, and above the recessed portion 6 is provided with a through product 16 placement hole 7, and the inner wall of the placement hole 7 is provided with a number of supporting bosses 8 that cooperate with the product 16, and the turntable The seat 2 is provided with an annular groove 9, the turntable 3 is rotatably connected in the annular groove 9 and is located between the bottom plate 1 and the turntable seat 2, and the bottom surface of the recess 6 is provided with five guide grooves 10, which are slidingly connected There is a collet 11, the bottom of the collet 11 is connected with a short column 12, and the turntable 3 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com