Air tightness detecting device for engine cylinder head and detecting method of air tightness detecting device

An engine cylinder head and air tightness detection technology, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement, and measuring the acceleration and deceleration rate of fluid, etc. Automation and other issues, to achieve the effect of compact structure, ensuring connection sealing, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

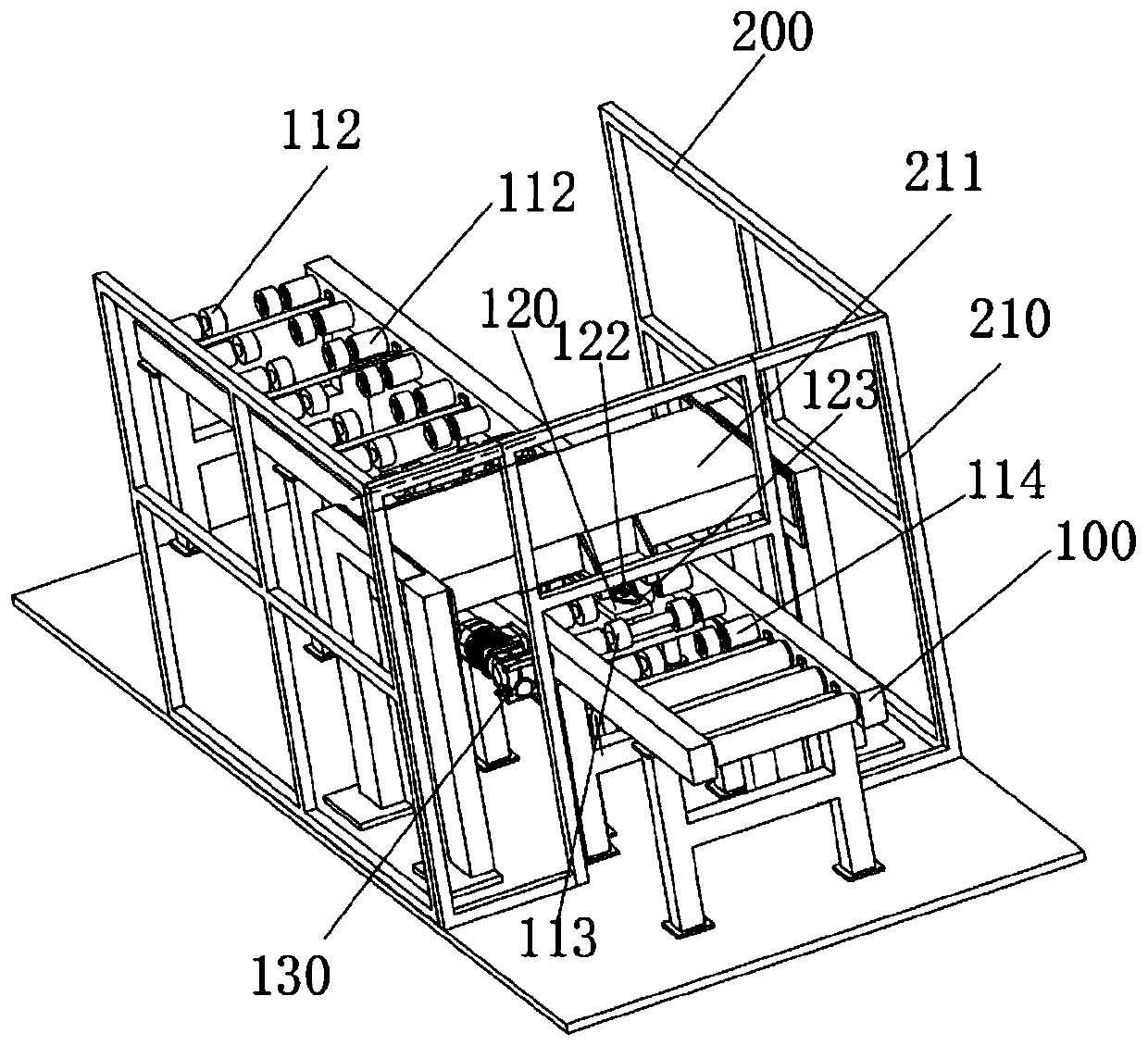

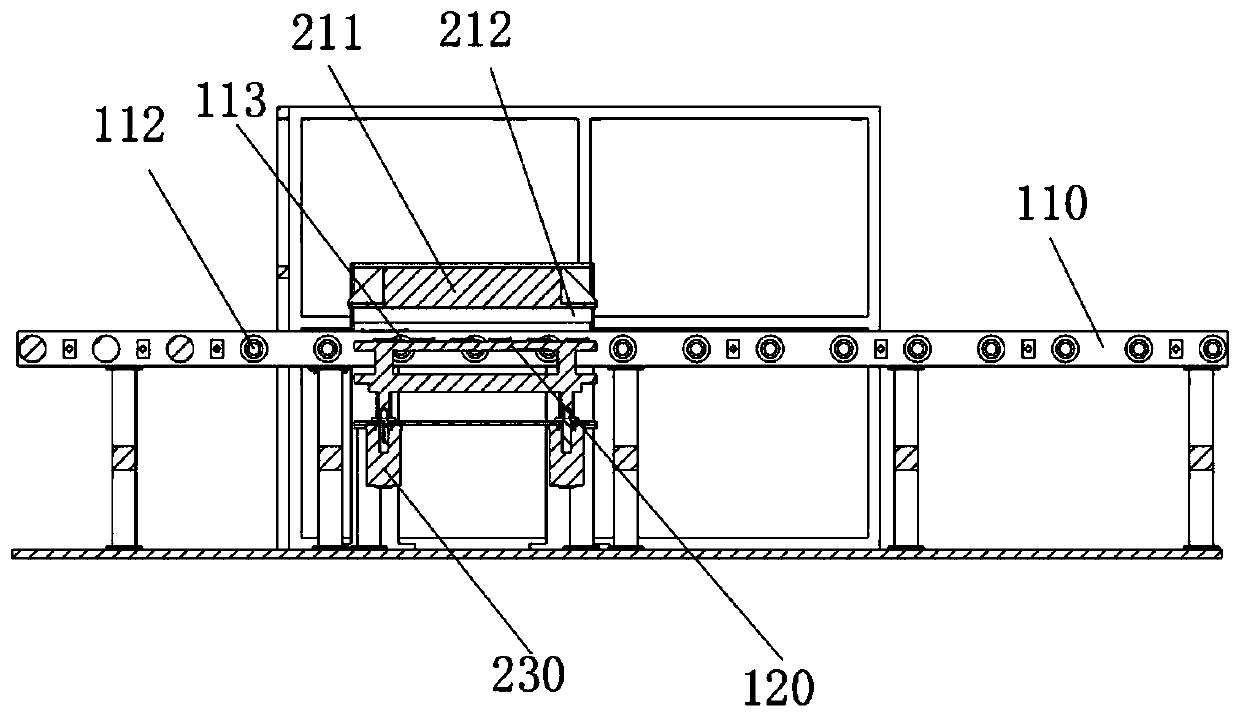

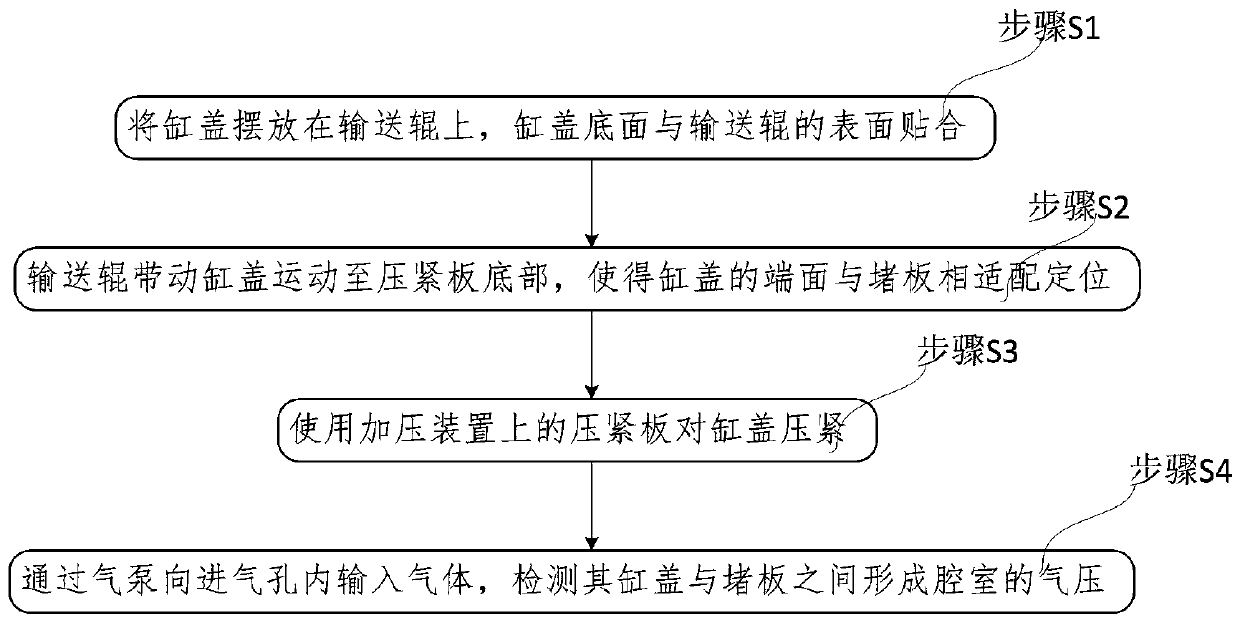

[0026] see figure 1 As shown, the present invention provides a kind of engine cylinder head air tightness detection device, comprises conveying roller bed 100 and pressurization device 200, and conveying roller bed 100 comprises conveying frame 110 and conveying roller 112, and conveying roller 112 is installed in parallel at intervals On the conveyor frame 110, the conveyor rollers 112 are connected to each other by chains or belts, and a drive motor 130 is installed at the bottom of the conveyor frame 110. The drive motor 130 drives the chain or belt to rotate, and drives the conveyor roller 112 to rotate, thereby realizing the automatic operation of the conveyor roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com